Professional Documents

Culture Documents

139 Casting Concreting

Uploaded by

王志伟0 ratings0% found this document useful (0 votes)

40 views4 pagesJHA

Original Title

139 Casting Concreting

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJHA

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views4 pages139 Casting Concreting

Uploaded by

王志伟JHA

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

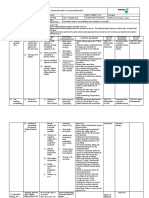

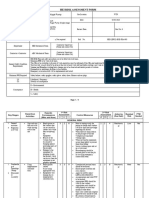

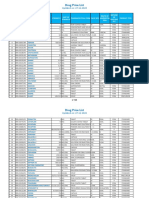

JOB HAZARD ANALYSIS [JHA] WORKSHEET

JHA NO. PTW NO WORK PERMIT TYPE Cold work

SPECIFIC WORK

FACILITY GIFT LOCATION GIFT / NEAR GIS SEPCOO III early comb

STATION

WORK

EQUIPMENT NO Casting Concrete Using mix truck

DESCRIPTION

NOTE:

1. JHA shall be applicable for all work activities which requires PTW.

2. The pre-prepared JHA and JHA prompters will be used as a reference/guide during the development of JHA.

3. Personnel carrying out the work shall be fully familiar with the written Work/Operating Procedures developed for the job. The Work/Operating Procedures shall

describe, in step-by-step instructions, the correct method of executing the specified work.

4. Prior to commencement of work (after PTW has been approved), the task-specific JHA shall be discussed amongst all personnel involved in the execution; and

requirements contained therein shall be fully understood and agreed by all involved personnel.

DESCRIPTION OF POTENTIAL ACTION RECOVERY

JOB STEP POTENTIAL HAZARD CONTROL BARRIERS

JOB STEP CONSEQUENCES PARTY BARRIERS

a) Access to a) Preparation to a) Slip, trip & fall Minor injury Obtain/ display approved PTW at Site SEPCOO Communication

working Area make proper hazards if improper Organize toolbox meeting & share the approved

(Laceration, , JHA with all personnel that involve with the work Work leader s must be

access and storing of material, contusion or Ensure adequate precaution and access or HSE available during

egress into the equipment, etc. wound) are in place to allow the work to progress safely Supervisor the work

work area Mixer machine must be inspected and approved

b) Pinch point while by PCIHBV personnel activity.

Body strain and

Ensure entire work area barricaded and properly

unloading of blocks sprain if poor secured from unauthorized personnel.

b) Driving to the or tools lifting or Wear appropriate PPE including any other as

jobsite handling required

c) Manual handling/ Provide traffic controller or banksman to control

any vehicles movement

ergonomics issue Serious injury; Inspect and ensure all other working tool free from

Fracture or damage

d) Vehicular accident: body or part of Competent driver: watch turning radius or apply

wide turns if required

taking turns too the body crush Provide first aider c/w 1 unit of First aid box with sufficient

sharp; hitting upon contact content

Close monitoring & supervision required

objects or people with vehicles

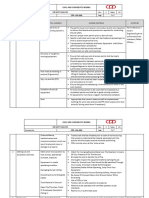

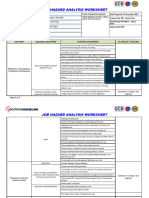

a) Carry out a) Caught in Inspect tools Place the temporary sign boards such SEPCOO Communication

:B: Casting survey between/ strike before use as “man at work” or any related Work leader s must be

work hazards sign around the work area. or HSE available during

Concrete Using that cause

Make safety soft barricade around the Supervisor the work

mix truck harm/damage Body strain and

Traffic accidents work area

to people and sprain Thoroughly inspect equipment before

activity.

b) Tripping environment.

,falling use. Make sure all equipment are free

Health issue: from defect and operable.

c) Framework, b) Struck by or heat stress, Lifting/ removing hollow block using

tying the caught in heat manpower at permissible limit is

rebar equipment or exhaustion, strongly required or not over lifting

hitting body cramp, Use proper bending, lifting and

equipment or etc. stooping techniques for any manpower

people lifting

c) Damage to Serious injury Provide & use proper ladder for access

equipment or part of the & egress while working at higher level.

body fracture Also secure the ladder in the top or

d) Manual bottom

Manage work/ Wear body harness if working above

handling/

ergonomics rest times. 2.0 meter Continuously maintain good

issues housekeeping especially storage of

materials

e) Hot weather Provide sufficient drinking water at site

temperature Report to Supervisor/ MSK for any

incident/ injury

f) Falling hazards Competent drivers must have

for roof Knowledge about the defensive driving on

installation the site/ Traffic management plan must be

work implemented, Flag man to control the

g) Collision, run traffic movement especially sharing the

over road with the public/ Speed signs all the

way from &to the disposal area.

