Professional Documents

Culture Documents

ITP031 ELH Master Copy - Pavement Drains

Uploaded by

shazniSCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITP031 ELH Master Copy - Pavement Drains

Uploaded by

shazniSCopyright:

Available Formats

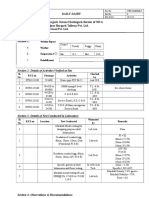

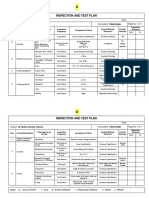

Inspection and Test Plan (I. T. P.

)

I.T.P. # : 031 Page 1 of 3

Project : ELH Master Copy Rev. Date Reason For Revision Prepared By Approved For Use

Draft 29/11/00 Initial Issue P.Stathis I.Karaban

ITP Description : Excavate, Install & Backfill Sub- Pavement Drains 0.0 6/12/00 Issue for construction use P.Stathis I.Karaban

Item Inspection/Test Activity (Spec./Dwg. Refs.) Responsibility Frequency Inspn/Test Method Acceptance Criteria Record Notes

No. Q&E PE/ PES/ S/C

Eng Fore RTA

man

1.0

Materials

1.1 Type “A” Filter Material One per 100m3 Grading, T201 Table R32.1 Nata Test Report

One per 100m3 Wet/Dry Strength >100kN & W/D < 35% Nata Test Report

variation, T215

1.2 Type “S” Filter Material / Cement Stabilised Sand One per 100m3 Grading, T201 Annexure R32/1 Nata Test Report

3

One per 100m Permeability, T1311 Co-efficient Permeability > Nata Test Report

8m/day & compacted to 100%

of standard compaction.

3% Cement Stabilised Sand to

be prepared in accordance with Hold Point Release

R50.

1.3 No-Fines Concrete One per 50m3 28 day compressive > 20Mpa Nata Test Report

strength, T306

Particle size

Initial submission Table R32.2 Nata Test Report

distribution, RTA T201

Wet/Dry strength

One per 500m3 variation, RTA T215 >150kN & W/D < 35% Nata Test Report

One per 500m3 Fractured faces, T239 80% mass retained on 4.75mm Nata Test Report

AS sieve – min two fractured

faces & 98% mass – min one

fractured face.

1.4 Corrugated Perforated Plastic Drainage Pipe One per 500m Physical properties, RTA 3552 Manufacturers Certification.

T1505.

Stiffness properties .

One per 500m Manufacturers Certification.

T1506

1.5 Geocomposite Plastic Strip Filter One per 500m Strength. ASTM D2412 Manufacturers Certification.

ITP031 REV: 0.0 22 March, 2010

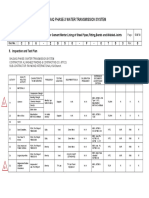

Inspection and Test Plan (I. T. P.)

I.T.P. # : 031 Page 2 of 3

Project : ELH Master Copy Rev. Date Reason For Revision Prepared By Approved For Use

Draft 29/11/00 Initial Issue P.Stathis I.Karaban

ITP Description : Excavate, Install & Backfill Sub- Pavement Drains 0.0 6/12/00 Issue for construction use P.Stathis I.Karaban

Item Inspection/Test Activity (Spec./Dwg. Refs.) Responsibility Frequency Inspn/Test Method Acceptance Criteria Record Notes

No. Q&E PE/ PES/ S/C

Eng Fore RTA

man

1.6 Seamless Tubular Filter Fabric One per 500m Ladderring, Deweaving RTA 3553 Manufacturers Certification

or Unravelling, T1521.

