Professional Documents

Culture Documents

Tube Benders PDF

Tube Benders PDF

Uploaded by

André Luiz Lopes da SilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tube Benders PDF

Tube Benders PDF

Uploaded by

André Luiz Lopes da SilvaCopyright:

Available Formats

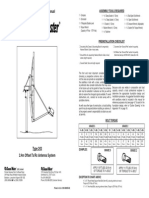

Instructions For Operating Lever Type Tube Benders

TB04, TB06, TB08

This bender can be used for bending steel, stainless steel, copper, aluminum and other metal tubing of bending

temper. Extremely thin walled and/or hard temper tubing should be avoided.

FORM HANDLE BENDER SETUP

USE THIS

MARK FOR

L

R

45

0

DEGREES

TUBE TUBING OF BEND

CLAMP

0 R L

45

0 0

45 45

90 FORM 90

135 WHEEL 135

180 180

PULL HANDLE THIS DIRECTION

FORM

WHEEL

HANDLE

1. Raise form handle. (Fig. 1)

2. Position tubing in groove as shown. FIGURE 1 FIGURE 2

Also be sure that the tube is engaged

with the tube clamp.

3. Lower the form handle to position 5. Degree of bend is indicated by mark on

shown. (Fig. 2) form handle and shown in Fig. 2. Bends

4. Pull lever handle to direction of arrow up to 180° can be made in one sweep of

until the desired bend is obtained. the handle.

FORM FORM

HANDLE HANDLE

TUBE

X CLAMP

USE “L” MARK

0 R L

45

0 R L

45

0 0

45 45

90 90 USE THIS MARK

135 135

180 180 X

FIGURE 5

FORM WHEEL FORM WHEEL

FIGURE 3 FIGURE 4

X X

90° Bends

45° Bends

1. Measure from end of tube (first bend) and place mark on tubing.

A single 45° bend may be made by measuring from end of tube to where

2. Position tube in bender as shown in Fig. 3. If the end from which you

bend is to be located and placing a mark at this point. Place tube in bender

measured is left of the tube clamp, the measured mark should be directly

so that the mark on tube is located directly in line with the “45” graduation

over graduation “L” located on the right side of the form lever and shown

on form handle shown in Fig. 6.

in Fig. 3.

3. If the end from which you measured is placed to the right clamp, set the

mark on the tube directly over graduation “R” located on the form lever and Double 45° or 30° offset Bends

shown in Fig. 4. With a steady motion, pull form lever handle around until When forming a tube offset, it is necessary to make two bends. It is important

the “0” mark on form handle is directly opposite the 90° mark on form wheel. to mark the tube at both bend locations before proceeding. After marking

4. If more than one bend is required (Fig. 5), measure from the center line the tube, proceed as explained under “45° BENDS”.

of the first bend leg and mark per drawing dimension. Proceed with bend

as described in Step 2.

Reed Manufacturing Company Phone: 800-666-3691 or 814-452-3691

1425 West 8th Street Fax: 800-456-1697 or 814-455-1697

Erie, PA 16502 USA www.reedmfgco.com

0413-56450

4 EASY STEPS FOR FIGURING OFFSET BENDS FOR TB04, TB06, TB08

X

USE “45”MARK MARK "A"

"X

BE DI "

TW MEN

EE SIO

OF N C N

0 R L

BE ENT

45

ND ER

0 S S

45

90 OFFSET MARK "B"

"Y"

180

135

DIMENSION

"Z"

DIMENSION

FIGURE

FIGURE 66 FIGURE 7

OFFSET BEND CALCULATOR

STEP 1 — Determine the total amount of offset required (dimension “Y” ANGLE OF OFFSET 30° ANGLE OF OFFSET 45°

in diagram) and angle of offset. Wherever possible use 45° offset bends. AMOUNT OF OFFSET AMOUNT OF OFFSET

