Professional Documents

Culture Documents

Gear Box Scania

Gear Box Scania

Uploaded by

Budhie FedefaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gear Box Scania

Gear Box Scania

Uploaded by

Budhie FedefaCopyright:

Available Formats

05:01-04

Issue 1 en

Gearbox

GRS890

GRS900

GRS920

GRSH900

GRSO900

Shafts

Work Description

©Scania CV AB 2005, Sweden

1 714 660

Contents

Contents

Input shaft Exploded view drawings .......................................... 3

Dismantling .............................................................. 4

Assembly .................................................................. 7

Mainshaft Exploded view drawing .......................................... 10

Dismantling ............................................................ 12

Renewing bearing races for splitter gearwheel....... 15

Assembly ................................................................ 17

Layshaft Exploded view drawing .......................................... 24

Dismantling ............................................................ 25

Assembly ................................................................ 29

Specifications Materials ................................................................. 33

Tightening torques .................................................. 33

©Scania CV AB 2005, Sweden

2 05:01-04

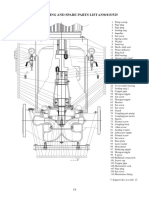

Input shaft

Input shaft

Exploded view drawings

GRS890, GRS/GRSH900

2

7

8

7

6 1 Shaft

2 Snap ring

3 Bearing

4

4 Gear

5

5 Needle bearing

3

6 Sealing ring

7 Piston ring

8 Spacing ring

9 Pipe

1

136 218

GRS920, GRSO900

2

7

6 1 Shaft

2 Snap ring

3 Bearing

4 4 Gear

5 5 Needle bearing

3 6 Sealing ring

7 Piston ring

8 Pipe

1

136 219

©Scania CV AB 2005, Sweden

05:01-04 3

Input shaft

Dismantling

Special tools

Number Description Illustration Tool board

87 596 Slide hammer 87 596 D2

00 1610

99 136 Hollow drift 99 136

P1

00 1622

99 141 Support ring 99 141

P1

00 1623

Other tools

Number Description Illustration

587 312 Snap ring pliers 587 312

111 445

©Scania CV AB 2005, Sweden

4 05:01-04

Input shaft

1 Remove the two piston rings by hand.

Earlier gearboxes may have a spacing ring

between the piston rings.

2 Remove the snap ring. Use snap ring pliers

587 312. It may be necessary to tap the

bearing inner race with something first, such

as a drift and hammer.

3 Place the shaft on hollow drift 99 136 and

support ring 99 141. Press out the bearing

and gear. Place something soft underneath

to protect the shaft when it comes loose.

©Scania CV AB 2005, Sweden

05:01-04 5

Input shaft

4 Remove the bearing and the gear. Remove

the bearing shells.

If the input shaft is the old type, i.e. with the

oil pipe pressed into the input shaft, remove

as follows.

5 Tap the oil pipe using an M10 pilot tap.

6 Pull out the oil pipe using an M10 bolt with

welded-on washer and slide hammer

87 596. Clean the oilway.

©Scania CV AB 2005, Sweden

6 05:01-04

Input shaft

Assembly

Special tools

Number Description Illustration Tool board

98 224 Pressplate 98 224

G1

110 065

98 334 Counterholding tube 98 334

G3

110 120

98 450 Shank R2, AD2, AM1

00 1633

98 450

98 636 Assembly drift 98 636

G1

110 815

99 136 Hollow drift 99 136

P1

00 1622

99 141 Support ring 99 141

P1

00 1623

Other tools

Number Description Illustration

587 312 Snap ring pliers 587 312

111 445

©Scania CV AB 2005, Sweden

05:01-04 7

Input shaft

If the input shaft is the old type, i.e. with the oil

pipe pressed into the shaft, fit as described in

steps 1-2.

1 Place the shaft in pressplate 98 224.

2 Press in the oil pipe using shank 98 450.

Press in the pipe so that it protrudes at least

21.5 mm (dimension A). Check that the

lubricating holes are clear. The pipe must

not be upset.

3 Fit the bearing shells and the gear with the

splines downwards.

4 Press on the bearing using counterholding

tube 98 334 and assembly drift 98 636.

