Professional Documents

Culture Documents

RD-M662 Instruction Manual

Uploaded by

geeen115797Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RD-M662 Instruction Manual

Uploaded by

geeen115797Copyright:

Available Formats

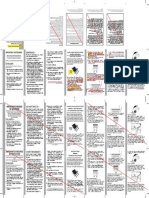

General Safety Information Technical Service Instructions SI-5WM0A-002 3.

Chain length on bicycles with rear suspension

The length of A will vary depending on the movement of the rear Note:

suspension. Because of this, an excessive load may be placed Set the inner cable so that it protrudes by a

WARNING on the drive system if the chain length is too short. Set the length of less than about 30 mm, and then

length of the chain by adding two links to the chain when the rear check that the inner cable does not interfere with

• If it is difficult to install the wheel, install the quick release lever on the rotor side.

If doing this, make sure that the quick release lever does not interfere with the rotor and that

burns do not occur.

RD-M662 Rear derailleur suspension is at a position where dimension "A" is longest and

the chain is on the largest sprocket and the largest chainring. If

the spokes of the wheel. Stop the wheel from

turning while carrying out this step.

the amount of movement of the rear suspension is large, the

• Use neutral detergent to clean the chain. Do not use alkali-based or acid based detergent such slack in the chain may not be taken up properly when the chain is

as rust cleaners as it may result in damage and/or failure of the chain. Less than 30 mm

on the smallest chainring and smallest sprocket.

• Use the reinforced connecting pin only for connecting the narrow type of chain.

• There are two different types of reinforced connecting pins available. Be sure to check the table In order to realize the best performance, we recommend that the following

below before selecting which pin to use. If connecting pins other than reinforced connecting pins combination be used. Chain

are used, or if a reinforced connecting pin or tool which is not suitable for the type of chain is Largest Largest

used, sufficient connection force may not be obtained, which could cause the chain to break or Series SLX sprocket chainring 5. How to use the B-tension adjustment screw

fall off. Mount the chain on the smallest chainring and the largest

RAPIDFIRE (Shifting lever) SL-M660 sprocket, and turn the crank arm to shift gears. Then turn the B-

Chain

Reinforced

Chain tool Outer casing SIS-SP41 tension adjustment screw Largest sprocket Smallest sprocket

connecting pin to adjust so that the guide

Rear derailleur RD-M662

9-speed super narrow pulley does not interfere

chain such as Silver TL-CN32 / TL-CN27 Type SGS / GS with the sprocket but not so

CN-7701 / CN-HG93 6.5mm Add 2 links (with the chain on both the largest close that it touches the

Freehub FH-M665 sprocket and the largest chainring)

8- / 7- / 6-speed narrow chain. Next, set the chain

chain such as Black TL-CN32 / TL-CN27 Gears 9 to the smallest sprocket

CN-HG50 / CN-HG40 7.1mm B-tension

Cassette sprocket CS-HG80 and repeat the above to adjustment screw

• If it is necessary to adjust the length of the chain due to a change Reinforced Connecting Pin 4. Outer casing length make sure that the pulley

Chain CN-HG73

in the number of sprocket teeth, make the cut at some other place (1) Loosen the B-tension adjustment screw until it is in the does not touch the

than the place where the chain has been joined using a Bottom bracket guide SM-SP17 position shown in the illustration. sprocket.

reinforced connecting pin or an end pin. The chain will be (2) Check that there is enough slack in the outer casing. Next,

damaged if it is cut at a place where it has been joined with a End Pin Link Pin align the outer casing with the bottom <Checking the distance between the largest sprocket

reinforced connecting pin or an end pin. Specifications edge of the outer casing holder at the Outer casing (2) and the guide pulley>

• Check that the tension of the chain is correct and that the chain is not damaged. If the tension is rear derailleur and then cut of any excess Set the rear derailleur to the lowest gear

too weak or the chain is damaged, the chain should be replaced. If this is not done, the chain length of outer casing. position, stop the wheel from turning, and then

Rear Derailleur

may break and cause serious injury. check that the distance from the edge of the

• Obtain and read the service instructions carefully prior to installing the parts. Loose, worn or Model number RD-M662 guide pulley to the edge of the largest sprocket

(1)

damaged parts may cause the bicycle to fall over and serious injury may occur as a result. We Type SGS GS is within the range of 5 - 6 mm. Turn the crank

strongly recommend only using genuine Shimano replacement parts. arm to shift gears and check that there is no

Gears 9 9

• Obtain and read the service instructions carefully prior to installing the parts. If adjustments roughness in the feel. If the number of teeth for the cassette

are not carried out correctly, the chain may come off and this may cause you to fall off the bicycle Total capacity 45T 35T sprocket is changed, carry out this setting again.

