Professional Documents

Culture Documents

Splices, Development and STD - Hooks

Uploaded by

jem guiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Splices, Development and STD - Hooks

Uploaded by

jem guiCopyright:

Available Formats

An information series from the national authority on concrete masonry technology

SPLICES, DEVELOPMENT AND

STANDARD HOOKS FOR TEK 12-6

CONCRETE MASONRY Reinforcement & Connectors (2007)

INTRODUCTION the 2003 IBC are encouraged to compare these requirements

to the corresponding 2006 IBC requirements.

Building codes include requirements for minimum rein-

forcement development lengths and splice lengths, as well as ALLOWABLE STRESS DESIGN

requirements for standard hooks, to ensure the adequate transfer

of stresses between the reinforcement and the masonry. This 2003 IBC Allowable Stress Design

TEK presents these requirements, based on the provisions of By reference to the 2002 edition of Building Code Re-

both the 2003 and 2006 editions of the International Building quirements for Masonry Structures (MSJC) (ref. 5), the 2003

Code (IBC) (refs. 1, 2). TEK 12-4D (ref. 3) includes basic IBC requires the minimum development length for reinforcing

material requirements, corrosion protection and placement toler- bars and wires designed by the allowable stress method to be

ances for reinforcement used in concrete masonry construction. calculated using Equation 1 (see Tables 1 and 2).

In addition, prestressing steel is discussed in Post-Tensioned ld = 0.0015db Fs, (Eqn. 1)

Concrete Masonry Wall Construction, TEK 3-14 (ref. 4). but not less than 12 in. (305 mm) for bars or 6 in. (152 mm)

for wires.

SPLICES AND DEVELOPMENT When epoxy coated bars or wires are used, the development

length determined by Equation 1 is required to be increased

Minimum development lengths are necessary to adequately by 50 percent.

transfer stresses between reinforcement and the grout or mor- Although development lengths and lap splice lengths have

tar in which it is embedded. Splicing of reinforcement serves historically been assumed to be related and calculated in a

a similar purpose; to adequately transfer stresses from one similar manner, the 2003 IBC provides a unique design equa-

reinforcing bar to another. tion for determining the minimum length of lap for reinforcing

Reinforcement can be developed by embedment length, bars, in accordance with Equation 2. Table 5 contains tabulated

hook, or mechanical anchoring device. The development of values for common design variables shown in Equation 2.

the reinforcing bars relies on mechanical interlock of the bar 0.16db 2 f yg 1.95db 2 f yg

deformations, hook, and/or anchor along with sufficient = ma- ld = SI: ld

K f 'm K f 'm

sonry cover to prevent splitting of the masonry. Reinforcing , (Eqn. 2)

bars may be spliced by lapping the reinforcement, by proprietary but not less than 15 in. (380 mm)

mechanical splices or by welding. For use in Equation 2, the reinforcement size factor, γ,

The required length of lap or development is determined is taken equal to 1.0 for No. 3 through No. 5 (M#10–M#16)

according to the design procedure used and type of detail em- reinforcing bars; 1.4 for No. 6 and No. 7 (M#19 and M#22)

ployed. In addition, these detailing requirements have been reinforcing bars; and 1.5 for No. 8 and No. 9 (M#25 and M#29)

frequently revised in recent years. As a result, the minimum reinforcing bars. Reinforcing bars larger than No. 9 (M#29)

lap and development lengths can vary considerably from one are required to be spliced using mechanical connectors. When

code to the next as well as from one design method to another. noncontact lap splices are used, the bars must be spaced no

For this reason, the following sections present the requirements farther apart than one-fifth the required length of lap nor more

for both the 2003 IBC and 2006 IBC for both allowable stress than 8 in. (203 mm).

and strength design. Because the detailing requirements for As an alternative to lap splicing, reinforcing bars can

these two codes can be significantly different, designers using be spliced by welding. Welded splices require the bars to be

Related TEK: Keywords: allowable stress, development, embedment, joint reinforce-

ment, reinforcing bars, reinforcing steel, splices, standard hooks, strength

design, working stress

NCMA TEK 12-6 1

butted or shortly lapped and welded to develop in tension at suitable device. The bar ends are required to terminate in flat

least 125% of the specified yield strength of the bar. All weld- surfaces within 11/2 degrees of a right angle to the axis of the

ing is required to conform to AWS D 1.4 (ref. 6). In practice, bars and be fitted within 3 degrees of full bearing after assembly.

however, welding tends to be an expensive splicing option.

Finally, mechanical splicing of reinforcement typically 2006 IBC Allowable Stress Design

employs proprietary couplers specifically designed for this With the publication of the 2006 IBC, which in turn refer-

application. Mechanical splices are required to have the bars ences the 2005 MSJC (ref. 7), the majority of the splicing and

connected to develop in tension or compression, as required, development detailing requirements have remained the same,

at least 125% of the specified yield strength of the bar. with the notable exception that Equation 2 has been superseded

Reinforcing bars can also be spliced using end-bearing for determining the minimum length of lap splices.

splices, but only in members containing closed ties, closed While the 2005 MSJC includes an equation to determine

stirrups or spirals for bars subject to compression only. End- development length, which is also used to determine lap splice

bearing splices rely on the transmission of compressive stress length, the 2006 IBC modifies the MSJC lap splice length.

by bearing of square cut ends held in concentric contact by a In accordance with the 2006 IBC, the minimum required lap

Table 1—2003 IBC Allowable Stress Design Table 2—2003 and 2006 IBC Allowable Stress Design