This will enable you to figure the total amount of tubing required for a given (Y Dimension) (X Dimension) (Y Dimension) (X Dimension)

application as explained in section on How to Figure Length of Tubing 1 2 1 1-13/32

Required For 45° Offset Applications. -1/8 2-1/4 -1/8 1-19/32

-1/4 2-1/2 -1/4 1-25/32

STEP 2 — Figure the length of the tube which is needed to meet your offset -3/8 2-3/4 -3/8 1-15/16

requirements (X in dimension diagram) from table below. For example: -1/2 3 -1/2 2-1/8

The amount of offset you require (“Y” dimension, Step 1) is 2-1/2” and -5/8 3-1/4 -5/8 2-5/16

-3/4 3-1/2 -3/4 2-15/32

the offset angle is 45°. Check the 45° column and find 2-1/2”. The figure

-7/8 3-3/4 -7/8 2-21/32

next to this is the amount of tubing required for the offset bend you want

2 4 2 2-13/16

(“X” dimension). In this case it’s 3-17/32”.

-1/8 4-1/4 -1/8 3

-1/4 4-1/2 -1/4 3-3/16

STEP 3 — Determine where you want the center of the offset bend on the -3/8 4-3/4 -3/8 3-11/32

tube and make a reference mark (A). Now measure off the “X” dimension -1/2 5 -1/2 3-17/32

(determined in Step 2, example 3-17/32”) starting from the reference mark -5/8 5-1/4 -5/8 3-23/32

and make a second mark (B). You are now ready to make the bends. -3/4 5-1/2 -3/4 3-7/8

-7/8 5-3/4 -7/8 4-1/16

STEP 4 — Align mark (A) with reference mark 45° on bender and make 3 6 2 4-1/4

second bend in proper direction. -1/8 6-1/4 -1/8 4-13/32

-1/4 6-1/2 -1/4 4-19/32

NOTE: When the amount of offset exceeds what is listed on the table, -3/8 6-3/4 -3/8 4-25/32

choose an offset from the table which is multiple of the offset you need. -1/2 7 -1/2 4-15/16

Look this up on the table and multiply the “X” dimension by the multiple 3-5/8 7-1/4 3-5/8 5-1/8

-3/4 7-1/2 -3/4 5-1/16

you used. Example: For an offset of 20” for a 45° bend. Look up 5” offset

-7/8 7-3/4 -7/8 5-15/32

on the table in the 45° column and multiply “X” dimension (7-1/16”) by 4.

4 8 4 5-21/32

The resulting “X” dimension you would use is 28-1/4”.

-1/8 8-1/4 -1/8 5-27/32

-1/4 8-1/2 -1/4 6

-3/8 8-3/4 -3/8 6-3/16

-1/2 9 -1/2 6-3/8

-5/8 9-1/4 -5/8 6-17/32

-3/4 9-1/2 -3/4 6-23/32

-7/8 9-3/4 -7/8 6-29/32

5 10 5 7-1/16

-1/8 10-1/4 -1/8 7-1/4

-1/4 10-1/2 -1/4 7-7/16

-3/8 10-3/4 -3/8 7-19/32

-1/2 11 -1/2 7-25/32

-5/8 9-1/4 -5/8 7-31/32

-3/4 9-1/2 -3/4 8-1/8

-7/8 9-3/4 -7/8 8-5/16

6 12 6 8-15/16

NOTE: Keep bender and form handle grooves lubricated. Keep oil away from form wheel grooves.

