Professional Documents

Culture Documents

OHSE Project HIRA - Fencing Work - R 01

Uploaded by

Pankaj SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OHSE Project HIRA - Fencing Work - R 01

Uploaded by

Pankaj SinghCopyright:

Available Formats

Project Management, India

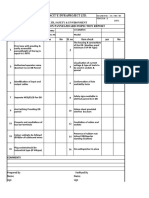

PROJECT RISK INDEX FOR HIRA

CATEGORY OF COMPLIANCE WITH

SEVERITY LEVEL EXPOSOURE PROBABLITY LEGISLATION AND REGULATIONS Remarks

SR NO.

DISCRIPTION FREQUENCY DISCRIPTION

(S) RATING (E) RATING (P) RATING LEGISLATION RATING

All aspects to which

No health effect /injury /No

1 1 Rarely 1 Never heard in OFFICE 1 legislation/regulatio YES Significant

damage.

ns applies

The existence of

Slight health effect /injury /

legislation/regulatio

2 little damage to property (Can 2 Once in month 2 Heard in offices outside 2 NO No Significance

ns has no influence

be recovered in 2 days.)

on significance

Incident happened in

Minor health (illness) effect /

3 3 Once in a week 3 our organization / 3

injury (Keeps person away

company 2-3 times in a

from work 2-3 days.) year.

Major health effect /illness / Happened in our

4 injury (fractures, breaking of 4 Once/twice a day 4 organization / company 4

organs, injury to body parts). 5-6 times in a year

Fatal\Permanent loss of Happened several times

5 organs\functions (eyes, legs, 5 Continuous 5 in a year in our 5

hands.) sites/offices

Risk Evaluation

LOW: MODERATE: HIGH:

IMPACT RISK UPTO 30 IMPACT RISK 31 TO 60 IMPACT RISK 61 & ABOVE

Note:

1 In the event Severity is 5 or the legislation is 'NO'- irrespective of overall low score the Risk is always high.

CBRE South Asia Pvt Ltd Page 1 of 8

Project Management, India

Fencing work Activity - HIRA

<Mumbai>

Project Name: MUMBAI

Activity - Fencing Work Activities

Reviewed by: Approved by:

Date : Prepared by Audit Comments

Revision

Rev.No.01No:00 Name MAHESH A GANGURDE

Date 13.11.2019

IMPACT

EXPOSOURE EXISTING

SEVERITY LEGISLATION RISK

SR NO. ACTIVITY HAZARDS ASSOCIATED RISK FREQUENCY PROBABLITY P CONTROL RISK LEVEL

S L

E IN PLACE

(SxExP)

1. Improper access

2. Lone worker near grass area 1. Body injury

3. Untrained worker

4. Snake bite 2. Back pain

5. Hot engine parts 3. Fatality

6. Rotating machinery 4. Burn injury

Grass cutting by grass cutting 5. Cut/Lacerations

1

machine & tools

7. Overturning of machine by worker

6. Hand arm vibration/full body 5 3 3 No 45 Yes High

8. Vibration

vibration

9. Flying grass parts 7. Eye injury

10. Defective tools/machine 8. Cut/Amputation

11. Loose cloths 9. Serious injury

12. Non use of PPE's

1. Improper access

2. Over load 1. Back pain

3. Wet floor 2. Body pains

4. Falling of Materials 3. Sprains

Manual Material Handling of

2 5. Sharp edges 4. Temporary Disabilities. 2 2 2 No 8 YES Low

heavy/bulky objects

6. Untrained workers 5. Spinal cord injuries

7. Not uses of PPE's 6. Body part injury

7. Cut injury

CBRE South Asia Pvt Ltd Page 2 of 8

Project Management, India

1. Sharp edges of digging

equipment's

2. Unskilled worker 1. Cut injury

3. Lone worker near grass area 2. Back pain

3 Manually digging/ excavation 4. Snake bite 3. Body pains 5 3 3 No 45 Yes High

for fixing vertical members 5. Non uses of PPE's 4. Body part injury

6. Underground utilities 5. Electrocution

(like live cable, water pipeline, gas 6. Fatality

pipeline)