Development Lengths (ref. 1) Development Lengths for Wires (refs. 1, 2)

Minimum Minimum

Bar size development lengthA, B, Wire size development lengthA, B,

in. (mm) in. (mm)

No. 3 (M#10) 14 (356) W1.1 (11 gage, MW 7) 6 (152)

No. 4 (M#13) 18 (457) W1.7 (9 gage, MW 11) 7 (178)

No. 5 (M#16) 23 (584) W2.1 (8 gage, MW 13) 8 (203)

No. 6 (M#19) 27 (686) W2.8 (3/16 in., MW 17) 9 (229)

No. 7 (M#22) 32 (813) W4.9 (1/4 in., MW 32) 12 (305)

No. 8 (M#25) 36 (914)

No. 9 (M#29) 41 (1,041) A

See Equation 1. Based on Fs = 30,000 psi (207 MPa) for

No. 10 (M#32) 46 (1,168) wire joint reinforcement. Development length not less

No. 11 (M#36) 51 (1,295) than 6 in. (152 mm).

B

Development lengths are to be increased by 50% when

A

See Equation 1. Based on Fs = 24,000 psi (165 MPa) for epoxy coated wire is used.

Grade 60 reinforcement. Development length not less than

12 in. (305 mm).

B

Development lengths are to be increased by 50% when

epoxy coated reinforcement is used.

Table 3—2006 IBC Allowable Stress Design Development Lengths for Reinforcing Bars (ref. 2)

Minimum development lengthA, in. (mm) based on:

Bar in center of: K=

6-in. 8-in. 10-in. 12-in. 11/2 in. 2 in.

Bar size (152-mm) CMU (203-mm) CMU (254-mm) CMU (305-mm) CMU (38 mm) (51 mm)

No. 3 (M #10) 16 (406) B 16 (406) B 16 (406) B 16 (406) B 19 (483) 16 (406) B

No. 4 (M#13) 21 (533) B 21 (533) B 21 (533) B 21 (533) B 34 (864) 26 (660)

No. 5 (M#16) 32 (813) D

26 (660) B

26 (660) B

26 (660) B 53 (1,346) 40 (1,016)

No. 6 (M#19) 61 (1,549) D 43 (1,092) 40 (1,016) B 40 (1,016) B 99 (2,515) 74 (1,880)

No. 7 (M#22) NP C

60 (1,524) 46 (1,168) 46 (1,168) B 134 (3,404) 101 (2,565)

No. 8 (M#25) NP C 92 (2,337) D 71 (1,803) 61 (1,549) B 202 (5,131) 151 (3,835)

No. 9 (M#29) NP NP

C C

91 (2,311) 74 (1,880) 257 (6,528) 193 (4,902)

No. 10 (M#32) NP C NP C NP C 95 (2,413) 325 (8,255) 244 (6,198)

No. 11 (M#36) NP C

NP C

NP C

118 (2,997)

401 (10,185) 301 (7,645)

A

See Equation 4. Based on fy = 60,000 psi (414 MPa) for Grade 60 steel and f'm = 1,500 psi (10.3 MPa).

B

K = 5db governs.

C

Bar is too large for this wall; db exceeds 1/4 of the least clear dimension of the cell to be grouted, 1/8 of the nominal unit thick-

ness, or 6% of the cell area to be grouted. Dimensions are based on specified minimum dimensions for a two-core, square

core unit and take into account a cell taper of 1/4 in. (6.4 mm) and mortar protrusions not exceeding 1/2 in. (13 mm).

D

Permitted only if mortar fins are removed from the cell to be grouted. Not permitted if mortar fins are not removed.

2 NCMA TEK 12-6

length for spliced reinforcing bars is determined using Equa- bars, however, the 2005 MSJC minimum development length

tion 3. Table 4 lists tabulated values. was not modified by the IBC, and so is determined by Equation

ld = 0.002db fs (SI: ld = 0.29db fs), (Eqn. 3) 4 (see Table 3).

but not less than 12 in. (305 mm) or 40db, whichever 0.13db 2 f yg 1.5db 2 f yg

is greater = ld = SI: ld

K f 'm K f 'm

Further, in regions of flexure where the design tensile , (Eqn. 4)

stresses in the reinforcement, fs, exceed 80% of the allowable but not less than 12 in. (305 mm)

steel tensile stress, Fs, the required length of lap determined by For use in Equation 4, the reinforcement size factor, γ,

Equation 3 must be increased by 50%. Alternatively, equivalent is taken equal to 1.0 for No. 3 through No. 5 (M#10–M#16)

means of stress transfer to accomplish the same 50% increase reinforcing bars; 1.3 for No. 6 and No. 7 (M#19 and M#22)

is permitted. Where epoxy coated bars are used, lap length is bars; and 1.5 for No. 8 through No. 11 (M#25–M#36) bars.

also required to be increased by 50%. When epoxy coated bars are used, the development length

For wires, minimum development length is determined determined by Equation 4 is required to be increased by 50%.

in accordance with Equation 1 (see Table 2). For reinforcing

Allowable Stress Design Lap Splice Lengths

Table 4—2006 IBC Allowable Stress Design Lap Splice Lengths (ref. 2)

Bar size Minimum lap splice lengthA, D, in. (mm) Minimum lap splice lengthB, D, in. (mm)

No. 3 (M#10) 15 (381) 27 (686)

No. 4 (M#13) 20 (508) 36 (914)

No. 5 (M#16) 25 (635) 45 (1,143)

No. 6 (M#19) 30 (762) 54 (1,372)

No. 7 (M#22) 35 (889) 63 (1,600)

No. 8 (M#25) 40 (1,016) 72 (1,829)

No. 9 (M#29) C 46 (1,168) 82 (2,083)

A

See Equation 3. Based on the stresses in the steel, fs, being limited to 80% of the allowable reinforcement tensile stress (Fs

= 24,000 psi (165 MPa) for Grade 60 reinforcement). Lap splice length not less than 12 in. (305 mm) nor 40db. Minimum

lap lengths may be smaller in cases where fs < 0.8Fs.