Abrasion resistance,

One per 500m

T1522

One per 500m

Weave stability, T1523

Determination of

One per 500m Opening Size, T1524

1.7 PVC Carrier Pipe Initial Submission Each batch AS 1260 Manufacturers Certification

1.8 Delivery & Produce Compliance for Geotextile HP 14 days prior to Each batch AS 3706.1 or ASTM D5261-96 Certificate of Compliance

installation

1.9 Geotextile WP Initial 10,000 m2, AS 2001.2.3 and AS R63 Table 63.1 & 63.2 Surveillance by superintendent

each subsequent 3706.1 & 3706.3

20,000 m2

2.0 Survey Setout HP Sur Each Lot Visual / measure Survey pegs placed and marked Survey records

v

3.0 Excavation

3.1 Width, Depth Each Lot Visual / Measure Locate existing services Check List, ITP031-CL001/CL002

Drawings

3.2 Grade – Trench Drains Each Lot Measure/survey Drawings or direction from Check List, ITP031-CL001

Superintendents Representative

3.3 Grade – Edge Drains Each Lot Measure/survey 0.5% min grade Check List, ITP031-CL002

4.0 Backfilling

4.1 Trench Drains HP Each Lot, prior to Visual Inspection Superintendents Representative Check List, ITP031-CL001; Min 24 hrs max 5 days notice

laying pipe required

Hold Point Release Form

ITP031 REV: 0.0 22 March, 2010

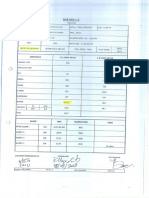

Inspection and Test Plan (I. T. P.)

I.T.P. # : 031 Page 3 of 3

Project : ELH Master Copy Rev. Date Reason For Revision Prepared By Approved For Use

Draft 29/11/00 Initial Issue P.Stathis I.Karaban

ITP Description : Excavate, Install & Backfill Sub- Pavement Drains 0.0 6/12/00 Issue for construction use P.Stathis I.Karaban

Item Inspection/Test Activity (Spec./Dwg. Refs.) Responsibility Frequency Inspn/Test Method Acceptance Criteria Record Notes

No. Q&E PE/ PES/ S/C

Eng Fore RTA

man

4.2 Edge Drains HP Each Lot, prior to Visual Inspection Superintendents Representative Check List, ITP031-CL002; Min 24 hrs max 5 days notice

backfilling, required

proceeding laying of Hold Point Release Form

pipe

4.3 Flushing Trench drains Proceeding backfill Discharge water at 100 Flush until water at outlet is Check List, ITP031-CL001

of each Lot. litre/minute clean

5.0 Relative Compaction

5.1 Compaction – Type S One per 150m T166 > 100% NATA Certificate

5.2 Compaction – No-fines Concrete Each Lot Visual; to be compacted BH foreman. Check List, ITP031-CL002

by hand tamping.

5.3 Compaction – Earth backfill One per 50m T166 > 95% NATA Certificate

6.0 Cleanouts Beginning of each Visual/measure BH Foreman Check List

Lot & as shown on

the drawings

7.0 Outlets As shown on the Visual/measure BH Foreman Check List

drawings

8.0 Work As Executed (W.A.E) Within 28 days on Complete half size Submit to the Superintendents W.A.E Drawing

completion of each drawings (A3) Representative

Lot

8.0 Marking of Drains Each Lot Measure 75mm x 75mm x 90mm Check List

hardwood marker pegs, painted

lemon – yellow placed opposite

the start & finish of drains

opposite junctions, bends and

sumps.

ITP031 REV: 0.0 22 March, 2010

You might also like

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsFrom EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNo ratings yet

- Itp TTRK PDFDocument5 pagesItp TTRK PDFrahmath nawazNo ratings yet

- Inspection and Test Plan For Cement Mortar Lining of Steel Pipes, Fittings, Bends and Welded JointsDocument5 pagesInspection and Test Plan For Cement Mortar Lining of Steel Pipes, Fittings, Bends and Welded Jointsrahmath nawazNo ratings yet

- ITP For Bitumen 6070Document1 pageITP For Bitumen 6070jerin sam kurianNo ratings yet

- Itp For Building MaterialsDocument38 pagesItp For Building MaterialsNavneet YaduvanshiNo ratings yet

