0% found this document useful (0 votes)

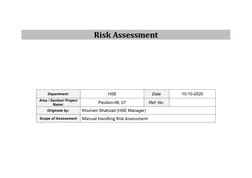

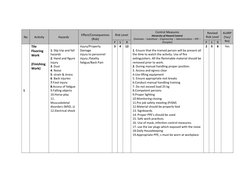

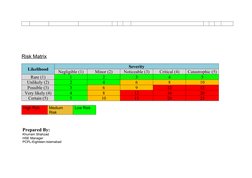

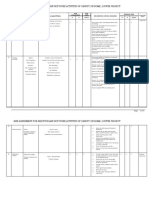

435 views3 pagesManual Handling Risk Guide

Risk Assessment of Manual Handling will be beneficial for all HSE professional to evaluate the risks of manual handling.

Uploaded by

khurram shahzadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

435 views3 pagesManual Handling Risk Guide

Risk Assessment of Manual Handling will be beneficial for all HSE professional to evaluate the risks of manual handling.

Uploaded by

khurram shahzadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd