Professional Documents

Culture Documents

EWB Water Tower: Department of Civil and Environmental Engineering CE484 Design Lab Design Submittal Report

Uploaded by

Arvin De Guzman SantosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EWB Water Tower: Department of Civil and Environmental Engineering CE484 Design Lab Design Submittal Report

Uploaded by

Arvin De Guzman SantosCopyright:

Available Formats

Department of Civil and Environmental Engineering

CE484 Design Lab

Design Submittal Report

EWB Water Tower

Submitted to:

Kent Lall, Ph.D., P.E.

Portland State University

Department of Civil and Environmental Engineering

PO Box 751

Portland, OR 97207-0751

PHONE: (503) 725-4245

FAX: (503) 725-5950

kent@cecs.pdx.edu

Submitted by:

Tom Wharton-Project Manager

Nick Carey

Helen Oppenheimer

Erin Qureshi

Ivan Perez

Rob Allan

May 22, 2007

EWB Water Tower Design Proposal

Introduction............................................................................................................................... 2

Background ............................................................................................................................... 2

Selection of Design .................................................................................................................... 3

Project Design............................................................................................................................ 3

Geotechnical Recommendations.......................................................................................... 4

Foundation Design ................................................................................................................ 4

Tank Tower Design............................................................................................................... 4

Tank Flow Connections Design ........................................................................................... 5

Work Plan.................................................................................................................................. 5

Costs ........................................................................................................................................... 6

Appendix A: Geotechnical ....................................................................................................... 7

Appendix B: Foundation Design ............................................................................................. 8

Appendix C: Tank Tower Design............................................................................................ 9

Appendix D: Tank Flow Connections Design ...................................................................... 22

Appendix E: Design Plan Set ................................................................................................. 25

97 Uniform Building Code ..................................................................................................... 26

Breakdown of Billable Hours................................................................................................. 27

References ................................................................................................................................ 29

Portland State University 1

EWB Water Tower Design Proposal

Introduction

The Jessie F. Richardson Foundation, in conjunction with the Institute on Aging at Portland State

University has been working to provide accessible care for the elderly of Nicaragua. Both

agencies have also prompted coordination with Engineers Without Borders to update elder-care

facilities within Nicaragua. Of specific concern is the facility in the city of Jinotepe, which was

originally built to handle 14 residents. The current number of residents is at 37 persons and is

expected to keep increasing as the population of the aged increases. The resident population

growth is causing increased costs to the home as well as the city of Jinotepe which provides

water and electricity to the facility free of charge.

N↑

Figure 1 Pacific coast region of Nicaragua

Background

In the spring of 2006 an Engineers Without Borders student group, under the auspices of the

Jessie F. Richardson Foundation and Portland State University’s Institute on Aging, installed a

secondary potable water storage tank at an elderly care facility in Jinotepe Nicaragua. The

original project design was to install a pump and plumbing lines to a preexisting open top

concrete tank. Upon inspection of the concrete tank it was found to not be suitable for water

storage as it leaked its entire contents over the course of one evening. As a solution to the faulty

tank and time constraints, a prefabricated vinyl water tank was purchased and installed on the

ground next to the original elevated water tank utilizing the original pump system design. When

the final inspection occurred with the facility administrator, the issue of paying for electricity to

pump water from the lower tank to the main facility tank was questioned for the long term

maintenance. The primary reservation brought up by the facility administrator was that the

installed tank, unlike the concrete tank, should have been placed on another tower as an

expansion of the current gravity feed system for the water supply.

In agreement with the facility administrator and Keren Brown Wilson of the Jessie F. Richardson

Foundation, the student assessment team committed to returning the following year to remove

the electrical reliance of the pump in the water supply system. Currently, the city water line

supplies enough pressure to fill the elevated water storage tank and the ground-level storage tank

Portland State University 2

EWB Water Tower Design Proposal

at the site. The elevated tank directly supplies potable water into the facility. The lower tank acts

solely as secondary storage unit and pumps water to the elevated tank once it is empty.

Selection of Design

The goal of this design was to provide a clear cost effective and maintainable design that fits into

the cultural paradigm of this Pacific Coast region of Nicaragua. One of the alternatives

considered was a solar-powered system. The physical environment as well as the application

and installation of the solar power system would have been feasible. The problem with the solar

system lies in the cost. Although the installation cost is possible to meet, battery replacement

costs would be cost-prohibitive. The gel batteries, which are encased and sealed from the

environment, are costly. The present value of battery replacement is upwards of $375, not

accounting for shipping and possible installation costs.

A second alternative considered involved using human power, such as a pedal-powered bicycle

pumping system. Installation costs could have been met, but we cannot guarantee that the device

would be used as regularly as necessary to generate enough power.

Wind power was another alternative considered. A wind turbine could have functioned as a

back-up device to the pump, but several factors make this option prohibitive. The wind turbine

would require two sealed deep-cell batteries, which would need replacing every 10 years, and

which would cost approximately $750 before shipping and installation. The turbine itself would

require specialized mechanical maintenance which would be costly. Another hindrance to wind-

turbine installation is the fact that the mast would need to be sufficiently tall to clear the trees,

and the town administrators would likely not approve a structure of the required height.

The design selected, based on client expectations and cost feasibility, is a raised water tank and

tower. Erecting a tower to elevate the secondary storage tank will eliminate the need for a pump

system. Raising the water tank will provide hydrostatic pressure (about 0.44 PSI per foot of

height) which would provide sufficient pressure for the gravity feed system that requires little or

no maintenance for a design life based on the durability of the steel tower. A frame made from

steel will best withstand the weather conditions and be an acceptable structure at the facility.

The project is also feasible because it utilizes the talents and skills of civil and mechanical

engineering students and fits within the time constraints of the volunteer workforce.

Project Design

Fundamental aspects of the design are a steel frame tower with concrete and rebar footings. The

tower will provide the support for a 2500 liter water tank. The new tower will be connected,

structurally, to the existing water tower to mitigate seismic risk issues. The connection will also

provide a rigid support to guard the pipe connections that are susceptible to shearing due to

differential settlement of the tower relative to the existing structure.

Portland State University 3

EWB Water Tower Design Proposal

Geotechnical Recommendations

Seismic data for the country of Nicaragua shows that seismic activity is a serious potential

hazard. (Hedberg, 87). According to the 1997 Uniform Building Code (UBC) and United States

Geological Survey (USGS) Central America Hazard Map it was concluded that Jinotepe has

been categorized Zone 4, the most severe earthquake hazard category. See Appendix.A for

Managua, Nicaragua fault map.

During the course of the original assessment it was noted that the soil specific to the construction

site is tuff-based non-cohesive low-density silt. Since no direct soil sampling was performed the

97-UBC was referenced and utilizing a soil SD type the following recommendations were made:

• Allowable foundation pressure - 1000 psf (47.9 kPa)

• Lateral bearing of depth below natural grade – 100 psf per ft (15.7 kPa per m)

• Lateral sliding resistance – 130 psf (6.227 kPa)

Foundation Design

Due to the limited information regarding soil properties in Jinotepe other than preliminary basic

information, it can be assumed a worst-case scenario for design purposes under ASD.

After calculations, it was determined that the maximum seismic load was 2,053 lb. See

Appendix B for calculations of the seismic load. The main problem in water towers is the

potential for overturning due to lateral forces such as seismic and wind loads. Thus, the main

design considerations were bearing and overturning.

The foundation system will utilize 2' x 2' spread footings, 19-in thick, and reinforced with four

#3 rebar, spaced at 6" o.c. in both directions under each column of the 2500L tower at mid-depth.

A detailed view of the foundation design parameters can be seen in Appendix B, Foundation

Design.

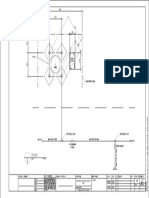

Tank Tower Design

The tower was designed to hold a five foot diameter, 2500L tank, ten feet in the air under gravity

and seismic loading using the 97 Universal Building Code and the United States Geological

Survey Central America Hazard map. The existing tower was analyzed using SAP modeling

software with a 100 lb DL, 5500 lb LL, and a seismic base shear of V=.35W. Analysis

concluded that the existing tower design is stable and all members are within their capacities.

The loading results are available in appendix B.

Columns will be HSS3 x 3 x ⅛, the perimeter members of the tank platform will be L3 x 3 x ¼

and all other members will be L2 x 2 x ⅛. The maximum joint loading is1050 ft-lb moment and

2300 lb axial load. Considering the tower will be assembled in the field by amateur welders, an

1/8” fillet weld with a capacity of 1.28 kips per inch of weld on all contact surfaces will be

sufficient to overcome any weld flaws.

Portland State University 4

EWB Water Tower Design Proposal

A bending moment induced into the main support columns at the one-third point could be

avoided by running the x-bracing all the way to the footing; however, for ease of installation,

design was kept as is. Considering the low load to capacity ratios of the column members, this is

acceptable.

Tank Flow Connections Design

Upon assessment of required flow between the towers, it is suggested that a PVC pipe with a 1-in

diameter be used. The water supply to the tank system is provided by the city water system. The

city water supply pressure fluctuates between 30 to 50psi which is sufficient to feed the elevated

tanks.

A minimum inner pipe diameter of ½ inch would work for the system and the flow calculations

are shown in Appendix D. The current design, however utilizes 1 inch PVC piping. The 1”

diameter pipe has an inner diameter of 7/8 inches and will allow the system to manage any

increased demand that is unforeseen in this analysis without being too conservative. It is also

good practice to stay with the current sizing that has sufficiently supported the current potable

water feeds into the facility.

