Professional Documents

Culture Documents

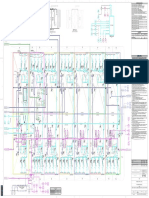

PILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C2

Uploaded by

Ravi TyagiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C2

Uploaded by

Ravi TyagiCopyright:

Available Formats

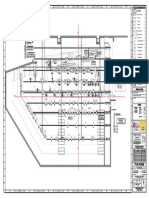

O

N

M

L

K

[ NO COATING ]

[ NO COATING ]

[ NO COATING ]

J

I

[ COATING ]

[ COATING ]

H

G

F

E

D

1651.0 990.6 4267.2 31394.4 16142.9 C

5'-5" 3'-3" 14'-0" 103'-0" 53'-0" B 13/11/21 SA

1524.0 A 3/11/21 SA

5'

Ø1219.2

Issue Revision Date Initial

100

105

110

115

120

125

130

135

140

145

150

155

160

165

170

175

50

55

60

65

70

75

80

85

90

95

45

10

15

20

25

30

35

40

0

5

48"

OD

Notes:

PILE BOTTOM

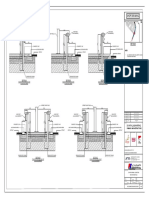

304.8 WELDED SPLICE (TYP.) WELDED SPLICE (TYP.)

1' (REFER DETAIL-X) (REFER DETAIL-X)

All dimensions in inches

PILE TOP

12000.0 12000.0 12000.0 12000.0 6446.1

39'-4" 39'-4" 39'-4" 39'-4" 21'-1"

54446.14

178'-7"

ESC Client:

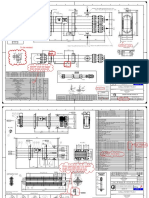

PILE PIPE CHS48" x 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW

LENGTH - 54.446M Manufacturer:

ONE QTY PILE AS MARKED C2 ESC STEEL LLC

18805 W. Catawba Ave

Suite 207

Cornelius

NC 28031

USA

T : (980) 689-4388

Email : info@escsteel.com

1651.0 (5'-5") 990.6(3'-3")

[ NO COATING ] [ COATING ]

Project Title:

TEXT HEIGHT 8" 12.7 21-0609 - Panama Pipe Piles

1/2" TYP

10

5

239.0

PILE O.D 9.4"

FPBW 60°

609.6

635.0

2'-0"

DET - A

381.0

35

2ea Lifting Eyes of

Ø 66.35mm 180°.

each other

PILE BOTTOM

1" WIDE AND 2" WIDE AND

15" LENGTH 25" LENGTH

Drawing Title:

DETAIL-X TYPICAL PILE MARKING DETAILS PILE DRIVING SHOE

AT BOTTOM

PILE PIPE CHS48" x 1.375"

LENGTH - 54.446M

PILE SHOE PLATE 35.0 Pile Marking:

1/2" THK THK

1. All pipe piles are to be marked with a white line at least 15" long and 1" wide, PILE ROW MARKING - C2

every foot from the pile tip for full length. The foot marks are to be numbered QTY - 1 NO

sequentially every 5' starting from the tip with white numbers approx. 8" high.

°

Every 5-foot mark shall be longer than intermediate foot marks and 2" wide.

45

Stamp: Signature:

Welding : Corrosion protection:

1. Welding procedure prepared proof certificate that all welders satisfy the 1. Painting on piles marked as per the drawing MANUFACTURING DRAWING

requirement of AWS D1.1/D1.1M 2. Auto blasting Sa2.5

DETAIL - A

and minimum frequency of shop welding shall be 3. NACE N.2 / SSPC-SP 10 (Near White Metal) Designed Drawn Checked Rev.