B

Based on the stresses in the steel, fs, taken equal to 100% of the allowable reinforcement tensile stress of 24,000 psi (165

MPa) for Grade 60 reinforcement. Lap splice length increased by 50 % not less than 12 in. (305 mm) or 40db.

C

Bars larger than No. 9 (M#29) are required to be spliced by mechanical connectors.

D

Lap splice lengths are to be increased by 50% when epoxy coated reinforcement is used.

Table 5—2003 IBC Allowable Stress Design Lap Splice Lengths (ref. 1)

Minimum lap splice lengthA, in. (mm) based on:

Bar in center of: K=

6-in. 8-in. 10-in. 12-in. 11/2 in. 2 in.

Bar size (152-mm) CMU (203-mm) CMU (254-mm) CMU (305-mm) CMU (38 mm) (51 mm)

No. 3 (M #10) 19 (483) B 19 (483) B 19 (483) B 19 (483) B 24 (610) 19 (483) B

No. 4 (M#13) 25 (635) B

25 (635) B

25 (635) B

25 (635) B 42 (1,067) 31 (787)

No. 5 (M#16) 39 (991) 31 (787) B

31 (787) B

31 (787) B 65 (1,651) 49 (1,245)

No. 6 (M#19) 81 (2,057) F

57 (1,448) 53 (1,346) B

53 (1,346) B 131 (3,327) 98 (2,489)

No. 7 (M#22) NP C

79 (2,007) 61 (1,549) 61 (1,549) B 178 (4,521) 133 (3,378)

No. 8 (M#25) NP C

113 (2,870) 87 (2,210) 75 (1,905) B 248 (6,299) 186 (4,724)

No. 9 (M#29) NP NP

D C C

112 (2,845) 91 (2,311) 316 (8,026) 237 (6,020)

A

See Equation 2. Based on fy = 60,000 psi (414 MPa) for Grade 60 steel, f'm = 1,500 psi (10.3 MPa).

B

K = 5db governs.

C

Bar is too large for this wall; db exceeds 1/4 of the least clear dimension of the cell to be grouted, 1/8 of the nominal unit thick-

ness, or 6% of the cell area to be grouted. Dimensions are based on specified minimum dimensions for a two-core, square

core unit and take into account a cell taper of 1/4 in. (6.4 mm) and mortar protrusions not exceeding 1/2 in. (13 mm).

D

Bars larger than No. 9 (M#29) are required to be spliced by mechanical connectors.

F

Permitted only if mortar fins are removed from the cell to be grouted. Not permitted if mortar fins are not removed.

NCMA TEK 12-6 3

STRENGTH DESIGN reinforcing bars; 1.4 for No. 6 and No. 7 (M#19 and M#22)

reinforcing bars; and 1.5 for No. 8 and No. 9 (M#25 and M#29)

2003 IBC Strength Design reinforcing bars.

By reference to the 2002 MSJC (ref. 5), the 2003 IBC The 2003 IBC modifies the MSJC requirements for welded

requires the minimum development length and lap splice and mechanical splices as follows. The IBC stipulates that

length for reinforcing bars designed by the strength method mechanical splices be classified as Type 1 or 2 according to

to be calculated by Equation 5 (see Table 7). Section 21.2.6.1 of ACI 318 (ref. 8). Type 1 splices may not be

0.13db 2 f yg 1.5db 2 f yg used within the plastic hinge zone nor within a beam-column

ld = SI: ld (Eqn. 5) joint of intermediate or special reinforced masonry shear walls

f K f 'm f K f 'm

, or special moment frames.

but not less than 12 in. (305 mm) Welded splices must be able to develop at least 125% of

For use in Equation 5, the reinforcement size factor, γ, the bar's specified yield strength in tension or compression, as

is taken equal to 1.0 for No. 3 through No. 5 (M#10–M#16) required. Welded splices must use ASTM A 706 (ref. 9) steel

Strength Design Development and Lap Splice Lengths

Table 6—2006 IBC Strength Design Development and Lap Splice Lengths (ref. 2)

Minimum lap splice lengthA, in. (mm) based on:

Bar in center of: K=

6-in. 8-in. 10-in. 12-in. 11/2 in. 2 in.

Bar size (152-mm) CMU (203-mm) CMU (254-mm) CMU (305-mm) CMU (38 mm) (51 mm)

No. 3 (M #10) 16 (406) B 16 (406) B 16 (406) B 16 (406) B 19 (483) 16 (406) B

No. 4 (M#13) 21 (533) B

21 (533) B

21 (533) B

21 (533) B 34 (864) 26 (660)

No. 5 (M#16) 32 (813) F

26 (660) B

26 (660) B

26 (660) B 45 (1,143) D 40 (1,016)

No. 6 (M#19) 61 (1,549) F

43 (1,092) 40 (1,016) B

40 (1,016) B 54 (1,372) D 54 (1,372) D

No. 7 (M#22) NP C

60 (1,524) 46 (1,168) 46 (1,168) B 63 (1,600) D 63 (1,600) D

No. 8 (M#25) NP C

72 (1,889) D,F

71 (1,803) 61 (1,549) B 72 (1,829) D 72 (1,829) D

No. 9 (M#29) NP NP

E C C

82 (2,083) D

74 (1,880) 82 (2,083) D 82 (2,083) D

A

See Equation 6. Based on fy = 60,000 psi (414 MPa) for Grade 60 steel and f'm = 1,500 psi (10.3 MPa).