Work Plan

Day 0 (before construction crew arrival): Drainage of current tank system, system disconnection

from municipal water supply by facilities’ maintenance

Day 1: Dig piers, install reinforcing bars, and pour piers.

Day 2: Lay out steel, cut to length, and begin tower erection.

Day 3: Tower erection.

Day 4: Tower erection, raise tank.

Day 5: Connect plumbing, check for leaks.

Day 6: Approval from administrator to close-out project prior to departure.

Figure 2 Project work plan with predecessor constraints

Portland State University 5

EWB Water Tower Design Proposal

Costs

The itemized cost breakdown is as follows:

Unit Cost x #Units = Cost of Supply

Rebar (3/8 x 20ft)….……………….. $ 4.00 stick x 4 sticks = $ 16.00

Concrete………..…………………… $ 35.00 P bag x 12 bags = $ 420.00

Steel angle iron (L2x2x1/8)…...……. $ 2.50 PLF x 200ft = $ 500.00

Steel channel iron (L3x3x1/4).............$ 4.45 PLF x 45ft = $ 200.00

Steel tube iron (3x3)……..………..... $ 4.00 PLF x 50ft = $ 200.00

PVC (1 inch x 10ft)..……………….. $ 1.50 stick x 2 sticks = $ 3.00

Total Cost = $ 1339.00

The labor and travel accommodations for implementation of the project design have all been paid

for through financial grants provided by the Jessie F Richardson Foundation and the student

chapter of Engineers Without Borders, Portland State University.

Portland State University 6

EWB Water Tower Design Proposal

Appendix A: Geotechnical

Seismic Issues

There are three sources capable of creating seismic events in the Pacific Region of Nicaragua:

the subduction zone, volcanoes, and local faults as shown in Figure 1.

Figure 3 local faults located in the pacific coast region

Geology

The geological stratigraphy is comprised of volcanic tuff from the upper Las Sierras group,

regionally called “cantera”. Tuff is pyroclastic materials composed of ash and dust from volcanic

eruptions. It dates from the early quaternary volcanic events. Overall, the stiffness of the soil

increases gradually with depth and there is no defined demarcation between the lower

stratigraphy and upper subsurface layers with in the pacific coast region of Nicaragua.

Soil Profile

The basic soil profile of silts and as observed during the site investigation, the silts have a great

ability for water absorption and appear to have a low weight. For these reasons it was concluded

that they have a high porosity and low density. Since no laboratory testing of the soil is available

for the use of determining the foundation footing design depth and geometry, the design

parameters were based on the UBC code (1997 pg 2-34 table 16-Q) for a predominately silty soil

(ML) and shown as a soil Profile type SD for seismic zone 4.

Foundation Recommendations

Since no direct soil testing was performed at the time of the site assessment the capacities of the

soil were based on the UBC code (1997 pg 2-49 table 18-I-A) for soil type SD. The code provides

for the following parameters to be utilized for the footing design as:

• Allowable foundation pressure - 1000 psf (47.9 kPa)

• Lateral bearing of depth below natural grade – 100 psf per ft (15.7 kPa per m)

• Lateral sliding resistance – 130 psf (6.227 kPa)

Portland State University 7

EWB Water Tower Design Proposal

Appendix B: Foundation Design

According to code, there are three types of failures that can occur: bearing, shear and turnover

due to seismic or wind loads. Potential seismic activity is a greater concern because Nicaragua is

under Zone 4 risk, where the seismic force for a building is

Vmin = 1.6ZNvIW/R (Equation 34-3, 1997 UBC).

The following were assumed about the soil conditions based on region assessment, Zone 4

hazard classification, and previous data from last year’s assessment at the site.

Nv = 1.2

I = 1.0

R = 2.2

After calculations, it was determined that the maximum seismic load was 2,053 lb. The main

problem in water towers is overturning due to seismic and wind loads. Thus the main design

parameter was bearing and overturning. The vertical shearing force due to moment was 3.7 kips,

which was the higher force that would cause bearing in the foundation. The minimum area of

the foundation with consideration for bearing is 20'' x 20''. Thus, the standard foundation would

be 2' x 2'. With a 19'' thick foundation depth, the uplift force can be neglected.

For the 5000-L tower, the seismic load would be 4045 lb, and the shear force due to overturning

is 6.61 kips. In order to prevent bearing failure, the foundation needs a minimum area of 2'3'' x

2'3''. The uplift force of 1.16kips would then be counteracted by the 19” thick foundation.

(More information about the rebar needed.)

The foundation system will be 2' x 2' spread footings with a thickness of 19", reinforced with 4

#3 rebar spaced at 3" o.c. in both directions under each column of the 2500 L tower at mid-depth.

The design foundation system for the 5000 L tower is estimated at 2'3" x 2'3" footings with 19"

thickness, 4 #3 reinforced rebar spaced at 3" o.c. at mid-depth.