©Scania CV AB 2005, Sweden

8 05:01-04

Input shaft

5 Fit the snap ring using snap ring pliers

587 312. Select a snap ring which provides

the least possible clearance between the ring

and bearing. Check that the snap ring goes

down into the groove.

6 Place the shaft on hollow drift 99 136 and

support ring 99 141. Press the bearing

against the snap ring using a press force of

70 kN max. (7 tonnes).

7 Fit the two piston rings. Earlier versions

also have a spacing ring between the piston

rings.

©Scania CV AB 2005, Sweden

05:01-04 9

Mainshaft

Mainshaft

Exploded view drawing

©Scania CV AB 2005, Sweden

10 05:01-04

Mainshaft

1 Mainshaft 29 Cone

2 Bearing 30 Driver

3 Nut 31 Compression spring

4 Roller bearing 32 Plunger

5 Spacing ring 33 Clevis pin

6 Shim 34 Shift sleeve

7 Gear 35 Latch cone

8 Gear 36 Cone

9 Needle bearing 37 Synchromesh cone

10 Gear 38 Driver

11 Snap ring 39 Compression spring

12 Needle bearing 40 Plunger

13 Gear 41 Clevis pin

14 Slide bearing 42 Shift sleeve

15 Driver 43 Latch cone

16 Coupling sleeve 44 Coupling disc

17 Gear 45 Spring pin

18 Slide bearing 46 Snap ring

19 Slide bearing 47 Synchromesh

20 Nozzle 48 Intermediate cone

21 Shim 49 Latch cone

22 Spacing ring 50 Driver plate

23 Shift sleeve 51 Compression spring

24 Snap ring 52 Plunger

25 Sun wheel 53 Clevis pin

26 Spacing washer 54 Washer

27 Shim 55 Shift sleeve

28 Nut 56 Driver

©Scania CV AB 2005, Sweden

05:01-04 11

Mainshaft

Dismantling

Special tools

Number Description Illustration Tool board

87 237 Support drift G2

98 322 Lifting handle 98 322

G2

109 805

98 575 Support drift 98 575

G2

00 1621

99 136 Hollow drift 99 136

00 1622

P1

99 140 Support ring 99 140

P1

111 007

99 202 Split support ring 99 201

P1

111 022

Other tools

Number Description Illustration

587 318 Puller plate

114 693

587 319 Puller

587 600 Socket D

Di

L

00 1890

©Scania CV AB 2005, Sweden

12 05:01-04

Mainshaft

1 Pull off the front bearing. Use support drift

87 237, puller plate 587 318 and puller

587 319.

! WARNING!

Wear protective goggles. There is a risk

of flying fragments if the bearing breaks.

2 Remove the round nut, use socket 587 600.

3 Fit lifting handle 98 322 and lift the shaft

onto the press.

©Scania CV AB 2005, Sweden

05:01-04 13

Mainshaft

4 Lower the shaft into hollow drift 99 136.

When the shift sleeve is down in the hollow

drift, fit the split support ring 99 202. Centre 98 575

carefully. Place, for example, a rubber cloth

in the drift to cushion the fall.

5 Press out the rear bearing, reverse shaft gear,

crawl and first gears. Protect the ends of the

shaft using support drift 98 575. Remove the

bearing, gears and synchromesh assembly. 99 202

Keep the synchromesh assembly as a unit.

Mark the parts and place the assembly to 99 136

one side.

133 794

6 Turn the shaft and place it in hollow drift

99 136. Use support ring 99 140. Protect the

ends of the shaft using support drift 98 575.

7 Press out the shaft. Remove the second gear

and splitter gear with their corresponding

synchromesh assembly. Mark the splitter

gearwheel so that it faces in the same

direction during assembly. Keep the

synchromesh assembly as a unit. Mark the

parts and place the assembly to one side.

©Scania CV AB 2005, Sweden

14 05:01-04

Mainshaft

Renewing bearing races for splitter gearwheel

Special tools

Number Description Illustration Tool board

87 446 Drift 87 446

AD2

00 1581

87 758 Drift 87 758

G1

00 1611

Other tools

Number Description Illustration

587 316 Counterhold

114 058

587 530 Puller

115 110

©Scania CV AB 2005, Sweden

05:01-04 15

Mainshaft

1 Mount the gearwheel in a vice with soft

jaws. Use puller 587 530 and counterhold

587 316 to pull out one bearing race. Use a

separator plate made of e.g. aluminium

sheet.