B

K = 5db governs.

C

Bar is too large for this wall; db exceeds 1/4 of the least clear dimension of the cell to be grouted, 1/8 of the nominal unit thick-

ness, or 4% of the cell area to be grouted. Dimensions are based on specified minimum dimensions for a two-core, square

core unit and take into account a cell taper of 1/4 in. (6.4 mm) and mortar protrusions not exceeding 1/2 in. (13 mm).

D

Maximum splice length of 72db governs.

E

Strength design provisions do not permit the use of reinforcing bars larger than No. 9 (M#29) (ref. 2).

F

Permitted only if mortar fins are removed from the cell to be grouted. Not permitted if mortar fins are not removed.

Table 7—2003 IBC Strength Design Development and Lap Splice Lengths (ref. 1)

Minimum lap splice lengthA, in. (mm) based on:

Bar in center of: K=

6-in. 8-in. 10-in. 12-in. 11/2 in. 2 in.

Bar size (152-mm) CMU (203-mm) CMU (254-mm) CMU (305-mm) CMU (38 mm) (51 mm)

No. 3 (M #10) 19 (483) B 19 (483) B 19 (483) B 19 (483) B 24 (610) 19 (483) B

No. 4 (M#13) 25 (635) B

25 (635) B

25 (635) B

25 (635) B 42 (1,067) 31 (787)

No. 5 (M#16) 39 (991) E

31 (787) B

31 (787) B

31 (787) B 65 (1,651) 49 (1,245)

No. 6 (M#19) 81 (2,057) E

57 (1,448) 53 (1,346) B

53 (1,346) B 131 (3,327) 98 (2,489)

No. 7 (M#22) NP C

79 (2,007) 61 (1,549) 61 (1,549) B 178 (4,521) 133 (3,378)

No. 8 (M#25) NP C

113 (2,870) E

87 (2,210) 75 (1,905) B 248 (6,299) 186 (4,724)

No. 9 (M#29) NP NP

D C C

112 (2,845) 91 (2,311) 316 (8,026) 237 (6,020)

A

See Equation 5. Based on fy = 60,000 psi (414 MPa) for Grade 60 steel, f'm = 1,500 psi (10.3 MPa) and f = 0.80.

B

K = 5db governs.

C

Bar is too large for this wall; db exceeds 1/4 of the least clear dimension of the cell to be grouted, 1/8 of the nominal unit thick-

ness, or 4% of the cell area to be grouted. Dimensions are based on specified minimum dimensions for a two-core, square

core unit and take into account a cell taper of 1/4 in. (6.4 mm) and mortar protrusions not exceeding 1/2 in. (13 mm).

D

Strength design provisions do not permit the use of reinforcing bars larger than No. 9 (M#29) (ref. 2).

E

Permitted only if mortar fins are removed from the cell to be grouted. Not permitted if mortar fins are not removed.

4 NCMA TEK 12-6

reinforcement. Welded splices are not permitted to be used in A combination of hook and development length must be

plastic hinge zones of intermediate or special reinforced walls used when the equivalent embedment length of the hook, le,

nor in special moment frames of masonry. is less than the required minimum development length, ld. In

this case, development length equal to (ld - le) must be provided

2006 IBC Strength Design in addition to the hook. This additional development length is

For development and lap splice length requirements, the measured from the start of the hook (point of tangency with

2006 IBC references the 2005 MSJC (see Equation 6 and Table the main portion of the bar).

6), but limits the maximum length to 72db.

0.13db 2 f yg 1.5db 2 f yg JOINT REINFORCEMENT SPLICES

ld = SI: ld

K f 'm K f 'm

, (Eqn. 6) While not currently addressed by the MSJC or IBC, wire

but not less than 12 in. (305 mm) and not more than 72db, and joint reinforcement is typically spliced 6 in. (152 mm) mini-

For Equation 6, the reinforcement size factor, γ, is taken mum to transfer shrinkage stresses. Slippage of the deformed

equal to 1.0 for No. 3 through No. 5 (M#10–M#16) reinforcing side wires is resisted by surface bond as well as by mechanical

bars; 1.3 for No. 6 and No. 7 (M#19, M#22) bars; and 1.5 for anchorage of the embedded portions of the cross wires.

