Professional Documents

Culture Documents

Curriculum Guide Carpentry PDF

Curriculum Guide Carpentry PDF

Uploaded by

NORMAN BREGENTEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Curriculum Guide Carpentry PDF

Curriculum Guide Carpentry PDF

Uploaded by

NORMAN BREGENTECopyright:

Available Formats

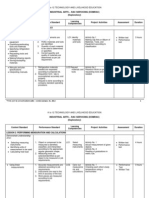

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – CARPENTRY

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

LESSON 1: PREPARING CONSTRUCTION MATERIALS AND TOOLS

Demonstrate understanding

of/on:

• Types and uses of 1. Tools and materials are LO1. Identify 1. Enumerating and describing • Written test 6 hours

construction materials identified as per job materials and the tools and materials used • Performance

• Kinds of carpentry tools requirements. tools in carpentry works. test

• Description of materials 2. Tools are classified according applicable for

and tools to their functions per job a specific

• Listing of materials as requirements. construction

per company standards. 3. Materials are classified job.

. according to their uses in a

specific construction project.

4. Tools and materials are

selected per job requirement.

• Different forms 1. Needed materials and tools LO2. Request 1. Fill up necessary forms as • Written test 3 hours

• Job order slip are listed as per job appropriate per job requirement. • Performance

• Tools and materials requirement. materials and test

requisition slip 2. Materials and tools are tools.

• Borrower’s slip requested according to the list

• Requisition procedures prepared.

• Use of hand tools 3. Requests are done as per

company’s standard operating

procedures (SOP).

4. Materials and tools are

substituted and provided for

unavailable ones without

sacrificing cost and quality of

work.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 1

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – CARPENTRY

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

• Procedures in receiving 1. Materials and tools as per LO3. Receive 1. Writing the possible defects • Written test 2 hours

tools and materials quantity and specification based and inspect and/or damages of • Performance

• Proper inspection of tools on requisition are received and materials materials and tools used in test

and materials received. inspected. carpentry.

• Proper handling of tools 2. Tools and materials are

and materials. checked for damages and

manufacturing defects.

3. Materials and tools received are

handled with appropriate safety

devices.

4. Materials and tools are stored in

aside to appropriate locations

nearest the workplace.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 2

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – CARPENTRY

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

LESSON 2: MAINTAINING TOOLS AND EQUIPMENT

Demonstrate understanding

of/on:

• Types of Tools and 1. Tools and equipment are LO1. Check 1. Performing the actual • Performance 3 hours

Equipment identified according to condition of segregation of functional test

• Classification of functional classification/specification and tools and and non-functional tools and • Written test

and non-functional tools job requirements. equipment. equipment.

• Uses of Personal 2. Functional and non-functional

Protective Equipment tools and equipment are

(PPE). segregated and labeled

according to classification.

3. Safety of tools and equipment

are observed in accordance

with manufacturer’s

instructions.

4. Conditions of PPE are

checked in accordance with

manufacturer’s instructions.

• Types and uses of 1. Lubricants are identified LO2. Perform basic 1. Performing the proper • Written test 4 hours

lubricants according to types of preventive selection and application of • Performance

• Types and uses of equipment. maintenance. lubricants used for test

cleaning 2. Tools and equipment are preventive maintenance.

materials/solvent lubricated according to

• Types and uses of preventive maintenance

measuring instruments schedule or manufacturer’s

and equipment. specifications.

• Preventive maintenance 3. Measuring instruments are

techniques and checked and calibrated in

procedures accordance with

*TWG on K to 12 Curriculum Guide – version January 31, 2012 3

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – CARPENTRY

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

• OSHC workplace manufacturer’s instructions.

regulations 4. Tools are cleaned and

lubricated according to

standard procedures.

5. Defective equipment and tools

are inspected and replaced

according to manufacturer’s

specification.

6. Work place is cleaned and

kept in safe state in line with

OSHC regulations

• Inventory of tools and 1. Inventory of tools, LO3. Store tools 1. Applying proper storing of • Written test 2 hours

equipment instruments, and equipment and tools. • Performance

• Tools and equipment are conducted and recorded equipment. test

handling as per company practices.