100% visual inspection of all weld and steel surfaces; 4. 1st and 2nd coat: Coal Tar Epoxy total DFT of 508 microns (20 mils) MANUEL STV

10% magnetic particle inspection of all fillet welds; Scale Date Job No. C2 B

100% ultrasonic or radiographic inspection of all complete joint penetration weld

2021.11.03

You might also like

- PILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C5Document1 pagePILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C5Ravi TyagiNo ratings yet

- PILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C4Document1 pagePILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C4Ravi TyagiNo ratings yet

- PILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C1Document1 pagePILE PIPE CHS48" X 1.375" PIPE PILES ASTM A252 Grade 50ksi - LSAW LENGTH - 54.446M One Qty Pile As Marked C1Ravi TyagiNo ratings yet

- Coating thickness comparison testDocument1 pageCoating thickness comparison testRavi TyagiNo ratings yet

- TQ-5133502 TQ-5133501A TQ-5133503: D.O. Service TK P D.O. Settling TK S D.O. Storage TK SDocument1 pageTQ-5133502 TQ-5133501A TQ-5133503: D.O. Service TK P D.O. Settling TK S D.O. Storage TK SRobles DreschNo ratings yet

- Ref docs for commissioningDocument1 pageRef docs for commissioningRobles DreschNo ratings yet

- Typical Detail Ii Typical Detail Iv Typical Detail Iii Typical Detail IDocument1 pageTypical Detail Ii Typical Detail Iv Typical Detail Iii Typical Detail IChoong K WNo ratings yet

- Joanne Sophia - Teachers Training Institute and Icse SchoolDocument28 pagesJoanne Sophia - Teachers Training Institute and Icse SchoolGayathri KathiravanNo ratings yet

- Module M-04: EquipmentDocument1 pageModule M-04: EquipmentRobles DreschNo ratings yet

- Drive basketball skills with Lochatto drillsDocument24 pagesDrive basketball skills with Lochatto drillsRoLando Bautista Rotol Jr.No ratings yet

- Shop Drawing: Key PlanDocument1 pageShop Drawing: Key Planlibin513No ratings yet

- Apr.2010 A1UD-B001-0A 3/4Document1 pageApr.2010 A1UD-B001-0A 3/4Oswaldo GuzmanNo ratings yet

- Fixed Point Side View Looking Toward South Front View Looking Toward EastDocument1 pageFixed Point Side View Looking Toward South Front View Looking Toward EastDima Fon NmskNo ratings yet

- Plan Plan: Department of Public Works and HighwaysDocument1 pagePlan Plan: Department of Public Works and HighwaysEngr'Shemaiah JimenezNo ratings yet

- PF-602 Wiring DiagramDocument2 pagesPF-602 Wiring DiagramStefan TintilaNo ratings yet

- Bp2021-C026s-Jwn02-A01-Drainage System-Fp-1001-Ground and Roof Floor Plans - CafeteriaDocument1 pageBp2021-C026s-Jwn02-A01-Drainage System-Fp-1001-Ground and Roof Floor Plans - CafeteriaMohammad IsmailNo ratings yet

- Fixed Point Side View Looking Toward South Front View Looking Toward EastDocument1 pageFixed Point Side View Looking Toward South Front View Looking Toward EastDima Fon NmskNo ratings yet

- U7 Mark Up UDocument1 pageU7 Mark Up URobles DreschNo ratings yet

- Ø5000 Ext Ø5000 Ext: Gusset x12 Anchorage x12Document1 pageØ5000 Ext Ø5000 Ext: Gusset x12 Anchorage x12Mahmoud ElboraeNo ratings yet

- Isolation Bay Isolation Bay Isolation Bay: RESA 240M X 90M RESA 240M X 90M RESA 240M X 90MDocument1 pageIsolation Bay Isolation Bay Isolation Bay: RESA 240M X 90M RESA 240M X 90M RESA 240M X 90MErSoravNo ratings yet

- Ecku@I@Eke@Lj Ecku@I@Eke@Lj Ufgvj Ufgvj Uv Uv Fu) KML Fu) KML I@U@EL I@U@ELDocument3 pagesEcku@I@Eke@Lj Ecku@I@Eke@Lj Ufgvj Ufgvj Uv Uv Fu) KML Fu) KML I@U@EL I@U@ELJohanna Zapata AmaroNo ratings yet