Portland State University 8

EWB Water Tower Design Proposal

Appendix C: Tank Tower Design

Portland State University 9

EWB Water Tower Design Proposal

Portland State University 10

EWB Water Tower Design Proposal

Portland State University 11

EWB Water Tower Design Proposal

Portland State University 12

EWB Water Tower Design Proposal

Portland State University 13

EWB Water Tower Design Proposal

TABLE: Steel Design 1 - Summary Data - AISC-LRFD93

Frame DesignSect DesignType Status Ratio RatioType Combo Location

Text Text Text Text Unitless Text Text ft

6 L3X3X.25 Beam No Messages 0.067325 PMM DSTL31 0

8 L3X3X.25 Beam No Messages 0.067325 PMM DSTL31 5

13 HSS3X3X1/8 Column No Messages 0.125045 PMM DSTL30 6.015

14 HSS3X3X1/8 Column No Messages 0.121147 PMM DSTL30 0

15 HSS3X3X1/8 Column No Messages 0.108522 PMM DSTL31 6.015

16 HSS3X3X1/8 Column No Messages 0.104824 PMM DSTL32 0

17 HSS3X3X1/8 Column No Messages 0.125045 PMM DSTL30 6.015

18 HSS3X3X1/8 Column No Messages 0.121147 PMM DSTL30 0

19 HSS3X3X1/8 Column No Messages 0.112423 PMM DSTL31 6.015

20 HSS3X3X1/8 Column No Messages 0.111555 PMM DSTL31 0

21 L2X2X1/8 Beam No Messages 0.025512 PMM DSTL31 1.8667

22 L2X2X1/8 Beam No Messages 0.030643 PMM DSTL31 1.8667

23 L2X2X1/8 Beam No Messages 0.025812 PMM DSTL30 1.8667

24 L2X2X1/8 Beam No Messages 0.030309 PMM DSTL30 1.8667

25 L2X2X1/8 Brace See WarnMsg 0.05597 PMM DSTL30 4.0056

26 L2X2X1/8 Brace See WarnMsg 0.335328 PMM DSTL31 4.0056

27 L2X2X1/8 Brace See WarnMsg 0.320336 PMM DSTL30 4.0056

28 L2X2X1/8 Brace See WarnMsg 0.066553 PMM DSTL30 4.0056

29 L2X2X1/8 Brace See WarnMsg 0.059401 PMM DSTL31 4.0056

30 L2X2X1/8 Brace See WarnMsg 0.320336 PMM DSTL30 4.0056

31 L2X2X1/8 Brace See WarnMsg 0.335328 PMM DSTL31 4.0056

32 L2X2X1/8 Brace See WarnMsg 0.050281 PMM DSTL30 4.0056

9 L2X2X1/8 Beam See WarnMsg 0.034809 PMM DSTL31 3.5355

10 L2X2X1/8 Beam See WarnMsg 0.034985 PMM DSTL30 0

33 L3X3X1/4 Beam No Messages 0.102719 PMM DSTL31 0

34 L3X3X1/4 Beam No Messages 0.119785 PMM DSTL31 1

35 L3X3X1/4 Beam No Messages 0.119786 PMM DSTL31 0

36 L3X3X1/4 Beam No Messages 0.119785 PMM DSTL31 0

37 L3X3X1/4 Beam No Messages 0.133024 PMM DSTL30 1

38 L3X3X1/4 Beam No Messages 0.143103 PMM DSTL31 0

39 L3X3X1/4 Beam No Messages 0.116155 PMM DSTL31 1

40 L3X3X1/4 Beam No Messages 0.116155 PMM DSTL31 1

41 L3X3X1/4 Beam No Messages 0.116155 PMM DSTL31 0

42 L3X3X1/4 Beam No Messages 0.143103 PMM DSTL31 1

43 L3X3X1/4 Beam No Messages 0.003227 PMM DSTL31 3.3333

44 L3X3X1/4 Beam No Messages 0.002575 PMM DSTL31 3.3333

45 L3X3X1/4 Beam No Messages 0.002606 PMM DSTL30 3.3333

46 L3X3X1/4 Beam No Messages 0.003529 PMM DSTL30 3.3333

Portland State University 14

EWB Water Tower Design Proposal

TABLE: Steel Design 2 - PMM Details - AISC-LRFD93

Frame DesignSect DesignType Status Combo Location Pu MuMajor MuMinor

Text Text Text Text Text ft Lb Lb-ft Lb-ft

6 L3X3X.25 Beam No Messages DSTL31 0 56.49 -376.46 -63.06

8 L3X3X.25 Beam No Messages DSTL31 5 56.49 -376.46 -63.06

13 HSS3X3X1/8 Column No Messages DSTL30 6.015 -1191.45 1213.48 1209.43

14 HSS3X3X1/8 Column No Messages DSTL30 0 -821.68 1213.48 1209.43

15 HSS3X3X1/8 Column No Messages DSTL31 6.015 -1193.08 1211.21 -872.02

16 HSS3X3X1/8 Column No Messages DSTL32 0 -1114.79 -1032.61 -1031.28

17 HSS3X3X1/8 Column No Messages DSTL30 6.015 -1191.45 1213.48 -1209.43

18 HSS3X3X1/8 Column No Messages DSTL30 0 -821.68 1213.48 -1209.43

19 HSS3X3X1/8 Column No Messages DSTL31 6.015 -1838.36 -872.51 -1211.95

20 HSS3X3X1/8 Column No Messages DSTL31 0 -2573.97 -872.51 -1211.95

21 L2X2X1/8 Beam No Messages DSTL31 1.8667 71.74 10.27 0

22 L2X2X1/8 Beam No Messages DSTL31 1.8667 311.81 10.27 0

23 L2X2X1/8 Beam No Messages DSTL30 1.8667 85.79 10.27 0

24 L2X2X1/8 Beam No Messages DSTL30 1.8667 296.18 10.27 0

25 L2X2X1/8 Brace See WarnMsg DSTL30 4.0056 -92.4 15.67 0

26 L2X2X1/8 Brace See WarnMsg DSTL31 4.0056 -787.69 15.67 0

27 L2X2X1/8 Brace See WarnMsg DSTL30 4.0056 -748.78 15.67 0

28 L2X2X1/8 Brace See WarnMsg DSTL30 4.0056 -146.53 15.67 0

29 L2X2X1/8 Brace See WarnMsg DSTL31 4.0056 -109.95 15.67 0

30 L2X2X1/8 Brace See WarnMsg DSTL30 4.0056 -748.78 15.67 0

31 L2X2X1/8 Brace See WarnMsg DSTL31 4.0056 -787.69 15.67 0

32 L2X2X1/8 Brace No Messages DSTL30 4.0056 577.54 15.67 0

9 L2X2X1/8 Beam See WarnMsg DSTL31 3.5355 -19.19 11.7 -6.03

10 L2X2X1/8 Beam See WarnMsg DSTL30 0 -19.19 -12.17 4.64

33 L3X3X1/4 Beam No Messages DSTL31 0 -243.62 -880.43 -47.98

34 L3X3X1/4 Beam No Messages DSTL31 1 -243.62 923.26 72.06

35 L3X3X1/4 Beam No Messages DSTL31 0 -243.62 923.26 72.06

36 L3X3X1/4 Beam No Messages DSTL31 0 -243.62 923.26 72.06

37 L3X3X1/4 Beam No Messages DSTL30 1 -196.81 -1231.78 49.73

38 L3X3X1/4 Beam No Messages DSTL31 0 -150 -901.77 -118.16

39 L3X3X1/4 Beam No Messages DSTL31 1 -150 901.92 69.9

40 L3X3X1/4 Beam No Messages DSTL31 1 -150 901.92 69.9

41 L3X3X1/4 Beam No Messages DSTL31 0 -150 901.92 69.9

42 L3X3X1/4 Beam No Messages DSTL31 1 -150 -901.77 -118.16

43 L3X3X1/4 Beam No Messages DSTL31 3.3333 -50.78 29.94 0

44 L3X3X1/4 Beam No Messages DSTL31 3.3333 8.38 29.94 0

45 L3X3X1/4 Beam No Messages DSTL30 3.3333 13.71 29.94 0

46 L3X3X1/4 Beam No Messages DSTL30 3.3333 -72.66 29.94 0

Portland State University 15

EWB Water Tower Design Proposal

TABLE: Steel Design 2 - PMM Details - AISC-LRFD93

Frame DesignSect DesignType Fy E Length SectClass FramingType

Text Text Text Lb/ft2 Lb/ft2 ft Text Text

6 L3X3X.25 Beam 5184000 4176000000 5 Compact Moment Resisting Frame

8 L3X3X.25 Beam 5184000 4176000000 5 Compact Moment Resisting Frame

13 HSS3X3X1/8 Column 5184000 4176000000 6.015 Non-Compact Moment Resisting Frame

14 HSS3X3X1/8 Column 5184000 4176000000 4.01 Non-Compact Moment Resisting Frame

15 HSS3X3X1/8 Column 5184000 4176000000 6.015 Non-Compact Moment Resisting Frame

16 HSS3X3X1/8 Column 5184000 4176000000 4.01 Non-Compact Moment Resisting Frame

17 HSS3X3X1/8 Column 5184000 4176000000 6.015 Non-Compact Moment Resisting Frame

18 HSS3X3X1/8 Column 5184000 4176000000 4.01 Non-Compact Moment Resisting Frame

19 HSS3X3X1/8 Column 5184000 4176000000 6.015 Non-Compact Moment Resisting Frame

20 HSS3X3X1/8 Column 5184000 4176000000 4.01 Non-Compact Moment Resisting Frame

21 L2X2X1/8 Beam 5184000 4176000000 5.6 Slender Moment Resisting Frame

22 L2X2X1/8 Beam 5184000 4176000000 5.6 Slender Moment Resisting Frame

23 L2X2X1/8 Beam 5184000 4176000000 5.6 Slender Moment Resisting Frame

24 L2X2X1/8 Beam 5184000 4176000000 5.6 Slender Moment Resisting Frame

25 L2X2X1/8 Brace 5184000 4176000000 8.0112 Slender Moment Resisting Frame

26 L2X2X1/8 Brace 5184000 4176000000 8.0112 Slender Moment Resisting Frame

27 L2X2X1/8 Brace 5184000 4176000000 8.0112 Slender Moment Resisting Frame

28 L2X2X1/8 Brace 5184000 4176000000 8.0112 Slender Moment Resisting Frame

29 L2X2X1/8 Brace 5184000 4176000000 8.0112 Slender Moment Resisting Frame

30 L2X2X1/8 Brace 5184000 4176000000 8.0112 Slender Moment Resisting Frame

31 L2X2X1/8 Brace 5184000 4176000000 8.0112 Slender Moment Resisting Frame

32 L2X2X1/8 Brace 5184000 4176000000 8.0112 Slender Moment Resisting Frame