h) Collision, run

over

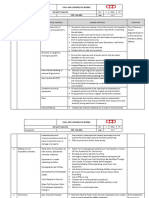

C) House a) Remove all a) Slips, Trips, Falls Personal Wear adequate PPE including SEPCOO Communication

keeping the work due to uneven injury suitable hand gloves Work leader s must be

materials, surface or poor (Laceration, Remove all the surplus material/ or HSE available during

equipment house keeping wound, waste and keep the area clean & Supervisor the work

and tools from fracture) intact. activity.

the work area b) Pinch between Finger and Ensure close supervision

materials or hand injury Manage rest and working

machineries Body strain time

c) Manual handling/ and sprain if

ergonomics poor lifting

issues Trip/ slip

Fatigue

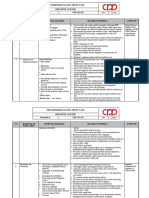

JHA APPROVAL DURING PTW APPLICATION

ACCEPTED BY RECEIVING AUTHORITY ACCEPTED BY RECEIVING AUTHORITY

NAME NAME

DESIGNATION DESIGNATION

SIGNATURE SIGNATURE

DATE DATE

AFTER PTW HAS BEEN APPROVED

WORK TEAM (CONFIRAMTION TEAM JHA HAS BEEN COMMUNICATED TO WORK TEAM AS PART OFPRE-JOB/TOOLBOX MEETING –

AFTER PTW BEEN APPROVED)

NAME(S) DESIGNATION SIGNATURE NAME(S) DESIGNATION SIGNATURE

You might also like

- JOB HAZARD ANALYSIS FOR EXCAVATION AND BACKFILLINGDocument4 pagesJOB HAZARD ANALYSIS FOR EXCAVATION AND BACKFILLING王志伟No ratings yet

- JHA Worksheet for Excavation WorkDocument3 pagesJHA Worksheet for Excavation Work王志伟No ratings yet

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Jsa for Concreate and CivilworksDocument7 pagesJsa for Concreate and CivilworksAnna JisabaNo ratings yet

- JSA FOR CONCREATE AND CIVILWORKSDocument7 pagesJSA FOR CONCREATE AND CIVILWORKSAnna JisabaNo ratings yet

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocument7 pagesJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- Jsa For Installation of Pipe Railing On SkidDocument6 pagesJsa For Installation of Pipe Railing On SkidLokesh Aravindan100% (1)

- JSA For HDPE Liner Fusion Welding2Document6 pagesJSA For HDPE Liner Fusion Welding2Mohammed Minhaj100% (8)

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- JSA For Construction of E - P WorkshopDocument5 pagesJSA For Construction of E - P Workshopm.rehanhseNo ratings yet

- Jsa For Intallation of Sub Pipe Rack Incuding Grinding Cutting and Welding Near Condensate DrumsDocument6 pagesJsa For Intallation of Sub Pipe Rack Incuding Grinding Cutting and Welding Near Condensate DrumsMohammed MinhajNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- JSA - Mechanical Excavation PDFDocument4 pagesJSA - Mechanical Excavation PDFMohammed MinhajNo ratings yet

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocument7 pagesJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing Spoolsm.rehanhseNo ratings yet

- Jsa For Intallation of Sub Pipe RackDocument7 pagesJsa For Intallation of Sub Pipe RackMohammed Minhaj100% (2)

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Flare Pit AreaDocument8 pagesJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Flare Pit Areanoahlungu96No ratings yet

- JHSA for Temporary Plastic Septic TankDocument4 pagesJHSA for Temporary Plastic Septic TankAnna JisabaNo ratings yet

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaDocument8 pagesJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreamarvinNo ratings yet

- JSA for Mobilization and Installation of Process Area SpoolsDocument8 pagesJSA for Mobilization and Installation of Process Area SpoolsMohammed MinhajNo ratings yet

- JSA For Removal of Broken Bolts and Installation of Switch Pannel On Compressor at Process AraeDocument4 pagesJSA For Removal of Broken Bolts and Installation of Switch Pannel On Compressor at Process AraeMohammed MinhajNo ratings yet

- 1 SurveyDocument5 pages1 Survey王志伟0% (1)

- 021 Manual Excavation JSA For FLS SiteDocument3 pages021 Manual Excavation JSA For FLS SiteViron BaxhiaNo ratings yet