Outer casing holder

which could result in serious injury. Applicable sprocket combination 11 - 32T, 11 - 34T

• Read these Technical Service Instructions carefully, and keep them in a safe place for later Note:

reference. Smallest sprocket 11T 11T 6. SIS Adjustment

The distance between the outer stopper to the outer casing Operate the shifting lever several times to move the chain to the

Front chainwheel tooth difference 22T 22T holder of the rear derailleur may change when the rear 2nd sprocket. Then, while pressing the lever just enough to take

suspension moves, so determine the length of the outer casing at up the play in the lever, turn the crank arm.

Note the point where this length is at its greatest.

• If gear shifting operations do not feel smooth, wash the derailleur and lubricate all moving parts.

• If the amount of looseness in the links is so great that adjustment is not possible, you should Installation of the rear derailleur When shifting to When no sound

replace the derailleur. 3rd at all is heard

• You should periodically clean the derailleur and lubricate all moving parts (mechanism and 5 mm Allen key Dropout

pulleys). Cutting the outer casing

• If gear shifting adjustment cannot be carried out, check the degree of parallelism at the rear end Bracket

After cutting the outer casing, make the end round so that the

of the bicycle. Also check if the cable is lubricated and if the outer casing is too long or too short. inside of the hole has a uniform diameter.

• If you hear abnormal noise as a result of looseness in a pulley, you should replace the pulley. Adjustment bolt Adjustment bolt

• If the chain keeps coming off the sprockets during use, replace the sprockets and the chain.

• Use a frame with internal cable routing is strongly discouraged as it has tendencies to impair the

SIS shifting function due to its high cable resistance. Attach the same outer

• Always be sure to use the sprocket set bearing the same group marks. Never use in combination end cap to the cut end Outer end cap

with a sprocket bearing a different group mark. of the outer casing.

• Use an outer casing which still has some length to spare even when the handlebars are turned Tighten the outer casing Loosen the outer casing

all the way to both sides. Furthermore, check that the shifting lever does not touch the bicycle Bracket spindle

Tightening torque : The sealed cap with Be careful not to bend adjustment barrel until the adjustment barrel until the

frame when the handlebars are turned all the way. tongue and the rubber Rubber shield chain returns to the 2nd chain touches the 3rd sprocket

8 - 10 N·m {70 - 86 in. lbs.}

• A special grease is used for the gear shifting cable (SIS-SP41). Do not use Group marks shield should be sprocket. (clockwise) and makes noise. (counter

DURA-ACE grease or other types of grease, otherwise they may cause Note: Periodically check that there is installed to the outer clockwise)

Sealed cap with tongue

deterioration in gear shifting performance. ag - 18T

no gap between the dropout and the casing stopper of the

• Grease the inner cable and the inside of the outer casing before use to ag -15

T

ag

-1

3T bracket as shown in the illustration. frame. Rubber shield

ensure that they slide properly. If there is a gap between these two

• For smooth operation, use the specified outer casing and the bottom bracket parts, problems with gear shifting Best setting

cable guide. performance may occur. The best setting is when the shifting lever is

SH

IM

• Operation of the levers related to gear shifting should be made only when

AN

O

HYPERGL I DE - C

operated just enough to take up the play and the

the front chainwheel is turning.

chain touches the 3rd sprocket and makes noise.

• Parts are not guaranteed against natural wear or deterioration resulting from normal use.

• For maximum performance we highly recommend Shimano lubricants and maintenance products SIS Adjustment * Return the lever to its original position (the position where

the lever is at the 2nd sprocket setting and it has been

• For any questions regarding methods of installation, adjustment, maintenance or operation,

1. Top adjustment released) and then turn the crank arm clockwise. If the

please contact a professional bicycle dealer. Outer line of

chain is touching the 3rd sprocket and making noise, turn the outer

Turn the top adjustment screw to adjust so smallest sprocket Connect the cable to the rear

derailleur and, after taking up Note: Be sure that the cable is casing adjustment barrel clockwise slightly to tighten it until the noise

that the guide pulley is in line with the outer securely in the groove. stops and the chain runs smoothly.

line of the smallest sprocket when looking the initial slack in the cable,

from the rear. re-secure to the rear Operate lever to change gears, and check that no noise occurs

derailleur as shown in the in any of the gear positions.

illustration.

Top adjustment

screw

For the best SIS performance, periodically lubricate all

power-transmission parts.