• Tool safe- 2. Tools are inspected and

keeping/storage replaced after use.

3. Tools and equipment are

stored safely in accordance

with manufacturer’s

specifications or company

procedures.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 4

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – CARPENTRY

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

LESSON 3: PERFORM MENSURATION AND CALCULATION

Demonstrate understanding

of/on:

• Measuring instruments 1. Measuring tools are LO1. Select 1. Demonstrating the proper • Actual 2 hours

and tools selected/identified as per measuring handling of measuring tools. demonstration

• Proper handling of object to be measured or job instruments. • Direct

measuring instruments requirements. observation

2. Correct specifications are • Written

obtained from relevant test/questioning

sources.

3. Measuring instruments are

selected according to job

requirements.

4. Alternative measuring tools are

used without sacrificing cost

and quality of work.

5. Measurements are obtained

according to job requirements.

• Kinds of measurement 6. Accurate measurements are LO2. Carry out 1. Measuring lengths, width, • Written Test 4 hours

• Dimensions obtained according to job measurement and thickness of pieces of • Performance

• Ratio and proportion requirements. and wood. Test

• Conversion 7. Work pieces are measured calculations.

according to job requirements

*TWG on K to 12 Curriculum Guide – version January 31, 2012 5

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – CARPENTRY

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

LESSON 4: INTERPRETING DRAWINGS AND PLANS

Demonstrate understanding

of/on:

• Drawing symbols and 1. Signs, symbols, and data are LO1. Analyze signs, 1. Drawing and describing the • Written test 4 hours

signs identified according to job symbols, and different signs and symbols • Performance

specifications. data. used in the project plans. test

2. Signs, symbols, and data are

determined according to

classification or

appropriateness in drawing.

• Basic technical drawing 1. Necessary tools, materials, LO2. Interpret 1. Explaining the specific uses • Performance 2 hours

• Technical plans and and equipment are identified technical of lines in the drawing. test

schematic diagram according to the plan. drawings and • Written test

2. Components, assemblies or plans.

object are recognized as per

job requirement.

3. Dimensions and

specifications are identified

according to job

requirements.

• Correct freehand 4. Correct freehand sketching is LO3. Apply freehand 2. Demonstrating freehand • Performance

sketching produced in accordance with sketching sketching test

the job requirements • Written test

*TWG on K to 12 Curriculum Guide – version January 31, 2012 6

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – CARPENTRY

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

LESSON 5: PRACTICING OCCUPATIONAL HEALTH AND SAFETY PROCEDURES

Demonstrate understanding

of/on:

• Hazards and risks 1. Workplace hazards and risks LO1. Identify 1. Listing down the possible • Performance

identification and control are identified and clearly hazards and hazards and risks common test

• Organizational safety and explained. risks. in the workplace. • Written test

health protocol 2. Hazards/risks and their

• Threshold limit value corresponding indicators are

(TLV) identified in accordance with

• OHS indicators the company procedures.

3. Contingency measures are

recognized and established in

accordance with organizational

procedures.

• TLV table 1. Terms of maximum tolerable LO2. Evaluate 1. Writing some possible • Performance

• Philippine OHS standards limits are identified based on hazards and remedies of known hazards test

• Effects of hazards in the threshold limit values (TLV) risks. and risks in the workplace • Written test

workplace 2. Effects of hazards are

• Ergonomics determined.

• ECC Regulations 4. OHS issues and concerns are

identified in accordance with

workplace requirements and

relevant workplace OHS

legislation.

• Safety regulations 1. OHS procedures for controlling LO3. Control 1. Writing the importance of • Written test 4 hours

Clean air act hazards and risks are strictly hazards and knowing the hazardous and • Performance

Electrical and fire followed. risks. risky objects/fixtures in the test

safety code workplace.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 7

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – CARPENTRY

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

Waste management 2. Procedures in dealing with

Disaster preparedness workplace accidents, fire, and

and management emergencies are followed in

• Contingency measures accordance with the

and procedures organization’s OHS policies.

3. Personal protective equipment

(PPE) is correctly used in

accordance with organization’s

OHS procedures and

practices.

4. Procedures in providing

appropriate assistance in the

event of workplace

emergencies are identified in

line with the established

organizational protocol.

