Professional Documents

Culture Documents

Low Hydrogen Electrode Baking

Uploaded by

nksCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Low Hydrogen Electrode Baking

Uploaded by

nksCopyright:

Available Formats

BAKING OVEN/MOTHER OVEN>> This is the main oven where baking temperature

(as recommended by manufacturer) will be set to perform baking. It takes some time to

rise the temperature from ambient to Baking Range. Baking time will be considered after

reaching the baking temp.

HOLDING OVEN >> Baking cannot be continued beyond recommendation period. So

there should be one more oven to hold the electrode after baking at 1000c & this oven will

be on line continuously. Excess & returned electrodes will be kept in this oven for the use

in next time.

PORTABLE OVEN>> This is used to carry electrode from baking/holding oven to job site

& during welding operation at job site. This oven will be on line continuously at site.

Electrode can be kept in holding when welding activity is not going on for some time at

site. Required temperature to be maintained in this oven is 650C minimum. Cover of

portable oven to be kept closed to reduce heat radiation.

BAKING PROCEDURE:

Only QC passed/Client approved electrodes are subject to baking. Electrodes will be placed

inside the baking oven/Mother oven. Baking Time will be noted after rising the baking

temperature only. Baking will be carried out at 2500C - 3000C or (manufacturer’s

recommendation) for 01 Hr or as per manufacturer’s recommendation. After Baking

electrodes shall be shifted to holding oven.

The Baking oven & Holding oven shall be calibrated yearly & verified randomly to ensure

proper working condition.

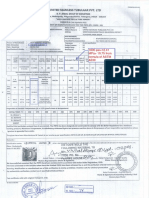

A logbook shall be maintained to cover all relevant parameters involved in the baking of

electrodes. This shall include electrode class / batch no / size / quantity / baking in time,

baking out time, quantity returned etc.

Electrodes shall be properly kept in the sealed cartons until required for baking.

When using different types of electrodes, they shall be segregated carefully with proper

identification in the oven.

A thermostat-set to the specified range shall properly control the drying oven while in

service.

You might also like

- Heat Treatment of Thin Wall Tanks by Internal Oil Firing MethodDocument7 pagesHeat Treatment of Thin Wall Tanks by Internal Oil Firing MethodKrishna VachaNo ratings yet

- Material Test Certificate: For: Priminox OverseasDocument2 pagesMaterial Test Certificate: For: Priminox OverseasDSAFNo ratings yet

- 4620D Test Report (For Thickness AA15)Document2 pages4620D Test Report (For Thickness AA15)weiiiiiNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- Thermal Power Project Weld Inspection ReportDocument1 pageThermal Power Project Weld Inspection ReportAshwani DograNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless PipeashokkahirwarNo ratings yet

- Epoxy Primer for Corrosion ProtectionDocument2 pagesEpoxy Primer for Corrosion ProtectionsreeNo ratings yet

- Purchase Spec. For Tubes (Sa789 S31803)Document6 pagesPurchase Spec. For Tubes (Sa789 S31803)Daison PaulNo ratings yet

- CV Mechanical Engineer with Extensive Experience in Oil & Gas ProjectsDocument3 pagesCV Mechanical Engineer with Extensive Experience in Oil & Gas Projectshamza brahmiNo ratings yet

- Rockwool Insulation LRB MatressDocument1 pageRockwool Insulation LRB MatressJaveed KhanNo ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- Guide For Internal Audit and Management Review For Conformity Assessment Bodies (Laboratories / PTP / RMP)Document26 pagesGuide For Internal Audit and Management Review For Conformity Assessment Bodies (Laboratories / PTP / RMP)karthikkanda100% (1)

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Test Certificate AnalysisDocument1 pageTest Certificate AnalysisSagar KumarNo ratings yet

- The NEW Company ProfileDocument26 pagesThe NEW Company ProfilewisandhaNo ratings yet

- Zhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Document1 pageZhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Sales HBS SolutionsNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- ISO 9001 Certified Stainless Steel Fastener Manufacturer Test CertificateDocument16 pagesISO 9001 Certified Stainless Steel Fastener Manufacturer Test CertificateSales ITANo ratings yet

- Specification SRE-004-SFBDocument1 pageSpecification SRE-004-SFBvictorNo ratings yet

- ST 37Document7 pagesST 37rendra.farisrNo ratings yet

- Welding Inspection ReportDocument1 pageWelding Inspection ReportbimboNo ratings yet

- Helium leak test procedureDocument7 pagesHelium leak test procedureChandrasekhar mishraNo ratings yet

- Sample Report AudioDocument33 pagesSample Report AudioraulNo ratings yet

- Area Handover FormDocument1 pageArea Handover FormsivagaaneshNo ratings yet

- STD-InSP-0007 (Fitting Inspection Report)Document3 pagesSTD-InSP-0007 (Fitting Inspection Report)airbroomNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- TDC-10B Heat Treatment For C12A Steel CastingsDocument2 pagesTDC-10B Heat Treatment For C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- Form UT, MT, PT, RTDocument5 pagesForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Quality Assurance and QA PlansDocument13 pagesQuality Assurance and QA PlansAKHIL JOSEPH100% (1)