- To Be Revised: N Brown Fint Ube France SaDocument4 pagesTo Be Revised: N Brown Fint Ube France Sadhiaa mohammedNo ratings yet

- To Be Re Vise D: Brown Fintube France Sa NDocument4 pagesTo Be Re Vise D: Brown Fintube France Sa Ndhiaa mohammedNo ratings yet

- 1 Plano de Senalizacion 20230829 140421 351Document1 page1 Plano de Senalizacion 20230829 140421 351MarilynNo ratings yet

- Fun Home PlotDocument1 pageFun Home PlotMike WoodNo ratings yet

- HS2 Map West Midlands wm15103Document1 pageHS2 Map West Midlands wm15103HighSpeedRailNo ratings yet

- Denah RafterDocument1 pageDenah RafterYusuf KhoirNo ratings yet

- Citation VII: Ap Off Yd Off CMPRTR Warn HYD Temp LOW Flap O SPD Ap Off Yd Off CMPRTR Warn HYD Temp LOW Flap O SPDDocument2 pagesCitation VII: Ap Off Yd Off CMPRTR Warn HYD Temp LOW Flap O SPD Ap Off Yd Off CMPRTR Warn HYD Temp LOW Flap O SPDFernando GalindezNo ratings yet

- TER30006Document1 pageTER30006luis marcelino chuquimango muñozNo ratings yet

- Road Crossing DuctsDocument1 pageRoad Crossing Ductsmohan890No ratings yet

- Printer Control Board PRCB (2/2) : Bizhub 363/283/223 Bizhub 423Document1 pagePrinter Control Board PRCB (2/2) : Bizhub 363/283/223 Bizhub 423Oswaldo GuzmanNo ratings yet

- Electric Diagram Bizhub C253-C353Document1 pageElectric Diagram Bizhub C253-C353schumi_kaiserNo ratings yet

- PDF La Administracion en La Antigua Roma - CompressDocument1 pagePDF La Administracion en La Antigua Roma - CompressYanii RojasNo ratings yet

- Proarc: Section AADocument1 pageProarc: Section AASyed AbuthahirNo ratings yet

- Module M-04: EquipmentDocument1 pageModule M-04: EquipmentRobles DreschNo ratings yet

- PLANS_Student Services CenterDocument23 pagesPLANS_Student Services Centerronulfo fabulaNo ratings yet

- SDP1Document1 pageSDP1Liezel GasparNo ratings yet

- Elevation of Tower - 2 (Facing North) Part 3 of 3: Section L-LDocument1 pageElevation of Tower - 2 (Facing North) Part 3 of 3: Section L-LHozien OnofreNo ratings yet

- OT3073-20 L3 LAB Condenseur R3Document1 pageOT3073-20 L3 LAB Condenseur R3becemNo ratings yet

- Johnson Controls - Building Efficiency: Label Wiring - Haf Fan Wiring Std/Inv Opt 5-Fan System 1-1Document2 pagesJohnson Controls - Building Efficiency: Label Wiring - Haf Fan Wiring Std/Inv Opt 5-Fan System 1-1PetricaNo ratings yet

- Plan SPGGDocument1 pagePlan SPGGGerardo FernandezNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanGhulam Mustafa KhanNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanArfan SialNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanImranNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanmehrunisaNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanadnanjamilNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanmehrunisaNo ratings yet

- Political Map Pakistan-1 PDFDocument1 pagePolitical Map Pakistan-1 PDFOmerNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanHamza J. KhanNo ratings yet

- Political Map Pakistan PDFDocument1 pagePolitical Map Pakistan PDFAtif NaeemNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanpartookNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanAhmet ÖzdenNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanAsif AliNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanUzair AhmadNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map Pakistansydasif78No ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanRehan ShahwaniNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanAhver BaigNo ratings yet

- Pakistan Map PDFDocument1 pagePakistan Map PDFMaiymona ShahNo ratings yet

- Political Map PakistanDocument1 pagePolitical Map PakistanZaheer BaltistaniNo ratings yet