2 Press out the other bearing race using drift

87 758.

3 Press in new bearing races using drift

87 446.

©Scania CV AB 2005, Sweden

16 05:01-04

Mainshaft

Assembly

Special tools

Number Description Illustration Tool board

87 089 Drift 87 089

AM2, D3

110 283

87 550 Drift 87 550

AD2

00 1628

87 932 Drift 87 932

D3, G1

00 1636

88 292 Pull rod 88 292

00 1848

G2

98 075 Dial gauge 98 075

D2

0

90 10

10 90

80 20

20

80

15 5

30 10

70

70 30

40 60

60 50 40

50

00_1637

98 568 Drift 98 568

AM1

00_1618

98 575 Support drift 98 575

G2

00 1621

99 127 Drift 99 127 AM1

00 1629

99 136 Hollow drift 99 136

P1

00 1622

©Scania CV AB 2005, Sweden

05:01-04 17

Mainshaft

Number Description Illustration Tool board

99 140 Support ring 99 140

P1

111 007

99 190 Drift 99 190

G4

00 1638

99 191 Drift 99 191

G4

109 785

99 199

99 199 Counterhold G4

111 021

Other tools

Number Description Illustration

587 250 Indicator stand with magnetic

base

102350

587 600 Socket D

Di

L

00 1890

1 Fit the needle bearing.

2 Fit the second gear with the spline flange

upwards.

©Scania CV AB 2005, Sweden

18 05:01-04

Mainshaft

3 Fit the synchromesh assembly for second

and third gears with the longer neck of the

driver downwards. Guide onto the splines

and press if necessary.

05_3289

4 Press one bearing onto the splitter

gearwheel, use drifts 99 190 and 99 191.

5 Fit the spacing ring first and then the shims.

When measuring the clearance, you should

start with too much clearance. Therefore fit

one shim more than before.

6 Fit the splitter gearwheel. Fit it onto the

splines on the synchromesh cone.

©Scania CV AB 2005, Sweden

05:01-04 19

Mainshaft

7 Press on the other bearing using drift 99 190

and 99 191. Rotate the gear while pressing.

Stop pressing if it is hard to rotate the wheel

and change to a thicker shim. See step 11.

8 Fit the round nut. Use counterhold 99 199,

pull rod 88 292 and socket 587 600.

Tightening torque 400 Nm.

9 Check the splitter gearwheel clearance.

Leave the shaft on counterhold 99 199, or

clamp the shaft in a press with 10 - 20 kN.

Fit dial gauge 98 075 and indicator stand

587 250.

10 Rotate the gear a few turns, always in the

same direction. Prise the gear upwards using

two screwdrivers. Rotate the gear and

perform at least three measurements, mark

the gear so that the measurements are

carried out at the same position. Take the

average. Correct clearance: 0.03 - 0.09 mm.

©Scania CV AB 2005, Sweden

20 05:01-04

Mainshaft

11 Adjusting the clearance: Press up the shift

sleeve to gear position 3. Place the shaft in

hollow drift 99 136 with support rings

99 140 and press out the bearing using drift

98 575. Fit new shims and begin again from

step 6.

12 Lock the nut on the two recesses provided

for the purpose and remove counterhold

99 199.

122 564

13 Turn the mainshaft over. Use drift 98 568 as

a support under the shaft if the front bearing

is pressed on.

14 Lubricate and fit the needle bearing.

©Scania CV AB 2005, Sweden

05:01-04 21

Mainshaft

15 Line up the synchromesh assembly and

place it in position on the first gear. Then fit

the gear with the synchromesh assembly on

the shaft.

16 Lubricate and press on the inner ring for the

crawl gear needle bearing. Use drifts 87 550

and 99 127. Fit the needle bearing.

17 Fit the crawl gear with the coupling teeth

upwards. Fit the driver, press if necessary.

Use drifts 87 550 and 99 127.

18 Fit the shift sleeve.

©Scania CV AB 2005, Sweden

22 05:01-04

Mainshaft

19 Lubricate and press on the inner ring for the

reverse gear needle bearing. Use drifts

87 932 and 99 127.

20 Fit the reverse gear needle bearing and the

gear with the coupling teeth downwards.

