Professional Documents

Culture Documents

Mody Pump g500

Uploaded by

pramod ku. nayakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mody Pump g500

Uploaded by

pramod ku. nayakCopyright:

Available Formats

G-500/530/550 G-500/530/550

SERIES DESIGN ADVANTAGES

PORTABLE ELECTRIC

SUBMERSIBLE PUMP FOR • Stainless Steel Strainer, Shaft, Impeller, Outlet and

Hardware for maximum corrosion resistance.

CORROSIVE & ABRASIVE

APPLICATIONS • Choice of impeller materials:

…………………………………………………………

1) 316 Stainless Steel for sea water and corrosive

5 HP (3.7kW) applications and;

G 502T / G 504T / G 506T 2) Nitride Hardened 410 Stainless Steel for abrasive

4"(100mm) / 4"(100mm) / 3"(75/80mm) NPT or Hose applications. (Standard)

…………………………………………………………

• Tandem Tungsten Carbide/Tungsten Carbide and

7.5 HP (5.5kW) Tungsten Carbide/Tungsten Carbide mechanical seals.

G 530T / G 536T

• Mechanical Seals in wholly enclosed pressure

4"(100mm) / 3"(75/80mm) NPT or Hose compensated oil chamber.

…………………………………………………………

• Field adjustable Nitrile Rubber-lined Diffuser/Wear Plate

10 HP (7.5kW) Optimizes efficiency throughout the life of the pump. Optional

Polyurethane Diffusers and Wear Plates are available.

G 554T / G 556T

4"(100mm) / 3"(75/80mm) NPT or Hose • Automatic ON/OFF/ON Thermal Overloads embedded in Stator

………………………………………………………… Winding Optional - requires 6 core cable and external controls.

• Equipped with Sacrificial Zinc Anodes for maximum life

in a saline fluid environment.

• Available in complete 316 Stainless Steel Construction with

Silicon Carbide/Silicon Carbide Mechanical Seals and Viton®

Elastomers.

Mody Pumps® Inc.

2166 Zeus Court, Bakersfield, CA 93308. USA

Tel.: (661) 392-7600 • Fax: (661) 392-7601

http://www.modypump.com

E-mail: sales@modypump.com

03.10.Rev.0

G-500/530/550 SERIES G-500/530/550 SERIES

5HP(3.7kW) / 7.5(5.5kW) / 10HP(7.5kW) MATERIALS OF CONSTRUCTION

AND ENGINEERING DATA

MOTOR

2-pole induction continuous rated motor with squirrel cage rotor.

Stator insulation class 'H' (180ºC)

Speed : 3400 RPM @ 60 Hz, 2800 RPM @ 50 Hz

Power Rating : 5HP/7.5HP/10HP @ 60 Hz, 3.7kW/5.5kW/7.5kW @ 50Hz Full Load

Current FLA: 7.1, 11, 14 Amps @ 460v. 8.1, 12.5, 16 @ 400v.

Max. temperature of the pump liquid: 104°F/40°C

Max. start/stop per hour : 15

POWER SUPPLY

3 phase, 50/60 Hz, AC Supply. Available in any voltage frequency

combination.(208/220/230/380/415/460/575/1000V)

MODEL A

BALL BEARINGS

G-502 25-1/4” (640mm)

The rotor shaft is carried in two single row, deep groove ball bearings.

G-504

The bearings are enclosed with high temperature grease-containing special

G-506

Anti-corrosion additive.

G-530 28-1/2” (725mm)

G-536 POWER CABLE

Waterproof/oil proof, rubber-insulated, neoprene-sheathed copper conductor

G-554 29-1/2” (750mm) flexible cable, 50ft. (15m) length standard. Type SOOW in North America,

G-556 EPR in the Middle East and HO7RN in the EU. 6 Core with thermal overloads

optional.

SHAFT SEAL

Tandem Tungsten Carbide/Tungsten Carbide and Tungsten Carbide/Tungsten

Carbide Mechanical seals wholly enclosed in a pressure compensated oil chamber.