1. Falling of materials .

2. Unskilled workers

3. Lone worker near grass area

4. Snake bite 1. Back pain

5. Non uses of PPE's 2. Body pains

Concrete breaking by chipper 6. Underground utilities 3. Body part injury

machine / concrete drill (like live cable, water pipeline, gas 4. Electrocution

4 5 3 3 No 45 Yes High

machine ( Portable power pipeline) 5. Hearing problem

Tools) 7. Noise 6. Hand arm vibration/full

8. Vibration body vibration

9. Defective power tools 7. Fatality

10. Loose and damaged electrical

wires and plug top

1. Fire (due to combustible material

around site

2. Radiation

3. Hot part or Surfaces

4. Untrained welder 1. Burn injury

2.Ill health

5. Flying welding spark

3. Fatality

5 Welding/gas cutting & Cutting 6. Flammable Cylinder set 5 3 3 Yes 45 Yes High

4. Cylinder explosion

7. Fall of materials

5. Body part injury

8. Loose and damaged electrical

6. Electrocution

wires and plug tops

9. Damaged gas cylinder valve / flow

regulator

10. Absence of flash back arrestor

1. Loose and damaged wirings and 1.Burn

Temporary Electrical plug tops / switch boards 2.Property damage

6 5 3 3 Yes 45 Yes High

connection 2. Short circuit due to spark 3.Fatality

3. Defective tools. 4. Electrocution

CBRE South Asia Pvt Ltd Page 3 of 8

Project Management, India

1.Poor visibility 1. Injuries due to slip and

7 Working at night 2.Improper access trips. 5 4 3 Yes 60 Yes High

3. Snake bite 2. Eye strain.

4. Poor illumination 3. Fatal

Format No. J014-OHS-SO-HIRA-Tp-004/Rev05/Nov2016

CBRE South Asia Pvt Ltd Page 4 of 8

Project Management, India

CBRE South Asia Pvt Ltd Page 5 of 8

Project Management, India

Audit Comments

ACTION MEASURE FOR RISK CONTROL

( please provide the second level document title and number from OHSE master list of documents for

each activity )

1. Obtained daily general work permit prior to start the work

Format No. L010-OHS-GP-Fr-010/Rev03/Feb2019

2. Provide adequate training to the workers and staff as per the user manual and

guideline of machine.

3. Snake catcher must be full time available on site during the work.

4. Tie-up with nearest hospital which may having Anti-snake venom doses.

5. Emergency vehicle/ambulance must be available at site.

6. Provide proper information, training and instruction regarding snake bite.

7. Only to be used in accordance with use manual/ manufactures instructions.

8. Close monitoring or supervision to be required near working area.

9. Before starting the machine check whether machine is cool if not then wait for the

machine to cool.

10. Worker is started cutting machine when it is safe to do so - bystanders in the vicinity.

11. Shields, guard, interlocks and other safety devices are in place and working properly.

12. Engine shut off before cleaning out clogged chute or any other obstructions.

13. The equipment's is inspected and serviced by competent person.

14. Defects are reported immediately and equipment is taken out of use until repaired.

15. No loose clothing should be worn when operating the machine.

16. Area checked for stones, glass, metal and debris before starting.

17. No workers/Staff are allowed on machine operating area.

18. The machine is used for time periods as specified by manufactures instructions.

19. Proper and required PPE i.e. safety helmet, safety gumboots with steel toe, dotted

hand gloves, clear Safety goggle, ear plug.

Format No. K005-OHS-PP-Ch-007/Rev03/Jan2016.

1. A risk assessment must be completed for lifting heavy and bulky loads that present a

risk of injury.

2. High shelves for light items only.

3. Training in lifting techniques should be provided for anyone who undertakes the lifting

of heavy loads.

Format No. L004-OHS-Atn-Fr-004/Rev02/May2015

4. Obtained daily general work permit prior to start the work.

Format No. L010-OHS-GP-Fr-010/Rev03/Feb2019

5. Proper and required PPE i.e. safety helmet, safety shoes with steel toe, dotted hand

gloves, clear Safety goggle, Full body safety belt if required etc.

