Professional Documents

Culture Documents

QCD-F-18 TDC - 165, Rev.00, Dtd. - 14.04.2022

Uploaded by

Ravi TyagiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QCD-F-18 TDC - 165, Rev.00, Dtd. - 14.04.2022

Uploaded by

Ravi TyagiCopyright:

Available Formats

EMBOSAL STEEL MILLS LLC

PLOT NO – M161A, Al Ghail Industrial Zone– NFZ RAK, United Arab Emirates

PHONE: 065540990, EMAIL: mail@embosal.com www.embosal.com

TDC No: 165, Rev.00, Dtd. 14.04.2022

TECHNICAL DELIVERY CONDITION (TDC)

Raw Material Specification & Grade: API 5L 46th Edition, 2018 / Grade - L245 or B PSL 1

Supply Condition: As Rolled / Fully Killed / Fine Grained

Heat treatment: NA

Process of Manufacturing: Steel shall be made in basic oxygen furnace or electric arc furnace

continuously cast and shall be fully killed. H.R. Coil shall be made by Hot rolling to attain ferritic grain size

equal to or finer than 6 when measured in accordance with EN ISO 643.

Coils shall be rolled to attain uniform and consistent mechanical properties and microstructure together

with high toughness and good weld ability & Ultrasonically tested.

Manufacturer shall have to submit following.

1) Manufacturing Procedure Specification.

2) QAP

Chemical Requirement:

The chemical composition of each heat of the steel on product analyses shall be in accordance w

i-th following table.

ELEMENT Chemical Requirement ELEMENT Chemical Requirement

(%) max. (%) max.

C 0.26 Cu 0.50

Mn 1.65 Ni 0.50

Si -- Cr 0.50

P 0.030 Mo 0.15

S 0.030 B --

V -- Nb+V+Ti 0.15

Nb -- Nb+V 0.06

Ti --

CE(IIW) -- CE(PCM) --

Mechanical Requirement:

The Mechanical properties shall be as follows: ‐

MATERIAL GRADE YIELD STRENGTH TENSILE STRENGTH % ELONGATION YS/UTS

L245 Or B PSL 1 245 MPA Min 415 MPA Min 28% Min. --

Charpy Impact Test: (As per ASTM A370)

FORM NO: QCD-F-18 REV. NO.: 00 REV. DT.:01-07-2021 Page 1 of 2

EMBOSAL STEEL MILLS LLC

PLOT NO – M161A, Al Ghail Industrial Zone– NFZ RAK, United Arab Emirates

PHONE: 065540990, EMAIL: mail@embosal.com www.embosal.com

TDC No: 165, Rev.00, Dtd. 14.04.2022

Absorbed energy at 0° C - 27 Joule (Min) average of 3 samples

21 Joule (Min) Individual test values for any test piece.

Bend Test: NA

UT Test: NA

Visual Inspection: Coil shall be free from laminations (skin & mid) segregation, scale, surface flaws like

slivers & Seams and other defects. The coil or plate used for the manufacture of PSL 2 pipe shall not

contain any repair welds.

TPIA: NA

Dimension Tolerances:

Coil Width - (+15.00, -0) Coil Thickness supplied must be as per API Spec. 5L 46th Edition, 2018

requirements.

Marking: Each coil shall be marked with following details at outer surface with stickers;

(i) Name of Supplier (ii) Heat No (iii) Plate No (iv) Weight (v) Size (Width X Thickness)

(vi) Specification & Grade

Coil Size & Qty:

As per PO.

Documentation:

Material shall be supplied along with manufacturer test certificates having test results of chemical

composition of all specified elements and Mechanical properties.

T.C should be provided as per the standard EN 10204 Type 3.1. The testing specification and its year shall

be mentioned in MTC. Finishing temperature / Cooling temperature to be maintained on MTC.

Special Requirement (If any):

Remarks:

The general technical delivery requirements shall be in accordance with ISO 404.