CORROSION RESISTANT

Epoxy coated Aluminum Outer Casing

PERFORMANCE CURVES Epoxy coated Extruded Aluminum Stator Casing

Nitrile Rubber– Lined Diffuser/Wear plate. Polyurethane Optional.

Shaft: 431 Stainless Steel

Hardware: 304 Stainless Steel

Impeller: Nitride Hardened 410SS to 56HRC is Standard.

pH Range 5 - 8

STRAINER

304 Stainless Steel with 1” (25mm) X 1/4” (6mm) {G 502/504},

1-3/16” (30mm) X 3/8” (9.5mm) {G530/554},

1/4” (6mm) Round Holes {G 506/536/556}

SUBMERGENCE

Submergence below liquid surface min 5” (127mm) max. 50’ (15m).

WEIGHTS (Approx. without cable)

G 502/504: 110lbs. (50Kg)

G 506: 115lbs. (52Kg)

G 530: 130lbs. (59Kg)

G 536: 135lbs. (61Kg)

G 554: 142lbs. (64Kg)

G 556: 147lbs. (67Kg)

Due to continuous product development, specifications are subject to change without notice.

03.10 Rev.0

You might also like

- Submersible PumpDocument2 pagesSubmersible Pumpshresthaganesh47No ratings yet

- Mody M100T 50 60Document2 pagesMody M100T 50 60NAHASALI11No ratings yet

- 4530 Spec SheetDocument2 pages4530 Spec SheetLye YpNo ratings yet

- Series 950: Unidirectional Knife Gate ValveDocument4 pagesSeries 950: Unidirectional Knife Gate ValveAmol PhadaleNo ratings yet

- G554T LocalDocument2 pagesG554T LocalAmardeep HansdaNo ratings yet

- GE Motor PDFDocument30 pagesGE Motor PDFcmrig74No ratings yet

- Butter Mueller 5bt520e0015wf00g1000Document2 pagesButter Mueller 5bt520e0015wf00g1000Manusawin PinsongNo ratings yet

- Firelock Butterfly Valve: Series 705 With Weatherproof ActuatorDocument7 pagesFirelock Butterfly Valve: Series 705 With Weatherproof ActuatorDefy BbalNo ratings yet

- Flexible Sprinkler Drops Data SheetDocument3 pagesFlexible Sprinkler Drops Data SheetJOSE GABRIELNo ratings yet

- Submersible Pumps: For Dewatering, Sewage, Marine and Rental MarketsDocument20 pagesSubmersible Pumps: For Dewatering, Sewage, Marine and Rental MarketsDebora MaryantiNo ratings yet

- 350PSI SWING CHECK VALVEDocument2 pages350PSI SWING CHECK VALVEPedro Alberto Tello CNo ratings yet

- JG JgaDocument4 pagesJG Jgaivan.mehanikNo ratings yet

- Tsurumi CatalogDocument35 pagesTsurumi CatalogfirfourNo ratings yet

- 09-Thai Cooling TowerDocument27 pages09-Thai Cooling TowerEnergy4You100% (1)

- Fan Adta-En-50hz-March-2018 - 20180315Document52 pagesFan Adta-En-50hz-March-2018 - 20180315Andi JatmikoNo ratings yet

- Jaw Crusher Spec SheetDocument2 pagesJaw Crusher Spec SheetDilnesa EjiguNo ratings yet

- Norm Ex ValvesDocument6 pagesNorm Ex Valvesapi-3712612No ratings yet

- Flaring and Grooving MachinesDocument12 pagesFlaring and Grooving MachinesAlbert SomendraNo ratings yet

- FL6003 PDFDocument4 pagesFL6003 PDFMauricio Barrios CastellanosNo ratings yet

- Biro 3334SS 4003FHDocument2 pagesBiro 3334SS 4003FHУуганбаяр ЭрдэнэхүүNo ratings yet

- EZ Series Cast Iron and Stainless Steel Booster PumpsDocument32 pagesEZ Series Cast Iron and Stainless Steel Booster PumpsGarrett McMichaelNo ratings yet

- Samoa-Section 4 Pages43-54Document12 pagesSamoa-Section 4 Pages43-54Wiki YuanditraNo ratings yet