- LBK JSA-Redrill 04012022 EnglishDocument6 pagesLBK JSA-Redrill 04012022 EnglishHSE BGP HONo ratings yet

- JSA For HDPE SLEEVING DEL 89Document3 pagesJSA For HDPE SLEEVING DEL 89Mohammed Minhaj100% (1)

- JSA Installation of PumpsDocument6 pagesJSA Installation of Pumpsyc safety100% (2)

- Installation JSADocument4 pagesInstallation JSAMohammed Minhaj100% (1)

- JSA For Concrete PouringDocument8 pagesJSA For Concrete Pouringfayaz fayazhotmail.com100% (1)

- JSA For Installation of Precast SlabDocument4 pagesJSA For Installation of Precast SlabMohammed Minhaj100% (3)

- Copy (2) of Jsa For Mechanical Excavation at Brown Field Are Includes WeldingDocument4 pagesCopy (2) of Jsa For Mechanical Excavation at Brown Field Are Includes WeldingViron Baxhia100% (1)

- JSA For Concrete Pouring Using Crane and Bucket3Document8 pagesJSA For Concrete Pouring Using Crane and Bucket3Mohammed Minhaj100% (1)

- Sunmow Jha 001Document3 pagesSunmow Jha 001Douglas DellyNo ratings yet

- JSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyDocument4 pagesJSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyMuhammad TariqNo ratings yet

- Gas Cutting JsaDocument4 pagesGas Cutting JsaMohammed Minhaj100% (1)

- DEL - 064 Jsa For Load Test of Davit ArmsDocument4 pagesDEL - 064 Jsa For Load Test of Davit ArmsMohammed Minhaj100% (1)

- HEI JHA Leakage RectificationDocument7 pagesHEI JHA Leakage RectificationJavid AaqibNo ratings yet

- Work Method Statement: Wms Rev. NoDocument5 pagesWork Method Statement: Wms Rev. NoKarthik babu100% (1)

- Pa Hsec 02 040 002 F03Document4 pagesPa Hsec 02 040 002 F03Abdul KhaliqNo ratings yet

- JSA For Installation of Precast SlabDocument4 pagesJSA For Installation of Precast Slabyc safety100% (3)

- Jsa For TIE INS in Accommodation BlockDocument4 pagesJsa For TIE INS in Accommodation BlockAliNo ratings yet

- JSA For Working at HeightDocument2 pagesJSA For Working at HeightXUE JIANNo ratings yet

- JSA For Screeding With MeshDocument4 pagesJSA For Screeding With MeshMohammed Minhaj100% (1)

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pages5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisNo ratings yet

- Overhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Document5 pagesOverhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Javid AaqibNo ratings yet

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNo ratings yet

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Minhaj60% (5)

- Diesel Filling JSADocument6 pagesDiesel Filling JSAMohammed Ali QaziNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- Jsa For Erection of Pipes Welding Cutting Grinding-Imtiaz SBDocument6 pagesJsa For Erection of Pipes Welding Cutting Grinding-Imtiaz SBMohammed MinhajNo ratings yet

- Copy (2) of JSA For HDPE Liner Fusion Welding Includes Night Works1Document7 pagesCopy (2) of JSA For HDPE Liner Fusion Welding Includes Night Works1noahlungu96No ratings yet

- JSA For SURGE VESSEL WorkDocument6 pagesJSA For SURGE VESSEL Workathul subashNo ratings yet

- JSA-Confined Space Activity - 05Document4 pagesJSA-Confined Space Activity - 05babjihanumanthuNo ratings yet

- 5.19.3 Job Safety Practices Rev 02-BlankDocument4 pages5.19.3 Job Safety Practices Rev 02-BlankShafie ZubierNo ratings yet

- Risk Assessment - CableDocument6 pagesRisk Assessment - Cablemohamad hafiz0% (2)

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- JHA - Unloading of Sheet PileDocument3 pagesJHA - Unloading of Sheet PileJensen Sunga100% (1)

- Copy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksDocument7 pagesCopy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksMohammed Minhaj80% (5)

- Work Method Statement: Wms Rev. NoDocument5 pagesWork Method Statement: Wms Rev. NoKarthik babuNo ratings yet

- Action On Agricultural. Calculating Agricultural EmissionsDocument27 pagesAction On Agricultural. Calculating Agricultural EmissionsXoel UrriagaNo ratings yet

- Time and Motion Study of OPDDocument15 pagesTime and Motion Study of OPDsaurabh100% (1)

- VAC Form 2 CityMunicipal Consolidated FormDocument1 pageVAC Form 2 CityMunicipal Consolidated Formalex almarioNo ratings yet