9 L2X2X1/8 Beam 5184000 4176000000 7.0711 Slender Moment Resisting Frame

10 L2X2X1/8 Beam 5184000 4176000000 7.0711 Slender Moment Resisting Frame

33 L3X3X1/4 Beam 5184000 4176000000 1 Compact Moment Resisting Frame

34 L3X3X1/4 Beam 5184000 4176000000 1 Compact Moment Resisting Frame

35 L3X3X1/4 Beam 5184000 4176000000 1 Compact Moment Resisting Frame

36 L3X3X1/4 Beam 5184000 4176000000 1 Compact Moment Resisting Frame

37 L3X3X1/4 Beam 5184000 4176000000 1 Compact Moment Resisting Frame

38 L3X3X1/4 Beam 5184000 4176000000 1 Compact Moment Resisting Frame

39 L3X3X1/4 Beam 5184000 4176000000 1 Compact Moment Resisting Frame

40 L3X3X1/4 Beam 5184000 4176000000 1 Compact Moment Resisting Frame

41 L3X3X1/4 Beam 5184000 4176000000 1 Compact Moment Resisting Frame

42 L3X3X1/4 Beam 5184000 4176000000 1 Compact Moment Resisting Frame

43 L3X3X1/4 Beam 5184000 4176000000 5 Compact Moment Resisting Frame

44 L3X3X1/4 Beam 5184000 4176000000 5 Compact Moment Resisting Frame

45 L3X3X1/4 Beam 5184000 4176000000 5 Compact Moment Resisting Frame

46 L3X3X1/4 Beam 5184000 4176000000 5 Compact Moment Resisting Frame

Portland State University 16

EWB Water Tower Design Proposal

TABLE: Element Joint Forces - Frames

Frame Joint OutputCase CaseType F1 F2 F3 M1 M2 M3

Text Text Text Text Lb Lb Lb Lb-ft Lb-ft Lb-ft

6 7 SERV2 Combination -56.39 -16.39 123.09 -0.03521 -266.2 -45.45

6 8 SERV2 Combination 56.39 16.39 -78.17 0.03521 -236.93 -36.5

8 6 SERV2 Combination 56.39 -16.39 -78.17 -0.03521 -236.93 36.5

8 5 SERV2 Combination -56.39 16.39 123.09 0.03521 -266.2 45.45

9 7 SERV2 Combination 14.13 12.52 9.72 5.92 -6.02 -8.26

9 6 SERV2 Combination -14.13 -12.52 7.65 -0.74 0.84 0.18

10 8 SERV2 Combination -14.13 12.52 7.65 0.74 0.84 -0.18

10 5 SERV2 Combination 14.13 -12.52 9.72 -5.92 -6.02 8.26

13 8 SERV2 Combination -128.54 -269.75 -1608.25 -887.54 236.1 -56.18

13 11 SERV2 Combination 128.54 269.75 1696.26 -235.31 1030.83 -63.31

14 11 SERV2 Combination 371.29 -54.76 -2242.39 235.31 -1030.83 63.31

14 4 SERV2 Combination -371.29 54.76 2301.07 2.293E-14 2.47E-13 -1.519E-14

15 5 SERV2 Combination -275.98 244.94 -1136.44 877.71 272.22 -30.27

15 12 SERV2 Combination 275.98 -244.94 1224.45 237.76 1029.5 39.59

16 12 SERV2 Combination 203.69 -5.75 -1044.41 -237.76 -1029.5 -39.59

16 2 SERV2 Combination -203.69 5.75 1103.09 -5.23E-15 -1.535E-13 1.469E-14

17 7 SERV2 Combination -275.98 -244.94 -1136.44 -877.71 272.22 30.27

17 13 SERV2 Combination 275.98 244.94 1224.45 -237.76 1029.5 -39.59

18 13 SERV2 Combination 203.69 5.75 -1044.41 237.76 -1029.5 39.59

18 1 SERV2 Combination -203.69 -5.75 1103.09 9.728E-15 4.038E-13 -5.196E-14

19 6 SERV2 Combination -128.54 269.75 -1608.25 887.54 236.1 56.18

19 14 SERV2 Combination 128.54 -269.75 1696.26 235.31 1030.83 63.31

20 14 SERV2 Combination 371.29 54.76 -2242.39 -235.31 -1030.83 -63.31

20 3 SERV2 Combination -371.29 -54.76 2301.07 -1.672E-14 6.55E-13 -1.982E-15

21 13 SERV2 Combination -70.18 0 6.88 0 0 0

21 11 SERV2 Combination 70.18 0 6.88 0 0 0

22 11 SERV2 Combination 0 -303.15 6.88 0 0 0

22 14 SERV2 Combination 0 303.15 6.88 0 0 0

23 14 SERV2 Combination 70.18 0 6.88 0 0 0

23 12 SERV2 Combination -70.18 0 6.88 0 0 0

24 12 SERV2 Combination 0 281.27 6.88 0 0 0

24 13 SERV2 Combination 0 -281.27 6.88 0 0 0

25 13 SERV2 Combination -232.3 -13.15 -253.14 0 0 0

25 8 SERV2 Combination 232.3 13.15 272.83 0 0 0

26 11 SERV2 Combination -386.61 21.88 447.51 0 0 0

26 7 SERV2 Combination 386.61 -21.88 -427.83 0 0 0

27 7 SERV2 Combination -2.48 43.73 -39.66 0 0 0

27 12 SERV2 Combination 2.48 -43.73 59.35 0 0 0

28 12 SERV2 Combination -232.3 13.15 -253.14 0 0 0

28 6 SERV2 Combination 232.3 -13.15 272.83 0 0 0

29 6 SERV2 Combination 3.75 -66.27 -65.18 0 0 0

29 11 SERV2 Combination -3.75 66.27 84.86 0 0 0

30 8 SERV2 Combination 3.75 66.27 -65.18 0 0 0

30 14 SERV2 Combination -3.75 -66.27 84.86 0 0 0

31 14 SERV2 Combination -386.61 -21.88 447.51 0 0 0

31 5 SERV2 Combination 386.61 21.88 -427.83 0 0 0

Portland State University 17

EWB Water Tower Design Proposal

TABLE: Element Joint Forces - Frames

Frame Joint OutputCase CaseType F1 F2 F3 M1 M2 M3

Text Text Text Text Lb Lb Lb Lb-ft Lb-ft Lb-ft

32 5 SERV2 Combination -2.48 -43.73 -39.66 0 0 0

32 13 SERV2 Combination 2.48 43.73 59.35 0 0 0

33 5 SERV2 Combination -29.95 -226.96 1471.13 -871.83 -5.35E-15 -23.44

33 9 SERV2 Combination 29.95 226.96 -900.64 -314.05 5.35E-15 -6.51

34 9 SERV2 Combination -44.24 -226.96 878.18 314.05 -5.339E-15 6.51

34 10 SERV2 Combination 44.24 226.96 -307.7 -906.99 5.339E-15 -50.75

35 10 SERV2 Combination 1.126E-12 -226.96 285.24 906.99 -5.353E-15 50.75

35 15 SERV2 Combination -1.126E-12 226.96 285.24 -906.99 5.353E-15 -50.75

36 15 SERV2 Combination 44.24 -226.96 -307.7 906.99 -4.72E-15 50.75

36 16 SERV2 Combination -44.24 226.96 878.18 -314.05 4.72E-15 -6.51

37 16 SERV2 Combination 29.95 -226.96 -900.64 314.05 -4.72E-15 6.51

37 7 SERV2 Combination -29.95 226.96 1471.13 871.83 4.72E-15 23.44

38 6 SERV2 Combination -113.83 -161.43 1471.13 -886.77 -3.562E-15 -92.86

38 17 SERV2 Combination 113.83 161.43 -900.64 -299.12 3.562E-15 -20.97

39 17 SERV2 Combination -27.65 -161.43 878.18 299.12 -5.008E-15 20.97

39 18 SERV2 Combination 27.65 161.43 -307.7 -892.06 5.008E-15 -48.62

40 18 SERV2 Combination 4.821E-13 -161.43 285.24 892.06 -5.343E-15 48.62

40 19 SERV2 Combination -4.821E-13 161.43 285.24 -892.06 5.343E-15 -48.62

41 19 SERV2 Combination 27.65 -161.43 -307.7 892.06 -4.68E-15 48.62

41 20 SERV2 Combination -27.65 161.43 878.18 -299.12 4.68E-15 -20.97

42 20 SERV2 Combination 113.83 -161.43 -900.64 299.12 -4.681E-15 20.97

42 8 SERV2 Combination -113.83 161.43 1471.13 886.77 4.681E-15 92.86

43 9 SERV2 Combination 50.23 0 22.46 0 0 0

43 17 SERV2 Combination -50.23 0 22.46 0 0 0

44 10 SERV2 Combination -8.29 0 22.46 0 0 0

44 18 SERV2 Combination 8.29 0 22.46 0 0 0

45 15 SERV2 Combination -8.29 0 22.46 0 0 0

45 19 SERV2 Combination 8.29 0 22.46 0 0 0

46 16 SERV2 Combination 50.23 0 22.46 0 0 0

46 20 SERV2 Combination -50.23 0 22.46 0 0 0

6 7 SERV1 Combination -49.78 3.373E-13 22.46 -5.108E-14 -14.9 -5.75

6 8 SERV1 Combination 49.78 -3.373E-13 22.46 5.108E-14 14.9 5.75

8 6 SERV1 Combination 63.01 -3.423E-13 22.46 5.116E-14 14.37 -3.2

8 5 SERV1 Combination -63.01 3.423E-13 22.46 -5.116E-14 -14.37 3.2

9 7 SERV1 Combination 14.13 12.52 9.76 6.02 -6.12 -4.43

9 6 SERV1 Combination -14.13 -12.52 7.61 -0.64 0.73 -3.65

10 8 SERV1 Combination -14.13 12.52 9.76 6.02 6.12 4.43

10 5 SERV1 Combination 14.13 -12.52 7.61 -0.64 -0.73 3.65

13 8 SERV1 Combination 62.96 -457.36 -1135.33 -1123.79 -21.02 -55.14

13 11 SERV1 Combination -62.96 457.36 1223.34 -1266.58 -2.93 -63.18

14 11 SERV1 Combination 52.96 262.95 -1044.53 1266.58 2.93 63.18

14 4 SERV1 Combination -52.96 -262.95 1103.2 -5.133E-13 -5.908E-15 1.217E-14

15 5 SERV1 Combination -84.48 57.33 -1609.36 641.46 15.1 -31.32

15 12 SERV1 Combination 84.48 -57.33 1697.37 -793.51 -4.25 39.46

16 12 SERV1 Combination -114.64 311.96 -2242.28 793.51 4.25 -39.46

16 2 SERV1 Combination 114.64 -311.96 2300.95 -4.178E-13 -3.125E-15 3.627E-14