- Goulds Pumps 3355 SeriesDocument7 pagesGoulds Pumps 3355 Seriesmcastillo7385100% (1)

- 3.3 Valvula Os&y - SanfloDocument2 pages3.3 Valvula Os&y - SanfloYhonny ValenzuelaNo ratings yet

- Wafer: 700 Series Rubber Seated Butterfly Valves For General UseDocument48 pagesWafer: 700 Series Rubber Seated Butterfly Valves For General UseHeru SACNo ratings yet

- Series 520 Technical Information General Description: Maximum Working PressureDocument2 pagesSeries 520 Technical Information General Description: Maximum Working PressurePartsGopher.comNo ratings yet

- 8" Encapsulated 30 °C: Submersible MotorsDocument2 pages8" Encapsulated 30 °C: Submersible Motorswpt_meNo ratings yet

- FTS250PFDocument2 pagesFTS250PFjanusfireNo ratings yet

- Warrior 500i With Warrior Feed 304: Ordering InformationDocument4 pagesWarrior 500i With Warrior Feed 304: Ordering InformationcarlosNo ratings yet

- Reel Craft GS3050Document5 pagesReel Craft GS3050kherlambangNo ratings yet

- Knife Gate Valve: Product DescriptionDocument2 pagesKnife Gate Valve: Product DescriptionAyman RiyadhNo ratings yet

- ARIEL JG AND JGA COMPRESSOR SPECSDocument4 pagesARIEL JG AND JGA COMPRESSOR SPECSparathasiNo ratings yet

- V5 Borewell: Submersible PumpsetDocument7 pagesV5 Borewell: Submersible Pumpsetsandhya thimmappaNo ratings yet

- Catalog For Pahala BahariDocument4 pagesCatalog For Pahala BahariMuhammad Reza GadranNo ratings yet

- Metal Seated Ball ValveDocument24 pagesMetal Seated Ball Valvehiep nguyenNo ratings yet

- Specsheet XH200-636Document3 pagesSpecsheet XH200-636Abe BustomiNo ratings yet

- KMT Aqua Dyne Bare Shaft Series 500 - REV 03 10 - L2Document2 pagesKMT Aqua Dyne Bare Shaft Series 500 - REV 03 10 - L2Jeff RyersonNo ratings yet

- Models HRSB & HRSD: Model FeaturesDocument9 pagesModels HRSB & HRSD: Model FeaturesAlejandro DuranNo ratings yet

- HH220 CAT-C13 pump spec sheetDocument3 pagesHH220 CAT-C13 pump spec sheetAdrie AmaiaNo ratings yet

- MKT - 656 - A SHELCO - Multi-Cartridge Housing-FinalDocument2 pagesMKT - 656 - A SHELCO - Multi-Cartridge Housing-FinalMsach RoysNo ratings yet

- 5340 252 00Document4 pages5340 252 00IvicaNo ratings yet

- Ficha Tecnica AURORA PICSA Series 380Document8 pagesFicha Tecnica AURORA PICSA Series 380Sergio HZNo ratings yet

- J6 Series, MS-02-214 R1Document2 pagesJ6 Series, MS-02-214 R1herysyam1980No ratings yet

- Knife Gate Valve LVC Figure 93 Stainless Steel Metal Seated - (PRATT)Document2 pagesKnife Gate Valve LVC Figure 93 Stainless Steel Metal Seated - (PRATT)juantamad02No ratings yet

- CC Marine 2013-14 Catalogue - PumpsDocument94 pagesCC Marine 2013-14 Catalogue - PumpsGregGGH100% (1)

- RESILIENT SEATED BUTTERFLY VALVES FEATURESDocument4 pagesRESILIENT SEATED BUTTERFLY VALVES FEATURESahmad zavyNo ratings yet

- Storagetech 100 Pressure Vacuum Relief Valve SMDocument4 pagesStoragetech 100 Pressure Vacuum Relief Valve SMkhaled SAYEDNo ratings yet