Prepared by: Reviewed &Approved by:

FORM NO: QCD-F-18 REV. NO.: 00 REV. DT.:01-07-2021 Page 2 of 2

You might also like

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 pageTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- Technical Delivery Conditions For Seamless Carbon Steel FittingsDocument2 pagesTechnical Delivery Conditions For Seamless Carbon Steel FittingsTanpreet Singh100% (1)

- Welding Filler Metals For Power Plant EngineeringDocument20 pagesWelding Filler Metals For Power Plant EngineeringShoaib AhmedNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- CTC-224 Engine SystemsDocument331 pagesCTC-224 Engine Systemsjivomir100% (1)

- QCD-F-18 TDC 166 - Welding ElectrodesDocument3 pagesQCD-F-18 TDC 166 - Welding Electrodesvg869030No ratings yet

- Certificado Bothwell Ca1469Document1 pageCertificado Bothwell Ca1469erssonNo ratings yet

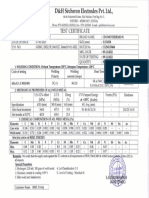

- S6cheron Electrodes PVT.: CertificateDocument1 pageS6cheron Electrodes PVT.: CertificateMetal EraNo ratings yet

- A RM 105 19 18 096 SourDocument5 pagesA RM 105 19 18 096 SourGuilherme RochaNo ratings yet

- Specification FOR Carbon Steel Seamless Linepipe For Submarine Pipelines (Sour Service)Document27 pagesSpecification FOR Carbon Steel Seamless Linepipe For Submarine Pipelines (Sour Service)GomathyselviNo ratings yet

- As-Rolled Plate Product With Improved Yield Strength, Toughness, and Weldability For Pressurized Railroad Tank CarsDocument16 pagesAs-Rolled Plate Product With Improved Yield Strength, Toughness, and Weldability For Pressurized Railroad Tank CarssurendarNo ratings yet

- 1%ni For Improved Toughness: Data SheetDocument4 pages1%ni For Improved Toughness: Data Sheetmohamed AdelNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel Unalloyed, MachinedDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel Unalloyed, Machinedbaskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 143, - , - : Bright Steel Unalloyed, Cold DrawnDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 143, - , - : Bright Steel Unalloyed, Cold Drawnbaskaran ayyapparajNo ratings yet

- Certified Mill Test Report: Phoenix Capitol CamcoDocument1 pageCertified Mill Test Report: Phoenix Capitol CamcoAlexydami CamposNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- Mat 3820 For Suppliers PDFDocument3 pagesMat 3820 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- WCS 15 - Rev 4 Updations-15.02.2016 - Final Uploaded To DMSDocument9 pagesWCS 15 - Rev 4 Updations-15.02.2016 - Final Uploaded To DMSsingaravelan narayanasamyNo ratings yet

- Datasheet For Steel Grades Specialsteel X6Crnimob17-12-2Document3 pagesDatasheet For Steel Grades Specialsteel X6Crnimob17-12-2axis inspection solutionsNo ratings yet

- Asme Sec IxDocument46 pagesAsme Sec Ixmurshid badshahNo ratings yet

- Seamless Pipes - API 5L Grade X65 PSL 2Document2 pagesSeamless Pipes - API 5L Grade X65 PSL 2isan.structural TjsvgalavanNo ratings yet

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoNo ratings yet

- Technical Specifications For Boiler Quality Steel Plates For LPGDocument51 pagesTechnical Specifications For Boiler Quality Steel Plates For LPGGerick Eleazar RogadoNo ratings yet

- MAT 3407 MCGB - Data Sheet For Suppliers Old MAT Nos.: 33EDocument3 pagesMAT 3407 MCGB - Data Sheet For Suppliers Old MAT Nos.: 33EengfaridmalkNo ratings yet

- Datasheet For Steel Grades Specialsteel 06Cr25Ni20Document3 pagesDatasheet For Steel Grades Specialsteel 06Cr25Ni20nagmech07No ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- 30 MM Gi Threaded Rod GR 8.8 - Tbi PDFDocument1 page30 MM Gi Threaded Rod GR 8.8 - Tbi PDFm.aliNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel Unalloyed, MachinedDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: - , - , - : Bright Steel Unalloyed, Machinedbaskaran ayyapparajNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 344, - , - : Heat-Resistant Cast Steel, Cr-Ni-AlloyedDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 344, - , - : Heat-Resistant Cast Steel, Cr-Ni-AlloyedgraduateNo ratings yet

