Professional Documents

Culture Documents

JSA For SURGE VESSEL Work

Uploaded by

athul subash0 ratings0% found this document useful (0 votes)

15 views6 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views6 pagesJSA For SURGE VESSEL Work

Uploaded by

athul subashCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

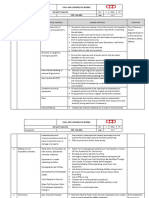

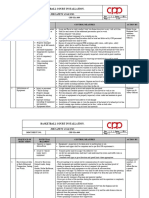

JSA-SURGE VESSEL

Project/Facility: BERG INDUSTRIAL LLC Reference No:

Client: Date of Assessments:

Assessed by: ATHUL SUBASH Date of Next Assessment:

Reviewed by: SADDAM HUSSAIN Approved by:

Activity: SURGE VESSEL MAKING

Emergency Plans. Standard PPE’s: First aid kit must be present at the worksite and the HSE personnel will be the first response in case of emergency, ERPs &

Emergency contact numbers to be in place at the job location

Review Process. After the job has been completed, JSA leader should note: any hazards, which were identified in the original JSA? In case of any new hazard

identified by any of the working team members during the job, the JSA review process should be carried on.

Sr. Activity Potential Hazards Control Measures

Poor communication between work parties. Work permit from the client, with all concurring party’s signatures

1. Site Preparation Inexperience persons/lack of safety awareness approval, must be obtained before the start of work and display at the

Heat stress site

Noise Safety requirements mentioned in the permit to work (PTW) must be

Vehicles Movement available on-site and strictly followed

Toolbox talk shall be conducted to all personnel on-site & documented

before the start of work.

Appropriate PPE shall be worn by all personnel at the site.

Assigned trained dedicated Banks man for the job with a reflective jacket.

Enough availability of water should be there.

Work Schedule according to heat Index

Ear protection shall be worn where required.

Noise meter will be made available at the site.

Maintenance of equipment regularly.

Use of Approved/Trained license drivers.

Banks man must be always available for the vehicle movement control.

Appropriate signage to be provided.

Scaffolding erection dismantling and modification work including inside

Tanks

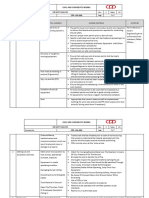

2. Transportation of Failure of equipment/crane /Trailer/ Pickup/Truck e Conduct toolbox talk and MOL before the

material/shifting of tc. start of work at the specific location.

Road vehicle Ensure the condition of equipment, inspected, sticker Placed and for appr

scaffolding by Using Crane,

traffic accident during transportation of Tanks shell opriate colour cod

Trailer, Boom Truck Pickup

plates, pipe spools/ supports and other material All rigging gear shall be certified.

etc. and or objects. Fabricated belt or nylon sling shall be used instead of steel wire rope for h

Body part injury during olding of material.

Loading and unloading operation Make sure that crane operators and riggers are competent and fully

Pinch point. understand all work tasks and hazards.

The load shall be secured on the trailer bed to prevent accidental fall.

Crane operator shall have the third party, certified, competent,

experienced and applicable license.

Use appropriate tag line during loading /off-loading material or other

heavy objects.

Access route shall be properly surveyed before transporting the Shell

Plates, pipes & support material or other objects etc.

Barricade with an appropriate signboard on the effective area.

Riggers shall be experienced and the third party certified.

Use leather gloves for hand protection.

Always keep away parts of the

body (hand, feet, head, etc.) from the line of fire.

The appropriate length of the trailer shall be arranged according to the

length of Shell Plates, pipe spools, material and supports etc.

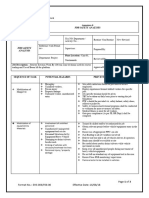

3. Scaffolding Erection SIMPOS Conduct ‘TBT’ before the start of the activity. Prepare, develop and

Dismantling Segregation and Stacking Failure conduct toolbox talks based on JSA and specific job site requirements

Incorrect Manual Handling Obtain PTW, review and communicate to all involved in the task.

Including Material Storage

Pinch point Participate and communicate with area management to ensure no

Eye injury adverse interface impact or hazard.

Fire Install correct warning signage and barricading for the observation by

Slips, Trips and Falls other parties. Follow recommended maximum stacking guidelines.

Lack of proper and enough All scaffold materials shall be stacked and segregated safely and by type.

knowledge by scaffolders regards correct erection a Stacking and storage guidelines shall be prominently signposted in an

nd Safe Working Load easy visual display.