Page 2 of 2

0413-56450

You might also like

- Sheet Metal Duct Layout BookDocument40 pagesSheet Metal Duct Layout BookRyan Murray77% (13)

- Copper Pipework BendingDocument2 pagesCopper Pipework BendingbendeniNo ratings yet

- Midea SERVICE MANUAL PDFDocument44 pagesMidea SERVICE MANUAL PDFAhmed Azad67% (3)

- Bending Race WaysDocument9 pagesBending Race Waysyomero1969No ratings yet

- Thrust Block and Anchor BlockDocument8 pagesThrust Block and Anchor Blockwikoboy50% (4)

- The Pochade and Wet Panel Carrier Do It Yourself PlanFrom EverandThe Pochade and Wet Panel Carrier Do It Yourself PlanRating: 4 out of 5 stars4/5 (1)

- EMT Conduit Bending Guide - Elliott Electric SupplyDocument2 pagesEMT Conduit Bending Guide - Elliott Electric SupplyManuel Da Silva100% (1)

- DIY Bench Top Tubing BenderDocument17 pagesDIY Bench Top Tubing BenderMalcolm DiamondNo ratings yet

- Chapter 7 Cycle Diagrams and The Simple Saturated Cycle - Page117Document18 pagesChapter 7 Cycle Diagrams and The Simple Saturated Cycle - Page117Ahmed AzadNo ratings yet

- Flammable Refrigerants SafetyDocument75 pagesFlammable Refrigerants SafetyAhmed AzadNo ratings yet

- Dobladores de TubingDocument19 pagesDobladores de TubingJuan Chan CanulNo ratings yet

- Bending MachineDocument2 pagesBending Machinesubbiah1986No ratings yet

- INS P 032, Axis AlignmentDocument5 pagesINS P 032, Axis AlignmentDeepakNo ratings yet

- Emt Bending: Done by Ismaa-Eel IbrahimDocument10 pagesEmt Bending: Done by Ismaa-Eel IbrahimIs IbrahimNo ratings yet

- Conduit Bender GuideDocument12 pagesConduit Bender Guideyomero1969100% (4)

- Parts & Service NewsDocument10 pagesParts & Service NewsJose A. Basanta H.No ratings yet

- Bending Spring LoadingDocument2 pagesBending Spring LoadingNisha NtaNo ratings yet

- Front and Rear SphereDocument4 pagesFront and Rear SphereRamalingam PrabhakaranNo ratings yet

- Modern Blanking and Piercing DiesDocument58 pagesModern Blanking and Piercing DiesMustafa Sert100% (4)

- Tube Bending SeminarDocument48 pagesTube Bending Seminarhopkhtn100% (1)

- Tecnolco Institute of Hvac Mep Nampally HYD.: Layout and Fabrication of Sheet-Metal and Fiber-Glass DuctDocument40 pagesTecnolco Institute of Hvac Mep Nampally HYD.: Layout and Fabrication of Sheet-Metal and Fiber-Glass DuctAnkush NayarNo ratings yet

- G1975 - Instruction ManualDocument36 pagesG1975 - Instruction ManualLeon GalindoNo ratings yet

- 600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)Document8 pages600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)LeonardNo ratings yet

- Calculating Length of Reinforcing BarsDocument3 pagesCalculating Length of Reinforcing BarsswarluNo ratings yet

- Power ScrewDocument37 pagesPower ScrewShikhar Saurav100% (1)

- BW FittingsDocument38 pagesBW FittingsTheo SeriyeNo ratings yet

- Lathe Milling Attach PlansDocument7 pagesLathe Milling Attach Plansdodgydonkey100% (1)

- Instruction Manual: TH-500 Tool HolderDocument28 pagesInstruction Manual: TH-500 Tool HolderDanijel MacakanjaNo ratings yet

- Handouts Trunking and Tray WorkDocument4 pagesHandouts Trunking and Tray WorkZi MingNo ratings yet

- Unit 11 Layout Work and Safety Issues: StructureDocument11 pagesUnit 11 Layout Work and Safety Issues: StructureakashkumardevNo ratings yet

- Agricultural Engineering in Development Advanced Blacksmithing A Training Manual Author J.B. StokesDocument96 pagesAgricultural Engineering in Development Advanced Blacksmithing A Training Manual Author J.B. StokesGabriel LourencoNo ratings yet