- En 10305 1 Sunny SteelDocument6 pagesEn 10305 1 Sunny Steelmohamed belkadiNo ratings yet

- Material 1.4057 PDFDocument3 pagesMaterial 1.4057 PDFengfaridmalkNo ratings yet

- Forging - Case Hardening For 1.5%Ni-Cr-Mo SteelsDocument8 pagesForging - Case Hardening For 1.5%Ni-Cr-Mo SteelsJaison JoseNo ratings yet

- Filler Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysDocument8 pagesFiller Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysimreNo ratings yet

- Quality Requirements For CrMo Alloys SAG Mill Liner and GratesDocument16 pagesQuality Requirements For CrMo Alloys SAG Mill Liner and GratesFrancis ChavezNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-Mobaskaran ayyapparajNo ratings yet

- Inspection Certificate Acc, To/ En-35 22.1.2: Technical Requirements: ASME B-16.20 ANSI B16.5 Heat N°Document3 pagesInspection Certificate Acc, To/ En-35 22.1.2: Technical Requirements: ASME B-16.20 ANSI B16.5 Heat N°Raul Esteban Jaimes GalvisNo ratings yet

- Cromarod Duplex B-1Document1 pageCromarod Duplex B-1Matija BušićNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardschetanNo ratings yet

- Mat 3810 For Suppliers PDFDocument3 pagesMat 3810 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- Cr-Product Manual - PDFDocument28 pagesCr-Product Manual - PDFThơ Thẫn ThờNo ratings yet

- MAT 2011 MCGB - Data Sheet For Suppliers Old MAT Nos.: 142Document3 pagesMAT 2011 MCGB - Data Sheet For Suppliers Old MAT Nos.: 142engfaridmalk100% (1)

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 203, - , - : Heat-Treatable Steel, Carbon SteelDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 203, - , - : Heat-Treatable Steel, Carbon Steelbaskaran ayyapparaj100% (1)

- Scheda Tecnica: IT-T1 ITB-T1Document1 pageScheda Tecnica: IT-T1 ITB-T1ITALFIL S.p.A.No ratings yet

- Koc MP 016Document18 pagesKoc MP 016Ravi MahetoNo ratings yet

- Pages From Fs-1046!22!23-Tdc - r1 LTDocument1 pagePages From Fs-1046!22!23-Tdc - r1 LTtiroco8756No ratings yet

- Alloy Steel Astm A217 Grade Wc6 1Document1 pageAlloy Steel Astm A217 Grade Wc6 1didi sudiNo ratings yet

- Mat 5850 For Suppliers PDFDocument3 pagesMat 5850 For Suppliers PDFgraduateNo ratings yet

- CHARPY V NOTCH Impact Values (J) (I)Document1 pageCHARPY V NOTCH Impact Values (J) (I)trivendra kumarNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- Inspection Certificate 21.1914: RequiredDocument1 pageInspection Certificate 21.1914: RequiredMichał IlińskiNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Ficha Técnica CarborodDocument1 pageFicha Técnica CarborodAndres NuñezNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, Mobaskaran ayyapparajNo ratings yet

- MAT 2002 MCGB - Data Sheet For Suppliers Old MAT Nos.Document3 pagesMAT 2002 MCGB - Data Sheet For Suppliers Old MAT Nos.engfaridmalkNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: Weldox 500 DDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: Weldox 500 Dbaskaran ayyapparajNo ratings yet

- Your Reliable Welding Business Partner Worldwide"Document70 pagesYour Reliable Welding Business Partner Worldwide"Anonymous SLI4aGNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 140, - , - : Bright Steel, Unalloyed, Cold DrawnDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 140, - , - : Bright Steel, Unalloyed, Cold Drawnbaskaran ayyapparajNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Certificate: National Institute of Standards & TechnologyDocument2 pagesCertificate: National Institute of Standards & TechnologyRavi TyagiNo ratings yet

- PILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C4Document1 pagePILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C4Ravi TyagiNo ratings yet

- PILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C2Document1 pagePILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C2Ravi TyagiNo ratings yet

- PILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C5Document1 pagePILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C5Ravi TyagiNo ratings yet