- Itp Atwts PDFDocument3 pagesItp Atwts PDFrahmath nawazNo ratings yet

- Inspection & Testing Plan For AggregatesDocument2 pagesInspection & Testing Plan For Aggregatesjerin sam kurianNo ratings yet

- Date:13-10-2012 Section 1:: A. B. C) CDocument2 pagesDate:13-10-2012 Section 1:: A. B. C) CbalaNo ratings yet

- ITP For MaterialDocument8 pagesITP For Material王正勤No ratings yet

- Standard TestsDocument1 pageStandard Testsy.s.6saputroNo ratings yet

- Qap 900000236 R0Document4 pagesQap 900000236 R0meet bhavsarNo ratings yet

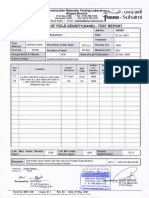

- I Grade I: No.: Date - No. NoDocument1 pageI Grade I: No.: Date - No. NoMechtek LabNo ratings yet

- Backfilling of Reclamation Area: Document Ref - CORP-SYS-01F01 Rev1Document1 pageBackfilling of Reclamation Area: Document Ref - CORP-SYS-01F01 Rev1Belal hassanNo ratings yet

- STEAG Energy Services (India) PVT LTD.: Name of The CustomerDocument2 pagesSTEAG Energy Services (India) PVT LTD.: Name of The CustomerJayam kondanNo ratings yet

- QA RMS 611 Forging 01S18110005 - Rev - 05Document2 pagesQA RMS 611 Forging 01S18110005 - Rev - 05AnilkumarchalliNo ratings yet

- 28-29052022-Pull Off Test (Trial) - Pemb. Dermaga Terminal LPG Presurized Kupang (Piping) - PQT-Pertamina PN-NK-AMM-AKDDocument7 pages28-29052022-Pull Off Test (Trial) - Pemb. Dermaga Terminal LPG Presurized Kupang (Piping) - PQT-Pertamina PN-NK-AMM-AKDudin cupuNo ratings yet

- Concrete Trial Mix Laboratory Testing: Document Ref - CORP-SYS-01F01 Rev1Document2 pagesConcrete Trial Mix Laboratory Testing: Document Ref - CORP-SYS-01F01 Rev1Belal hassanNo ratings yet

- Data Book de BombaDocument7 pagesData Book de BombaSharon Botiny100% (1)

- Qap Dross ShedDocument21 pagesQap Dross ShedSasanka SekharNo ratings yet

- 2 Inspection FormatsDocument40 pages2 Inspection FormatsSatish ReddyNo ratings yet

- Updated Scope PDFDocument3 pagesUpdated Scope PDFAfzal RiazNo ratings yet

- Qap CPVC Pro Fitting SDR 11Document1 pageQap CPVC Pro Fitting SDR 11amit rajputNo ratings yet

- PT Indonesia Asahan Aluminium (Persero) : Comparation ResultDocument1 pagePT Indonesia Asahan Aluminium (Persero) : Comparation Resultlapet busukNo ratings yet

- Shuqaiq Phase-3 Water Transmission SystemDocument5 pagesShuqaiq Phase-3 Water Transmission Systemrahmath nawazNo ratings yet

- Sample Quality Assurance Plan For Nuts ANNEXURE-1Document2 pagesSample Quality Assurance Plan For Nuts ANNEXURE-1x yNo ratings yet

- Secpl RW QapDocument1 pageSecpl RW QapmaheshpanditNo ratings yet

- Formula Performance Archives: SeriesDocument13 pagesFormula Performance Archives: SeriesElias QuirozNo ratings yet

- Ce Thermal and Moisture Emulsion Solvent RC-815 Inivest Haider Saleh Al-Haider & Partner CoDocument1 pageCe Thermal and Moisture Emulsion Solvent RC-815 Inivest Haider Saleh Al-Haider & Partner Cosudeep karunNo ratings yet