(SWL), wind speeds, scaffold ties incorrect, etc Shelving/racking shall be stable and appropriate; pallets

Incorrect or no supervision at the worksite When used shall be in good condition without defect.

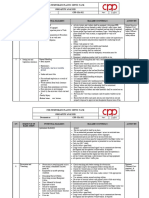

Not up to standard. Do not conform to BS Pipes and/or tubular components shall be adequately chocked.

Not inspected leading to failure. Not sufficient for t All scaffold personnel shall have attended and passed the project ‘Manual

he purpose or task Handling’ training programs.

Injury to worker/employee through incorrect mech Weight and packaging shall be checked and evaluated before handling.

anical or improper manual handling. Pinch Pints shall be identified and hands shall not be placed in the ‘Line of

Musculoskeletal damage, dropped objects, pinch po Fire’ between unsecured items or under loads being raised or landed.

ints. Eye protection shall be worn dust particle injury.

Lack of competence Eyewash facilities shall be provided and First Aid equipment and

Dropped objects personnel shall be available Scaffold personnel shall be trained in the use

Working overhead. of fire extinguisher and/or other firefighting equipment (blankets, etc.).

People entering the danger zone Emergency numbers and fire hazard signage shall be prominently

Dropped tools, work carried out incorrectly displayed.

Lack of experience. The work areas shall be maintained with good housekeeping.

The incorrect sequence of work Access ways and Scaffolds are clear and free of obstruction Determine at

Incorrect Couplers used. PTW and Toolbox talk stage what type of scaffold is required (BASIC, ADV

Lack of training in manual handling techniques ANCED, SUPPORT, DESIGN required)

Incorrect Couplers used. Supervisor or foreman present at the work area to oversee the worksite.

Lack of training in manual handling techniques Meet all BS/EN requirements.

Falls through access openings placed centrally with Are inspected before delivery to site

out handrails All lifting equipment inspected regularly as per site procedure.

Manual handling techniques, inspected cranes, forklifts, ancillary

Incorrect erection procedure

Equipment, etc.

Does not meet and Safe Working Load (SWL) or

Materials to be stored in a safe manner

there is a potential for the scaffold to fall over if not

Do not stack too high to prevent collapse

tied

Third-party training.

Potential falls of end-users and scaffolders

Ensure all of the workforces including supervisors, vehicle operators and

Likelihood scaffold will fall over at the early stages if

other technical staff have enough

the height to base ratio is exceeded or

experience, theoretical and practical training before commencing the sca

if ties are removed

ffold work.

The scaffold has a high potential to fall over

Make sure that barricades, multi-language HSE

Scaffold falling over and or

warning signs, warning tape, flagman (where applicable) are in place

collapse causing serious injury or asset damage

before the work commences

No design.

Ensure Gin Wheel areas are barricaded

No competent person. Place correct warning signage ‘men working overhead’.

Lack of supervision Adequate Gin Wheel and Lifting bag signage are displayed.

No experience. A flagman placed preventing entry to a high-risk area.

Use of two systems. PPE hall is worn at all times.

Use of incompatible material.

Supporting structure inadequate. Tools shall be of the correct type and secured with lanyards at height.

Use of inferior materials Competent scaffolders with knowledge of basic scaffolding.

Potential falls of scaffolders and end-users Ensure the base is adequate to support the scaffold

Not fit for purpose Ensure the correct sequence of the

Incorrect couplers used. erection and that all components meet the BS EN criteria.

Lack of training in manual techniques. Joints in standards to be diagonally conflicted or

Incorrect erection procedure. opposed with no more than Two-2 joints per bay.

The likelihood that scaffold will fall over at an early Ensure the correct sequence of the

stage erection and that all components meet the BS EN criteria.

Not fit for purpose incorrect couplers used. Joints in standards to be diagonally opposed with no more

Lack of training in manual handling techniques than 2 joints per bay.

Joints in the same bay. Ensure the correct sequence of the

erection and that all components meet the BS criteria

Joints in standards to be diagonally opposed with no more than

2 joints per bay.

Follow the PRL procedure on scaffolds.

Always make sure that

correct ladder access is placed with ladders at a 75-degree angle or 1 in 4.

Ensure ties are fixed and are not removed throughout the scaffolds ‘life’.

Any activity such as removal of ties should be undertaken by competent

and advanced scaffolder or under the direct supervision from the

Foreman.

