Professional Documents

Culture Documents

JSA - Fire Proofing Works

Uploaded by

Anis Uddin100%(3)100% found this document useful (3 votes)

2K views5 pagesThe JSA document provides safety guidelines for fire proofing works. It identifies potential hazards such as falling, tripping, improper equipment, and lack of training. It then lists mitigation measures to reduce risks such as ensuring proper permits and procedures are followed, equipment is inspected, the work area is barricaded, and personnel are trained and use appropriate PPE. Emergency response plans and communication protocols are also established to quickly address any incidents.

Original Description:

jsa1

Original Title

JSA- Fire Proofing works

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe JSA document provides safety guidelines for fire proofing works. It identifies potential hazards such as falling, tripping, improper equipment, and lack of training. It then lists mitigation measures to reduce risks such as ensuring proper permits and procedures are followed, equipment is inspected, the work area is barricaded, and personnel are trained and use appropriate PPE. Emergency response plans and communication protocols are also established to quickly address any incidents.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(3)100% found this document useful (3 votes)

2K views5 pagesJSA - Fire Proofing Works

Uploaded by

Anis UddinThe JSA document provides safety guidelines for fire proofing works. It identifies potential hazards such as falling, tripping, improper equipment, and lack of training. It then lists mitigation measures to reduce risks such as ensuring proper permits and procedures are followed, equipment is inspected, the work area is barricaded, and personnel are trained and use appropriate PPE. Emergency response plans and communication protocols are also established to quickly address any incidents.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 5

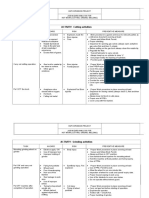

Job Safety Analysis

JSA No: EF-1931-HSE-

Activity: FIRE PROOFING WORKS

016 Rev. 00

GC 32 – NEW GATHERING CENTRE FOR SEK EF 1931 / JI

Project Title: Project No: JI - 2035

2035

Site/Facility: Work Area: AREA-2, ISBL Permit No:

KOC Emergency Contact Number: 160

Date:

972 99 100 (Mobile)

Hard Hat, Safety Shoes, Safety Goggles, Hand Gloves, Covera

Personal Protective Equipment’s: disposable coverall, ear plugs, respiratory protections, full body harnes

etc.

RESIDUA

RISK RISK

JOB STEPS POTENTIAL HAZARDS MITIGATION MEASURES

RATING RATING

Pre - work Permit to Work procedure

(KOC.SA.004) shall be complied.

Mobile Equipment procedure

Non-compliance of KOC Mediu (KOC.SA.013) shall be complied.

Low

HSEMS Procedure m Working at Height Procedure

(koc.sa.031) shall be complied.

Waste Handling Procedure

(KOC.EV.008) shall be complied.

Poor Task Planning Medium Physically check all equipment tools Low

Defective tools by an authorized person and ensure

Unauthorized personnel color coding.

Ensure pre-task briefing before fire

proofing activity about the safe

procedure and prior inspection of

equipment to be carried out.

All equipment to have KOC CC and

the same shall be displayed with

equipment.

Conduct TBT and ensure that PPE

appropriate to the work to be

undertaken is correctly identified and

used.

Ensure the equipment and tool to be

used are free from defect.

Ensures all hoses and connections

are properly crimped and jubilee clip

shall not be used.

Ensure all emergency exits at work

location are not blocked.

Personnel trained as per training

matrix.

Ensure the area is fully barricaded

and adequate signage’s posted around

Page 1 of 5 JSA No. EF 1931-HSE-016; Rev-00

the working area.

First Aid kit and trained first aider shall

always be available at the work

location.

Ensure gas testing is carried out to

confirm free from flammable / toxic

vapor.

Only authorized personnel shall be

allowed near the work area.

Ensure all personnel have completed

safety awareness trainings as per

Untrained Personnel and training matrix.

Medium Low

Poor supervision Ensure supervisor on site and workers

involved in fire proofing are trained &

competent to carry out the work safely.

Adequate number of lighting plants

shall be placed.

Reflector coveralls / jackets shall be

Working at night Medium Low

provided to the crew members.

White glass shall be provided to all

crew members.

Ensure that the Emergency Numbers

are posted at site, and personnel are

informed in during the TBT.

Lack of ERP All incidents and emergencies to be

Lack of adequate Medium communicated to KOC Emergency Low

communication number – 160.

All incidents and emergencies to be

communicated to PIL Emergency

number – 900 30 980.

Ensure barricading of area with

authorized personnel entry.