17 7 SERV1 Combination -62.96 -457.36 -1135.33 -1123.79 21.02 55.14

17 13 SERV1 Combination 62.96 457.36 1223.34 -1266.58 2.93 63.18

18 13 SERV1 Combination -52.96 262.95 -1044.53 1266.58 -2.93 -63.18

18 1 SERV1 Combination 52.96 -262.95 1103.2 9.943E-14 -4.392E-15 -6.981E-15

Portland State University 18

EWB Water Tower Design Proposal

TABLE: Element Joint Forces - Frames

Frame Joint OutputCase CaseType F1 F2 F3 M1 M2 M3

Text Text Text Text Lb Lb Lb Lb-ft Lb-ft Lb-ft

19 6 SERV1 Combination 84.48 57.33 -1609.36 641.46 -15.1 31.32

19 14 SERV1 Combination -84.48 -57.33 1697.37 -793.51 4.25 -39.46

20 14 SERV1 Combination 114.64 311.96 -2242.28 793.51 -4.25 39.46

20 3 SERV1 Combination -114.64 -311.96 2300.95 -5.927E-13 1.979E-16 7.087E-15

21 13 SERV1 Combination -60.34 0 6.88 0 0 0

21 11 SERV1 Combination 60.34 0 6.88 0 0 0

22 11 SERV1 Combination 0 -292.21 6.88 0 0 0

22 14 SERV1 Combination 0 292.21 6.88 0 0 0

23 14 SERV1 Combination 80.01 0 6.88 0 0 0

23 12 SERV1 Combination -80.01 0 6.88 0 0 0

24 12 SERV1 Combination 0 292.21 6.88 0 0 0

24 13 SERV1 Combination 0 -292.21 6.88 0 0 0

25 13 SERV1 Combination 64.62 3.66 82.99 0 0 0

25 8 SERV1 Combination -64.62 -3.66 -63.31 0 0 0

26 11 SERV1 Combination -64.62 3.66 82.99 0 0 0

26 7 SERV1 Combination 64.62 -3.66 -63.31 0 0 0

27 7 SERV1 Combination -20.5 362.11 -400.09 0 0 0

27 12 SERV1 Combination 20.5 -362.11 419.78 0 0 0

28 12 SERV1 Combination 89.68 -5.08 111.37 0 0 0

28 6 SERV1 Combination -89.68 5.08 -91.69 0 0 0

29 6 SERV1 Combination -14.27 252.11 295.25 0 0 0

29 11 SERV1 Combination 14.27 -252.11 -275.57 0 0 0

30 8 SERV1 Combination 20.5 362.11 -400.09 0 0 0

30 14 SERV1 Combination -20.5 -362.11 419.78 0 0 0

31 14 SERV1 Combination -89.68 -5.08 111.37 0 0 0

31 5 SERV1 Combination 89.68 5.08 -91.69 0 0 0

32 5 SERV1 Combination 14.27 252.11 295.25 0 0 0

32 13 SERV1 Combination -14.27 -252.11 -275.57 0 0 0

33 5 SERV1 Combination 29.4 -194.2 1375.73 -640.82 0.001244 24.47

33 9 SERV1 Combination -29.4 194.2 -805.25 -449.67 -0.001244 4.93

34 9 SERV1 Combination -5.52 -194.2 782.79 449.67 0.001244 -4.93

34 10 SERV1 Combination 5.52 194.2 -212.31 -947.22 -0.001244 -0.59

35 10 SERV1 Combination -0.96 -194.2 189.85 947.22 0.001244 0.59

35 15 SERV1 Combination 0.96 194.2 380.63 -851.83 -0.001244 -1.54

36 15 SERV1 Combination 11.06 -194.2 -403.09 851.83 0.001244 1.54

36 16 SERV1 Combination -11.06 194.2 973.57 -163.5 -0.001244 9.52

37 16 SERV1 Combination -54.48 -194.2 -996.03 163.5 0.001244 -9.52

37 7 SERV1 Combination 54.48 194.2 1566.52 1117.77 -0.001244 -44.96

38 6 SERV1 Combination -29.4 -194.2 1375.73 -640.82 -0.001244 -24.47

38 17 SERV1 Combination 29.4 194.2 -805.25 -449.67 0.001244 -4.93

39 17 SERV1 Combination 5.52 -194.2 782.79 449.67 -0.001244 4.93

39 18 SERV1 Combination -5.52 194.2 -212.31 -947.22 0.001244 0.59

40 18 SERV1 Combination 0.96 -194.2 189.85 947.22 -0.001244 -0.59

40 19 SERV1 Combination -0.96 194.2 380.63 -851.83 0.001244 1.54

41 19 SERV1 Combination -11.06 -194.2 -403.09 851.83 -0.001244 -1.54

41 20 SERV1 Combination 11.06 194.2 973.57 -163.5 0.001244 -9.52

42 20 SERV1 Combination 54.48 -194.2 -996.03 163.5 -0.001244 9.52

42 8 SERV1 Combination -54.48 194.2 1566.52 1117.77 0.001244 44.96

43 9 SERV1 Combination 34.91 0 22.46 0 0 0

43 17 SERV1 Combination -34.91 0 22.46 0 0 0

Portland State University 19

EWB Water Tower Design Proposal

TABLE: Element Joint Forces - Frames

Frame Joint OutputCase CaseType F1 F2 F3 M1 M2 M3

Text Text Text Text Lb Lb Lb Lb-ft Lb-ft Lb-ft

44 10 SERV1 Combination -4.56 0 22.46 0 0 0

44 18 SERV1 Combination 4.56 0 22.46 0 0 0

45 15 SERV1 Combination -12.02 0 22.46 0 0 0

45 19 SERV1 Combination 12.02 0 22.46 0 0 0

46 16 SERV1 Combination 65.55 0 22.46 0 0 0

46 20 SERV1 Combination -65.55 0 22.46 0 0 0

6 7 DSTL33 Combination -0.46 -23.41 163.97 -0.05031 -370.37 -58.75

6 8 DSTL33 Combination 0.46 23.41 -123.54 0.05031 -348.4 -58.32

8 6 DSTL33 Combination 0.46 -23.41 -123.54 -0.05031 -348.4 58.32

8 5 DSTL33 Combination -0.46 23.41 163.97 0.05031 -370.37 58.75

9 7 DSTL33 Combination 1.13 1.06 9.3 9.9 -9.91 -6.22

9 6 DSTL33 Combination -1.13 -1.06 6.34 -2.5 2.51 5.83

10 8 DSTL33 Combination -1.13 1.06 6.34 2.5 2.51 -5.83

10 5 DSTL33 Combination 1.13 -1.06 9.3 -9.9 -9.91 6.22

13 8 DSTL33 Combination -278.15 -37.46 -447.94 -66.33 345.89 -20.61

13 11 DSTL33 Combination 278.15 37.46 527.15 -12.18 1469.29 -74.07

14 11 DSTL33 Combination 423.34 -52.97 -1093.89 12.18 -1469.29 74.07

14 4 DSTL33 Combination -423.34 52.97 1146.69 -8.066E-15 3.554E-13 -2.435E-14

15 5 DSTL33 Combination -299.73 2.01 226.07 52.3 380.27 16.4

15 12 DSTL33 Combination 299.73 -2.01 -146.86 15.68 1474.04 72.92

16 12 DSTL33 Combination 398.06 -33.48 617.51 -15.68 -1474.04 -72.92

16 2 DSTL33 Combination -398.06 33.48 -564.71 -1.457E-17 -2.181E-13 1.265E-14

17 7 DSTL33 Combination -299.73 -2.01 226.07 -52.3 380.27 -16.4

17 13 DSTL33 Combination 299.73 2.01 -146.86 -15.68 1474.04 -72.92

18 13 DSTL33 Combination 398.06 33.48 617.51 15.68 -1474.04 72.92

18 1 DSTL33 Combination -398.06 -33.48 -564.71 8.014E-16 5.792E-13 -6.697E-14

19 6 DSTL33 Combination -278.15 37.46 -447.94 66.33 345.89 20.61

19 14 DSTL33 Combination 278.15 -37.46 527.15 12.18 1469.29 74.07

20 14 DSTL33 Combination 423.34 52.97 -1093.89 -12.18 -1469.29 -74.07

20 3 DSTL33 Combination -423.34 -52.97 1146.69 8.624E-15 9.322E-13 -5.42E-15

21 13 DSTL33 Combination -7.03 0 6.19 0 0 0

21 11 DSTL33 Combination 7.03 0 6.19 0 0 0

22 11 DSTL33 Combination 0 -33.48 6.19 0 0 0

22 14 DSTL33 Combination 0 33.48 6.19 0 0 0

23 14 DSTL33 Combination 7.03 0 6.19 0 0 0

23 12 DSTL33 Combination -7.03 0 6.19 0 0 0

24 12 DSTL33 Combination 0 2.22 6.19 0 0 0

24 13 DSTL33 Combination 0 -2.22 6.19 0 0 0

25 13 DSTL33 Combination -433.61 -24.54 -482.03 0 0 0

25 8 DSTL33 Combination 433.61 24.54 499.74 0 0 0

26 11 DSTL33 Combination -450.55 25.5 518.91 0 0 0

26 7 DSTL33 Combination 450.55 -25.5 -501.19 0 0 0

27 7 DSTL33 Combination 0.49 -8.71 18.72 0 0 0

27 12 DSTL33 Combination -0.49 8.71 -1.01 0 0 0

28 12 DSTL33 Combination -433.61 24.54 -482.03 0 0 0

28 6 DSTL33 Combination 433.61 -24.54 499.74 0 0 0

29 6 DSTL33 Combination 1.33 -23.49 -17.73 0 0 0

29 11 DSTL33 Combination -1.33 23.49 35.45 0 0 0

30 8 DSTL33 Combination 1.33 23.49 -17.73 0 0 0

30 14 DSTL33 Combination -1.33 -23.49 35.45 0 0 0

Portland State University 20

EWB Water Tower Design Proposal

TABLE: Element Joint Forces - Frames

Frame Joint OutputCase CaseType F1 F2 F3 M1 M2 M3

Text Text Text Text Lb Lb Lb Lb-ft Lb-ft Lb-ft

31 14 DSTL33 Combination -450.55 -25.5 518.91 0 0 0

31 5 DSTL33 Combination 450.55 25.5 -501.19 0 0 0

32 5 DSTL33 Combination 0.49 8.71 18.72 0 0 0

32 13 DSTL33 Combination -0.49 -8.71 -1.01 0 0 0

33 5 DSTL33 Combination -100.63 -58.58 83.14 -42.44 -7.871E-15 -81.37

33 9 DSTL33 Combination 100.63 58.58 -66.05 -32.15 7.871E-15 -19.26

34 9 DSTL33 Combination -51.77 -58.58 45.84 32.15 -7.858E-15 19.26

34 10 DSTL33 Combination 51.77 58.58 -28.76 -69.45 7.858E-15 -71.03

35 10 DSTL33 Combination 1.613E-12 -58.58 8.54 69.45 -7.871E-15 71.03