No. 8 and No. 9 (M#25, M#29) bars. When epoxy coated bars

are used, the development length determined by Equation 6 is

db

required to be increased by 50%. Bars spliced by noncontact

lap splices must be spaced no farther apart than one-fifth the Di

required length of lap and no more than 8 in. (203 mm). Standard 180° hook

The 2006 IBC includes the same modifications for mechani-

At least 4d b but not less

cal and weld splices listed under 2003 IBC Strength Design.

db than 2 1 2 in. (64 mm)

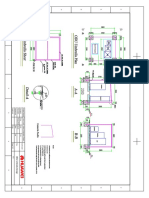

STANDARD HOOKS

Di

Standard 90° hook

Figure 1 illustrates the requirements for standard hooks, 12db

when reinforcing bars are anchored by hooks or by a combina-

tion of hooks and development length. Table 8 lists minimum db

dimensions and equivalent embedment lengths for standard

5db

hooks of various sizes. The equivalent embedment length for 90° stirrup or tie

6db

allowable stress design (le = 11.25db) is based on an allow-

able stress of 7,500 psi (51.7 MPa), the accepted permissible db

value in masonry design (ref. 10). To achieve this capacity, the

hook itself must be embedded a sufficient amount to prevent 5db

135° stirrup or tie

breakout/pullout. It is recommended that a minimum of 21/2 6db

in. (630 mm) embedment over the hook be provided (ref. 8),

unless a more detailed analysis is performed. Figure 1—Standard Hooks

Table 8—Standard Hooks—Dimensions and Equivalent Embedment Lengths

Minimum 180o hook, 135o hook, 90o hook, Equivalent embedment length

Bar Bar inside diameter 4db 6db 12db le, in. (mm) for:

size diameter of bendA extension extension extension Allowable stress Strength design

no. db, in. (mm) Di , in. (mm) in. (mm) in. (mm) in. (mm) design, le = 11.25db le = 13db

3 (M#10) 0.375 (9.5) 2.3 (57) 2.5B (64) 4.0C (102) 4.5 (114) 4.2 (107) 4.8 (122)

4 (M#13) 0.500 (13) 3.0 (76) 2.5B (64) 4.0C (102) 6.0 (152) 5.6 (143) 6.5 (165)

5 (M#16) 0.625 (16) 3.8 (95) 2.5 (64) 4.0C (102) 7.5 (191) 7.0 (178) 8.1 (206)

6 (M#19) 0.750 (19) 4.5 (114) 3.0 (76) 4.5 (114) 9.0 (229) 8.4 (214) 9.7 (246)

7 (M#22) 0.875 (22) 5.3 (133) 3.5 (89) 5.3 (133) 10.5 (267) 9.8 (250) 11.3 (287)

8 (M#25) 1.000 (25) 6.0 (152) 4.0 (102) 6.0 (152) 12.0 (305) 11.2 (286) 13.0 (330)

9 (M#29) 1.128 (29) 9.0 (229) 4.5 (115) 6.8 (172) 13.5 (343) 12.6 (322) 14.6 (371)

10 (M#32) 1.270 (32) 10.2 (259) 5.1 (130) 7.6 (193) 15.2 (386) 14.3 (363) NP D

11 (M#36) 1.410 (36) 11.3 (287) 5.6 (142) 8.5 (216) 16.9 (429) 15.9 (404) NP

D

A Based on Grade 60 reinforcing bars as follows: Di must equal or exceed 6db for bar sizes No. 3 through 8 (M#10–M#25);

8db for No. 9–11 (M #29–M#36) bars. Diameters of bend may be decreased to 5db for Grade 40, No. 3–7 (M#10–M#22).

B For 180o standard hooks, bar extensions may not be less than 21/2 in. (64 mm).

C For 135o standard hooks, bar extensions may not be less than 4 in. (102 mm).

D Maximum reinforcing bar size for strength design is No. 9 (M#29)

NCMA TEK 12-6 5

NOTATIONS:

Di = min. inside diameter of bend for standard hooks, in. (mm) ld = embedment length or lap splice length of straight rein-

db = nominal diameter of reinforcement, in. (mm) forcement, in. (mm)

K = the least of the masonry cover, 5db and the clear spacing le = equivalent embedment length provided by standard hooks

between adjacent reinforcement, in. (mm) measured from the start of the hook (point of tangency),

Fs = allowable tensile stress in reinforcement, psi (MPa) in. (mm)

f'm = specified compressive strength of masonry, psi (MPa) g = reinforcement size factor

fs = calculated tensile or compressive stress in steel, psi (MPa) f = strength reduction factor

fy = specified yield strength of steel, psi (MPa)

REFERENCES

1. International Building Code 2003. International Code Council, 2003.

2. International Building Code 2006. International Code Council, 2006.

3. Steel Reinforcement for Concrete Masonry, TEK 12-4D. National Concrete Masonry Association, 2006.

4. Post-Tensioned Concrete Masonry Wall Construction, TEK 3-14. National Concrete Masonry Association, 2002.

5. Building Code Requirements for Masonry Structures, ACI 530-02/ASCE 5-02/TMS 402-02. Reported by the Masonry Standards

Joint Committee, 2002.

6. Structural Welding Code—Reinforcing Steel, AWS D 1.4-98. American Welding Society, 1998.

7. Building Code Requirements for Masonry Structures, ACI 530-05/ASCE 5-05/TMS 402-05. Reported by the Masonry Standards

Joint Committee, 2005.

8. Building Code Requirements for Structural Concrete and Commentary, ACI 318-02. American Concrete Institute, 2002.

9. Standard Specification for Low-Alloy Steel Deformed and Plain Bars for Concrete Reinforcement, ASTM A 706/A 706M-01.

ASTM International, Inc., 2001.

10. Commentary on Building Code Requirements for Masonry Structures, ACI 530-05/ASCE 5-05/TMS 402-05. Reported by the

Masonry Standards Joint Committee, 2005.

NCMA and the companies disseminating this technical information disclaim any and all responsibility and liability for the accuracy

and the application of the information contained in this publication.