Format No. K005-OHS-PP-Ch-007/Rev03/Jan2016

6. Access should be cleared from any obstruction

Format No. K006-OHS-HK-Ch-008/Rev02/Jan2016

7. Stringent supervision to be provided

8. Sufficient man power to be provided of as per load .

CBRE South Asia Pvt Ltd Page 6 of 8

Project Management, India

1. Obtained daily general work permit prior to start the work

Format No. L010-OHS-GP-Fr-010/Rev03/Feb2019

2. Proper and required PPE i.e. safety helmet, safety shoes with steel toe, dotted hand

gloves, clear Safety goggle, if required to be wear.

Format No. K005-OHS-PP-Ch-007/Rev03/Jan2016

3. Stringent supervision to be provided

4. Manual materials handling Training to be provided .

Format No. L004-OHS-Atn-Fr-004/Rev02/May2015

5. Co-worker should be present full time while during work near by grass or overall site

area.

6. Snake catcher must be full time available on site during the work.

7. Emergency vehicle/ambulance must be available at site.

8. Clearance by authorised person regarding Underground utilities.

1. Obtained daily general work permit from prior to start the work. Format No. L010-

OHS-GP-Fr-010/Rev03/Feb2019

2.Ensure electrical safety joint inspection checklist should be filled by the contractor once

in a week Format No. K012-OHS-EW-Ch-014/Rev02/Jan2016

3. Only certified electrician should authorized to doing electrical related work

4. Proper and required PPE i.e. safety helmet, safety shoes, hand gloves, Safety goggle,

Ear plug, Reflecting jacket etc. Format No.K005-OHS-PP-Ch-007/Rev03/Jan20166.

5. Keep CO2 fire extinguisher with sand bucket near main electrical panel

Format No. K033-OHS-FE-Ch-34/Rev00/May 2019

6. Use only IP 65 industrial electrical equipment in project

7. Follow electrical. inspection check list (Format No.

K012-OHS-EW-Ch-014/Rev02/Jan2016).

8. Emergency vehicle/ambulance must be available at site.

9. Anti vibration hand gloves can be used.

10. Strict supervision has to be provided.

1. HOT work permit to be obtained before start work. Format No. L016-OHS-HoP-Fr-

016/Rev04/Feb2019

2. Supply to be taken from ELCB board 30 mA (Format

NoK012-OHS-EW-Ch-014/Rev02/Jan2016

3. Welding m/c to be check as per check list. Format No.

K048-OHS-WM-Ch-49/Rev00/May 2019

4. Cylinder store area separate and marked

5. Use industrial lighter for ignition

6. Follow gas cylinder inspection check list Format No. K034-OHS-GC-Ch-35/Rev00/May

2019

7. Proper supervision to be provided from site supervisor

1. Obtained daily general work permit from prior to start the work. Format No. L010-

OHS-GP-Fr-010/Rev03/Feb2019

2.Ensure electrical safety joint inspection checklist should be filled by the contractor once

in a week Format No. K012-OHS-EW-Ch-014/Rev02/Jan2016

3. Only certified electrician should authorized to doing electrical related work

4. Proper and required PPE i.e. safety helmet, safety shoes, hand gloves, Safety goggle

etc. Format No. K005-OHS-PP-Ch-007/Rev03/Jan20166.

5. Appropriate Electrical rubber hand gloves has to be used

6. Keep CO2 fire extinguisher with sand bucket near main electrical panel

Format No. K033-OHS-FE-Ch-34/Rev00/May 2019

7. Use only IP 65 industrial electrical equipment in project

8. Follow electrical. inspection check list (Format No.

K012-OHS-EW-Ch-014/Rev02/Jan2016)

CBRE South Asia Pvt Ltd Page 7 of 8

Project Management, India

1. Ensure adequate illumination.

2. Ensure night work permit refer -Format No. L017-OHS-NP-Fr- 017/Rev04/May2019

3. Ensure emergency lights available.

4. Ensure use of personal protective equipment's .

Format No. K005-OHS-PP-Ch-007/Rev03/Jan2016

5. Ensure close supervision and presence of electrician.

6. Contractor should conduct regular Tool Box Talk -Refer Tool box talk, format no. L003-

OHS-TB-Fr-003/Rev01/Feb2013).