35 15 DSTL33 Combination -1.613E-12 58.58 8.54 -69.45 7.871E-15 -71.03

36 15 DSTL33 Combination 51.77 -58.58 -28.76 69.45 -6.968E-15 71.03

36 16 DSTL33 Combination -51.77 58.58 45.84 -32.15 6.968E-15 -19.26

37 16 DSTL33 Combination 100.63 -58.58 -66.05 32.15 -6.968E-15 19.26

37 7 DSTL33 Combination -100.63 58.58 83.14 42.44 6.968E-15 81.37

38 6 DSTL33 Combination -104.77 35.04 83.14 -63.78 -5.518E-15 -84.77

38 17 DSTL33 Combination 104.77 -35.04 -66.05 -10.82 5.518E-15 -20

39 17 DSTL33 Combination -50.93 35.04 45.84 10.82 -7.362E-15 20

39 18 DSTL33 Combination 50.93 -35.04 -28.76 -48.11 7.362E-15 -70.93

40 18 DSTL33 Combination 6.937E-13 35.04 8.54 48.11 -7.832E-15 70.93

40 19 DSTL33 Combination -6.937E-13 -35.04 8.54 -48.11 7.832E-15 -70.93

41 19 DSTL33 Combination 50.93 35.04 -28.76 48.11 -6.891E-15 70.93

41 20 DSTL33 Combination -50.93 -35.04 45.84 -10.82 6.891E-15 -20

42 20 DSTL33 Combination 104.77 35.04 -66.05 10.82 -6.891E-15 20

42 8 DSTL33 Combination -104.77 -35.04 83.14 63.78 6.891E-15 84.77

43 9 DSTL33 Combination 2.49 0 20.21 0 0 0

43 17 DSTL33 Combination -2.49 0 20.21 0 0 0

44 10 DSTL33 Combination -0.42 0 20.21 0 0 0

44 18 DSTL33 Combination 0.42 0 20.21 0 0 0

45 15 DSTL33 Combination -0.42 0 20.21 0 0 0

45 19 DSTL33 Combination 0.42 0 20.21 0 0 0

46 16 DSTL33 Combination 2.49 0 20.21 0 0 0

46 20 DSTL33 Combination -2.49 0 20.21 0 0 0

6 7 DSTL32 Combination 8.99 4.931E-13 20.21 -7.244E-14 -11.36 -2.03

6 8 DSTL32 Combination -8.99 -4.931E-13 20.21 7.244E-14 11.36 2.03

8 6 DSTL32 Combination 9.91 -4.891E-13 20.21 7.094E-14 10.61 1.61

8 5 DSTL32 Combination -9.91 4.891E-13 20.21 -7.094E-14 -10.61 -1.61

9 7 DSTL32 Combination 1.13 1.06 9.36 10.05 -10.05 -0.75

9 6 DSTL32 Combination -1.13 -1.06 6.28 -2.36 2.36 0.37

10 8 DSTL32 Combination -1.13 1.06 9.36 10.05 10.05 0.75

10 5 DSTL32 Combination 1.13 -1.06 6.28 -2.36 -2.36 -0.37

13 8 DSTL32 Combination -4.58 -305.48 227.66 -403.84 -21.42 -19.12

13 11 DSTL32 Combination 4.58 305.48 -148.45 -1485.43 -7.5 -73.9

14 11 DSTL32 Combination -31.42 400.9 617.35 1485.43 7.5 73.9

14 4 DSTL32 Combination 31.42 -400.9 -564.54 -7.741E-13 -5.85E-15 1.474E-14

15 5 DSTL32 Combination -26.16 -266.01 -449.53 -285.21 12.97 14.91

15 12 DSTL32 Combination 26.16 266.01 528.74 -1457.57 -2.76 72.74

16 12 DSTL32 Combination -56.7 420.4 -1093.72 1457.57 2.76 -72.74

16 2 DSTL32 Combination 56.7 -420.4 1146.53 -5.893E-13 -3.34E-15 4.349E-14

17 7 DSTL32 Combination 4.58 -305.48 227.66 -403.84 21.42 19.12

17 13 DSTL32 Combination -4.58 305.48 -148.45 -1485.43 7.5 73.9

Portland State University 21

EWB Water Tower Design Proposal

Appendix D: Tank Flow Connections Design

Jinotepe System Curve

10.6

10.5

10.4

10.3

Head (ft)

10.2

10.1

10

9.9

9.8

0 1 2 3 4 5 6 7 8

Q (gpm)

The supply requirements for the community specify a supply flow rate, Q, of 7.5 Gallons per

minute. This is equivalent to .002 Cubic feet per second. The maximum elevation of the water in

the full tanks indicates 10.5 ft of hydraulic head. The analysis assumes an average water

temperature of 60 degrees Fahrenheit.

Inspection of the energy grade lines for the current and future system indicates they are

equivalent in terms of analysis and sizing of elements.

Sizing of the pipe elements of the new system should be a close match to the system in use.

The Bernoulli equation allows us to calculate the energy flow through the system. Starting from

point one, when the tank is full, to point two where the check valve indicates the end of our

system.

For gravity feed systems with the check valve fully open:

Bernoulli

P1 V12 P V2

Z1 + = Z 2 + 2 + 2 + H loss

+

γ 2* g γ 2* g

10.5 + 0 + 0 = 0 + 0 + 0 + H l 0 ss

The head loss in the system is the sum of two factors, the friction losses and the minor losses.

H loss = h f + hm

The friction loss is defined by the Darcy Weisbach equation:

Portland State University 22

EWB Water Tower Design Proposal

FrictionLoss

f * L Q2

hf =

d 5 39.68

MinorLoss

∑ k * Q2

hm =

39.68 * d 4

Combining the equations above gives:

f * L Q2 ∑ k * Q2

Eqn 4 : Hloss = + = 10.5 cfs

d 5 39.68 39.68 * d 4

This will require us to assume a friction factor, f=.03, later in the analysis Moody’s Diagram is

used to check this assumption.

The total length of pipes active in either system is L = 20 feet.

The ∑ K values for the system components:

K values

• Enter tank from pipe

o Flush 0.5

o Projecting 1

• Exit tank from pipe 1

• 90 degree threaded bend 0.9

• Check valve open 3

∑ K = 1(1) + 1(1) + .9(2) + 3(1) = 6.8

Then

.03 * 20 ft (.oo 2cfs ) 2 6.8 * (.002cfs ) 2

Eqn 4 becomes: + = 10.5 cfs

d5 39.68 39.68 * d 4

We can now solve for the unknown value of pipe diameter, d.

The assumed friction value of .03 gives a diameter of .0236 feet or .282 inches.

We can now find the appropriate friction factor using the moody diagram.

When f=.03 and d= .021

Portland State University 23

EWB Water Tower Design Proposal

π *d2 π * (.0236 ft ) 2

A= = = 4.37 * 10− 4 ft

4 4

Q .002cfs ft

V = = −4

= 4.57

A 4.37 * 10 ft s

ft

4.57 * .0236 ft

V *d s

Re = = 2

= 1 * 10 4

ν ft

1.22 * 10 − 5

s

−5

ε 1 * 10

= = 4.24 * 10 − 4

d .0236 ft

Moody

ε

( )

f RE , = f 1 * 10 4 ,4.24 * 10 − 4 = 0.031

d

Evaluating equation 4 with the new friction factor allows us to arrive at the minimum diameter

for our system.

.031 * 20 ft (.oo 2cfs ) 2 6.8 * (.002cfs ) 2

Eqn 4 becomes: + = 10.5 cfs

d5 39.68 39.68 * d 4

d = .023715 ft = .285inches Minimum!

A minimum inner pipe diameter of ½ inch would work for the system. The current design uses

PVC piping with an outer diameter of 1”. The 1” diameter pipe has an inner diameter of 7/8

inches, this will allow the system to manage any increased demand that is unforeseen in this

analysis without being too conservative. It is also good practice to stay with the current sizing

that has sufficiently supported the current potable water feeds into the facility.

Portland State University 24

EWB Water Tower Design Proposal

Appendix E: Design Plan Set

Portland State University 25

EWB Water Tower Design Proposal

97 Uniform Building Code Utilized

The following pages were referenced for:

• The geotechnical recommendations for design

• Foundation criteria for design

• Seismic considerations for structural design

Portland State University 26

EWB Water Tower Design Proposal

Breakdown of Billable Hours

Reported Hours for Billing

General Administration: 40 hours

Meetings with clients, preparation of reports and presentations, project meetings.

Alternatives: 68 hours

Establishment, research, analysis and recommendation of alternative designs.

Geotechnical Design: 15 hours

Analysis of seismicity and soil conditions, design of soil footings.

Foundation Design: 26 hours

Analysis of wind loads, design of foundation.

Tower Design: 37 hours

Design of tower in SAP.

Pipes and Connections Design: 29 hours

Analysis of desired flow rate, design pipe sizings.

Establishment of Work Plan: 23 hours

Logistics analysis for materials and labor.

Cost Analysis: 26 hours

Analysis of capitol and maintenance costs.