- Certificate: National Institute of Standards & TechnologyDocument2 pagesCertificate: National Institute of Standards & TechnologyRavi TyagiNo ratings yet

- Certificate: National Institute of Standards & TechnologyDocument2 pagesCertificate: National Institute of Standards & TechnologyRavi TyagiNo ratings yet

- Method of Statements (Rolling Rolling Procedure)Document12 pagesMethod of Statements (Rolling Rolling Procedure)Ravi TyagiNo ratings yet

- PILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C3Document1 pagePILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C3Ravi TyagiNo ratings yet

- PILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C1Document1 pagePILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C1Ravi TyagiNo ratings yet

- Usage: Power: Brand Name: Weight: Model Number:: Digital Display Impact Testing Machine JB-300SDocument7 pagesUsage: Power: Brand Name: Weight: Model Number:: Digital Display Impact Testing Machine JB-300SRavi TyagiNo ratings yet

- Impact Tester and Tensile TestDocument22 pagesImpact Tester and Tensile TestRavi TyagiNo ratings yet

- ADM 002 ACRS Product Certification Scheme Rules (Version 12) WEBDocument43 pagesADM 002 ACRS Product Certification Scheme Rules (Version 12) WEBRavi TyagiNo ratings yet

- HCH310 Portable Hardness TesterDocument6 pagesHCH310 Portable Hardness TesterRavi TyagiNo ratings yet

- GQ-HW2H Chemical TestingDocument2 pagesGQ-HW2H Chemical TestingRavi TyagiNo ratings yet

- Ultrasonic Testing Machine UHC2100eDocument4 pagesUltrasonic Testing Machine UHC2100eRavi TyagiNo ratings yet

- Jindal Steel SpecificationsDocument76 pagesJindal Steel SpecificationsVignesh Chellappan NatarajanNo ratings yet

- Maharashtra Seamless Limited: Location de Test SpecimensDocument3 pagesMaharashtra Seamless Limited: Location de Test SpecimensRavi TyagiNo ratings yet

- Quality Procedure Manual: Vol - XiiDocument2 pagesQuality Procedure Manual: Vol - XiiRavi TyagiNo ratings yet

- Application For Acrs Product Certification: InstructionsDocument6 pagesApplication For Acrs Product Certification: InstructionsRavi TyagiNo ratings yet

- Application For Acrs Product Certification: InstructionsDocument6 pagesApplication For Acrs Product Certification: InstructionsRavi TyagiNo ratings yet

- ADM 016 ACRS Certification Agreement (Version 3.1) WebDocument23 pagesADM 016 ACRS Certification Agreement (Version 3.1) WebMonica SinghNo ratings yet

- ADM 002 01 List of Applicable Product Requirements Version 2.6 WEBDocument3 pagesADM 002 01 List of Applicable Product Requirements Version 2.6 WEBRavi TyagiNo ratings yet

- Maharashtra Seamless Limited: Location de Test SpecimensDocument3 pagesMaharashtra Seamless Limited: Location de Test SpecimensRavi TyagiNo ratings yet

- ADM 002 01 List of Applicable Product Requirements Version 2.6 WEBDocument3 pagesADM 002 01 List of Applicable Product Requirements Version 2.6 WEBRavi TyagiNo ratings yet

- Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and ShapesDocument6 pagesCold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and ShapesMizha GomezNo ratings yet

- Api Monogram Program/Erw 20'' (Api 5L) : Embosal Steel Mills LLCDocument2 pagesApi Monogram Program/Erw 20'' (Api 5L) : Embosal Steel Mills LLCRavi TyagiNo ratings yet

- ADM 002 ACRS Product Certification Scheme Rules (Version 12) WEBDocument43 pagesADM 002 ACRS Product Certification Scheme Rules (Version 12) WEBRavi TyagiNo ratings yet

- Web Generated Bill: Feeder: Manawan Sub Division: Bata Pur Division: ShalamarDocument1 pageWeb Generated Bill: Feeder: Manawan Sub Division: Bata Pur Division: ShalamarahsanNo ratings yet

- Assembly and Parts Drawing IG2600: 3KW Generator KD (M) 30 (A) - 02000 Control Panel Assembly KGE3000Ti-13100Document6 pagesAssembly and Parts Drawing IG2600: 3KW Generator KD (M) 30 (A) - 02000 Control Panel Assembly KGE3000Ti-13100Youssef BeheryNo ratings yet