- Method of Statements (Rolling Rolling Procedure)Document12 pagesMethod of Statements (Rolling Rolling Procedure)Ravi TyagiNo ratings yet

- Certificate: National Institute of Standards & TechnologyDocument2 pagesCertificate: National Institute of Standards & TechnologyRavi TyagiNo ratings yet

- Certificate: National Institute of Standards & TechnologyDocument2 pagesCertificate: National Institute of Standards & TechnologyRavi TyagiNo ratings yet

- Certificate: National Institute of Standards & TechnologyDocument2 pagesCertificate: National Institute of Standards & TechnologyRavi TyagiNo ratings yet

- Impact Tester and Tensile TestDocument22 pagesImpact Tester and Tensile TestRavi TyagiNo ratings yet

- Ultrasonic Testing Machine UHC2100eDocument4 pagesUltrasonic Testing Machine UHC2100eRavi TyagiNo ratings yet

- GQ-HW2H Chemical TestingDocument2 pagesGQ-HW2H Chemical TestingRavi TyagiNo ratings yet

- Jindal Steel SpecificationsDocument76 pagesJindal Steel SpecificationsVignesh Chellappan NatarajanNo ratings yet

- Usage: Power: Brand Name: Weight: Model Number:: Digital Display Impact Testing Machine JB-300SDocument7 pagesUsage: Power: Brand Name: Weight: Model Number:: Digital Display Impact Testing Machine JB-300SRavi TyagiNo ratings yet

- HCH310 Portable Hardness TesterDocument6 pagesHCH310 Portable Hardness TesterRavi TyagiNo ratings yet

- J-Weld Impact and Tensile Test SpecimensDocument3 pagesJ-Weld Impact and Tensile Test SpecimensRavi TyagiNo ratings yet

- Application For Acrs Product Certification: InstructionsDocument6 pagesApplication For Acrs Product Certification: InstructionsRavi TyagiNo ratings yet

- ADM 002 ACRS Product Certification Scheme Rules (Version 12) WEBDocument43 pagesADM 002 ACRS Product Certification Scheme Rules (Version 12) WEBRavi TyagiNo ratings yet

- ADM 002 01 List of Applicable Product Requirements Version 2.6 WEBDocument3 pagesADM 002 01 List of Applicable Product Requirements Version 2.6 WEBRavi TyagiNo ratings yet

- Quality Procedure Manual: Vol - XiiDocument2 pagesQuality Procedure Manual: Vol - XiiRavi TyagiNo ratings yet

- ADM 016 ACRS Certification Agreement (Version 3.1) WebDocument23 pagesADM 016 ACRS Certification Agreement (Version 3.1) WebMonica SinghNo ratings yet

- J-Weld Impact and Tensile Test SpecimensDocument3 pagesJ-Weld Impact and Tensile Test SpecimensRavi TyagiNo ratings yet

- ADM 002 ACRS Product Certification Scheme Rules (Version 12) WEBDocument43 pagesADM 002 ACRS Product Certification Scheme Rules (Version 12) WEBRavi TyagiNo ratings yet

- ADM 002 01 List of Applicable Product Requirements Version 2.6 WEBDocument3 pagesADM 002 01 List of Applicable Product Requirements Version 2.6 WEBRavi TyagiNo ratings yet

- API Monogram Program Documentation and Audit TimelineDocument2 pagesAPI Monogram Program Documentation and Audit TimelineRavi TyagiNo ratings yet

- Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and ShapesDocument6 pagesCold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and ShapesMizha GomezNo ratings yet

- Application For Acrs Product Certification: InstructionsDocument6 pagesApplication For Acrs Product Certification: InstructionsRavi TyagiNo ratings yet

- Influence of Matric Suction On The Shear Strength Behaviour of Unsaturated SandDocument7 pagesInfluence of Matric Suction On The Shear Strength Behaviour of Unsaturated SandKashif MuhammadNo ratings yet

- Basic Civil Engineering ... Unit I ... Materials and Its PropertiesDocument8 pagesBasic Civil Engineering ... Unit I ... Materials and Its Propertiesnageshshingane7No ratings yet