21 Lubricate the rear bearing and press it on

using drift 87 932.

22 Turn the shaft and press on the front

bearing, use drift 87 089.

©Scania CV AB 2005, Sweden

05:01-04 23

Layshaft

Layshaft

Exploded view drawing

All versions of GRS gearboxes have a layshaft

which is designed in the same way, what differs

is, for example, the number of teeth and the

strength of the gearwheels.

1 Shaft

2 Retaining ring

3 Bearing

4 Gear

5 Gear

6 Spacing sleeve

7 Gear

8 Bearing

9 O-ring

10 Shim

11 Retaining ring

©Scania CV AB 2005, Sweden

24 05:01-04

Layshaft

Dismantling

Special tools

Number Description Illustration Tool board

98 575 Support drift 98 575

G2

00 1621

98 647 Support drift G2

99 136 Hollow drift 99 136

P1

00 1622

99 140 Support ring 99 140

P1

111 007

99 142 Support ring 99 142 P1

00 1624

99 143 Split support ring 99 143

P1

111 008

99 450 Split support ring PT1

128 352

©Scania CV AB 2005, Sweden

05:01-04 25

Layshaft

Other tools

Number Description Illustration

587 312 Snap ring pliers 587 312

111 445

587 318 Puller plate

114 693

587 319 Puller

1 Pull off the rear bearing using puller plate

587 318 and puller 587 319. Use support

drift 98 647. If the bearing breaks, split it.

! WARNING!

Wear protective goggles.

2 Pull off the front bearing using puller plate

587 318 and puller 587 319. Use support

drift 98 647. Loosen the bearing slightly

first, then grasp it again. If the bearing

breaks, split it.

©Scania CV AB 2005, Sweden

26 05:01-04

Layshaft

3 Remove the snap ring. Use snap ring pliers

587 312.

4 Place the layshaft in a press. Centre

carefully.

GRSO900: Press off the layshaft high split

gearwheel. Use hollow drift 99 136 with

split support ring 99 450 and support drift

98 575.

OTHERS: Press off the layshaft low split

gearwheel. Use hollow drift 99 136 with

split support ring 99 143 and support drift

98 575.

GRSO900

Place, for example, a rubber cloth in the

hollow drift to cushion the fall of the shaft

when it drops down.

Other gearboxes

5 Press off the next splitter gearwheel. Use

hollow drift 99 136 with support ring

99 140. Remove the spacing ring.

©Scania CV AB 2005, Sweden

05:01-04 27

Layshaft

6 Press out the second gear. Use hollow drift

99 136, support ring 99 142 and support

drift 98 575.

©Scania CV AB 2005, Sweden

28 05:01-04

Layshaft

Assembly

Special tools

Number Description Illustration Tool board

98 575 Support drift 98 575

G2

00 1621

98 638 Assembly drift 98 638

G3

110 816

99 136 Hollow drift 99 136

P1

00 1622

99 142 Support ring 99 142

P1

00 1624

99 190 Drift 99 190

G4

00 1638

99 191 Drift 99 191

G4

109 785

99 450 Split support ring PT1

128 352

Other tools

Number Description Illustration

587 312 Snap ring pliers 587 312

111 445

©Scania CV AB 2005, Sweden

05:01-04 29

Layshaft

All gears are bonded onto the layshaft. Before

the gears are bonded onto the shaft, the surfaces

must be carefully cleaned with degreasing

solvent. Then use locking compound 584 075

(Loctite 16 705) which is spread evenly over

both surfaces for good adhesion.

IMPORTANT! To guarantee the strength of the

locked joint, the press force when fitting must

reach at least 300 kN (30 tonnes) just before the

gears reach the bottom. If the force is not

attained, the shaft and/or gear should be

scrapped. The reason for this is that if you do

not use the correct locking compound and attain

the correct press force, the gears will rotate on

the shaft.

1 Place the second gear on support ring

99 142 and press in the shaft.

Note: Protect the ends of the shaft using support

drift 98 575. The press force must reach at least

300 kN (30 tonnes) before the gear reaches the

bottom.

©Scania CV AB 2005, Sweden

30 05:01-04

Layshaft

2 Place the high split gear (low split gear for

GRSO900) on support ring 99 142. Fit the

spacing ring on the shaft and press on the

gear.