• Operational health and 1. Procedures in emergency LO4. Maintain 1. Explain the advantages of • Written test 3 hours

safety procedures, related drill are strictly followed occupational practicing safety • Performance

practices, and regulations in line with the established health and precautions in the work test

• Emergency-related drills organizational guidelines and safety area.

and training procedures. awareness.

2. OHS personal records are

filled up in accordance with

workplace requirement

3. PPEs are maintained in line

with organizational guidelines

and procedures.

39 hours

*TWG on K to 12 Curriculum Guide – version January 31, 2012 8

You might also like

- Chemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignFrom EverandChemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignRating: 4 out of 5 stars4/5 (16)

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (4)

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationFrom EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationRating: 5 out of 5 stars5/5 (1)

- Tle Plumbing LMDocument131 pagesTle Plumbing LMAdrian Goze Reformina93% (14)

- Hot Works Risk AssessmentDocument5 pagesHot Works Risk AssessmentBilal100% (2)

- Maintain Tools and EquipmentDocument23 pagesMaintain Tools and Equipmentray100% (1)

- Mensuration and CalculationDocument35 pagesMensuration and CalculationValcy Madz100% (3)

- Materials Enabled Designs: The Materials Engineering Perspective to Product Design and ManufacturingFrom EverandMaterials Enabled Designs: The Materials Engineering Perspective to Product Design and ManufacturingRating: 4 out of 5 stars4/5 (1)

- Assess Notes Nursing AssessmentDocument206 pagesAssess Notes Nursing Assessmenttostc100% (7)

- HandbookDocument60 pagesHandbookyachiru121No ratings yet

- Painting Job Hazard AnalysisDocument2 pagesPainting Job Hazard Analysisisaacjoe77100% (1)

- Deped K To 12 Technology and Livelihood Education - MasonryDocument8 pagesDeped K To 12 Technology and Livelihood Education - Masonryyachiru121No ratings yet

- Deped K To 12 Technology and Livelihood Education - PlumbingDocument8 pagesDeped K To 12 Technology and Livelihood Education - Plumbingyachiru12175% (4)

- Deped K To 12 Technology and Livelihood Education - Tile SettingDocument9 pagesDeped K To 12 Technology and Livelihood Education - Tile Settingyachiru121100% (1)

- Deped K To 12 Technology and Livelihood Education - Mechanical DrawingDocument5 pagesDeped K To 12 Technology and Livelihood Education - Mechanical Drawingyachiru121100% (5)

- Deped K To 12 Technology and Livelihood Education - SmawDocument6 pagesDeped K To 12 Technology and Livelihood Education - Smawyachiru121No ratings yet

- Deped K To 12 Technology and Livelihood Education - EimDocument8 pagesDeped K To 12 Technology and Livelihood Education - Eimyachiru121100% (2)

- Deped K To 12 Technology and Livelihood Education - DomracDocument6 pagesDeped K To 12 Technology and Livelihood Education - Domracyachiru121No ratings yet

- Deped K To 12 Technology and Livelihood Education - Bread and Pastry Production - 001Document7 pagesDeped K To 12 Technology and Livelihood Education - Bread and Pastry Production - 001yachiru12183% (6)

- Deped K To 12 Technology and Livelihood Education - Novelty CraftsDocument6 pagesDeped K To 12 Technology and Livelihood Education - Novelty Craftsyachiru12167% (3)

- Deped K To 12 Technology and Livelihood Education - Household ServicesDocument6 pagesDeped K To 12 Technology and Livelihood Education - Household Servicesyachiru12191% (11)

- Deped K To 12 Technology and Livelihood Education - Nail CareDocument6 pagesDeped K To 12 Technology and Livelihood Education - Nail Careyachiru12175% (4)

- Unit of Competency: Prepare Construction Materials and Tools Code: Module Title: Preparing Construction Materials and ToolsDocument19 pagesUnit of Competency: Prepare Construction Materials and Tools Code: Module Title: Preparing Construction Materials and ToolsEva MarquezNo ratings yet