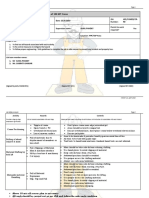

Tool box talk to discuss pinch points

and drop objects.

Only competent and authorized

Trip hazard personnel to set up the equipment.

Setting of

Pinch point Medium Equipment KOC CC to be displayed Low

Equipment’s

Drop objects on air compressors, Generator sets,

hopper, etc.

Ensure earthing connections are

properly fixed.

Ensure proper hoisting of equipment

at height.

Proper planning of work and provision Low

Medium of fall protection materials including

Working at Fall of person working at lanyards, snap hooks, full body safety

Height height harness has been provided to all

Fall of object from person workers involved.

working Ensure that a personal fall arrest

system is in place and available to all

Trip/Slip hazards workers involved, including but not

limited to anchorage connector, full

Page 2 of 5 JSA No. EF 1931-HSE-016; Rev-00

body safety harness, lanyard etc.

Supervisor to ensure that workers

assigned for the work are well trained

and highly competent in this type of

work, 100 % tie-off to maintained.

Conduct a toolbox talk briefing

workers on potential hazards and

precautionary measures required for

working at height has been made clear

to all workers to be involved in the

work.

All tools and materials shall be placed

in a safe container and properly

secured throughout the duration of

work at height.

Hand tools used during the work must

have a lanyard attached.

Ensure the work area to be free from

all slip/trip hazard. and proper access is

made available for all workers at

height.

Ensure that all precautionary

measures required for the safe

execution of work at height has been

taken prior to start of work.

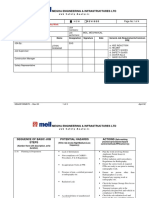

Fixing of Ensure sharp edges of the object are

Sharp edge

Wire Mesh protected by means of softener.

and Fire Pinch Point Ensure proper whiplash arrestor

Proofing provided to pressurized hose.

Caught by, striking,

crushing Ensure wire mesh properly fixed

before starting the fire proofing.

Stored Energy Ensure chemical mixing are perform

Irritation as per manufacturer recommendation.

Ensure all involve personnel adhere to

Fire approved and mandatory PPE’s

requirements while performing fire

proofing works.

Ensure equipment and vessel is

temporarily grounded to prevent static

electricity hazards.

Ensure first aid box and trained first

aider shall be available.

Ensure enough number fire

extinguisher available to the work

location.

Eye wash station shall be positioned

at work location.

Respiratory protection shall be readily

available for issuance to workers as

needed as per the SDS.

Ensure access/egress are always free

of obstruction.

Page 3 of 5 JSA No. EF 1931-HSE-016; Rev-00

Ensure job perform under the present

of competent supervisor or WSS.

Obtain SDS for the paint as well as

thinner.

Wear the required PPE (Long Sleeve

Coverall, Apron, Face Shield & suitable

respiratory protection etc.).

Ensure there is no naked flame or

spark generating equipment in the area

where spray painting is to be done.

Keep the suitable fire extinguishers in

Exposure to Harmful ready condition.

Vapor Do not eat or smoke wearing a paint-

Fire & Explosion Medium soaked coverall / gloves Low

Contaminated Clothing Clean / dispose safely the paint-

Un-attended Equipment / soaked coverall / gloves.

Painting Tool Wash properly before consuming any

Unsafe Storage of Paint food.

& Thinner Do not leave unattended the Spray

Paint Gun & Hose with on condition.

Isolate the equipment from all source of

energy when not in use.

Store the paint & thinners in safe &

designated location away from source

of ignition.

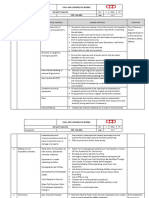

Slip/Trip/Fall Ensure the workplace is maintained

House

Personnel injury due to Low clear of debris, waste at all stages of Low

Keeping

poor house keeping job.

Ensure workers are training for heat

stroke and heat extortion

Ensure workers are medically fit for

the job

Additional Ensure adequate resting and welfare

facility provided at the site

Hazards Extreme weather

Ensure trained first aider with

(Other than condition Medium Low

adequate filled content of first aid kit is

indicated Heat Stroke/Extortion

available at site.

above)

Ensure sufficient/ enough cool

drinking water available at site.

Ensure toilet facility available at site in

compliance with KOC.HE.025

procedure.