Note: Protect the ends of the shaft using support

drift 98 575. The press force must reach at least

300 kN (30 tonnes) before the gear reaches the

bottom.

3 GRSO900: Place the high split gear on

support ring 99 450 and press in the shaft.

OTHERS: Place the low split gear on

support ring 99 142 and press in the shaft.

Note: Protect the ends of the shaft using support

drift 98 575. The press force must reach at least

300 kN (30 tonnes) before the gear reaches the 99 450

bottom.

GRSO900 Other gearboxes

4 Press on the rear bearing. Use drift 99 190

and drift 99 191.

©Scania CV AB 2005, Sweden

05:01-04 31

Layshaft

5 Turn the shaft in the press. Fit the snap ring.

6 Place the shaft on drift 99 191. Press on the

front bearing. Use assembly drift 98 638.

©Scania CV AB 2005, Sweden

32 05:01-04

Specifications

Specifications

Materials

Sealing agent part No. 584 010

Locking compound 561 200

Tightening torques

Round nut on mainshaft 400 Nm + locking

compound

Lock bolt for reverse gear shaft 50 Nm + locking

compound

Pressure relief valve 45 Nm

Oil pipe 26 Nm

Oil nozzle in shaft 80 Nm

Oil pump bolts 10 Nm

Clutch housing retaining bolts 210 Nm

Support sleeve retaining bolts 26 Nm

Round nut, end yoke 600 Nm

Drain and level plugs 100 Nm

©Scania CV AB 2005, Sweden

05:01-04 33

©Scania CV AB 2005, Sweden

34 05:01-04

©Scania CV AB 2005, Sweden

05:01-04 35

©Scania CV AB 2005, Sweden

36 05:01-04

You might also like

- Scania Opticruse GRS905Document2 pagesScania Opticruse GRS905fugega100% (14)

- Grs 900rDocument11 pagesGrs 900rslipsittin92% (13)

- Scania Retarder 3Document33 pagesScania Retarder 3neilevcvr88% (34)

- GRS 890 900 GR 801 900Document28 pagesGRS 890 900 GR 801 900Osmar Franco Pires100% (24)

- Scania EDC MS5 TroubleshootingDocument76 pagesScania EDC MS5 TroubleshootingMircea Gilca82% (22)

- Scania HPI Injection System and Edc S6Document70 pagesScania HPI Injection System and Edc S6Musharraf Khan83% (6)

- Scania Retarder PDFDocument39 pagesScania Retarder PDFGermainCampillay80% (5)

- APS - Scania FlowDocument5 pagesAPS - Scania FlowNoeRtjahya Ahmad100% (4)

- enDocument67 pagesenRegistr RegistrNo ratings yet

- Brake Diagram ScaniaDocument25 pagesBrake Diagram ScaniaPetrus Kanisius Wiratno92% (12)

- Scania R-Series Fuses P 2, Central Electric Unit: By:Omar Hussein Skype:eng - OmarhussienDocument9 pagesScania R-Series Fuses P 2, Central Electric Unit: By:Omar Hussein Skype:eng - OmarhussienGUILHERME100% (1)

- SM PC300-8 SN01983-01Document44 pagesSM PC300-8 SN01983-01aldy yasi79% (14)

- VIS SystemDocument10 pagesVIS SystemVincent Price50% (2)

- enDocument30 pagesenRegistr Registr100% (3)

- Brake ScaniaDocument25 pagesBrake Scaniarozak maskub100% (2)

- Scania Truck Abs Ems Fault CodesDocument16 pagesScania Truck Abs Ems Fault CodesSurafel Abebe50% (2)

- Spare Parts Catalogue PK 11001: (S106-EK-A)Document134 pagesSpare Parts Catalogue PK 11001: (S106-EK-A)Alfred HitchcockNo ratings yet

- ScaniaDocument6 pagesScaniaGustavo Paez100% (2)

- en PDFDocument44 pagesen PDFAlex Renne Chambi100% (1)

- Clucth ScaniaDocument2 pagesClucth ScaniaNoeRtjahya Ahmad100% (1)

- WSM 0000003 01Document52 pagesWSM 0000003 01Anderson Bombista90% (10)

- Desp. RetarderDocument4 pagesDesp. Retarderselukira71% (7)