Remove the Scaff-Tags, bring workforce/visitors or

people off and away from the scaffold

Full design drawings and calculations available

Scaffolders must be competent with knowledge of Advanced scaffolding

competency training and certifications.

Ensure the existing structure is appropriate to support the suspended

scaffold.

Follow the TG20:2008 and JGC procedure on scaffolds

Ensure proper fall arrest equipment is used for the specifical job e.g. full-

body safety harness, inertia reel and have been inspected and in proper

working condition. Inertia reel to have a

valid test certificate and be correctly colour-coded.

Follow BS EN applicable standards, requirement.

Lift to be no more than 2 m vertically.

Ensure the correct sequence of the

erection and that all components meet the BS EN criteria.

Joints in standards to be diagonally opposed with no more than 2 joints

per bay.

Communication between the scaffolding supervisor and the end-user sup

ervisor to ensure the scaffold is fit for the purpose intended

Ensure correct sequence of the

erection and that all components meet the BS EN criteria

Ensure sleeves are used and staggered.

Joints in various bays at each level of the scaffolding to ensure ‘sound’ con

struction method or techniques.

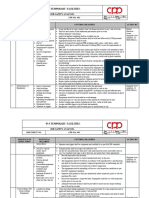

4. Confined Space Entry Lake of Communication All personnel working in confined space must have confined space

Ventilation. training.

Damage material PRL confined space procedure shall be followed.

Oxygen deficiency Hole-watcher is active/attentive all the time during confined space work.

Accumulation of toxic gases Lighting provided in CSE to be 24V.

Physical hazards An effective, easily understandable communication between hole-

Improper stacking of material watcher and supervisor is established all the time.

Unauthorized entrant Proper access/agrees should be maintained.

Lack of oxygen /oxygen/ air deficiency Gas test to be done by AGT before entering into the confined area

A well trained, competent and qualified individual should outside the tank

with the accountability of ensuring the safety of authorized work

performers (such as Fabricator, Fitter, Welder e.tc) through the

performance pre-task entry briefing, checking and inspecting PPE,

equipment and tools and performing regular monitoring ensuring person

conducting work activity inside pipe remains safe and secure for entry and

occupation.

A written Emergency rescue plan that has provision for carrying out a

timely rescue of individuals working inside the pipe (Confined Space)

should be kept on site.

Raising the Fire Alarm (FA) in the event of an emergency.

Using the radio/mobile phones provided to them.

Make sure that an effective communication system for the entry is tested

and in place.

Enough and appropriate required light should be provided less than 25v.

All material stacks are proper and category wise.

Emergency Rescue arrangement shall be made while working more than

five-meter inside large bore size.

HSE Procedure shall be followed.

Close supervision required while working inside.

Carry out the work under close supervision and presence of hole -

watcher. Proper air supplies to be provided or air mover will be provided.

Proper ventilation shall be there.

Working crew shell is trained for confined space working.

5. Protracted/Lengthy Improper lighting in and around work areas, causing Inadequate lighting at the work area and Access/Egress area.

Working Hour/Night Works shadows or poorly lit work areas that could result in The emergency route to muster point to be illuminated.

unsafe acts and the possibility of severe and critical Proper cable management

injuries. Use clear safety goggles for night work shift hours for good visibility to

avoid any unwanted incident.

Warning Lights and signboards.

Trained Flagman for equipment movement provided with a signal torch.

Close supervision needed while working in night shift.

6. Emergency Procedure/ Poor Communication Educate the workforce about Emergency Procedure.

Response Improper Access/ Egress All safety signboard shall be displayed properly at the site.

In case of any emergency, all work will be stopped, Shut down all running

equipment & Machinery and reported to Muster Point

Proper Access & Egress shall be available.

All Workforce shall have the proper knowledge

of the Muster Point location.

Emergency Procedure to be followed.

Emergency # 999/911, etc.

7. Housekeeping Trips and fall All waste generated shall be contained and disposed of in designated

Sharp Objects Waste skips.

Equipment damage Do not store materials/equipment inside the plant area.

Use appropriate and essential Personal protective equipment (PPE)

for the handling of waste.

Note: All materials, wastes or shall be removed from the worksite to a

safe storage location ASAP after the work.