- Ecodial Advance Calculation 4.1Document33 pagesEcodial Advance Calculation 4.1Youwan LeeNo ratings yet

- Format Bahasa Inggeris UPSR 2016 ENGLISH (013) Section ADocument33 pagesFormat Bahasa Inggeris UPSR 2016 ENGLISH (013) Section AVINOTININo ratings yet

- Periodontal DiseaseDocument4 pagesPeriodontal Diseasemojako_badboysNo ratings yet

- Nigelaycardo 1Document8 pagesNigelaycardo 1ANGELICA AYCARDO FLORESNo ratings yet

- Ergo in Workplace PDFDocument7 pagesErgo in Workplace PDFsightbdNo ratings yet

- Kami Export - Jervocus Aiken - Ecosystem Project TEMPLATE 2023Document7 pagesKami Export - Jervocus Aiken - Ecosystem Project TEMPLATE 2023Jervocus AikenNo ratings yet

- RMLNLU Moot Court Competition (Funding & Reimbursement) Policy, 2019.Document4 pagesRMLNLU Moot Court Competition (Funding & Reimbursement) Policy, 2019.Aakash ChauhanNo ratings yet

- Nurs478 Healthcaredelivery Audrey GohDocument12 pagesNurs478 Healthcaredelivery Audrey Gohapi-316372858No ratings yet

- Audi A6 Allroad Model 2013 Brochure - 2012.08Document58 pagesAudi A6 Allroad Model 2013 Brochure - 2012.08Arkadiusz KNo ratings yet

- Catalogue Perkins 4012 46TAG1A 46TAG2ADocument18 pagesCatalogue Perkins 4012 46TAG1A 46TAG2AAbdoul-aziz Ben Ousmanou100% (1)

- Hazard Identification 2. Risk AssessmentDocument5 pagesHazard Identification 2. Risk AssessmentNoreen Syakireen Binti NormanNo ratings yet

- Crop RotationsDocument19 pagesCrop RotationsSarwar M. RasheedNo ratings yet

- Why encouraging entrepreneurship to boost economies is flawedDocument9 pagesWhy encouraging entrepreneurship to boost economies is flawedLaureanoNo ratings yet

- FT-IR Analysis of Hock ProcessDocument4 pagesFT-IR Analysis of Hock ProcessmohsengolestanzadehNo ratings yet

- Dgca Module 06 Part 02Document15 pagesDgca Module 06 Part 02Deepak Choudhary DCNo ratings yet

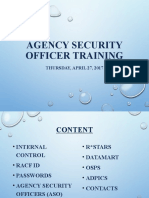

- 2017 Aso Security TrainingDocument60 pages2017 Aso Security TrainingTanzila SiddiquiNo ratings yet

- Corporate Governance at HavellsDocument16 pagesCorporate Governance at HavellsVishal Pundir100% (1)

- PPR - LISTS - Registered Medicine Price List - 20221127 BahrainDocument318 pagesPPR - LISTS - Registered Medicine Price List - 20221127 BahrainvdvedNo ratings yet

- Demand, Supply, and Market Equilibrium: Mcgraw-Hill/IrwinDocument34 pagesDemand, Supply, and Market Equilibrium: Mcgraw-Hill/IrwinLillian KobusingyeNo ratings yet

- SG Salary Guide 2021-22Document66 pagesSG Salary Guide 2021-22Gilbert ChiaNo ratings yet

- ASTM D7246-06 (Reapproved 2015)Document3 pagesASTM D7246-06 (Reapproved 2015)Phạm Thu HuyềnNo ratings yet

- Thermogravimetric Analysis - TGA: Analyzing & TestingDocument20 pagesThermogravimetric Analysis - TGA: Analyzing & TestingRusitaDessyNo ratings yet

- The Morning Calm Korea Weekly - Oct. 14, 2005Document26 pagesThe Morning Calm Korea Weekly - Oct. 14, 2005Morning Calm Weekly NewspaperNo ratings yet

- IB Student's Soil Systems GuideDocument7 pagesIB Student's Soil Systems GuideYohanes Sumantri RatnodiyantoNo ratings yet

- Lab Report 2Document5 pagesLab Report 2adrianeNo ratings yet

- Create Windows XP boot CD with McAfee Command Line ScannerDocument3 pagesCreate Windows XP boot CD with McAfee Command Line ScannerSudheesh PuthusseryNo ratings yet

- Bacnet® Fixed Function Thermostat: For Fan Coil/Heat Pump/Conventional SystemsDocument8 pagesBacnet® Fixed Function Thermostat: For Fan Coil/Heat Pump/Conventional Systemsamjadjaved033148100% (1)