- Hpi Work DescriptionDocument32 pagesHpi Work DescriptionHari100% (8)

- Scania HPI System EDCDocument29 pagesScania HPI System EDCnoran100% (2)

- ScaniaDocument39 pagesScaniarowan100% (7)

- Scania RET and GMS Fault CodesDocument211 pagesScania RET and GMS Fault Codesgrebnesor85% (20)

- Gearbox Scania BusDocument18 pagesGearbox Scania BusNoeRtjahya Ahmad89% (9)

- Scania Ralentizador 100507 PDFDocument39 pagesScania Ralentizador 100507 PDFGermainCampillayNo ratings yet

- Scania P, G, R, T Series Workshop Manual - Removing A Manual GearboxDocument11 pagesScania P, G, R, T Series Workshop Manual - Removing A Manual GearboxFachrie50% (2)

- 120302en PDFDocument35 pages120302en PDFduongpn100% (2)

- Scania Opticruise Transmission Fault Codes DTC & TroubleshootingDocument84 pagesScania Opticruise Transmission Fault Codes DTC & Troubleshootingfrank mutale100% (11)

- Tacometro y Velocimetro ScaniaDocument48 pagesTacometro y Velocimetro ScaniaChristian Ramos Campos60% (5)

- Communication ErrorDocument24 pagesCommunication Errorali wardana100% (3)

- Opticruise Grs-905: Detail C Detail A Detail BDocument2 pagesOpticruise Grs-905: Detail C Detail A Detail BRenan Mengatto100% (2)

- Scania Skrzynia BiegówDocument67 pagesScania Skrzynia Biegówandrzej100% (1)

- enDocument83 pagesenRegistr Registr100% (12)

- enDocument84 pagesenRegistr Registr100% (11)

- Tel88003012021 RT Bus FKNDocument12 pagesTel88003012021 RT Bus FKNWillian SantosNo ratings yet

- 030402en PDFDocument55 pages030402en PDFdaniel_jorge_10No ratings yet

- 03 TransmissionDocument121 pages03 TransmissionBeary McBeary100% (3)

- Chequeo Frenos ScaniaDocument68 pagesChequeo Frenos ScaniaOmar Zerna100% (3)

- Exhaust Gas Aftertreatment, Euro 6: en-GBDocument16 pagesExhaust Gas Aftertreatment, Euro 6: en-GBRuan100% (2)

- P 380 EngineDocument68 pagesP 380 EngineandraNo ratings yet

- Scania Sops RedaktorDocument7 pagesScania Sops Redaktorscania100% (3)

- SCANIA Suspension BT200 Work DescDocument32 pagesSCANIA Suspension BT200 Work DescHeri Suryo0% (1)

- Scania Diagnos & Programmer 3 2.28Document13 pagesScania Diagnos & Programmer 3 2.28scania100% (3)

- B - Bledding Procedurre On Page 13Document35 pagesB - Bledding Procedurre On Page 13EndraNo ratings yet

- Hpi Function DescriptionDocument64 pagesHpi Function DescriptionHari60% (5)

- 11 and 12 Litre Engines: en-GBDocument143 pages11 and 12 Litre Engines: en-GBKADİR50% (2)

- Scania P, G, S and R Series Workshop Manual - Removing The GearboxDocument16 pagesScania P, G, S and R Series Workshop Manual - Removing The GearboxEva Apriana100% (1)

- Ko OrdinatorDocument31 pagesKo Ordinatoruser100% (6)

- Air Suspention Work DescriptionDocument52 pagesAir Suspention Work DescriptionHari100% (1)

- SCANIA TCO Fault Codes DTCDocument12 pagesSCANIA TCO Fault Codes DTCfrank mutaleNo ratings yet

- enDocument44 pagesenRegistr Registr90% (10)

- Rocky WDocument2 pagesRocky Whenry vegaNo ratings yet

- 1624STK Parts ManualDocument40 pages1624STK Parts ManualGanesh SainavarapuNo ratings yet

- Assembly Drawing & Part ListDocument1 pageAssembly Drawing & Part ListCamila PenhaNo ratings yet

- Axle, Rear - Hub, Planetary - Prior To P.I.N. N8F203816Document2 pagesAxle, Rear - Hub, Planetary - Prior To P.I.N. N8F203816AlejandroNo ratings yet