Project Time Performance Tracking

Estimated Estimated Total

Name Project Type Start Finish Hours

Tom Wharton Project Management 12-Jan-2007 2-May-2007 23

Nick Carey Paper/Presentation Prep 12-Jan-2007 2-May-2007 5

Ivan Perez Paper/Presentation Prep 12-Jan-2007 2-May-2007 12

Nick Carey Cost Analysis 20-Mar-2007 15-Apr-2007 26

Helen Oppenheimer Geotechnical Design 6-Apr-2007 22-Apr-2007 15

Erin Qureshi Work Plan 20-Mar-2007 25-Apr-2007 23

Ivan Perez Foundation Design 8-Mar-2007 25-Apr-2007 26

Rob Allen Pipes/Connections Design 4-Mar-2007 29-Apr-2007 29

Tom Wharton Tower Design 5-Apr-2007 26-Apr-2007 21

Helen Oppenheimer Tower Design 5-Apr-2007 26-Apr-2007 9

Erin Qureshi Tower Design 5-Apr-2007 26-Apr-2007 7

Nick Carey Alternatives 10-Feb-2007 12-Mar-2007 13

Helen Oppenheimer Alternatives 10-Feb-2007 12-Mar-2007 20

Erin Qureshi Alternatives 10-Feb-2007 12-Mar-2007 14

Rob Allen Alternatives 10-Feb-2007 12-Mar-2007 15

Ivan Perez Alternatives 10-Feb-2007 12-Mar-2007 6

TOTAL 264

Portland State University 27

EWB Water Tower Design Proposal

Total Hours by Design Engineer

50

45

40

35

30

Total Hours

25

20

15

10

0

Erin Qureshi Helen Oppenheimer Ivan Perez Nick Carey Rob Allen Tom Wharton

Design Engineer

Total Hours by Work Item

80

70

60

50

Total Hours

40

30

20

10

0

Alternatives Cost Analysis Foundation Geotechnical General Plumbing Tower Design Work Plan

Design Design Administration Design

Work Item

Portland State University 28

EWB Water Tower Design Proposal

References

CE406 Assessment Project. “Nicaragua Assessment Report”, PSU, 2006.

Universal Building Code (2006) and International Building Code (2006)

Geologic and geotechnical hazards mapping for Nicaragua www.ineter.gob.ni/

Subduction and Seismic Study (Dept of Engineering, Lund University and Geoscientific Research Centre, National

Autonomous University of Nicaragua)

West, T. R., Geology: Applied to Engineering, Upper Saddle River NJ, Prentice Hall, 1995.

Portland State University 29

You might also like

- Structural Resilience in Sewer Reconstruction: From Theory to PracticeFrom EverandStructural Resilience in Sewer Reconstruction: From Theory to PracticeNo ratings yet

- Conceptual Design For Tidal Energy Power Plant: A Supplementary Power Generation Plant For Residential Use in Neighboring Areas of Sarangani BayDocument18 pagesConceptual Design For Tidal Energy Power Plant: A Supplementary Power Generation Plant For Residential Use in Neighboring Areas of Sarangani BayVanne Jo PajoNo ratings yet

- Hydroelectric Powerplant PDFDocument39 pagesHydroelectric Powerplant PDFMarc Joshua MACATANGAYNo ratings yet

- Research Paper Hydroelectric PowerDocument4 pagesResearch Paper Hydroelectric Powertrsrpyznd100% (1)

- NYC DEP Application To FERC For Hydropower PermitDocument47 pagesNYC DEP Application To FERC For Hydropower PermitWatershed PostNo ratings yet

- Energies: Intelligent Stability Design of Large Underground Hydraulic Caverns: Chinese Method and PracticeDocument21 pagesEnergies: Intelligent Stability Design of Large Underground Hydraulic Caverns: Chinese Method and PracticeGaddam Padmaja ReddyNo ratings yet

- A Project Proposal For "Small Scale Hydro - Electric Storage Tank"Document26 pagesA Project Proposal For "Small Scale Hydro - Electric Storage Tank"Mariel MirafloresNo ratings yet

- Concept Paper Group 10Document9 pagesConcept Paper Group 10Prince SiraNo ratings yet

- Research Paper On Footstep Power GenerationDocument8 pagesResearch Paper On Footstep Power Generationistdijaod100% (1)

- Design of Draft TubeDocument10 pagesDesign of Draft TubeGeet AgnihotriNo ratings yet

- Energies: Advancements in Hydropower Design and Operation For Present and Future Electrical DemandDocument2 pagesEnergies: Advancements in Hydropower Design and Operation For Present and Future Electrical DemandCertified Rabbits LoverNo ratings yet

- Proposal HydrologyDocument4 pagesProposal HydrologyClint Sunako FlorentinoNo ratings yet

- The Problem and Its BackgroundDocument14 pagesThe Problem and Its BackgroundJames GupoNo ratings yet

- Storage Tank Design - 9Document3 pagesStorage Tank Design - 9Riyan EsapermanaNo ratings yet

- Comparative Study On The Design of Elevated Rectangular and Circular Concrete Water TanksDocument9 pagesComparative Study On The Design of Elevated Rectangular and Circular Concrete Water TanksDavid Plata OrozcoNo ratings yet

- Tidal Report 06-10-06 PDFDocument0 pagesTidal Report 06-10-06 PDFAlexander WijesooriyaNo ratings yet

- Adapting Dedicated Hydrodam For Electrical Power Generation - Unilorin Case StudyDocument11 pagesAdapting Dedicated Hydrodam For Electrical Power Generation - Unilorin Case StudyjoolaoyeNo ratings yet

- 1 s2.0 S209580992200769X MainDocument3 pages1 s2.0 S209580992200769X Mainpablo ignacio olmedo lopezNo ratings yet

- To Study Rehabilitation of Old Elevated Water Tank and To Generate Non-Conventional EnergyDocument9 pagesTo Study Rehabilitation of Old Elevated Water Tank and To Generate Non-Conventional EnergyIJRASETPublicationsNo ratings yet

- Crandall FEDSM2014Document11 pagesCrandall FEDSM2014Jumana SharanikNo ratings yet

- Power Generation Through Underwater TurbineDocument4 pagesPower Generation Through Underwater TurbineArbab AlamNo ratings yet

- Enercon - Water WheelDocument9 pagesEnercon - Water WheelAudrey RoqueNo ratings yet

- Thesis On Micro Hydro Power PlantDocument6 pagesThesis On Micro Hydro Power Plantafktciaihzjfyr100% (2)

- The Construction of Oyster - A Nearshore Surging Wave Energy ConverterDocument7 pagesThe Construction of Oyster - A Nearshore Surging Wave Energy ConverterJasmeet Singh Loyal100% (1)

- Battery That Extracts Energy From Water Salinity DifferenceDocument8 pagesBattery That Extracts Energy From Water Salinity DifferencejahidulNo ratings yet

- Earthquake Engineering: SupervisorDocument12 pagesEarthquake Engineering: SupervisorMaria Montessa Calibo BarnigoNo ratings yet

- English Project Report 2007Document15 pagesEnglish Project Report 2007Srini BlackPearlNo ratings yet

- Seismic and Wind Design For Solar Panels J. M. Eidinger F. NikmanDocument8 pagesSeismic and Wind Design For Solar Panels J. M. Eidinger F. NikmanlaurenjiaNo ratings yet

- Chapter 1 4 Kamo Na Bahala Bai Humana Mi Ni FrancisDocument47 pagesChapter 1 4 Kamo Na Bahala Bai Humana Mi Ni FrancisMichael David SyNo ratings yet

- Feasibility Study For The Construction 1Document20 pagesFeasibility Study For The Construction 1Julian CeledioNo ratings yet

- CWA 316 (B) Compliance - Power Plant Cooling Water System AnalysisFeasibility Evaluations, Conceptual Designs, Site ModificationsDocument2 pagesCWA 316 (B) Compliance - Power Plant Cooling Water System AnalysisFeasibility Evaluations, Conceptual Designs, Site ModificationsEnformableNo ratings yet

- Research ProposalDocument2 pagesResearch Proposalapi-301422938No ratings yet

- Sample Project Proposal For UndergraduateDocument10 pagesSample Project Proposal For Undergraduateamin shukriNo ratings yet

- Energy Fabrication of Kinetic Electrical Rotational Door 2Document34 pagesEnergy Fabrication of Kinetic Electrical Rotational Door 2Cantera, Cris Bryan E.No ratings yet

- Lecture 2 Hydrological Analysis For HydropowerDocument34 pagesLecture 2 Hydrological Analysis For HydropowerAbram KhanNo ratings yet

- Ssc412: Final Year Research Project Topics For 2017 8 November 2016 ProgrammeDocument26 pagesSsc412: Final Year Research Project Topics For 2017 8 November 2016 ProgrammeAkash GundaleNo ratings yet

- Design of A Low Head Pico Hydro TurbineDocument186 pagesDesign of A Low Head Pico Hydro TurbineVidAlcca ZmNo ratings yet

- Design of A Low Head Pico Hydro TurbineDocument186 pagesDesign of A Low Head Pico Hydro Turbineomer babikirNo ratings yet

- Anchor Block - 1Document1 pageAnchor Block - 1Ameya KannamwarNo ratings yet

- MIT22 091S08 Lec21Document28 pagesMIT22 091S08 Lec21lux0008No ratings yet

- Behavior of Underground Piping Joints Due To Static and Dynamic LoadingDocument260 pagesBehavior of Underground Piping Joints Due To Static and Dynamic LoadingjbNo ratings yet