- M-25 OPC Cement Without AdmixtureDocument5 pagesM-25 OPC Cement Without Admixturesnigdha.0613No ratings yet

- KN-10069-CP-101-EL-MT-00009 OilDocument3 pagesKN-10069-CP-101-EL-MT-00009 Oilahffg nnffNo ratings yet

- Aac Bull NewDocument9 pagesAac Bull NewMADHURIMA ROYNo ratings yet

- C-15 AND C-35 Cube Test ReportDocument11 pagesC-15 AND C-35 Cube Test ReportSalmaan WasimNo ratings yet

- Annexure 2 Form 72 (Scope) Annexure IDocument4 pagesAnnexure 2 Form 72 (Scope) Annexure IVaghasiyaBipinNo ratings yet

- Heavy-Duty Diesel Engine Test Category For API CI-4 and CI-4 PLUSDocument1 pageHeavy-Duty Diesel Engine Test Category For API CI-4 and CI-4 PLUSsreehariNo ratings yet

- MQAP - Long Rod InsulatorDocument8 pagesMQAP - Long Rod InsulatorRajitha BoppaNo ratings yet

- Vistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore ADocument2 pagesVistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore AShalom JohnNo ratings yet

- UT Shaft Report-BdgDocument1 pageUT Shaft Report-BdgOm Ar Tan100% (1)

- Form Test ST MotorDocument1 pageForm Test ST MotorErik dwi KurniawanNo ratings yet

- Inspection and Test Plan ConcreteDocument2 pagesInspection and Test Plan Concreteavikshit yNo ratings yet

- 27 July ReportsDocument11 pages27 July Reportshammad21No ratings yet

- NDE Procedure: Leak Test and Test No. /Z 07-FiDocument4 pagesNDE Procedure: Leak Test and Test No. /Z 07-FiVũ Lê NguyênNo ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- STANDARD QUALITY ASSURANCE XXXDocument4 pagesSTANDARD QUALITY ASSURANCE XXXsanNo ratings yet

- Lotte Titanpro PM803 Product DataDocument1 pageLotte Titanpro PM803 Product DataJoni Sie MssNo ratings yet

- BR 32 Water, Aggregate & Cement Test ReportDocument4 pagesBR 32 Water, Aggregate & Cement Test ReportSravan KuppiliNo ratings yet

- GetFile (150 307)Document158 pagesGetFile (150 307)Dilmer VelasquezNo ratings yet

- Technical Note PM10 FiltersDocument1 pageTechnical Note PM10 Filtersvisa.tasicNo ratings yet

- Design Mix M-30 (Result Change)Document6 pagesDesign Mix M-30 (Result Change)sunil prajapatiNo ratings yet

- Section 1:: Daily DairyDocument2 pagesSection 1:: Daily DairybalaNo ratings yet

- 10CDCF LM-1600406 (PFGD)Document2 pages10CDCF LM-1600406 (PFGD)Sohaib AhmadNo ratings yet

- BTG 11.12.22-11.18.22 T-1 PDFDocument1 pageBTG 11.12.22-11.18.22 T-1 PDFKimberly DayoNo ratings yet

- Registry of Sleeve PlacementDocument10 pagesRegistry of Sleeve PlacementJorge Isaac Lara RamosNo ratings yet

- Mill Test Certificate: 121 1233.400 Tons.: 11.899Document6 pagesMill Test Certificate: 121 1233.400 Tons.: 11.899CarlosEduardoRodriguezNo ratings yet

- QAP WRTW Banke-05Document1 pageQAP WRTW Banke-05Jaljala NirmanNo ratings yet

- Monthly Quality Assurance Report For August-13, Elf RVNL DankuniDocument14 pagesMonthly Quality Assurance Report For August-13, Elf RVNL DankuniPrasanta ParidaNo ratings yet

- SEIP For 080-AC-001: GeneralDocument5 pagesSEIP For 080-AC-001: GeneralThinh NguyenNo ratings yet