NATIONAL CONCRETE MASONRY ASSOCIATION

13750 Sunrise Valley Drive, Herndon, Virginia 20171

www.ncma.org

To order a complete TEK Manual or TEK Index, contact NCMA Publications (703) 713-1900

6 NCMA TEK 12-6

You might also like

- TEK 12-6 Reinforcement & Connectors (2007)Document6 pagesTEK 12-6 Reinforcement & Connectors (2007)B0B_PNo ratings yet

- Tek 12-03C6 PDFDocument6 pagesTek 12-03C6 PDFAlex MaxNo ratings yet

- ACI Standard BendDocument8 pagesACI Standard Bends.skumar1No ratings yet

- PositionStmt 23 Web PDFDocument1 pagePositionStmt 23 Web PDFShashi KumarNo ratings yet

- PS 18 Concrete Tolerance CoordinationDocument1 pagePS 18 Concrete Tolerance CoordinationSeifeldinNo ratings yet

- Concrete Fall ASCC PDFDocument1 pageConcrete Fall ASCC PDFAkhirul AbrarNo ratings yet

- ASCC Position Statement 09Document1 pageASCC Position Statement 09Hanri PakpahanNo ratings yet

- Rebars Splicing Handbook - Dayton SuperiorDocument76 pagesRebars Splicing Handbook - Dayton SuperiorJimmy090% (1)

- ASCC Position Statement 14Document1 pageASCC Position Statement 14Hanri Pakpahan100% (1)

- PS 31 Acceptable Use Calcium Chloride ConcreteDocument1 pagePS 31 Acceptable Use Calcium Chloride ConcretekannankrivNo ratings yet

- Concrete Discharge Time (ASCC)Document1 pageConcrete Discharge Time (ASCC)V. ManilalNo ratings yet

- Slab ToleranceDocument1 pageSlab TolerancejoanarchNo ratings yet

- CRSI slab thickness and reinforcement recommendationsDocument1 pageCRSI slab thickness and reinforcement recommendationsJaime Manalili LandinginNo ratings yet

- TolerancesDocument44 pagesTolerancesThilan SenarathneNo ratings yet

- Construction Issues: Anchoring MEP Items Into Suspended SlabsDocument2 pagesConstruction Issues: Anchoring MEP Items Into Suspended SlabsMario SandovalNo ratings yet

- Jumbo structural hollow sections technical data and specificationsDocument8 pagesJumbo structural hollow sections technical data and specificationsalextentwentyNo ratings yet

- Tek 14-03a PDFDocument4 pagesTek 14-03a PDFdaveshitNo ratings yet

- Typical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BDocument4 pagesTypical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BfostbarrNo ratings yet

- RGL Explosion Proof Electrical Products Oil & Gas Construction IndustriesDocument4 pagesRGL Explosion Proof Electrical Products Oil & Gas Construction IndustriesJoyaxFernandezNo ratings yet

- Concrete Construction Article PDF - Mechanical vs. Lap SplicingDocument4 pagesConcrete Construction Article PDF - Mechanical vs. Lap SplicingGilven MedinaNo ratings yet

- Tek 18-01B5 PDFDocument8 pagesTek 18-01B5 PDFMohamed HNo ratings yet

- 4.8 Procedures For Nonstructural Components: CommentaryDocument20 pages4.8 Procedures For Nonstructural Components: CommentarymanohargudNo ratings yet

- Ncma Tek 10-03Document4 pagesNcma Tek 10-03Jeff HedmanNo ratings yet

- Tek 14-15BDocument6 pagesTek 14-15BalbertoxinaNo ratings yet

- Emperical Design of Concrete MasonryDocument8 pagesEmperical Design of Concrete MasonryKmrnKhnNo ratings yet

- UFC 1-200-01 General Building Requirements, With Change 1 (11!27!2007)Document14 pagesUFC 1-200-01 General Building Requirements, With Change 1 (11!27!2007)Bob Vines100% (1)

- TEK 10-2C - Control Joints For CMUDocument8 pagesTEK 10-2C - Control Joints For CMUAnonymous PjmE9RJcghNo ratings yet

- Preventing Water Penetration in Below-Grade Concrete Masonry WallsDocument4 pagesPreventing Water Penetration in Below-Grade Concrete Masonry WallsDenver AbanoNo ratings yet

- Tek 12-03CDocument16 pagesTek 12-03CponjoveNo ratings yet

- Free Fall Concrete Position StatementDocument1 pageFree Fall Concrete Position StatementBetonÇimentoNo ratings yet

- NCMA TEK 6-1B - R Values of Multi-Wythe Concrete Masonry Walls 2009Document4 pagesNCMA TEK 6-1B - R Values of Multi-Wythe Concrete Masonry Walls 2009SugarPOP666No ratings yet

- Tek 14-01B PDFDocument8 pagesTek 14-01B PDFzeek77No ratings yet

- Upcoming Changes To Aisc 341 - Seismic Provisions For Structural Steel BuildingsDocument6 pagesUpcoming Changes To Aisc 341 - Seismic Provisions For Structural Steel BuildingsFranco SerafiniNo ratings yet

- Carbon Fiber Beam Reinforcement CalculationDocument4 pagesCarbon Fiber Beam Reinforcement CalculationStructural SpreadsheetsNo ratings yet

- Grad Manual Design TipsDocument10 pagesGrad Manual Design TipsDebendra Dev KhanalNo ratings yet

- Application of Fiber Reinforced Concrete andDocument35 pagesApplication of Fiber Reinforced Concrete andDeep ShahNo ratings yet