- Tilt TableDocument2 pagesTilt TablenikhilNo ratings yet

- Procedure For R1300, R1300G, R1600, and R1600G Load Haul Dump MachinesDocument6 pagesProcedure For R1300, R1300G, R1600, and R1600G Load Haul Dump Machinesjong sunNo ratings yet

- SP DP 40M InstDocument20 pagesSP DP 40M InstMarcos Sergio MirettiNo ratings yet

- Drill Grinding With The PP-U3 Grinder Copy of The Deckel SO GrinderDocument14 pagesDrill Grinding With The PP-U3 Grinder Copy of The Deckel SO GrinderAndy L100% (1)

- Hand Bender InstructionsDocument27 pagesHand Bender InstructionsenkntadoNo ratings yet

- Conduit BendDocument11 pagesConduit Bendngyan100% (1)

- Kbu KBZ6Document4 pagesKbu KBZ6Andrew VNo ratings yet

- Channel Master 2-4m ManualDocument9 pagesChannel Master 2-4m ManualWilfredo AriasNo ratings yet

- Kiln DriveDocument83 pagesKiln DriveMohammed BNo ratings yet

- INS-P-033, Axis Alignment W-O RotationDocument7 pagesINS-P-033, Axis Alignment W-O RotationDeepakNo ratings yet

- United States Patent (191: SheppardDocument7 pagesUnited States Patent (191: SheppardandreNo ratings yet

- A Conduit Bending Guide On How To Bend An OffsetDocument6 pagesA Conduit Bending Guide On How To Bend An OffsetedgarNo ratings yet

- Power - Screw (Compatibility Mode)Document37 pagesPower - Screw (Compatibility Mode)Satyajit RoyNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Practical Stair Building and Handrailing: By the square section and falling line systemFrom EverandPractical Stair Building and Handrailing: By the square section and falling line systemNo ratings yet

- Watch and Clock Escapements A Complete Study in Theory and Practice of the Lever, Cylinder and Chronometer Escapements, Together with a Brief Account of the Origin and Evolution of the Escapement in HorologyFrom EverandWatch and Clock Escapements A Complete Study in Theory and Practice of the Lever, Cylinder and Chronometer Escapements, Together with a Brief Account of the Origin and Evolution of the Escapement in HorologyNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Mode NG I 111116Document68 pagesMode NG I 111116Ahmed AzadNo ratings yet

- 121 DC Circuits E104A Course Outline V2Document8 pages121 DC Circuits E104A Course Outline V2Ahmed AzadNo ratings yet

- IPM TroubleshootingDocument1 pageIPM TroubleshootingAhmed Azad100% (2)

- Correction of Service Manual Si-18 M-11011Document18 pagesCorrection of Service Manual Si-18 M-11011Ahmed AzadNo ratings yet

- Priceguide Section 7 2015Document18 pagesPriceguide Section 7 2015Ahmed AzadNo ratings yet

- Guide To Good Commercial Refrigeration Practice: Safety & Environmental Considerations & StandardsDocument20 pagesGuide To Good Commercial Refrigeration Practice: Safety & Environmental Considerations & StandardsAhmed AzadNo ratings yet

- Split Air Conditioner TrainerDocument2 pagesSplit Air Conditioner TrainerAhmed AzadNo ratings yet

- Commercial Dehumidifier ManualDocument10 pagesCommercial Dehumidifier ManualAhmed AzadNo ratings yet

- Chart Metric Imp ConvDocument1 pageChart Metric Imp ConvAhmed AzadNo ratings yet

- Ben 3proj3 RevDocument6 pagesBen 3proj3 RevAhmed AzadNo ratings yet

- Sound Insulation EngDocument8 pagesSound Insulation EngAhmed AzadNo ratings yet

- 00Document60 pages00Ahmed AzadNo ratings yet

- Johnson-Controls Informatiebrochure p216 enDocument8 pagesJohnson-Controls Informatiebrochure p216 enAhmed AzadNo ratings yet

- Unit 10Document14 pagesUnit 10Ahmed AzadNo ratings yet