Guide pulley

This service instruction explains how to use and maintain the Shimano bicycle parts which have been Pull

used on your new bicycle.

Groove

For any questions regarding your bicycle or other matters which are not related to Shimano parts, 2. Low adjustment Largest sprocket

please contact the place of purchase or the bicycle manufacturer. Turn the low adjustment screw so that the

guide pulley moves to a position directly in line Tightening torque :

with the largest sprocket. 5 - 7 N·m {44 - 60 in. lbs.}

Low adjustment

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003 screw

Guide pulley

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222 3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan

Please note: specifications are subject to change for improvement without notice. (English) © May 2008 by Shimano Inc. XBC SZK Printed in Japan.

You might also like

- Cummins - ISX15 CM2250 (2010-12)Document6 pagesCummins - ISX15 CM2250 (2010-12)Olvin OrtizNo ratings yet

- Master Log - LOGDocument15 pagesMaster Log - LOGAnandu AshokanNo ratings yet

- ASME B30.30 2019 Wire RopesDocument14 pagesASME B30.30 2019 Wire Ropesoka andreaNo ratings yet

- 5.transmission 2nd Housing 4 7Document1 page5.transmission 2nd Housing 4 7azry_alqadryNo ratings yet

- Training Doc Mercedes 900Document195 pagesTraining Doc Mercedes 900mliugong98% (40)

- Parts ListDocument38 pagesParts ListHfksosnaaoNo ratings yet

- Camshaft Timing M62 VanosDocument10 pagesCamshaft Timing M62 Vanosmjassbong100% (1)

- Wahl Clippers Instructions PDFDocument2 pagesWahl Clippers Instructions PDFmukadeNo ratings yet

- DODGE V Belt IOM PDFDocument8 pagesDODGE V Belt IOM PDFSupervisorNo ratings yet

- Understanding Your Boats Systems and Choices.From EverandUnderstanding Your Boats Systems and Choices.Rating: 3 out of 5 stars3/5 (1)

- Block Rotation and Rope Stability PDFDocument3 pagesBlock Rotation and Rope Stability PDFAnshul AsthanaNo ratings yet

- Proper Wire Rope UseDocument10 pagesProper Wire Rope Usekartoon_38No ratings yet

- Assembly Section: Mast - Contact Combilift Quoting The Truck Serial Number For Mast Parts ManualDocument71 pagesAssembly Section: Mast - Contact Combilift Quoting The Truck Serial Number For Mast Parts ManualÁrpád AndrisNo ratings yet

- Standard/Optional Equipment FeaturesDocument2 pagesStandard/Optional Equipment FeaturesAdmir BašićNo ratings yet

- 6R160010F Parts CatalogueDocument104 pages6R160010F Parts Catalogueniceashwin79No ratings yet

- Wire Rope End Treatments.: Preparation For InstallationDocument10 pagesWire Rope End Treatments.: Preparation For Installationegy pureNo ratings yet

- DP Operator Manual Section 8 Lightweight Taut Wire SystemsDocument5 pagesDP Operator Manual Section 8 Lightweight Taut Wire SystemsKunal SinghNo ratings yet

- Shimano Saint-Zee RD Service ManualDocument1 pageShimano Saint-Zee RD Service ManualJose Luis GutierrezNo ratings yet

- Si 5W70B 001 EngDocument1 pageSi 5W70B 001 EngFerhatNo ratings yet

- XT FD & Crank InstallationDocument1 pageXT FD & Crank InstallationMarNo ratings yet

- Shimano Deore Crankset User ManualDocument1 pageShimano Deore Crankset User ManualJose Luis GutierrezNo ratings yet

- Shimano Front DerailleurDocument1 pageShimano Front DerailleurAndreiNo ratings yet

- DR1000 Installation Instruction Rev JDocument4 pagesDR1000 Installation Instruction Rev JLupita ArriagaNo ratings yet

- SI-R917B-ENG v1 m56577569830657326Document1 pageSI-R917B-ENG v1 m56577569830657326Laurentiu GamanNo ratings yet

- Shimano Resetting Disc Brake PistonsDocument1 pageShimano Resetting Disc Brake PistonsJose Luis GutierrezNo ratings yet

- Si 6ngfa 004 EngDocument1 pageSi 6ngfa 004 EnglgsmartNo ratings yet

- Before Reading This User ManualDocument2 pagesBefore Reading This User ManualJeancarlos DominguezNo ratings yet

- 73603BR Transducer InstallationDocument2 pages73603BR Transducer InstallationFlorin PloscarNo ratings yet