- Tek 17-01B PDFDocument4 pagesTek 17-01B PDFJacky LeongNo ratings yet

- Anchor Bolt Tolerances PDFDocument1 pageAnchor Bolt Tolerances PDFwokeoooNo ratings yet

- Col - Stiff Properties - SAFE - CSIDocument1 pageCol - Stiff Properties - SAFE - CSIkilmasterNo ratings yet

- Seismic Technical Guide: ExemptionsDocument4 pagesSeismic Technical Guide: Exemptionsrex100% (1)

- PT Works Material Specification (22apr2021) IESDocument54 pagesPT Works Material Specification (22apr2021) IESYeoh chun yenNo ratings yet

- CCL PT Slabs Brochure Eng PDFDocument15 pagesCCL PT Slabs Brochure Eng PDFSharad BornarkarNo ratings yet

- Ncma Tek: Segmental Retaining Wall Units TEK 2-4BDocument4 pagesNcma Tek: Segmental Retaining Wall Units TEK 2-4BJorge Luis Arevalo LopezNo ratings yet

- Tek 10-01a PDFDocument4 pagesTek 10-01a PDFHeriberto Yau BNo ratings yet

- Precast Concrete DetailsDocument5 pagesPrecast Concrete Detailstwinkle4545No ratings yet

- G - Standards - TMP - Astm c503.c503m 2010Document2 pagesG - Standards - TMP - Astm c503.c503m 2010BALEN KAKLNo ratings yet

- Epoxy Structural Steel Plate BondingDocument5 pagesEpoxy Structural Steel Plate BondingShepherd NhangaNo ratings yet

- Seismic Behavior and Design of Steel Shear WallsDocument18 pagesSeismic Behavior and Design of Steel Shear Wallsastaneh100% (1)

- Tek 10-03Document4 pagesTek 10-03Thai DamNo ratings yet

- 0 4 Reinforced Concrete Slab Design Example 1 UnfilledDocument2 pages0 4 Reinforced Concrete Slab Design Example 1 UnfillednsureshbabuNo ratings yet

- UFC 3-490-06 - 2018.06 - ElevatorsDocument48 pagesUFC 3-490-06 - 2018.06 - ElevatorsMofasa ENo ratings yet

- Astm A-1005Document6 pagesAstm A-1005dennis_ugarteNo ratings yet

- Safe Load TablesDocument12 pagesSafe Load TablesdeviationzNo ratings yet

- Wide Beam Stirrup PDFDocument3 pagesWide Beam Stirrup PDFPatipol GunhomepooNo ratings yet

- Icc-Es Esr-1917Document15 pagesIcc-Es Esr-1917kmccrapmailNo ratings yet

- SRW Design FactorsDocument8 pagesSRW Design Factorslcruz117No ratings yet

- Analysis For Schedule-2009 PDFDocument2,393 pagesAnalysis For Schedule-2009 PDFVikrant Narayan VasudevaNo ratings yet

- Hollow Sections For Multi Storey ColumnsDocument37 pagesHollow Sections For Multi Storey ColumnsVimut SuttipongNo ratings yet

- Concrete Sampling and Testing ProceduresDocument22 pagesConcrete Sampling and Testing ProceduresAdnan JadoonNo ratings yet

- Highway Material Testing Manual: Dr. PVSN Pavan Kumar Professor, Guru Nanak Institutions Technical CampusDocument145 pagesHighway Material Testing Manual: Dr. PVSN Pavan Kumar Professor, Guru Nanak Institutions Technical CampusKomalesh CNo ratings yet

- Checklist For Masonry: Project: Doc. No.: Client: Project LocationDocument4 pagesChecklist For Masonry: Project: Doc. No.: Client: Project Locationjem guiNo ratings yet

- Contractor Quality Control Plan For Civil WorkDocument6 pagesContractor Quality Control Plan For Civil WorkUday PratapNo ratings yet

- Checklist For Masonry: Project: Doc. No.: Client: Project LocationDocument4 pagesChecklist For Masonry: Project: Doc. No.: Client: Project Locationjem guiNo ratings yet

- ACI Staggered Lap Splices PDFDocument4 pagesACI Staggered Lap Splices PDFk_maheswari3397100% (5)

- Checklist For ReinforcementDocument4 pagesChecklist For ReinforcementManish KapadneNo ratings yet

- Checklist For Masonry: Project: Doc. No.: Client: Project LocationDocument4 pagesChecklist For Masonry: Project: Doc. No.: Client: Project Locationjem guiNo ratings yet

- ACI Staggered Lap Splices PDFDocument4 pagesACI Staggered Lap Splices PDFk_maheswari3397100% (5)

- Reinforcement details for elevator pit foundationDocument1 pageReinforcement details for elevator pit foundationjem guiNo ratings yet

- Jobhazard Analysis SampleDocument6 pagesJobhazard Analysis Samplejem guiNo ratings yet

- Mathprint PDFDocument53 pagesMathprint PDFjem gui100% (1)

- Mathprint PDFDocument53 pagesMathprint PDFjem gui100% (1)

- Staad Advanced Concrete Design RCDC 63 PhilippinesDocument2 pagesStaad Advanced Concrete Design RCDC 63 Philippinesjem guiNo ratings yet

- Cutting List of RebarDocument1 pageCutting List of Rebarjem guiNo ratings yet

- Astm c470Document4 pagesAstm c470jem gui50% (2)

- 4 PDFDocument1 page4 PDFjem guiNo ratings yet

- GuidelinesDocument2 pagesGuidelinesMike2322No ratings yet

- Elevator pit reinforcement detailsDocument1 pageElevator pit reinforcement detailsjem guiNo ratings yet