- Steam Turbine Basic Training Module 2Document61 pagesSteam Turbine Basic Training Module 2Chintan RavalNo ratings yet

- Rebar Coupler SpecificationDocument7 pagesRebar Coupler SpecificationÇïvílìåñ ÑâvîñNo ratings yet

- DO 011 s2019Document6 pagesDO 011 s2019Sang Maquiling BaldomeroNo ratings yet

- Accepted Manuscript Not Copyedited: Assessment of Fracture Toughness Using Small Punch Tests of Pre Notched SpecimensDocument12 pagesAccepted Manuscript Not Copyedited: Assessment of Fracture Toughness Using Small Punch Tests of Pre Notched SpecimensRizal MaulanaNo ratings yet

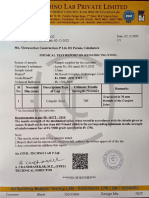

- Table ComplianceDocument1 pageTable ComplianceshazniSNo ratings yet

- Maulid Addhiya' Ullami' (LATIN)Document5 pagesMaulid Addhiya' Ullami' (LATIN)pitri100% (8)

- Maulid Addhiya' Ullami' (LATIN)Document5 pagesMaulid Addhiya' Ullami' (LATIN)pitri100% (8)

- GcsDocument88 pagesGcsshazniSNo ratings yet

- Kingdom of Saudi: Jubail Industrial City ProjectDocument45 pagesKingdom of Saudi: Jubail Industrial City ProjectshazniSNo ratings yet

- Jade Hills (Jenis D)Document6 pagesJade Hills (Jenis D)shazniSNo ratings yet

- Safety Learning: Could This Happen in Your Operation?Document1 pageSafety Learning: Could This Happen in Your Operation?shazniSNo ratings yet

- Kentaur Turnstiles Kentaur Full Height GatesDocument20 pagesKentaur Turnstiles Kentaur Full Height GatesshazniSNo ratings yet

- Auxiliary: Prepared For The Department of Industry, Canberra 22 October 2013Document60 pagesAuxiliary: Prepared For The Department of Industry, Canberra 22 October 2013shazniSNo ratings yet

- One Bedroom House DesignsDocument19 pagesOne Bedroom House DesignsshazniSNo ratings yet

- Guide To Filling CCC Forms May08 PDFDocument9 pagesGuide To Filling CCC Forms May08 PDFshazniSNo ratings yet

- Process Consideration CentrifugeDocument17 pagesProcess Consideration CentrifugeGueule D'angeNo ratings yet

- The Impact of Sugar On Setting - Time of Ordinary Portland Cement (OPC) Paste and Compressive Strength of ConcreteDocument8 pagesThe Impact of Sugar On Setting - Time of Ordinary Portland Cement (OPC) Paste and Compressive Strength of ConcreteJarek PlaszczycaNo ratings yet

- A Procedure For Calculation of Torque Specifications For Bolted Joints With Prevailing TorqueDocument8 pagesA Procedure For Calculation of Torque Specifications For Bolted Joints With Prevailing TorquedavlascNo ratings yet

- Rhinotuff CanvasDocument8 pagesRhinotuff CanvasRhinotuff CanvasNo ratings yet

- Product - MORGAN Home Appliances MalaysiaDocument6 pagesProduct - MORGAN Home Appliances MalaysiaAJ RobertNo ratings yet

- Indraero Siren 120 050 00Document40 pagesIndraero Siren 120 050 00bobbyflorezNo ratings yet

- QCD-F-18 TDC - 165, Rev.00, Dtd. - 14.04.2022Document2 pagesQCD-F-18 TDC - 165, Rev.00, Dtd. - 14.04.2022Ravi TyagiNo ratings yet

- Types of Chroma To Grap GyDocument75 pagesTypes of Chroma To Grap GyMohammad RehanNo ratings yet