- Deped K To 12 Technology and Livelihood Education - Tailoring DressmakingDocument5 pagesDeped K To 12 Technology and Livelihood Education - Tailoring Dressmakingyachiru121100% (1)

- Deped K To 12 Technology and Livelihood Education - Computer Hardware ServicingDocument7 pagesDeped K To 12 Technology and Livelihood Education - Computer Hardware Servicingyachiru121100% (4)

- Deped K To 12 Technology and Livelihood Education - Agri-CropsDocument7 pagesDeped K To 12 Technology and Livelihood Education - Agri-Cropsyachiru12193% (14)

- Deped K To 12 Technology and Livelihood Education - Commercial CookingDocument5 pagesDeped K To 12 Technology and Livelihood Education - Commercial Cookingyachiru121100% (7)

- Learning OutcomeDocument32 pagesLearning Outcomeivyjeanladlada20No ratings yet

- TG in PC Hardware ServicingDocument5 pagesTG in PC Hardware ServicingZel Ocampo TuazonNo ratings yet

- K To 12 CG - Pchs - v1.0Document5 pagesK To 12 CG - Pchs - v1.0Shaira Lhoan C. ReyesNo ratings yet

- CG Animal ProductionDocument5 pagesCG Animal ProductionFrancis A. BuenaventuraNo ratings yet

- Budget of Work G 7-8Document7 pagesBudget of Work G 7-8Marites Jolongbayan FloresNo ratings yet

- Deped K To 12 Technology and Livelihood Education - Care GivingDocument14 pagesDeped K To 12 Technology and Livelihood Education - Care Givingyachiru121100% (1)

- PLM NC II CommonDocument133 pagesPLM NC II CommonRegie Dumaran CubaNo ratings yet

- Heavy Equipment Servicing (Mechanical) NC IIDocument63 pagesHeavy Equipment Servicing (Mechanical) NC IIMichael Cancho100% (2)

- Deped K To 12 Technology and Livelihood Education - AquacultureDocument7 pagesDeped K To 12 Technology and Livelihood Education - Aquacultureyachiru121No ratings yet

- CPCCSF2003A Cut and Bend Materials Using Oxy LPG Equipment LR V1Document141 pagesCPCCSF2003A Cut and Bend Materials Using Oxy LPG Equipment LR V1FfdsfdsNo ratings yet

- K To 12 CG - Nail Care - v1.0Document5 pagesK To 12 CG - Nail Care - v1.0Levi Lico PangilinanNo ratings yet

- Common 4 PipefittingDocument29 pagesCommon 4 PipefittingValcy Madz100% (1)

- Deped K To 12 Technology and Livelihood Education - HorticultureDocument5 pagesDeped K To 12 Technology and Livelihood Education - Horticultureyachiru121No ratings yet

- TESDADocument77 pagesTESDAsarcastically-yours100% (1)

- Carpentry LessonDocument118 pagesCarpentry LessonJessica RebodosNo ratings yet

- PTS Module - Common - Uc1Document10 pagesPTS Module - Common - Uc1mariaestercampos22No ratings yet

- Ict - Computer Hardware Servicing CGDocument4 pagesIct - Computer Hardware Servicing CGnganodiliman100% (1)

- K To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Document14 pagesK To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Bri CorpuzNo ratings yet

- Plumbing Y2Document67 pagesPlumbing Y2Cygie Gador100% (1)

- Mecha Perform CalculationsDocument8 pagesMecha Perform CalculationsvorexxetoNo ratings yet

- Y2 - Module 1 - Preparing Plumbing Materials and ToolsDocument35 pagesY2 - Module 1 - Preparing Plumbing Materials and ToolsMichael ReyesNo ratings yet

- Practical Project Management: Learning to Manage the Professional, Second EditionFrom EverandPractical Project Management: Learning to Manage the Professional, Second EditionRating: 2.5 out of 5 stars2.5/5 (2)

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Guidelines to make your own SOP (Standard Operating Procedure)): 1, #1From EverandGuidelines to make your own SOP (Standard Operating Procedure)): 1, #1No ratings yet

- Cape Communication Studies: Practical Exercises for Paper 02 EssaysFrom EverandCape Communication Studies: Practical Exercises for Paper 02 EssaysNo ratings yet