Permit No: Work Area:

Name: Controlling Team:

JSA Done by

Permit Applicant

KOC. No. Signature:

Name: Controlling Team:

JSA Reviewed

Page 4 of 5 JSA No. EF 1931-HSE-016; Rev-00

by Permit Issuer

KOC. No. Signature:

Page 5 of 5 JSA No. EF 1931-HSE-016; Rev-00

You might also like

- Family Reunion Planning Meeting AgendaDocument3 pagesFamily Reunion Planning Meeting AgendaTika Wirdjo67% (3)

- JSA # 3 Column ErectionDocument6 pagesJSA # 3 Column ErectionRaghava Richhu100% (2)

- JSA Installation of GearboxDocument2 pagesJSA Installation of Gearboxprasong100% (2)

- JSA For Cable Tray Installation-Reviewed by CBREDocument10 pagesJSA For Cable Tray Installation-Reviewed by CBREPrakash Tiwari88% (8)

- JSA For Working at HeightDocument1 pageJSA For Working at HeightSafety& Security Supervisor100% (1)

- JSA Erection of Gathering TentDocument12 pagesJSA Erection of Gathering TentMuhammad Tariq100% (2)

- Confined Spaces: Job Safety AnalysisDocument2 pagesConfined Spaces: Job Safety Analysismalimsaidi_160040895No ratings yet

- JSA - Cathodic ProtectionDocument4 pagesJSA - Cathodic ProtectionAkash ShuklaNo ratings yet

- Jsa Cable TerminationDocument4 pagesJsa Cable TerminationSyed Yousuf Ali100% (1)

- Jsa For Civil Confined Space EntryDocument11 pagesJsa For Civil Confined Space EntryKhuda BukshNo ratings yet

- JSA For Scaffolding and Shed ErectionDocument1 pageJSA For Scaffolding and Shed ErectionAnonymous voA5Tb0No ratings yet

- JSA-Manual Lifting of MaterialsDocument3 pagesJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- JSA-009a Drilling and Mon Well Construction-SonicDocument4 pagesJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi86% (7)

- JSA Roof Sheeting V3 16 July 06Document6 pagesJSA Roof Sheeting V3 16 July 06Walt Flowers80% (5)

- Three Levels of SustainabilityDocument330 pagesThree Levels of SustainabilityChristian Prez100% (5)

- Design of Steel TowerDocument31 pagesDesign of Steel Towerudara89% (9)

- JSA For Holiday Testing PDFDocument4 pagesJSA For Holiday Testing PDFMohammed Minhaj67% (3)

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Document7 pagesHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- Jsa For Steel ErectionDocument7 pagesJsa For Steel ErectionRajuNo ratings yet

- Jsa Working at Height (Maintenance & Cleaning)Document2 pagesJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (2)

- Draft JSA Levelling & GradingDocument9 pagesDraft JSA Levelling & GradingAzeem Khan33% (3)

- JSA For Life Line InstolationDocument17 pagesJSA For Life Line InstolationShekh BabulNo ratings yet

- JSA For Installation of Precast SlabDocument4 pagesJSA For Installation of Precast Slabyc safety100% (3)

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- SINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONDocument12 pagesSINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONtusharDJNo ratings yet

- JSA For WrappingDocument6 pagesJSA For WrappingMohammed Minhaj100% (2)

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- JSA Cable LayingDocument2 pagesJSA Cable Layingnishanth100% (2)

- Battle of Five Armies - GW PDFDocument34 pagesBattle of Five Armies - GW PDFJustin Larson88% (17)

- ISLaw ComputationDocument6 pagesISLaw ComputationNurlailah Ali100% (1)

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 pagesEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Ali QaziNo ratings yet

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- Jsa Slip FormDocument5 pagesJsa Slip Formputrasejahtra50% (2)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- JSA For HILTIDocument3 pagesJSA For HILTIMohammed Minhaj100% (1)

- Tanks Confined Space JSADocument5 pagesTanks Confined Space JSAkosoko100% (1)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 pagesRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- JHA LiftingDocument4 pagesJHA Liftingsyamimi balkhisNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- Jobs Safety Analysis (JSA)Document9 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Document9 pagesSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- JSA For SealantDocument11 pagesJSA For SealantdipmipNo ratings yet

- JSA-002 JSA For TCFDocument4 pagesJSA-002 JSA For TCFRafeeq Ur RahmanNo ratings yet

- JSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling ActivityDocument12 pagesJSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling Activitybagas prakoso100% (1)

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 pagesSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- JSA FORMAT For Materials LoadingDocument2 pagesJSA FORMAT For Materials LoadingVikky KumarNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- Anchor Bolt Setting - Rev 01Document26 pagesAnchor Bolt Setting - Rev 01Geherson AbustanNo ratings yet