- 07 01 METALLURGY Principles and Methods of ExtractionDocument17 pages07 01 METALLURGY Principles and Methods of ExtractionrcraktimcNo ratings yet

- Effect of Additives On Formation of Natural Gas Hydrate: C.S. Zhang, S.S. Fan, D.Q. Liang, K.H. GuoDocument7 pagesEffect of Additives On Formation of Natural Gas Hydrate: C.S. Zhang, S.S. Fan, D.Q. Liang, K.H. GuopeNo ratings yet

- Small Capacity Industrial Cold Room With Sliding DoorDocument5 pagesSmall Capacity Industrial Cold Room With Sliding DoorEdy LasmanaNo ratings yet

- Optitome 15: Automatic Oxyacetylene and Plasma-Arc Cutting EquipmentDocument8 pagesOptitome 15: Automatic Oxyacetylene and Plasma-Arc Cutting EquipmentFlamur HasaniNo ratings yet

- XRAY NT18 Engine Instruction & Safety ManualDocument26 pagesXRAY NT18 Engine Instruction & Safety ManualAsierReloopNo ratings yet

- Honeywell's UOP: Biofuels Digest's 5-Minute Guide: Based In:illinois BusinessDocument2 pagesHoneywell's UOP: Biofuels Digest's 5-Minute Guide: Based In:illinois BusinessmanojiocindiatimesNo ratings yet

- Steam Line Mechanical DistributionDocument25 pagesSteam Line Mechanical DistributionNAYEEMNo ratings yet

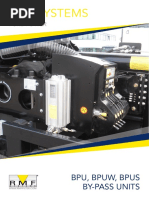

- Brochure by-Pass-Units 20160216 enDocument36 pagesBrochure by-Pass-Units 20160216 enHOryshorNo ratings yet

- 2181355g 2 3 PDFDocument32 pages2181355g 2 3 PDFPraxedes PxNo ratings yet

- Catalog - Small FUEL & OIL DRAIN VALVESDocument5 pagesCatalog - Small FUEL & OIL DRAIN VALVESJessie O.Bechayda100% (1)

- Technical Specification Supply Delivery and Installation of Furniture and Fixtures For The MARINA Building in The Cities of Iloilo and Bacolod PDFDocument5 pagesTechnical Specification Supply Delivery and Installation of Furniture and Fixtures For The MARINA Building in The Cities of Iloilo and Bacolod PDFSusie Vanguardia100% (1)

- Armstrong - Humidification Handbook PDFDocument40 pagesArmstrong - Humidification Handbook PDFJawwadTariqNo ratings yet

- STADIUM EstimateDocument13 pagesSTADIUM EstimateRajeswari Ramakrishnan100% (1)

- TPP - A Presentation On Thermal Power PlantsDocument30 pagesTPP - A Presentation On Thermal Power PlantsSounak SasmalNo ratings yet

- Transducers PDFDocument2 pagesTransducers PDFNahush BapatNo ratings yet

- Surge Suppression BrochureDocument16 pagesSurge Suppression BrochureselvamejiaNo ratings yet

- Clasificacion Universal de Los MaterialesDocument24 pagesClasificacion Universal de Los MaterialesMateo100% (1)

- PowerPoint Sample: BioDiesel Production Power Point PresentationDocument16 pagesPowerPoint Sample: BioDiesel Production Power Point PresentationJohn MelendezNo ratings yet

- Service Manual 38cvur13!16!42cvur13 16Document104 pagesService Manual 38cvur13!16!42cvur13 16Leo De ocampoNo ratings yet

- Geo Exam Question PaperDocument15 pagesGeo Exam Question PaperTerwabe WapagovskiNo ratings yet

- Tiêu Chuẩn Stone Paper 3Document3 pagesTiêu Chuẩn Stone Paper 3Huy NguyenNo ratings yet

- Super HDB Turbo 15W-40Document1 pageSuper HDB Turbo 15W-40izzybjNo ratings yet