Professional Documents

Culture Documents

Cable Laying - Docx4

Uploaded by

Dhaneswar SwainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable Laying - Docx4

Uploaded by

Dhaneswar SwainCopyright:

Available Formats

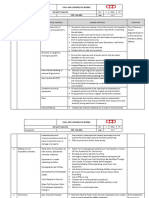

Form No.

JI 2027-FORM-HSE-002

Job Safety Analysis

JSA No:

Activity: Cable Pulling and Lying using cable pulling roller and winch. JI 2027-JSA-037

Project No:

Project: NEW GATHERING CENTRE, GC-29 IN NORTH KUWAIT

EF 1901

Site/Facility: Work Area: KOC Permit No & Date:

In Case of Emergency, contact KOC @ 160

PPE & Tools: Hard Hat, Safety Shoes, Safety Glasses, Hand Gloves, Coverall.

RESIDUAL

SEQUENCE OF RISK

POTENTIAL HAZARDS MITIGATION MEASURES RISK

JOB STEPS RATING

RATING

Ensure all personnel have undergone Project HSE

Induction and EOD training

Ensure to comply with KOC HSEMS procedures

Ensure all personnel have completed HSE awareness

Pre Task Planning trainings as applicable by Contractor

Physically check all equipment/ tools by a

Non Compliance of HSEMS Procedures competent Foremen or Supervisor

3 (C)

Pre - work Un trained People MEDIUM Ensure only competent/authorized personnel are 2 (B)

carrying out the task LOW

Defective electrical & hand tools Conduct TBT and ensure that PPE appropriate to the

,equipment work to be undertaken is correctly identified & used

Obtain required Permit to Work

Ensure that the Emergency all are aware about KOC

emergency number and procedures.

Ensure proper communication means available at

site. KOC Emergency # 160

All related activity to Lifting and Rigging operation

shall be covered by ( Lifting & Rigging JSA)

Ensure all the cable drums transported to site are

Loading and unloading of cable drum. fully secured on trailer by means of lashing belt or

chain.

Transportation of cable drums from Ensure competent riggers and rigging supervisors are

yard to site. performing rigging activity.

Loading and Ensure competent personnel have the inspection of

Manual Handling injury 4 (C) lifting equipment, tool and tackles with valid 2 (B)

unloading of

MEDIUM document. LOW

Cable Drums Slips /Trips /Falls Use appropriate PPE

Ensure to provide the appropriate cable stand to

Unstable support while placing cables hold the cable drum and place on a stable and level

on cable stand. ground.

Only trained personnel are allowed to do the work as

required.

All personnel to exit the rear of the truck when

cable drums are being loaded or unloaded.

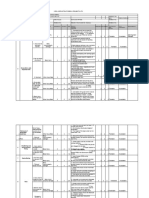

Trapping Personnel shall be suitably instructed in cable

pulling techniques including appropriate manual

Slips / Trip handling techniques so people can understand the

steps for the work and their roles.

Manual Handling Ensure appropriate hand gloves and using by cable

Cable Pulling & 3(C)

pulling staff. 2 (B)

Laying into Poor communication MEDIUM

Ensure competent personnel have the inspection and LOW

Trench

fit for the service.

Extreme weather condition ( heavy

Pulley should tethered in place in the event of them

wind/sandstorm/rain

become dislodged while overload.

Page 1 of 2 JSA No. JI-2027-JSA-037

Form No. JI 2027-FORM-HSE-002

Heat Stress Ensure connection point and support is rated for the

load that will be applied during the work.

Clear instruction to personnel shall be given to

ensure no incident during cable pulling that can be

resulted to a hand injury

Ensure all cable rollers are appropriate to the size of

the cable for pulling and it is secured and placed

properly.

Assessment shall be made by the concerned

supervisor about the number of personnel required

for the activity.

Close supervision of personnel during the activities

No cable pulling during heavy wind / sandstorm /

rain as required.