- ISO IEC 27001 Lead Implementer A Complete Guide - 2020 EditionFrom EverandISO IEC 27001 Lead Implementer A Complete Guide - 2020 EditionNo ratings yet

- Construction Supervisor II: Passbooks Study GuideFrom EverandConstruction Supervisor II: Passbooks Study GuideNo ratings yet

- Bacteriology ReviewDocument47 pagesBacteriology ReviewDeti ParidlahNo ratings yet

- Anatomy and Physiology I Fall 2009 Exam I Study GuideDocument1 pageAnatomy and Physiology I Fall 2009 Exam I Study Guideyachiru121No ratings yet

- API Review Muscles f2009Document1 pageAPI Review Muscles f2009yachiru121No ratings yet

- AP Review NotesDocument15 pagesAP Review Notesyachiru121No ratings yet

- Anatomy Lower Extr ReviewDocument12 pagesAnatomy Lower Extr Reviewabuzeid5No ratings yet

- Bones of The Upper LimbDocument14 pagesBones of The Upper Limbyachiru121No ratings yet

- Anatomy Levels and Planes ReviewDocument3 pagesAnatomy Levels and Planes Revieware4erNo ratings yet

- Anatomy Thorax ReviewDocument18 pagesAnatomy Thorax Reviewyachiru121No ratings yet

- Bones of The Pelvis and PerineumDocument6 pagesBones of The Pelvis and Perineumyachiru121No ratings yet

- Anatomy Tables - Bones of The Thorax: Bone Structure Description Notes RibDocument3 pagesAnatomy Tables - Bones of The Thorax: Bone Structure Description Notes Ribyachiru121No ratings yet

- Bones of The Back RegionDocument9 pagesBones of The Back Regionyachiru121No ratings yet

- Anatomy Head ReviewDocument34 pagesAnatomy Head ReviewJordan BrooksNo ratings yet

- First Aid ManualDocument225 pagesFirst Aid ManualHugo MartinsNo ratings yet

- Bones of The Abdominal RegionDocument7 pagesBones of The Abdominal Regionyachiru121No ratings yet

- DEPED 2012 - K TO 12 - MTB RationaleDocument30 pagesDEPED 2012 - K TO 12 - MTB Rationaleyachiru121100% (3)

- Anatomy and Physiology Unit III: Objectives/RationaleDocument16 pagesAnatomy and Physiology Unit III: Objectives/Rationaleyachiru121No ratings yet

- Bones and Cartilages of The Head and NeckDocument27 pagesBones and Cartilages of The Head and Neckyachiru121100% (1)

- Bones of The Lower LimbDocument15 pagesBones of The Lower Limbyachiru121No ratings yet

- DEPED 2012 - Classroom DR VillanezaDocument17 pagesDEPED 2012 - Classroom DR Villanezayachiru121100% (1)

- HandbookDocument48 pagesHandbookyachiru121100% (1)

- DEPED 2012 - K TO 12 - Learning DR VillanezaDocument32 pagesDEPED 2012 - K TO 12 - Learning DR Villanezayachiru121100% (1)

- DEPED - K To 12 Assessment & Rating - 2012Document44 pagesDEPED - K To 12 Assessment & Rating - 2012yachiru121No ratings yet

- DEPED 2012 - K TO 12 - L1-L2-L3-Dr. GironDocument56 pagesDEPED 2012 - K TO 12 - L1-L2-L3-Dr. Gironyachiru121No ratings yet

- HandbookDocument53 pagesHandbookyachiru121No ratings yet

- DEPED - The K To 12 Basic Education Programv2 - 2012Document38 pagesDEPED - The K To 12 Basic Education Programv2 - 2012yachiru121100% (1)

- GHCPregistrationform 2012Document1 pageGHCPregistrationform 2012yachiru121No ratings yet

- Safety and Health PolicyDocument10 pagesSafety and Health Policynurul lovelymineNo ratings yet

- Ficha Tecnica de Mobilarma 798Document14 pagesFicha Tecnica de Mobilarma 798Iker Astigarraga EpeldeNo ratings yet