- JSA ScaffoldingDocument2 pagesJSA ScaffoldingHrishikesh UnnikrishnanNo ratings yet

- Jsa For RadiographyDocument3 pagesJsa For Radiographyjithin shankarNo ratings yet

- Jsa For Brick WorkDocument4 pagesJsa For Brick WorkSushil Kumar YadavNo ratings yet

- S/N Sequence of Basic Steps Potential Hazards Hazards Control Action byDocument7 pagesS/N Sequence of Basic Steps Potential Hazards Hazards Control Action byjavithNo ratings yet

- Cable Laying - Docx4Document2 pagesCable Laying - Docx4Dhaneswar SwainNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- Kaitlyn Duron ResumeDocument2 pagesKaitlyn Duron Resumeapi-453866596No ratings yet

- P.E PresentationDocument10 pagesP.E PresentationJezelle Ann PeteroNo ratings yet

- Sadza: ChickenDocument13 pagesSadza: ChickenTsitsi Ngara SibandaNo ratings yet

- Cloning Quiz: Name: Date: ClassDocument1 pageCloning Quiz: Name: Date: ClassPhuong Lien LaiNo ratings yet

- Crimpro PreliminariesDocument46 pagesCrimpro PreliminariesHarold Saldy CasalemNo ratings yet

- Eight Hundred Meters From The Hypocenter - Student ExampleDocument4 pagesEight Hundred Meters From The Hypocenter - Student Exampleapi-452950488No ratings yet

- 0610 w13 Ms 12Document2 pages0610 w13 Ms 12Haider AliNo ratings yet

- Turla v. CaringalDocument2 pagesTurla v. CaringalTrina RiveraNo ratings yet

- Finance Notes at Mba FinanceDocument40 pagesFinance Notes at Mba FinanceBabasab Patil (Karrisatte)No ratings yet

- Jimmy Lim 2Document33 pagesJimmy Lim 2Ramsraj100% (1)

- Chapter 1 - Business Driven TechnologyDocument3 pagesChapter 1 - Business Driven TechnologyMary LisaNo ratings yet

- 1991 Indianapolis 500 - WikipediaDocument48 pages1991 Indianapolis 500 - WikipediabNo ratings yet

- Handbook 2018 v2 15Document20 pagesHandbook 2018 v2 15api-428687186No ratings yet

- Predestination Vs Free WillDocument4 pagesPredestination Vs Free WillFrancis Heckman100% (2)

- Architecture Firms: CCBA DesignsDocument1 pageArchitecture Firms: CCBA DesignspallaviNo ratings yet

- SEMINARS AND FIELDTRIPS (59041, 59042, 59071) : Electronics Engineering DepartmentDocument3 pagesSEMINARS AND FIELDTRIPS (59041, 59042, 59071) : Electronics Engineering DepartmentDaniel TamisenNo ratings yet

- MITC Employee Handbook: A Reference Guide For MITC Solutions Most Commonly Used by EmployeesDocument24 pagesMITC Employee Handbook: A Reference Guide For MITC Solutions Most Commonly Used by EmployeesDerek StarkNo ratings yet

- Tugas DMD GROUP 01Document8 pagesTugas DMD GROUP 01ulviqhj354No ratings yet

- Week 2 Reflection Sept 6 To Sept 10Document2 pagesWeek 2 Reflection Sept 6 To Sept 10api-534401949No ratings yet

- Random Puzzle Questions PDF For Ibps RRB Clerk Prelims ExamDocument22 pagesRandom Puzzle Questions PDF For Ibps RRB Clerk Prelims ExamApyrvaNo ratings yet

- Different Parts of The Engine and Their Function Explained in Detail Notes PDF (PDFDrive)Document20 pagesDifferent Parts of The Engine and Their Function Explained in Detail Notes PDF (PDFDrive)Andres RvNo ratings yet

- Science, Technoloy and Society Prelim ExamDocument14 pagesScience, Technoloy and Society Prelim ExamIman Official (Em-J)No ratings yet

- KZR 12247564Document3 pagesKZR 12247564Jan MulderNo ratings yet

- Ramesh Patel Resume (Civil) 02Document4 pagesRamesh Patel Resume (Civil) 02RameshNo ratings yet

- Swaps: Options, Futures, and Other Derivatives, 9th Edition, 1Document34 pagesSwaps: Options, Futures, and Other Derivatives, 9th Edition, 1胡丹阳No ratings yet