- Welded ConnectionsDocument8 pagesWelded ConnectionsNitesh SinghNo ratings yet

- Structural Modeling Notes Using ETABS, SAFE and SAP2000Document68 pagesStructural Modeling Notes Using ETABS, SAFE and SAP2000Irfan Khan100% (1)

- Corporate Trifold BrochureDocument2 pagesCorporate Trifold BrochureTech MongerNo ratings yet

- Geotechnical Report 10460 Slater Avenue-Fountain ValleyDocument38 pagesGeotechnical Report 10460 Slater Avenue-Fountain Valleypawee ramasNo ratings yet

- JKR Rates 2011Document45 pagesJKR Rates 2011Derek Martin100% (2)

- Curve Superelevation CalculationDocument7 pagesCurve Superelevation CalculationKhan EngrNo ratings yet

- List of Earthquake and Soil Engineering Research TopicsDocument11 pagesList of Earthquake and Soil Engineering Research TopicsShamsUlislamNo ratings yet

- Sewage Treatment Plant Design Project - Sewage Treatment - Sanitary SewerDocument101 pagesSewage Treatment Plant Design Project - Sewage Treatment - Sanitary SewerNikhil SachdevaNo ratings yet

- Geotechnical Engineering QBDocument11 pagesGeotechnical Engineering QBT Rajesh Asst. Prof. - CENo ratings yet

- 1319 013Document6 pages1319 013AseriNo ratings yet

- Design of Welded Steel Plate GirdersDocument87 pagesDesign of Welded Steel Plate GirdersHoran Malik100% (1)

- Kyle Danielle A. BrionDocument3 pagesKyle Danielle A. BrionMikee Valbares100% (1)

- Venkat Ramanan Resume 2Document3 pagesVenkat Ramanan Resume 2Ramanan VenkatNo ratings yet

- Presentation On Basic Knowledge Railway Siding & Its Major ComponentsDocument10 pagesPresentation On Basic Knowledge Railway Siding & Its Major Componentsengr.kapilgambhir7862No ratings yet

- Cutting Length StirrupsDocument12 pagesCutting Length StirrupsSwostik S SahooNo ratings yet

- Kursus PamDocument135 pagesKursus PamSeindahNyaNo ratings yet

- Tablas VigasDocument17 pagesTablas VigasPatricio Galván EscobarNo ratings yet

- Analytical Research On Ferrocement: Design, Strength and Servicibility AspectsDocument8 pagesAnalytical Research On Ferrocement: Design, Strength and Servicibility AspectsPiyush SharmaNo ratings yet

- P3 Price List Structural PDFDocument11 pagesP3 Price List Structural PDFLorena NovaNo ratings yet

- AGRD03-16 Guide To Road Design Part 3 Geometric Design Ed3.4Document390 pagesAGRD03-16 Guide To Road Design Part 3 Geometric Design Ed3.4fbturaNo ratings yet

- Project:SASEC Mugling-Pokhara Highway Improvement Phase I Project (SMPHIP) Contract No. SMPHIP/OCB/MAP/2 Contractor: Anhui Kaiyuan Highway and Bridge Co. LTDDocument4 pagesProject:SASEC Mugling-Pokhara Highway Improvement Phase I Project (SMPHIP) Contract No. SMPHIP/OCB/MAP/2 Contractor: Anhui Kaiyuan Highway and Bridge Co. LTDugrasen chaudharyNo ratings yet

- Review: Cross-Laminated Timber: Design and PerformanceDocument1 pageReview: Cross-Laminated Timber: Design and PerformanceJulian TumielewiczNo ratings yet

- Earthquake Engineering PDFDocument70 pagesEarthquake Engineering PDFSumanthNo ratings yet

- Trusswood Installation GuideDocument2 pagesTrusswood Installation GuidenustwentyfourNo ratings yet

- Standard Classroom Building - DPWH As of 021524 A1Document1 pageStandard Classroom Building - DPWH As of 021524 A1designers.starlightNo ratings yet