- General Specification: Model: Tipper Capacity: 16 Cu Mtr. Type: Box Body TIPPER WEIGHT: 3.363 Ton.Document2 pagesGeneral Specification: Model: Tipper Capacity: 16 Cu Mtr. Type: Box Body TIPPER WEIGHT: 3.363 Ton.uthayarajNo ratings yet

- Model 008 Cartridge Circulator: Water Circulation Pumps & CirculatorsDocument2 pagesModel 008 Cartridge Circulator: Water Circulation Pumps & CirculatorsFernando BarbosaNo ratings yet

- SpecSheet Pumps HH220 432 SRDocument3 pagesSpecSheet Pumps HH220 432 SRagung2 sepdieNo ratings yet

- General service centrifugal pump technical specificationsDocument14 pagesGeneral service centrifugal pump technical specificationsRafael toyoNo ratings yet

- Data Sheet: Adjustable Sheeter - Sheet Width MM 173 Bologna ELDocument2 pagesData Sheet: Adjustable Sheeter - Sheet Width MM 173 Bologna ELmuxadanNo ratings yet

- 355GF Data Sheet US - MetricDocument2 pages355GF Data Sheet US - Metricminov minovitchNo ratings yet

- Air Cooled Screw Chiller R134aDocument12 pagesAir Cooled Screw Chiller R134aalkaf08No ratings yet

- 013-Hose_2016Document4 pages013-Hose_2016Luis Carlos Mayorga GarciaNo ratings yet

- FESCO Fire PumpsDocument24 pagesFESCO Fire PumpsZeeshan HameedNo ratings yet

- S-Series Combines Specs PDFDocument1 pageS-Series Combines Specs PDFAlexandru ArdeleanNo ratings yet

- 60% Arrear On April PDFDocument1 page60% Arrear On April PDFpramod ku. nayakNo ratings yet

- Received With Thanks ' 4,746.29 Through Payment Gateway Over The Internet FromDocument1 pageReceived With Thanks ' 4,746.29 Through Payment Gateway Over The Internet Frompramod ku. nayakNo ratings yet

- Workman Exemption Conduct PDFDocument1 pageWorkman Exemption Conduct PDFpramod ku. nayakNo ratings yet

- SEO-Optimized Title for Electrical License AffidavitsDocument4 pagesSEO-Optimized Title for Electrical License Affidavitsjashobanta_sahooNo ratings yet

- Jaymac Bar Bending O&M Manual Ver3.1Document26 pagesJaymac Bar Bending O&M Manual Ver3.1prasanna221079% (14)

- CP-30 MCB - Contactor PDFDocument1 pageCP-30 MCB - Contactor PDFpramod ku. nayakNo ratings yet

- CF30 CONCRETE MIXING PLANTDocument8 pagesCF30 CONCRETE MIXING PLANTshivakumarpatgar100% (1)

- CF30 CONCRETE MIXING PLANTDocument8 pagesCF30 CONCRETE MIXING PLANTshivakumarpatgar100% (1)

- Zuper Inverter MMAW TIG WebDocument20 pagesZuper Inverter MMAW TIG Webpramod ku. nayakNo ratings yet

- Time Switch FM SeriesDocument2 pagesTime Switch FM Seriespramod ku. nayakNo ratings yet

- Heavy Duty 100mm Grinder Parts ListDocument1 pageHeavy Duty 100mm Grinder Parts Listpramod ku. nayakNo ratings yet

- BS en 00295-4-1995 (1999)Document19 pagesBS en 00295-4-1995 (1999)Shan Sandaruwan AbeywardeneNo ratings yet

- PL 009-005Document34 pagesPL 009-005ANTONIO GOMEZNo ratings yet

- Study of The Potentiality To Manufacture Forming Tools Via Waam (Wire + Arc Additive Manufacturing)Document10 pagesStudy of The Potentiality To Manufacture Forming Tools Via Waam (Wire + Arc Additive Manufacturing)jefferson segundoNo ratings yet

- Flooring2020 ENDocument372 pagesFlooring2020 ENMarianneNo ratings yet

- IPPTA 53 V X Rapid Displacement HeatingDocument6 pagesIPPTA 53 V X Rapid Displacement HeatingShivani SinghNo ratings yet