- 1 MTCDocument2 pages1 MTCRazvan CristeaNo ratings yet

- Asme 1325-18 (2007)Document1 pageAsme 1325-18 (2007)Matthew TaylorNo ratings yet

- Ovality Limits Cylindrical ShellsDocument4 pagesOvality Limits Cylindrical ShellsDeepakNo ratings yet

- Material Product Data SheetDocument4 pagesMaterial Product Data SheethungNo ratings yet

- Esab Buddy TIG400iDocument2 pagesEsab Buddy TIG400iJeganeswaranNo ratings yet

- Inspection CertificateDocument1 pageInspection CertificateAtanasio PerezNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- RTC-161-MIR-A-ID-174 - R0 - B Off Site Material Inspection Request For Free Standing Bathtub 21095T-0 (Option 2) From KHALID CORPORATIONDocument7 pagesRTC-161-MIR-A-ID-174 - R0 - B Off Site Material Inspection Request For Free Standing Bathtub 21095T-0 (Option 2) From KHALID CORPORATIONeslam100% (2)

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Raw Material MTC - API 5L GR B PSL 2Document3 pagesRaw Material MTC - API 5L GR B PSL 2ClarkFedele27No ratings yet

- 6063 Aluminum Alloy PropertiesDocument1 page6063 Aluminum Alloy Propertiestrieu vy phamNo ratings yet

- 21.02.15 Tuv Visit ReportDocument5 pages21.02.15 Tuv Visit ReportssmullaNo ratings yet

- MTC Sample Dia 36 Inch Heat 639914 4130Document2 pagesMTC Sample Dia 36 Inch Heat 639914 4130emadabdelsattarNo ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Astm A36 Chapa Grossa Ate 19mm PDFDocument1 pageAstm A36 Chapa Grossa Ate 19mm PDFHugo RodriguezNo ratings yet

- DIN EN Afnor/Air BS Mks or Jus Designation W.Nr. DesignationDocument24 pagesDIN EN Afnor/Air BS Mks or Jus Designation W.Nr. DesignationAndriana IlievskaNo ratings yet

- Assure Solutions: Hydro Test ReportDocument1 pageAssure Solutions: Hydro Test ReportKailas NimbalkarNo ratings yet

- CF8M VS CF8 Stainless Steel Casting - JC CastingDocument7 pagesCF8M VS CF8 Stainless Steel Casting - JC CastingSHivaprasad APITNo ratings yet

- TubacexDocument1 pageTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorNo ratings yet

- Attachment 22 - (SECL-PIP026) Welding Consumable Issue SlipDocument5 pagesAttachment 22 - (SECL-PIP026) Welding Consumable Issue SlipRjeb mohamedNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- Is 2062 - E250 Vs Is-1367 ComparisonDocument2 pagesIs 2062 - E250 Vs Is-1367 ComparisonDevang JaniNo ratings yet

- En 8Document3 pagesEn 8ajaykrishnaaNo ratings yet

- Instructions For Installation and Use: 60 CM Slot-In CookersDocument33 pagesInstructions For Installation and Use: 60 CM Slot-In CookerscancuniaNo ratings yet

- Ut2 PDFDocument1 pageUt2 PDFnksNo ratings yet

- Ut1 PDFDocument1 pageUt1 PDFnksNo ratings yet

- Quality QuizDocument2 pagesQuality QuiznksNo ratings yet

- Quality QuizDocument2 pagesQuality QuiznksNo ratings yet

- Low Hydrogen Electrode BakingDocument1 pageLow Hydrogen Electrode BakingnksNo ratings yet

- Procedure For Steel Structure: Fabrication & ErectionDocument2 pagesProcedure For Steel Structure: Fabrication & ErectionnksNo ratings yet

- Paint CautionDocument1 pagePaint CautionnksNo ratings yet

- MANUAL CLEANING Identified Members Can Be Manually CleanedDocument1 pageMANUAL CLEANING Identified Members Can Be Manually CleanednksNo ratings yet

- Low Hydrogen Electrode BakingDocument1 pageLow Hydrogen Electrode BakingnksNo ratings yet

- Painting ProcedureDocument1 pagePainting ProcedurenksNo ratings yet

- Painting PDFDocument1 pagePainting PDFnksNo ratings yet

- Electrode BakingDocument1 pageElectrode BakingnksNo ratings yet

- Welding Control 2Document1 pageWelding Control 2nksNo ratings yet

- Bake Electrodes at Precise Temps for 1 HourDocument1 pageBake Electrodes at Precise Temps for 1 HournksNo ratings yet

- Bake Electrodes at Precise Temps for 1 HourDocument1 pageBake Electrodes at Precise Temps for 1 HournksNo ratings yet

- Welding ControlDocument1 pageWelding ControlnksNo ratings yet

- RT Film Developing TimeDocument1 pageRT Film Developing TimenksNo ratings yet

- Welding ControlsDocument1 pageWelding ControlsnksNo ratings yet