7. Snake catcher must be full time available on site.

8. Qualified First aider must be full time available on site.

9. Tie-up with nearest hospital which may having Anti-snake venom doses.

10. Provide proper information, training and instruction regarding snake bite.

11. Emergency vehicle/ambulance must be available at site

CBRE South Asia Pvt Ltd Page 8 of 8

You might also like

- 5.1 HIRA For Installation of DUCTDocument3 pages5.1 HIRA For Installation of DUCTRAM KUMAR K RNo ratings yet

- OHSE Project HIRA - Fencing Work - R 00Document3 pagesOHSE Project HIRA - Fencing Work - R 00Pankaj SinghNo ratings yet

- HIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionDocument26 pagesHIRA & JSA - R1 Conveyor Gallery Dismantling and ErectionkrishnaengineeringhilNo ratings yet

- Hydra HiradecDocument1 pageHydra HiradecPankaj PandeyNo ratings yet

- Current Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryDocument3 pagesCurrent Total Summary: Sec Ehvpd Woa & Soa Project Rectification RegistryAhsan MumtazNo ratings yet

- 3 RN Sop PDFDocument4 pages3 RN Sop PDFDwitikrushna RoutNo ratings yet

- SOP For Tree Cutting at HPCL UNNAODocument3 pagesSOP For Tree Cutting at HPCL UNNAOamankumar100% (1)

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarNo ratings yet

- 48 Structural Steel Erection WorkDocument5 pages48 Structural Steel Erection WorkvasudevanmNo ratings yet

- Lifting Tools & Tackle RegisterDocument1 pageLifting Tools & Tackle RegisterDth InfraNo ratings yet

- Work Permit 2.13Document14 pagesWork Permit 2.13Oliva Del Rosario Sagpao100% (1)

- RCCB Testing Format - HSE-CTN-HPP-FMT-001Document1 pageRCCB Testing Format - HSE-CTN-HPP-FMT-001Radha Buildtech100% (1)

- ARA - For Emergency Diesel GeneratorDocument4 pagesARA - For Emergency Diesel GeneratorShaikh AftabNo ratings yet

- Risk Assessment: Job:Control Blasting For Wagon TipplerDocument1 pageRisk Assessment: Job:Control Blasting For Wagon Tipplerali rezaNo ratings yet

- Master Hira - 01Document4 pagesMaster Hira - 01Angw BasumataryNo ratings yet

- Job Safety Analysis (Jsa) ProcedureDocument7 pagesJob Safety Analysis (Jsa) ProcedurerinkusahuNo ratings yet

- 167-QHSE-ST167 QHSE-Oil Spill Kit Inspection ChecklistDocument1 page167-QHSE-ST167 QHSE-Oil Spill Kit Inspection ChecklistVigneshwaraNo ratings yet

- Fire Protection ChecklistDocument9 pagesFire Protection ChecklistMircea Ovidiu BecheruNo ratings yet

- Construction Site Dengue PreventionDocument27 pagesConstruction Site Dengue PreventionparthNo ratings yet

- Site Risk Register Summarizes Facility HazardsDocument4 pagesSite Risk Register Summarizes Facility HazardsvatasaNo ratings yet

- Hot Work Permit 2Document3 pagesHot Work Permit 2prabu lingamNo ratings yet

- Risk Assessment For Stone WorkDocument17 pagesRisk Assessment For Stone WorkKhuda BukshNo ratings yet

- Health and Safety EssentialsDocument29 pagesHealth and Safety EssentialsAbdelRahman AbdelRazek RashwanNo ratings yet

- Facility safety observations and risksDocument327 pagesFacility safety observations and risksSafetyNo ratings yet

- HIRA - MS Staircase ErectionDocument7 pagesHIRA - MS Staircase ErectionRamNo ratings yet

- Gas Cutting SetDocument1 pageGas Cutting SetProjects DepartmentNo ratings yet

- EHS October 2019 Calendar Safety Training AuditsDocument1 pageEHS October 2019 Calendar Safety Training AuditsSiddharth RanaNo ratings yet

- 10-F20 Fuel Driven Equipment InspectionDocument3 pages10-F20 Fuel Driven Equipment InspectionSn AhsanNo ratings yet