- Shimano Inter-M Rollerbrakes GuideDocument1 pageShimano Inter-M Rollerbrakes Guider4kemberNo ratings yet

- Eng Shimano Manu 07214Document1 pageEng Shimano Manu 07214RodrigoMacedoNo ratings yet

- Bike CalipersSI - 8C60H - en - v1 - m56577569830604598Document1 pageBike CalipersSI - 8C60H - en - v1 - m56577569830604598Stuart BaileyNo ratings yet

- Shimano SLX HG81 Cassette Service ManualDocument1 pageShimano SLX HG81 Cassette Service ManualJose Luis GutierrezNo ratings yet

- Maintenance Presentation SlideDocument56 pagesMaintenance Presentation Slidekapun kumar nayakNo ratings yet

- SI 6M10A en v1 m56577569830604102Document1 pageSI 6M10A en v1 m56577569830604102xjcaiNo ratings yet

- Climatic Conditions: BY S.B.M.Guptha (21011NB003) G.Chaithanya (21011NB005) M.Rachana (21011NB008)Document4 pagesClimatic Conditions: BY S.B.M.Guptha (21011NB003) G.Chaithanya (21011NB005) M.Rachana (21011NB008)Merugu RachanaNo ratings yet

- Howard Fluting Jig Manual Rev 4Document9 pagesHoward Fluting Jig Manual Rev 4EricsNo ratings yet

- 2007 RST Mid Models EnglishDocument1 page2007 RST Mid Models EnglishMaribe TshegoNo ratings yet

- Maintenance Notes: Ensure That Roller Chains Are Properly TensionedDocument8 pagesMaintenance Notes: Ensure That Roller Chains Are Properly TensionedBülent BulutNo ratings yet

- Resource: Sheepshank SheepshankDocument3 pagesResource: Sheepshank SheepshankKeanu100% (1)

- Alivio Front Drive SystemDocument1 pageAlivio Front Drive SystemMarNo ratings yet

- (New) - Rulmeca Return Belt Tracking BrochureDocument2 pages(New) - Rulmeca Return Belt Tracking BrochureSandiNo ratings yet

- Marina SlimFilter Manual HRDocument2 pagesMarina SlimFilter Manual HRRoberto E MoránNo ratings yet

- SI 6KFRB en v1 m56577569830612587Document1 pageSI 6KFRB en v1 m56577569830612587Tadele BefkaduNo ratings yet

- Shimano D CL LeversDocument1 pageShimano D CL LeversxjcaiNo ratings yet

- Manual FD 7900 ENDocument2 pagesManual FD 7900 ENGvbbNo ratings yet

- SI-8C90E-000-EnG (Jan. 2004) Disc Brake SystemDocument1 pageSI-8C90E-000-EnG (Jan. 2004) Disc Brake SystemboomissyNo ratings yet

- SI 6KFFB 001 ENG - v1 - m56577569830687361Document1 pageSI 6KFFB 001 ENG - v1 - m56577569830687361Onus Probandis HedonistaNo ratings yet

- Act Cycling Walking Map-1 PDFDocument2 pagesAct Cycling Walking Map-1 PDFMike LikesbikesNo ratings yet

- Chain drive transmits 15 kW powerDocument19 pagesChain drive transmits 15 kW powerPatrick NdlovuNo ratings yet

- Super Slings Rigging Catalog 2020 - 1D Slings Wire Rope 1001 - WebDocument30 pagesSuper Slings Rigging Catalog 2020 - 1D Slings Wire Rope 1001 - WebDouglasFariaNo ratings yet

- SFM Installation Guide 20190301 2Document22 pagesSFM Installation Guide 20190301 2Eric WilsonNo ratings yet

- 5603 Front Derailer ServiceDocument1 page5603 Front Derailer ServiceMichaelRMilaniNo ratings yet

- Manual de InstalareDocument6 pagesManual de InstalarePaul PopescuNo ratings yet

- .32 Marine Owner's Manual: Setting The Needle ValvesDocument2 pages.32 Marine Owner's Manual: Setting The Needle ValvesGodsniperNo ratings yet

- V Belt & Rope Drive ProblemsDocument18 pagesV Belt & Rope Drive ProblemsarulmuruguNo ratings yet

- Belden Fiber Optic CablesDocument10 pagesBelden Fiber Optic CablesIslam BarakatNo ratings yet

- Belt Routing GuideDocument87 pagesBelt Routing GuideBYRONGOSNo ratings yet

- Transducer Installation Guide: MaintenanceDocument2 pagesTransducer Installation Guide: MaintenanceJohn HedgepethNo ratings yet