Pre use equipment inspection has to be completed

by competent supervisor.

Ensure that sufficient water and shaded areas are

available and that personnel are allowed sufficient

rest breaks

Ensure adequate number of personnel deployed for

cable pulling.

Ensure cable stand and puller preventive and

corrective maintenance has been completed

periodically.

Ensure cable stand having adequate capacity.

If the cable puller is electrically operated machine

only authorized personal can operate the machine.

Before enter inside the cable trench inspect and

ensure no venoms reptile and insects in the trench.

Personnel injury due to poor Ensure the work place is maintained clear of debris,

housekeeping waste, other rubbish & make the place clean and

tidy

Additional Injury / accidents due to animal / 2(D) Provide adequate warning signage as required

reptile bites

2 (A)

hazards For welfare facility / short breaks, contractor

MEDIUM temporary facility on work location shall be used LOW

Exposure to extreme weather Trench has been inspected certified by competent

person before entering and ensure no cave-in,

collapse or water accumulation to prevent the

personnel injury

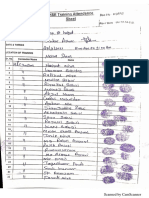

Worksite Supervisor Approved by Reviewed by

(Subcontractor or Petrofac) (Permit Applicant) (Permit Issuer.)

Name: Name: Name:

Company: Company: Petrofac International Ltd Company: M/s.Technip

Designation: Designation: Designation:

Signature:

Signature: Signature:

Date: Date: Date:

Page 2 of 2 JSA No. JI-2027-JSA-037

You might also like

- Substance Abuse Counseling Complete 5th EditionDocument379 pagesSubstance Abuse Counseling Complete 5th Editionnintendoagekid83% (6)

- Element 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetDocument14 pagesElement 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetGurumoorthy Rajavijayan100% (2)

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaDocument8 pagesJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreamarvinNo ratings yet

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- JSA - Mechanical Excavation PDFDocument4 pagesJSA - Mechanical Excavation PDFMohammed MinhajNo ratings yet

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocument7 pagesJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (2)

- EHS-SWI-037 - 0 Loadbank Testing - DraftDocument2 pagesEHS-SWI-037 - 0 Loadbank Testing - DraftChris Bonnington100% (1)

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaNo ratings yet

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 pagesEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNo ratings yet

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (3)

- JSA For Erection and Repair Work of TanksDocument19 pagesJSA For Erection and Repair Work of TanksMohamed Farouk100% (2)

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- JSA For Material ShiftingDocument3 pagesJSA For Material ShiftingMohammed Minhaj100% (1)

- JSA For Screeding With MeshDocument4 pagesJSA For Screeding With MeshMohammed Minhaj100% (1)

- Petrofac: Job Safety AnalysisDocument3 pagesPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (5)

- JSA Cable LayingDocument2 pagesJSA Cable Layingnishanth100% (2)

- DR - AC Ethical and Legal Issues in Midwifery Practice 2021Document91 pagesDR - AC Ethical and Legal Issues in Midwifery Practice 2021dr.anu RkNo ratings yet

- JI 2027 JSA 039 Lifting and Rigging Activities by Tandem Lifting PDFDocument3 pagesJI 2027 JSA 039 Lifting and Rigging Activities by Tandem Lifting PDFYawar Qureshi100% (3)

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaDocument8 pagesJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaMohammed MinhajNo ratings yet

- Hira - Back FillingDocument5 pagesHira - Back FillingSatya Naidu100% (1)

- Operations & Maintenance Handbook - LPG Storage Facilities (Propane Research Council)Document176 pagesOperations & Maintenance Handbook - LPG Storage Facilities (Propane Research Council)KannanGKNo ratings yet

- DexamethasoneDocument4 pagesDexamethasoneMits Valencia Karlsson0% (2)

- Jsa For TIE INS in Accommodation BlockDocument4 pagesJsa For TIE INS in Accommodation BlockAliNo ratings yet