- 2016 Summer Model Answer PaperDocument17 pages2016 Summer Model Answer PaperAbhishek ChavanNo ratings yet

- Oil / Chemical Tanker Instruction Manual: Controlled Copy #03Document381 pagesOil / Chemical Tanker Instruction Manual: Controlled Copy #03Nikita GalinNo ratings yet

- Yarway Cryogenic Desuperheater For LNG TerminalDocument13 pagesYarway Cryogenic Desuperheater For LNG Terminalwahid nurrohmanNo ratings yet

- BSBSUS211 Assessments Tasks 2Document18 pagesBSBSUS211 Assessments Tasks 2Raquel MaturanoNo ratings yet

- A Key To Sustainable Development-Solar Powered Water Cooling SystemDocument5 pagesA Key To Sustainable Development-Solar Powered Water Cooling SystemDebayani MishraNo ratings yet

- Cep PsocDocument31 pagesCep PsocEhtisham RajpootNo ratings yet

- BiTEC-whitepaper - Bifacial Trackers The Real Deal PDFDocument13 pagesBiTEC-whitepaper - Bifacial Trackers The Real Deal PDFNikhil MehtaNo ratings yet

- Factors Affecting Internal Resistance EMFDocument6 pagesFactors Affecting Internal Resistance EMFYuvan KumarNo ratings yet

- True or FalseDocument7 pagesTrue or Falsemohamed arifNo ratings yet

- TR IEC TS 62804-1-2019.previewDocument12 pagesTR IEC TS 62804-1-2019.previewFadhel GuesmiNo ratings yet

- 14-SAMSS-534 Oh TransformerDocument8 pages14-SAMSS-534 Oh TransformerHatemS.MashaGbehNo ratings yet

- XR200 X-Ray Source: Operator'S ManualDocument25 pagesXR200 X-Ray Source: Operator'S ManualEOD HOLDING UNITNo ratings yet

- 17S2 EE3010 PPT Lecture10-TransformersDocument27 pages17S2 EE3010 PPT Lecture10-Transformersming yangNo ratings yet

- Reducing Water Consumption With Sustainable Building Design A Case StudyDocument11 pagesReducing Water Consumption With Sustainable Building Design A Case StudyDivagaran A/L GunasekaranNo ratings yet

- Hoja Tecnica Inverter Mcquay Serie Mid MiuDocument3 pagesHoja Tecnica Inverter Mcquay Serie Mid MiuTatiana DiazNo ratings yet

- Mark Scheme (Results) January 2023Document19 pagesMark Scheme (Results) January 2023aamirudheen ali100% (1)

- Kasinski Mirage 150Document106 pagesKasinski Mirage 150Karolaay B.No ratings yet

- Greenheck HVLS Modbus RTU Wiring Instructions V2Document5 pagesGreenheck HVLS Modbus RTU Wiring Instructions V2marcp22No ratings yet

- Jetinox: Technical DataDocument6 pagesJetinox: Technical Datafopoku2k2No ratings yet

- TS SS Electronic Installation and Operation ManualDocument28 pagesTS SS Electronic Installation and Operation ManualismaelNo ratings yet

- CapacitanceDocument23 pagesCapacitanceChristianNo ratings yet

- Different Grounding Practices BenderrDocument32 pagesDifferent Grounding Practices BenderrSaurabh SharmaNo ratings yet

- Sent Tutorial 5 Prob OnlyDocument2 pagesSent Tutorial 5 Prob OnlyYu LoengNo ratings yet

- Stapler Folder: Instruction ManualDocument47 pagesStapler Folder: Instruction ManualVladislav RazinkovNo ratings yet

- H2 NOx AftertreatmentsDocument13 pagesH2 NOx AftertreatmentsFacu Spivak100% (1)

- MTK Mid Sem-2Document16 pagesMTK Mid Sem-2Subhodeep SadhuNo ratings yet

- Use The Law To Explain The Following ObservationsDocument6 pagesUse The Law To Explain The Following ObservationsCedric Adrian AblogNo ratings yet