- Nexus 7 Installation Service ManualDocument2 pagesNexus 7 Installation Service ManualsolerviNo ratings yet

- Install sprocket and cassette joint fixing ring safelyDocument1 pageInstall sprocket and cassette joint fixing ring safelysolerviNo ratings yet

- 303 - 1 Power Transmission Equipment Course PreviewDocument19 pages303 - 1 Power Transmission Equipment Course PreviewAnonymous q9eCZHMuS0% (2)

- Yamaha TDM 850 Scottoiler VSystem English8!8!2012Document1 pageYamaha TDM 850 Scottoiler VSystem English8!8!2012kojot-bg2640No ratings yet

- Dewalt DC845KA ManualDocument7 pagesDewalt DC845KA Manualtestmonger5237No ratings yet

- Cat07 p10LASHINGDocument1 pageCat07 p10LASHINGrivera1084No ratings yet

- Scottoiler: Kawasaki ZZR 600: Scottoiler Vsystem Installation GuideDocument1 pageScottoiler: Kawasaki ZZR 600: Scottoiler Vsystem Installation GuidejitmarineNo ratings yet

- Use and CareDocument4 pagesUse and CarechannarongNo ratings yet

- WA600-1 S/N 10001-UP (Overseas Version)Document2 pagesWA600-1 S/N 10001-UP (Overseas Version)Morteza BaratzadehNo ratings yet

- En500 c6fc7fc8fc9f Parts List PDFDocument90 pagesEn500 c6fc7fc8fc9f Parts List PDFOliverNo ratings yet

- Rock drill parts and seal kitsDocument5 pagesRock drill parts and seal kitsLestat LimboNo ratings yet

- Tajima TFGN 2007.06Document79 pagesTajima TFGN 2007.06alsubhantraders937No ratings yet

- Rtlo-16918b PartesDocument34 pagesRtlo-16918b PartesElmer Tintaya MamaniNo ratings yet

- Z-LOCK Shaft Locking Assemblies GuideDocument19 pagesZ-LOCK Shaft Locking Assemblies GuideRaymond BalladNo ratings yet

- Arctic Cat - 2002 - zr120 Parts ManualDocument22 pagesArctic Cat - 2002 - zr120 Parts ManualHarold GillNo ratings yet

- Lab Wiring 3Document10 pagesLab Wiring 3Nur Afiqah Mohamad NayanNo ratings yet

- sl35 Installation InstructionsDocument2 pagessl35 Installation InstructionsHenry CanalesNo ratings yet

- DZW position measuring system component partsDocument12 pagesDZW position measuring system component partsBang OchimNo ratings yet

- Matrix 2003 2zz 8Document10 pagesMatrix 2003 2zz 8alan lantiguaNo ratings yet

- Repair Wire Non-Waterproof Type PDFDocument13 pagesRepair Wire Non-Waterproof Type PDFw3286100% (1)

- Normativa Técnica Salvadoreña de AccesibilidadDocument2 pagesNormativa Técnica Salvadoreña de AccesibilidadmattkidoNo ratings yet

- Catálogo Renold-TyreflexDocument4 pagesCatálogo Renold-TyreflexLuis ValenzuelaNo ratings yet

- Load-Sensing Control Block in Mono Block/sandwich Plate Design M4-12Document40 pagesLoad-Sensing Control Block in Mono Block/sandwich Plate Design M4-12Israel RuizNo ratings yet

- Electric Parts Upper Care K 0310Document2 pagesElectric Parts Upper Care K 0310richard flamwellNo ratings yet

- Bray Válvula GuillotinaDocument8 pagesBray Válvula Guillotinajuniortrader05No ratings yet

- ARNS-1000FB Reel Parts ListDocument1 pageARNS-1000FB Reel Parts ListJuan TrujilloNo ratings yet

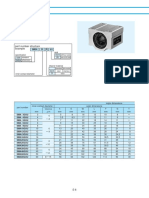

- NB BlocktypeDocument21 pagesNB BlocktypesunhuynhNo ratings yet

- JK Wrangler 3.6L V6 Front Axle DiagnosisDocument4 pagesJK Wrangler 3.6L V6 Front Axle Diagnosisetienne therrienNo ratings yet

- Audi A4 2005 - Oil Pump Gears PDFDocument3 pagesAudi A4 2005 - Oil Pump Gears PDFPloesteanu AndreeaNo ratings yet

- A4 Brake SystemDocument190 pagesA4 Brake SystemNPNo ratings yet