- JSA For Coating and Raping Activity in TankDocument7 pagesJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNo ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 5 out of 5 stars5/5 (2)

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Ra & Jsa FormatDocument19 pagesRa & Jsa Formatspecpro50% (2)

- Greggs AssignmentDocument7 pagesGreggs Assignmentlusha huangNo ratings yet

- 100 - So v. Tacla Jr.Document2 pages100 - So v. Tacla Jr.Alexis Elaine BeaNo ratings yet

- Petrofac: Job Safety AnalysisDocument2 pagesPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (1)

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- DB Termination JhaDocument2 pagesDB Termination JhafatimahNo ratings yet

- Job - Safety - Analysis - PS28 REV 1Document5 pagesJob - Safety - Analysis - PS28 REV 1Ben MutaiNo ratings yet

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pages5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisNo ratings yet

- PCW Pipe Installation JhaDocument2 pagesPCW Pipe Installation Jhafatimah100% (1)

- JSA For SURGE VESSEL WorkDocument6 pagesJSA For SURGE VESSEL Workathul subashNo ratings yet

- Safe Plan of Action Ramsu Enterprise: Project No.: 44AC6615Document5 pagesSafe Plan of Action Ramsu Enterprise: Project No.: 44AC6615Sanjeev KumarNo ratings yet

- Risk Assessment: Suroogelal RamkissoonDocument2 pagesRisk Assessment: Suroogelal RamkissoonKaavi MaharajNo ratings yet

- 139 Casting ConcretingDocument4 pages139 Casting Concreting王志伟No ratings yet

- 16-070331 JSA For The Tie-In of Chilled Water Lines Behind General OfficeDocument3 pages16-070331 JSA For The Tie-In of Chilled Water Lines Behind General Officeiftikhar ahmadNo ratings yet

- 8.safety Plan - SS 7914Document3 pages8.safety Plan - SS 7914GANESH KNo ratings yet

- OSH Officer Observation Report 03 - Jan-2024Document28 pagesOSH Officer Observation Report 03 - Jan-2024zaimNo ratings yet

- 08-030207 JSA For Installation of Precast Footings and Sleepers in Brown Zone.Document5 pages08-030207 JSA For Installation of Precast Footings and Sleepers in Brown Zone.iftikhar ahmadNo ratings yet

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Flare Pit AreaDocument8 pagesJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Flare Pit Areanoahlungu96No ratings yet

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocument7 pagesJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing Spoolsm.rehanhseNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument17 pagesJSA For Scaffolding Erection Dismantling and Modification Workshane.ramirez1980No ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- SWP 03 - Hacking WorksDocument3 pagesSWP 03 - Hacking WorksGerald Wong NttNo ratings yet

- Manual-Paintingdoc CompressDocument3 pagesManual-Paintingdoc CompressOP AryaNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- Jsa For Plaster WorkDocument4 pagesJsa For Plaster Workumar KhitabNo ratings yet

- JSA - TT 307 B InstallationDocument4 pagesJSA - TT 307 B Installationsuria qaqcNo ratings yet

- 29 HIRA Annexure HDocument328 pages29 HIRA Annexure HpradeepyellurNo ratings yet

- JSA For RadiographyDocument5 pagesJSA For RadiographyViron BaxhiaNo ratings yet

- Construction Safety Law, Management, and Technology: Hong Kong ExperienceFrom EverandConstruction Safety Law, Management, and Technology: Hong Kong ExperienceNo ratings yet

- The Importance of EffectiveDocument6 pagesThe Importance of EffectiveDhaneswar SwainNo ratings yet

- Powerpoint Heat SafetyDocument11 pagesPowerpoint Heat SafetyDhaneswar SwainNo ratings yet