- Plywood Material Safety Data Sheet For MR Plywood PDFDocument4 pagesPlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisNo ratings yet

- Bar Cutting Machine Safety Inspection ChecklistDocument1 pageBar Cutting Machine Safety Inspection ChecklistsanjeetNo ratings yet

- 2.8c Risk AssessmentDocument40 pages2.8c Risk AssessmentSn AhsanNo ratings yet

- 11 - Drilling Machine ChecklistDocument1 page11 - Drilling Machine ChecklistAfzal AkhtarNo ratings yet

- Aspect Impact New FormatDocument2 pagesAspect Impact New Formatpuri16No ratings yet

- 17.scafold Inspection UNISCO (PF) - 17Document2 pages17.scafold Inspection UNISCO (PF) - 17Benasher IbrahimNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Copy of RC HSEDocument5 pagesCopy of RC HSEAnwar Haji JavedNo ratings yet

- Warning MemoDocument10 pagesWarning MemoZaki AziziNo ratings yet

- Fire Extinguisher Inspection Record Jan-2021Document12 pagesFire Extinguisher Inspection Record Jan-2021Sarmad HussainNo ratings yet

- Site Safety Issues ReportedDocument1 pageSite Safety Issues ReportedhaniNo ratings yet

- Safety OfficerDocument16 pagesSafety OfficerAzad pravesh khanNo ratings yet

- DRL - Project Check List For Metal Cutting Machine: .RPM .RPMDocument1 pageDRL - Project Check List For Metal Cutting Machine: .RPM .RPMSachin Hse Rohtak100% (1)

- Visitor Safety BriefingDocument2 pagesVisitor Safety BriefingDoni TriatmojoNo ratings yet

- EEEPL - JSA Unloading MaterialsDocument3 pagesEEEPL - JSA Unloading MaterialsnishanthNo ratings yet

- No Photo Before Comments Risk Matrix Photo After Action TakenDocument4 pagesNo Photo Before Comments Risk Matrix Photo After Action TakenShafie ZubierNo ratings yet

- Check List (Pre Entry) For Gas Cutting SetDocument2 pagesCheck List (Pre Entry) For Gas Cutting SetAli KaziNo ratings yet

- 01 WI HSE 001 - Risk Assessment GroutingDocument4 pages01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (1)

- Plant observation and action planDocument4 pagesPlant observation and action planZeeshan Pathan0% (1)

- Work at Height ChecklistDocument4 pagesWork at Height ChecklistSanil KuriakoseNo ratings yet

- Draft PTWDocument1 pageDraft PTWmohamad nur saufiNo ratings yet

- Shop Safety Safe Work Procedure DRILL PRESSDocument1 pageShop Safety Safe Work Procedure DRILL PRESSTamoy CooreNo ratings yet

- Hira - CivilDocument20 pagesHira - Civilmurthy100% (1)

- RA (Working at Height)Document4 pagesRA (Working at Height)Yan Naing HtooNo ratings yet

- Hazrd Identification & Risk Assessment: Mmf100 Nov 2009 - Pm/105/01 © Mott Macdonald 2009Document2 pagesHazrd Identification & Risk Assessment: Mmf100 Nov 2009 - Pm/105/01 © Mott Macdonald 2009SuperuserAsadhussainNo ratings yet

- Risk Assessment ActivityDocument5 pagesRisk Assessment ActivityHarthwell CapistranoNo ratings yet

- Manual Handling (Risk Assessment)Document3 pagesManual Handling (Risk Assessment)khurram shahzadNo ratings yet

- Daily Safety Report TemplateDocument1 pageDaily Safety Report TemplateMarkNo ratings yet

- Contractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020Document5 pagesContractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020ManPower RecruitingNo ratings yet

- Safety InductionDocument35 pagesSafety Inductionsumit solankiNo ratings yet

- OHSE Project HIRA - Fencing Work - R 1Document1 pageOHSE Project HIRA - Fencing Work - R 1Pankaj SinghNo ratings yet

- Project Risk Index For Hira: Severity Level ProbablityDocument4 pagesProject Risk Index For Hira: Severity Level ProbablitysayleeNo ratings yet