You might also like

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument17 pagesJSA For Scaffolding Erection Dismantling and Modification Workshane.ramirez1980No ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (1)

- JSA For Erection and Repair Work of TanksDocument19 pagesJSA For Erection and Repair Work of TanksMohamed Farouk100% (2)

- JSA For Hydro Jetting, Removal and Cleaning of SludgeDocument18 pagesJSA For Hydro Jetting, Removal and Cleaning of Sludgesk sajidNo ratings yet

- Scaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking ShedDocument3 pagesScaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking ShedkrishnakumarNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTDocument6 pagesJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekarNo ratings yet

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pages5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisNo ratings yet

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTDocument6 pagesJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekarNo ratings yet

- 1st Aid Training Siemens ContractorDocument11 pages1st Aid Training Siemens ContractorTigor GurningNo ratings yet

- Jsa For Plaster WorkDocument4 pagesJsa For Plaster Workumar KhitabNo ratings yet

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- JSA For Road BarrierDocument3 pagesJSA For Road BarrierMohammed MinhajNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- Jsa For Excavation and BackfillingDocument5 pagesJsa For Excavation and Backfillingshaibaz chafekarNo ratings yet

- JHSA For Temporary Plastic Septic TankDocument4 pagesJHSA For Temporary Plastic Septic TankAnna JisabaNo ratings yet

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- PARCO - Mid Country Refinery: Job Safety AnalysisDocument6 pagesPARCO - Mid Country Refinery: Job Safety AnalysisGyanendra Narayan NayakNo ratings yet

- Sunmow Jha 001Document3 pagesSunmow Jha 001Douglas DellyNo ratings yet

- JHSA Water Supply and Sewer InstallationDocument4 pagesJHSA Water Supply and Sewer InstallationAnna JisabaNo ratings yet

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Job Safety & Environmental Analysis WorksheetDocument2 pagesJob Safety & Environmental Analysis WorksheetCherry BetonioNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Jsa For Installation of Pipe Railing On SkidDocument6 pagesJsa For Installation of Pipe Railing On SkidLokesh Aravindan100% (1)

- Project: Install Generator For Back Up Power Supply For Building 3056 For ShedgumDocument11 pagesProject: Install Generator For Back Up Power Supply For Building 3056 For ShedgumAnonymous voA5Tb0No ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- Job Safety Analysis: Shaybah NGL Recovery Plant DepartmentDocument4 pagesJob Safety Analysis: Shaybah NGL Recovery Plant DepartmentMadhan KannanNo ratings yet

- Adr Jsa 1711 002Document7 pagesAdr Jsa 1711 002Dada KhalandarNo ratings yet

- JSA For Materia/equipment Loading Unloading & Shifting Work JsaDocument3 pagesJSA For Materia/equipment Loading Unloading & Shifting Work JsaAKBAR ALINo ratings yet

- PCW Pipe Installation JhaDocument2 pagesPCW Pipe Installation Jhafatimah100% (1)

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Ali QaziNo ratings yet

- JSA For Construction of E - P WorkshopDocument5 pagesJSA For Construction of E - P Workshopm.rehanhseNo ratings yet

- Jsa Road BlockingDocument3 pagesJsa Road BlockingRam Krishna100% (1)

- Jsa For Temporary Facility Installations PS5Document9 pagesJsa For Temporary Facility Installations PS5Anna JisabaNo ratings yet

- Fill-Up This Card Before Commencement of Critical WorksDocument4 pagesFill-Up This Card Before Commencement of Critical WorksSiddhant choudharyNo ratings yet

- Jsa For Basket Ball C Ourt Installation.Document6 pagesJsa For Basket Ball C Ourt Installation.Anna JisabaNo ratings yet

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- DB Termination JhaDocument2 pagesDB Termination JhafatimahNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- Jsa - ExcavationDocument7 pagesJsa - ExcavationNOOR AISYA AMIRA ZUKAFLI100% (1)

- Safe Plan of Action Ramsu EnterpriseDocument5 pagesSafe Plan of Action Ramsu EnterpriseSanjeev Kumar100% (1)

- Equipment/reactor Erection Work JsaDocument3 pagesEquipment/reactor Erection Work JsaAKBAR ALINo ratings yet

- JSA For Suspended CielingDocument4 pagesJSA For Suspended Cielingumar KhitabNo ratings yet

- JSA Blasting and Coating KP 69.4Document5 pagesJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- JSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaDocument4 pagesJSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaMohammed Minhaj100% (1)

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document5 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- JSA SK Erection DismantlingDocument1 pageJSA SK Erection DismantlingSamuel Hugos100% (4)