- Training Title: Confined Space Entry (Especially Rescue) Location: Jebel Ali Terminal Dubai Trainer Name: Syed Neyaz AhmadDocument27 pagesTraining Title: Confined Space Entry (Especially Rescue) Location: Jebel Ali Terminal Dubai Trainer Name: Syed Neyaz AhmadDhaneswar SwainNo ratings yet

- TF-Chimney & VFD-16.04.15Document9 pagesTF-Chimney & VFD-16.04.15Dhaneswar SwainNo ratings yet

- Concrete Mixer Inspection ChecklistDocument1 pageConcrete Mixer Inspection ChecklistDhaneswar SwainNo ratings yet

- TrainingDocument16 pagesTrainingDhaneswar SwainNo ratings yet

- Sample HIRADocument18 pagesSample HIRADhaneswar SwainNo ratings yet

- Confined Space PermitDocument3 pagesConfined Space PermitDhaneswar SwainNo ratings yet

- At TC3CN006 18 T1 Ja101Document3 pagesAt TC3CN006 18 T1 Ja101Dhaneswar SwainNo ratings yet

- Gas Cutting & WeldingDocument37 pagesGas Cutting & WeldingDhaneswar SwainNo ratings yet

- EMP PlanDocument8 pagesEMP PlanDhaneswar SwainNo ratings yet

- Safety Quiz - Office Safety Answer KeyDocument2 pagesSafety Quiz - Office Safety Answer KeyDhaneswar SwainNo ratings yet

- Ladder Inspection Checklist 10-2017Document2 pagesLadder Inspection Checklist 10-2017Dhaneswar SwainNo ratings yet

- Civil 0042 CHECKLIST FOR CIVIL WORKSDocument30 pagesCivil 0042 CHECKLIST FOR CIVIL WORKSDhaneswar SwainNo ratings yet

- TF - Esp 1 & 2 22.01.15Document1 pageTF - Esp 1 & 2 22.01.15Dhaneswar SwainNo ratings yet

- Viviid Renewables PVT - LTDDocument37 pagesViviid Renewables PVT - LTDDhaneswar SwainNo ratings yet

- Safety Quiz - Electrical Answer KeyDocument2 pagesSafety Quiz - Electrical Answer KeyDhaneswar SwainNo ratings yet

- NTPC Solapur - Main Plant - 19.06.2014Document1 pageNTPC Solapur - Main Plant - 19.06.2014Dhaneswar SwainNo ratings yet

- Authorization Letter For New WorkersDocument2 pagesAuthorization Letter For New WorkersDhaneswar SwainNo ratings yet

- Work at Height Training SheetDocument1 pageWork at Height Training SheetDhaneswar SwainNo ratings yet

- 02 - Accident ReportDocument6 pages02 - Accident ReportDhaneswar SwainNo ratings yet

- Safety Quiz - Electrical Safety-1: DirectionsDocument2 pagesSafety Quiz - Electrical Safety-1: DirectionsshreyasNo ratings yet

- Hira BCN 22aDocument33 pagesHira BCN 22aDhaneswar SwainNo ratings yet

- HIRA - Erection by Crane - PannelDocument5 pagesHIRA - Erection by Crane - PannelDhaneswar SwainNo ratings yet

- Final Jsa & Method StatmentDocument11 pagesFinal Jsa & Method StatmentDhaneswar SwainNo ratings yet

- SHE Induction RegisterDocument2 pagesSHE Induction RegisterDhaneswar SwainNo ratings yet

- Methodlogy of Blasting For ICHSDocument10 pagesMethodlogy of Blasting For ICHSDhaneswar SwainNo ratings yet

- Hira - For Shot Blasting & Upto 2nd Coat of PaintingDocument15 pagesHira - For Shot Blasting & Upto 2nd Coat of PaintingDhaneswar SwainNo ratings yet

- Winch Machine Safety PrecautionDocument2 pagesWinch Machine Safety PrecautionDhaneswar SwainNo ratings yet