- TSB201801001Document2 pagesTSB201801001Víctor FaríasNo ratings yet

- DESMI Pump NSLDocument1 pageDESMI Pump NSLgustavoNo ratings yet

- Copia de NovatyecnicaDocument6 pagesCopia de NovatyecnicaAlexander JoyaNo ratings yet

- Valve Body Adjustments 904Document4 pagesValve Body Adjustments 904Petar RutesicNo ratings yet

- Trabajo Semana 45 PH03Document195 pagesTrabajo Semana 45 PH03Derlis Diego Yaringaño PerezNo ratings yet

- Revised Main & SubfeederDocument255 pagesRevised Main & SubfeederRaven James Angelo IgnacioNo ratings yet

- 07 M Roller Rocker ArmDocument21 pages07 M Roller Rocker ArmDavid Vilca MamaniNo ratings yet

- Articles Powx1021 Manuals 03-Powx1021-EnDocument8 pagesArticles Powx1021 Manuals 03-Powx1021-EnHewa PCNo ratings yet

- Digital Angle Gauge CMTDocument2 pagesDigital Angle Gauge CMTorione1953No ratings yet

- Eim Ncii Lmg9 p147-217Document70 pagesEim Ncii Lmg9 p147-217LleojVanceAguasClava100% (3)

- Product Bulletin No. - TDS Top Drive Drilling SystemDocument10 pagesProduct Bulletin No. - TDS Top Drive Drilling Systemali rezaNo ratings yet

- Drainage Piping CalculationDocument2 pagesDrainage Piping CalculationfebousNo ratings yet

- Differential and Axle Shaft PDFDocument16 pagesDifferential and Axle Shaft PDFDaniel OlariNo ratings yet

- Reid Furniture Store: Monthly TransactionsDocument15 pagesReid Furniture Store: Monthly TransactionsMintNo ratings yet

- Instruction Sheet Is Ie2825 - Style Number Ie2825Bn:: Package ContentsDocument4 pagesInstruction Sheet Is Ie2825 - Style Number Ie2825Bn:: Package Contentsdayshift5No ratings yet

- Anchor Systems: Product & Application GuideDocument36 pagesAnchor Systems: Product & Application GuideMarko MiticNo ratings yet

- The List of Suitable Brush Cutter's Models by ManufacturerDocument1 pageThe List of Suitable Brush Cutter's Models by ManufacturerMPNo ratings yet

- Philips 14pv135-14pv235-14pv385Document87 pagesPhilips 14pv135-14pv235-14pv385doraemon007No ratings yet

- 01 06 PM P425 XP375 HP375 WcuDocument83 pages01 06 PM P425 XP375 HP375 WcuTony EspinalNo ratings yet

- 25d Double Searmer ManualDocument21 pages25d Double Searmer Manuallisya liputoNo ratings yet

- John Deere - Parts Catalog - MWDocument2 pagesJohn Deere - Parts Catalog - MWmaximNo ratings yet

- df100 InstructionDocument20 pagesdf100 InstructionFranco SNo ratings yet

- Pipes DataDocument69 pagesPipes DatafeNo ratings yet

- Original Spare Parts Manual ReferenceDocument104 pagesOriginal Spare Parts Manual ReferenceJorge Rivera100% (1)

- HR2651TDocument6 pagesHR2651TAnonymous vQewJPfVXaNo ratings yet

- WALTER Preisliste 2019Document370 pagesWALTER Preisliste 2019Armagan CakirNo ratings yet

- Parts List: JTR-MOL254/LBADocument74 pagesParts List: JTR-MOL254/LBAJoseNo ratings yet

- 23B Auto Trans OverhaulDocument75 pages23B Auto Trans OverhaulMichael YazonNo ratings yet

- Format LRPDocument31 pagesFormat LRPEduardi FauzieNo ratings yet

- Connectors For HELIAX® HJ8-50 Coaxial Cab - 0d - 0a LeDocument4 pagesConnectors For HELIAX® HJ8-50 Coaxial Cab - 0d - 0a LeAnonymous cDWQYsjd9No ratings yet

- Testing of Frost Free Ref. CompontntsDocument4 pagesTesting of Frost Free Ref. Compontntssantosh Indulkar100% (2)