- Vega,: A. Ph.D. Gerard Nihous, PH.DDocument15 pagesVega,: A. Ph.D. Gerard Nihous, PH.DSrîkår SríNo ratings yet

- A Study On Maximizing The Bui Hydro-Dam To A Base Load Power Plant Using Solar EnergyDocument2 pagesA Study On Maximizing The Bui Hydro-Dam To A Base Load Power Plant Using Solar EnergyLucy AbutiateNo ratings yet

- Golden Gate Colleges Bachelor of Science in Mechanical EngineeringDocument64 pagesGolden Gate Colleges Bachelor of Science in Mechanical EngineeringKrishna Belela100% (1)

- Sustainability 12 01676 PDFDocument40 pagesSustainability 12 01676 PDFpradip panthaNo ratings yet

- Dynamic Response Analysis of Jacket Platform Integrated With Oscillating Water Column DeviceDocument12 pagesDynamic Response Analysis of Jacket Platform Integrated With Oscillating Water Column DeviceSthefanoNo ratings yet

- CEEn 2016CPST 005 - FinalReportDocument75 pagesCEEn 2016CPST 005 - FinalReportmirfanjpcgmailcomNo ratings yet

- Efficacy of Water Wheel in Generating EnergyDocument5 pagesEfficacy of Water Wheel in Generating EnergyAlcedo Karen R.No ratings yet

- An Ocean Wave Energy Harnessing Model Using Piezo-Electric DeviceDocument7 pagesAn Ocean Wave Energy Harnessing Model Using Piezo-Electric DeviceEngineer Arshad karimNo ratings yet

- Project Proposal For Design Project 2Document4 pagesProject Proposal For Design Project 2Shavin ChandNo ratings yet

- Transient Analysis of The Nuscale Power Helical-Coil Steam GeneraDocument204 pagesTransient Analysis of The Nuscale Power Helical-Coil Steam GenerasaibuNo ratings yet

- M.tech .Tech SynopsisDocument6 pagesM.tech .Tech SynopsisAnupNo ratings yet

- Design and Build A Water Channel For A Fluid Dynamics LabDocument10 pagesDesign and Build A Water Channel For A Fluid Dynamics Labsampath kumar K NNo ratings yet

- Intoduction JoannaDocument9 pagesIntoduction Joannajethro ganeloNo ratings yet

- Research PaperDocument7 pagesResearch PaperPatrick Jose Dela VegaNo ratings yet

- Collaboration of Faculty, Students, and Licensed Professional EngineersDocument9 pagesCollaboration of Faculty, Students, and Licensed Professional EngineersreluNo ratings yet

- Thesis Oscillating Water ColumnDocument5 pagesThesis Oscillating Water Columnfjoxrygig100% (1)

- Elevated Steel Water TankDocument8 pagesElevated Steel Water TankJodrish OmarNo ratings yet

- FinalRevision For SubmitDocument34 pagesFinalRevision For SubmitDela Cruz MelvinNo ratings yet

- Design of Pile FoundationsDocument106 pagesDesign of Pile Foundationserdilyn PradoNo ratings yet

- Purlin and Roof DesignDocument4 pagesPurlin and Roof DesignAnilkumar Cm100% (2)

- Road Traffic SignsDocument40 pagesRoad Traffic SignsRonald McRonaldNo ratings yet

- Water TankDocument1 pageWater TankArvin De Guzman SantosNo ratings yet

- 4 Combined FootingDocument22 pages4 Combined FootingKamel Jamal BesharahNo ratings yet

- I JR Et 20150425025Document9 pagesI JR Et 20150425025Froilan AngbengcoNo ratings yet

- RC 1 5 4 GradesDocument3 pagesRC 1 5 4 GradesArvin De Guzman SantosNo ratings yet

- Ch6 Fluid MechanicsDocument15 pagesCh6 Fluid MechanicsArvin De Guzman SantosNo ratings yet

- 2 Way SlabDocument22 pages2 Way SlabAhmed Al-AmriNo ratings yet

- Ch6 Fluid MechanicsDocument15 pagesCh6 Fluid MechanicsArvin De Guzman SantosNo ratings yet

- Dr. Seshu Adluri: Structural Steel DesignDocument72 pagesDr. Seshu Adluri: Structural Steel DesignSopheak ThapNo ratings yet

- Take Home Final EarthquakeDocument4 pagesTake Home Final EarthquakeArvin De Guzman SantosNo ratings yet

- 6.1.5 - Well Control Worksheet & Pump DataDocument4 pages6.1.5 - Well Control Worksheet & Pump DatadagingoNo ratings yet

- Penerapan Metode Sonikasi Terhadap Adsorpsi FeIIIDocument6 pagesPenerapan Metode Sonikasi Terhadap Adsorpsi FeIIIappsNo ratings yet

- Classical Theory of DetonationDocument20 pagesClassical Theory of Detonationalexander.lhoistNo ratings yet

- Additive ManufacturingDocument20 pagesAdditive Manufacturingjoeborderline100% (1)

- REFERENCESDocument3 pagesREFERENCESCaye AregladoNo ratings yet

- A4-P 4.0 enDocument32 pagesA4-P 4.0 enmkpqNo ratings yet

- Lighting and ShadingDocument44 pagesLighting and Shadingpalaniappan_pandianNo ratings yet

- Equilibrium of Rigid Bodies Structural AnalysisDocument20 pagesEquilibrium of Rigid Bodies Structural AnalysisJohn Lemmor G. CandelariaNo ratings yet

- Performance Under Cyclic Load of Built-Up T-Stubs For Double T Moment ConnectionsDocument14 pagesPerformance Under Cyclic Load of Built-Up T-Stubs For Double T Moment ConnectionsMilmxmenNo ratings yet

- Whole Numbers and Basic OperationsDocument6 pagesWhole Numbers and Basic Operationsapi-389461198No ratings yet

- Settlement Analysis of SoilsDocument22 pagesSettlement Analysis of SoilsMuhammad Hasham100% (1)

- Radar ReceiversDocument15 pagesRadar Receiversmas3565560100% (2)

- ANSYS Mechanical APDL Fluids Analysis Guide PDFDocument46 pagesANSYS Mechanical APDL Fluids Analysis Guide PDFda_pinon100% (1)

- Aperture 3Document355 pagesAperture 3Edu José MarínNo ratings yet

- Pythagorean TheoremDocument8 pagesPythagorean Theoremakiyama_ma83No ratings yet

- Learn CBSE: To Measure Diameter of A Given Wire Using Screw GaugeDocument4 pagesLearn CBSE: To Measure Diameter of A Given Wire Using Screw GaugeSuman SamantaNo ratings yet

- Industrial Training PresentationDocument16 pagesIndustrial Training PresentationChia Yi MengNo ratings yet

- Room Air Conditioner System Modeling: Acrc Tr-60 July 1994Document97 pagesRoom Air Conditioner System Modeling: Acrc Tr-60 July 1994eyob feshaNo ratings yet

- A Model For Traffic SimulationDocument5 pagesA Model For Traffic Simulationraci78No ratings yet

- The Klein-Gordon EquationDocument22 pagesThe Klein-Gordon EquationAnderson CalistroNo ratings yet

- PipephaseDocument32 pagesPipephaseZadeh NormanNo ratings yet

- 8.03 Fall 2004 Problem Set 2 SolutionsDocument15 pages8.03 Fall 2004 Problem Set 2 SolutionseviroyerNo ratings yet

- Power Cable StandardsDocument3 pagesPower Cable StandardsJamie 'Bear' ReaderNo ratings yet

- A Companion To Fourier Analysis For Physics Students: Gol Mohammad NafisiDocument25 pagesA Companion To Fourier Analysis For Physics Students: Gol Mohammad NafisiIridian ÁvilaNo ratings yet

- CE6405-Soil Mechanics PDFDocument18 pagesCE6405-Soil Mechanics PDFShanmuga SundaramNo ratings yet

- Nuclear and Particle Physics - Unit 8 - Week 6: Particle Detectors and Elementary ParticlesDocument1 pageNuclear and Particle Physics - Unit 8 - Week 6: Particle Detectors and Elementary ParticlesSamarjeet Kumar SinghNo ratings yet

- MSDS Full1Document92 pagesMSDS Full1Sunthron SomchaiNo ratings yet

- Bionanotechnology - E. Papazoglou, A. Parthasarathy (2007) WWDocument148 pagesBionanotechnology - E. Papazoglou, A. Parthasarathy (2007) WWbicarbonat100% (2)

- Vectors DPPDocument13 pagesVectors DPPAchyuth DaggumatiNo ratings yet

- "Quantum Physics" - S. GasiorowiczDocument522 pages"Quantum Physics" - S. Gasiorowicz11111__11__1111100% (2)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesFrom EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraRating: 4.5 out of 5 stars4.5/5 (4)

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsFrom EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsRating: 4 out of 5 stars4/5 (16)

- Advanced Design Examples of Seismic Retrofit of StructuresFrom EverandAdvanced Design Examples of Seismic Retrofit of StructuresRating: 1 out of 5 stars1/5 (1)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Design and Construction of Soil Anchor PlatesFrom EverandDesign and Construction of Soil Anchor PlatesRating: 5 out of 5 stars5/5 (1)