- r7 13-Ehs Req PofDocument9 pagesr7 13-Ehs Req PofDhaneswar SwainNo ratings yet

- Cover Letter For EportfolioDocument2 pagesCover Letter For Eportfolioapi-231487081No ratings yet

- Hygiene Code of ConductDocument4 pagesHygiene Code of ConductRugadya PaulNo ratings yet

- Mna Mini EnglishDocument1 pageMna Mini EnglishSyifa MustikaNo ratings yet

- IHG Green Engage-Solutions-Issued Feb 1 2011Document498 pagesIHG Green Engage-Solutions-Issued Feb 1 2011Jaime Lorraine KokNo ratings yet

- Pathology Solved Papers 2015Document35 pagesPathology Solved Papers 2015Lakshmi Venkataraman100% (3)

- HSE Competence Training Level 1 2 and 3Document2 pagesHSE Competence Training Level 1 2 and 3wahyuNo ratings yet

- Livingwater ProfileDocument6 pagesLivingwater ProfileMarco Antonio SalomonNo ratings yet

- Ovatum (Canarium Ovatum) As An Alternative Fuel ExtenderDocument17 pagesOvatum (Canarium Ovatum) As An Alternative Fuel ExtenderJMClosedNo ratings yet

- Dairy Best Ad - Focus Group DiscussionDocument5 pagesDairy Best Ad - Focus Group DiscussionUpasana SilNo ratings yet

- Brain As Part of An Enactive SystemDocument70 pagesBrain As Part of An Enactive SystemValéria MarquesNo ratings yet

- Millennium Development and Sustainable Development Goals New Topic PE Part 1Document5 pagesMillennium Development and Sustainable Development Goals New Topic PE Part 1Prgya SinghNo ratings yet

- Common Illnesses and Diseases of School-Aged ChildrenDocument2 pagesCommon Illnesses and Diseases of School-Aged ChildrenKnucasior BichNo ratings yet

- History SBA FinalDocument14 pagesHistory SBA Finalkeraj0% (1)

- Definition of TermsDocument4 pagesDefinition of TermsKenneth SastadoNo ratings yet

- Prevention of Arthropod and Insect Bites: Repellents and Other MeasuresDocument18 pagesPrevention of Arthropod and Insect Bites: Repellents and Other MeasuresMatheus FernandesNo ratings yet

- Fin435-TermPaper-Appraisal of Dividend Policy of The Selected CompaniesDocument41 pagesFin435-TermPaper-Appraisal of Dividend Policy of The Selected CompaniesNiloy MallickNo ratings yet

- Latest IMM GuidelinesDocument14 pagesLatest IMM GuidelinesUsama1987No ratings yet

- Mediterranean Baked Fish Recipe With Tomatoes and Capers (Video)Document3 pagesMediterranean Baked Fish Recipe With Tomatoes and Capers (Video)brianzflNo ratings yet

- Classifying Algae, Protozoa, Fungi, Molds, ParasitesDocument4 pagesClassifying Algae, Protozoa, Fungi, Molds, ParasitesMeri SunderNo ratings yet

- Q-NCOV-01D STANDARD Q COVID-19 IgM-IgG Duo Test INSERTODocument2 pagesQ-NCOV-01D STANDARD Q COVID-19 IgM-IgG Duo Test INSERTOechegarayNo ratings yet

- Charities USA Fall 2013: Reaching Out To Military Families & VeteransDocument25 pagesCharities USA Fall 2013: Reaching Out To Military Families & VeteransCatholic Charities USANo ratings yet

- Dental ElevatorsDocument20 pagesDental Elevatorsahmed amerNo ratings yet

- Focus Forward Style Guide-ALL DOCSDocument46 pagesFocus Forward Style Guide-ALL DOCSShahin AfridiNo ratings yet

- Case Study 5 - DESOASIDODocument2 pagesCase Study 5 - DESOASIDOEDDREI PAULLYNNE DESOASIDONo ratings yet