- Construction of Multi-Level ParkingDocument13 pagesConstruction of Multi-Level Parkingdunknown15No ratings yet

- Cistern Tank Footing and Rebar DetailsDocument1 pageCistern Tank Footing and Rebar Detailsjem guiNo ratings yet

- 4 PDFDocument1 page4 PDFjem guiNo ratings yet

- TechNote Concrete Sampling and TestingDocument5 pagesTechNote Concrete Sampling and TestingjjaavenidoNo ratings yet

- TechNote Concrete Sampling and TestingDocument5 pagesTechNote Concrete Sampling and TestingjjaavenidoNo ratings yet

- Concrete Cylinder Curing MethodsDocument8 pagesConcrete Cylinder Curing Methodsjem guiNo ratings yet

- DAO 05 2002 - pns49&211 - RSBDocument1 pageDAO 05 2002 - pns49&211 - RSBArvin RazonNo ratings yet

- 425-Chp7-Bond Development Length SplicesDocument41 pages425-Chp7-Bond Development Length SplicesAhsan BuriroNo ratings yet

- Mf-02 Cutting ListDocument1 pageMf-02 Cutting Listjem guiNo ratings yet

- Column Rebar ModelDocument1 pageColumn Rebar Modeljem guiNo ratings yet

- Reinforced Concrete Slab DesignDocument8 pagesReinforced Concrete Slab Designone hundredNo ratings yet

- Lecture 3: Operation Involving Particulate MatterDocument25 pagesLecture 3: Operation Involving Particulate MatterTaytoNo ratings yet

- Henry Dee Taking Off Beme For Office Building of 40m October 2016Document257 pagesHenry Dee Taking Off Beme For Office Building of 40m October 2016Henry DiyokeNo ratings yet

- ITP031 ELH Master Copy - Pavement DrainsDocument3 pagesITP031 ELH Master Copy - Pavement DrainsshazniSNo ratings yet

- Design Guidelines For Doubler Plate Repairs of Ship StructuresDocument21 pagesDesign Guidelines For Doubler Plate Repairs of Ship StructuresgilonnerNo ratings yet

- Non-Destructive Testing Methods Determine Concrete StrengthDocument9 pagesNon-Destructive Testing Methods Determine Concrete StrengthHaffizul SaidNo ratings yet

- Class Programme: Type ApprovalDocument13 pagesClass Programme: Type ApprovalGoran VNo ratings yet

- Solubility ListDocument6 pagesSolubility ListpomegranatesoupNo ratings yet

- Manual de Operação - Ahmc 03 - Export - GeralDocument77 pagesManual de Operação - Ahmc 03 - Export - Geralvalam ltdaNo ratings yet

- Solubility Curves - CPDocument2 pagesSolubility Curves - CPAna WinterNo ratings yet

- SpekrometerDocument16 pagesSpekrometerPutra AjaNo ratings yet

- 05 1113 01 5RP AFP tcm143-547009Document20 pages05 1113 01 5RP AFP tcm143-547009AnisahNo ratings yet

- Molykote 1000 Paste MSDSDocument9 pagesMolykote 1000 Paste MSDSNikola Polimenov100% (1)

- As 4312-2008 Atmospheric Corrosivity Zones in AustraliaDocument7 pagesAs 4312-2008 Atmospheric Corrosivity Zones in AustraliaSAI Global - APACNo ratings yet

- Loctite EA E-120HP: Product Description MixedDocument3 pagesLoctite EA E-120HP: Product Description MixedRavi ModyNo ratings yet

- Application Thermo MetallDocument415 pagesApplication Thermo Metalltopomono2No ratings yet

- Finned Tube Heat ExchangerDocument3 pagesFinned Tube Heat ExchangerShreya Sahajpal KaushalNo ratings yet

- CNG MsdsDocument2 pagesCNG MsdssamypalNo ratings yet

- CF5134 Promat Fire Protection PROMATEC HDocument28 pagesCF5134 Promat Fire Protection PROMATEC HJESSIKANo ratings yet

- Cronicon: Research Article An Investigation of Blast Performance of Mine Protective Military BootsDocument15 pagesCronicon: Research Article An Investigation of Blast Performance of Mine Protective Military BootsJOSE FREDY BARRETO FRANCONo ratings yet

- POLARITYDocument23 pagesPOLARITYMelanie MirandaNo ratings yet

- Produced WatersDocument87 pagesProduced WatersrakicbgNo ratings yet

- 08029ft ASTMDocument3 pages08029ft ASTMmadmaxberNo ratings yet

- Experiment 2Document6 pagesExperiment 2Rohann James Abrogueña ReañoNo ratings yet

- Consolidated-Undrained Tri-Axial Test (Cu - Test) : Problem 1Document14 pagesConsolidated-Undrained Tri-Axial Test (Cu - Test) : Problem 1Jemuel FloresNo ratings yet

- Heat Transfer Through FinDocument29 pagesHeat Transfer Through FinAayushGuptaNo ratings yet

- Electrode Potentials 2 PDFDocument93 pagesElectrode Potentials 2 PDFDedi WahyudinNo ratings yet

- BTS & Canopy Design PDFDocument2 pagesBTS & Canopy Design PDFDavid TombeNo ratings yet

- Conceps of RCC-PCCDocument63 pagesConceps of RCC-PCCurhenNo ratings yet

- TILE QUOTEDocument3 pagesTILE QUOTEHarsh SathvaraNo ratings yet