- Welding Procedure Qualification Record: Welded ToDocument6 pagesWelding Procedure Qualification Record: Welded ToParis VNo ratings yet

- Alucobest Aluminum Composite Panel For Sign, Display and Digital PrintingDocument12 pagesAlucobest Aluminum Composite Panel For Sign, Display and Digital PrintingAli ZhangNo ratings yet

- Lecture-3 PDFDocument13 pagesLecture-3 PDFaman prakashNo ratings yet

- GUJARAT TECHNOLOGICAL UNIVERSITY CHEMICAL PROCESS INDUSTRIESDocument3 pagesGUJARAT TECHNOLOGICAL UNIVERSITY CHEMICAL PROCESS INDUSTRIESNeel ShelatNo ratings yet

- Risks and Management of Textile WasteDocument25 pagesRisks and Management of Textile WasteAbril MonsalveNo ratings yet

- Study of Energy-Saving Reform in Garment Production EnterprisesDocument342 pagesStudy of Energy-Saving Reform in Garment Production EnterprisesAlemayehu AsinoNo ratings yet

- API 1104 2014 EditionDocument17 pagesAPI 1104 2014 EditionekkyNo ratings yet

- Everything You Need to Know About Welding ElectrodesDocument15 pagesEverything You Need to Know About Welding ElectrodesprashantNo ratings yet

- Chapter 2 Lesson 2 Properties of WaterDocument26 pagesChapter 2 Lesson 2 Properties of WaterSahar GhanemNo ratings yet

- A Paper Sizes - A0, A1, A2, A3, A4, A5, A6, A7, A8, A10Document5 pagesA Paper Sizes - A0, A1, A2, A3, A4, A5, A6, A7, A8, A10Benjie LatrizNo ratings yet

- 3 PBDocument12 pages3 PBfaagoldfishNo ratings yet

- Solvay Paint AdditivesDocument106 pagesSolvay Paint AdditivesMohamed HalemNo ratings yet

- PCI Standard Design Practice Manual - 2014Document32 pagesPCI Standard Design Practice Manual - 2014rahuljoagNo ratings yet

- Uni-Seals Spiral Wound Gasket Product CatalogDocument1 pageUni-Seals Spiral Wound Gasket Product CatalogademilsoncaetanooNo ratings yet

- Non-Woven Bag Dimensions and ColorsDocument36 pagesNon-Woven Bag Dimensions and ColorsIPP LANGKAWI (LPP-WPKL)No ratings yet

- Ionic Modification Turns Commercial Rubber Into A Self-HealingDocument8 pagesIonic Modification Turns Commercial Rubber Into A Self-HealingМаныч Хороший ГодNo ratings yet

- DacnisDocument1 pageDacnisironiteNo ratings yet

- Vanlube Ri-Zsn Vanlube TK-100 Vanlube W-324: R R SO 2 ZNDocument1 pageVanlube Ri-Zsn Vanlube TK-100 Vanlube W-324: R R SO 2 ZNAnalista De CalidadNo ratings yet

- PDF ResizeDocument56 pagesPDF ResizeAhmad SallehNo ratings yet

- Chemistry Std. 10 Prelim 1 PaperDocument6 pagesChemistry Std. 10 Prelim 1 PaperX ADINo ratings yet

- Fused Deposition Modeling (FDM)Document10 pagesFused Deposition Modeling (FDM)siddharthsainiNo ratings yet

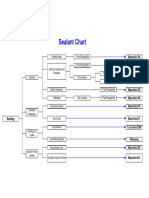

- Sealant Chart: Best Sealants for Waterproofing, Traffic Areas & MoreDocument1 pageSealant Chart: Best Sealants for Waterproofing, Traffic Areas & MoreDoby YuniardiNo ratings yet

- Design and Acceptability of a Universal Concrete SpacerDocument74 pagesDesign and Acceptability of a Universal Concrete SpacerJohn Aries Almelor SarzaNo ratings yet

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General Applicationsharon blushteinNo ratings yet

- ICP 0012 - Long Life High Output Tubular AnodesDocument4 pagesICP 0012 - Long Life High Output Tubular AnodesVCNo ratings yet