- Road safety insights from analysis of factors causing accidentsDocument14 pagesRoad safety insights from analysis of factors causing accidentsAnil DangiNo ratings yet

- Standardization and Upgrading of Barmm HospitalsDocument41 pagesStandardization and Upgrading of Barmm HospitalsApipah Datudacula-MacabangkitNo ratings yet

- 8501-00-2200 GentleMAX PRO Operators Manual RevADocument160 pages8501-00-2200 GentleMAX PRO Operators Manual RevAgamal elhanafeyNo ratings yet

- Stressful Family or Friend SituationsDocument2 pagesStressful Family or Friend SituationsCinthia Hoyos jiménezNo ratings yet

- Clostridioides Difficile Infection in Patients WitDocument10 pagesClostridioides Difficile Infection in Patients WitElena Cuiban100% (1)

- Hospital Architecture As An Active Medicine: Bilyana DochevaDocument146 pagesHospital Architecture As An Active Medicine: Bilyana DochevaGIANELLA NAJARRONo ratings yet

- Carcedo vs. Maine Marine PhilsDocument21 pagesCarcedo vs. Maine Marine PhilsDani McstNo ratings yet

- Public HealthDocument28 pagesPublic HealthDoc Weh Akut-Salutan100% (1)

- Development Stages in Middle and Late AdolescenceDocument19 pagesDevelopment Stages in Middle and Late AdolescenceJohn Anniel BundalianNo ratings yet

- Nursing DiagnosisDocument16 pagesNursing DiagnosisShemie TutorNo ratings yet

- Nursing Care Plan for Postpartum HemorrhageDocument4 pagesNursing Care Plan for Postpartum HemorrhageEvangeline Anne MacanasNo ratings yet

- Making Strides EbookDocument18 pagesMaking Strides EbooksamNo ratings yet

- Mifepristone & MisoprostolDocument6 pagesMifepristone & MisoprostolnanimadallaNo ratings yet

- Department of Social Welfare and DevelopmentDocument4 pagesDepartment of Social Welfare and DevelopmentJhana May PayatNo ratings yet

- Miller 2010 Chapter 2Document22 pagesMiller 2010 Chapter 2elsaNo ratings yet

- Social Pension Intake FormDocument1 pageSocial Pension Intake FormJazzera MustaphaNo ratings yet

- Tsinghua GSS 2022 Essay SubmissionDocument6 pagesTsinghua GSS 2022 Essay SubmissionNgọc BùiNo ratings yet

- Washington HospitalsDocument9 pagesWashington HospitalsJoe FrascaNo ratings yet

- Guia de Transductores Logiq P9Document4 pagesGuia de Transductores Logiq P9carolinaNo ratings yet

- Handout - EnoxaparinDocument2 pagesHandout - EnoxaparinVette Angelikka Dela Cruz100% (1)

- Determining The Effectiveness of Neem and Papaya L-2Document8 pagesDetermining The Effectiveness of Neem and Papaya L-2Ariana hazelNo ratings yet

- Session #8 SAS - TFNDocument8 pagesSession #8 SAS - TFNNiña Christel B. BarlomentoNo ratings yet

- No Timestamp Nama Lengkap Email Nomor Handphone OrganisasiDocument16 pagesNo Timestamp Nama Lengkap Email Nomor Handphone OrganisasiMeta WulandariNo ratings yet

- Wa0033Document10 pagesWa0033Obrian RobinsonNo ratings yet

- Pfe Family PreparednessDocument1 pagePfe Family PreparednessNicole ForrosueloNo ratings yet

- Writ CallDocument4 pagesWrit CallSandhya GurunathNo ratings yet

- Unlocking The Mysteries of DeafBlind InterpretingDocument74 pagesUnlocking The Mysteries of DeafBlind InterpretingMark Niño A. BrunoNo ratings yet

- Child Safety PresentationDocument19 pagesChild Safety Presentationalabama_medic100% (1)

- DUPHAT 2016 LeafletDocument2 pagesDUPHAT 2016 LeafletIPSF EMRONo ratings yet

- Diagnosis MataDocument168 pagesDiagnosis Mata19. Moh Hidayatullah AL AhyaNo ratings yet