- Leachaid Ul: Section 1 - Chemical and Product and Company InformationDocument4 pagesLeachaid Ul: Section 1 - Chemical and Product and Company InformationJose AndradeNo ratings yet

- Gas Innovations Liquefied Natural Gas LNG SDS 12.07.2018 1 PDFDocument7 pagesGas Innovations Liquefied Natural Gas LNG SDS 12.07.2018 1 PDFadershNo ratings yet

- GUIDELINES ON SURGICAL MANAGEMENT OF SUSPECTED OR CONFIRMED COVID-19 Annex 22Document10 pagesGUIDELINES ON SURGICAL MANAGEMENT OF SUSPECTED OR CONFIRMED COVID-19 Annex 22nurul fatma diyanaNo ratings yet

- TM 1-1500-344-23-3Document152 pagesTM 1-1500-344-23-3"Rufus"No ratings yet

- Safety Data Sheet Clean & SmoothDocument7 pagesSafety Data Sheet Clean & SmoothSarah Jane BroñolaNo ratings yet

- NEWAGE STAMFORD AvK Alternator Service Guide Rev06 2020Document88 pagesNEWAGE STAMFORD AvK Alternator Service Guide Rev06 2020morus100% (1)

- 3rd Party Guidelines HCCBPLDocument8 pages3rd Party Guidelines HCCBPLYashVanth Kumar NagarajaiahNo ratings yet

- 4th Periodical TestDocument3 pages4th Periodical TestShellane Blanco SarduaNo ratings yet

- BENZENE: Shell MSDS (2011)Document15 pagesBENZENE: Shell MSDS (2011)HeavenL77No ratings yet

- Commissioning CleanerDocument5 pagesCommissioning CleanerJezrell JaravataNo ratings yet

- Omala MSDSDocument4 pagesOmala MSDSmevansmetreelNo ratings yet

- Welding CatalogueDocument44 pagesWelding Catalogueyudistira bataviapcNo ratings yet

- Loctite LB 8008 C%-ADocument13 pagesLoctite LB 8008 C%-AAbdelrhman AlaaNo ratings yet

- Clyde-Savannah CSD School 2020 Reopening PlanDocument53 pagesClyde-Savannah CSD School 2020 Reopening PlanNews 8 WROCNo ratings yet

- Qhse 100-Day Implementation and Certification Plan With Myeasyiso Task No. Task Main Module Sub-Modules Timelin EsDocument7 pagesQhse 100-Day Implementation and Certification Plan With Myeasyiso Task No. Task Main Module Sub-Modules Timelin EsElias JarjouraNo ratings yet

- Flygt IOM 3153-095Document72 pagesFlygt IOM 3153-095jose03No ratings yet

- LD04817 - Super Hartolan-Pa - (RB) - UsensdsDocument8 pagesLD04817 - Super Hartolan-Pa - (RB) - Usensdsrovelo3405475No ratings yet

- Sample Personal Protective Equipment (PPE) Policy: Hanover Risk SolutionsDocument6 pagesSample Personal Protective Equipment (PPE) Policy: Hanover Risk SolutionskbonairNo ratings yet

- Technology and Livelihood Education: Agricultural Crops ProductionDocument25 pagesTechnology and Livelihood Education: Agricultural Crops Productionjohn ian subil100% (1)

- NETA Handbook Series II - Safety Vol 2 PDFDocument76 pagesNETA Handbook Series II - Safety Vol 2 PDFadmer_lauristaNo ratings yet

- Sds Cationic Guar GumDocument3 pagesSds Cationic Guar GumAry SukmaNo ratings yet

- MSDS Odc 900Document3 pagesMSDS Odc 900sri.ionexchangeNo ratings yet

- Work Method Statement Date of Revision 07 Sep 2015 Rev.01Document5 pagesWork Method Statement Date of Revision 07 Sep 2015 Rev.01Lanceal TanNo ratings yet

- MSDS - Sodium Hydrogen Sulfate MonohydrateDocument7 pagesMSDS - Sodium Hydrogen Sulfate MonohydrateBigbearBigbearNo ratings yet

- Laboratory and Workshop HandbookDocument134 pagesLaboratory and Workshop HandbookBidhan RajkarnikarNo ratings yet