- JSA - Cast in Place Reinforced Concrete ChamberDocument8 pagesJSA - Cast in Place Reinforced Concrete ChamberSkinhead TvNo ratings yet

- Jsa 14Document6 pagesJsa 14Abhi SandiNo ratings yet

- Jsa For Electrical Installation.Document2 pagesJsa For Electrical Installation.Anna JisabaNo ratings yet

- KPI Template HSEDocument3 pagesKPI Template HSEpyuditya75% (8)

- HSE Plan-TDDocument56 pagesHSE Plan-TDMohammed Ali Qazi100% (1)

- Specifications of 10T EOT Crane For 02 BlockDocument12 pagesSpecifications of 10T EOT Crane For 02 Blockathul subashNo ratings yet

- Athul SITE ENGINEER RESUMEDocument3 pagesAthul SITE ENGINEER RESUMEathul subashNo ratings yet

- HSE P 08 Corrective and Preventive Action Issue 2 1Document8 pagesHSE P 08 Corrective and Preventive Action Issue 2 1athul subashNo ratings yet

- Subcontractor Safety PrequalDocument3 pagesSubcontractor Safety PrequalKingsley PhangNo ratings yet

- Attachemnt RA Work at HeightDocument4 pagesAttachemnt RA Work at Heightathul subashNo ratings yet

- Attachment 8 RA LiftingDocument5 pagesAttachment 8 RA Liftingathul subash100% (2)

- DTL & TTL Based Logic GatesDocument4 pagesDTL & TTL Based Logic Gatesubaid umarNo ratings yet

- SkillELECTRIC 2023 Core Competences 11.01.23Document1 pageSkillELECTRIC 2023 Core Competences 11.01.23ahmad yasinNo ratings yet

- Slva642a PDFDocument22 pagesSlva642a PDFDheenã SagařNo ratings yet

- Chilled Water Cooling Plant Quarterly Insepction ReportDocument1 pageChilled Water Cooling Plant Quarterly Insepction ReportFaisal MuneerNo ratings yet

- 2N3791 & 2N3792Document3 pages2N3791 & 2N3792Juan David Velasquez BranNo ratings yet

- LG 42PQ30 Block DiagramDocument2 pagesLG 42PQ30 Block DiagrammakotoNo ratings yet

- Analog Input Module, 16-Bit, 8 Isolated Inputs: Product DescriptionDocument4 pagesAnalog Input Module, 16-Bit, 8 Isolated Inputs: Product DescriptionAlessandro InvitiNo ratings yet

- Circuit Breaker Analyzer & Timer CAT34: DescriptionDocument4 pagesCircuit Breaker Analyzer & Timer CAT34: Descriptionkenlavie2No ratings yet

- GS33K50F20 50eDocument4 pagesGS33K50F20 50eGolfkung PairojNo ratings yet

- SEBU6965-06 Before StartDocument6 pagesSEBU6965-06 Before StartLUIZ GUSTAVONo ratings yet

- Usbs - 27-1PS y 27-2PSDocument5 pagesUsbs - 27-1PS y 27-2PSKathy HolguinNo ratings yet

- Electrical SystemDocument368 pagesElectrical SystemAnonymous 28jRu2jNo ratings yet

- Rf-7800r-Rc Universal Remote Control System Tcm26-12078Document2 pagesRf-7800r-Rc Universal Remote Control System Tcm26-12078Lavanda Focsani50% (2)

- Acer Travelmate 4150 Dunlin LA-2601 SchematicsDocument51 pagesAcer Travelmate 4150 Dunlin LA-2601 SchematicsDoru Razvan100% (1)

- LS Swap Guide 73 - 87Document22 pagesLS Swap Guide 73 - 87abdallah ghunajuqNo ratings yet

- Om MFL67227304-7 PDFDocument92 pagesOm MFL67227304-7 PDFdan NONINONo ratings yet

- 198508-1985 American Aircraft Falcon XPDocument4 pages198508-1985 American Aircraft Falcon XPfabianmeschiniNo ratings yet

- Hydraulic System TroubleshootingDocument9 pagesHydraulic System TroubleshootingSantos Quiñones ParimangoNo ratings yet

- 714-52 Mifare ID Reader: With Selectable OutputsDocument7 pages714-52 Mifare ID Reader: With Selectable OutputsSergio Landete ExpositoNo ratings yet

- AccessoryDocument14 pagesAccessoryBuku DigitalNo ratings yet

- Service Manual: HTX29S31SDocument29 pagesService Manual: HTX29S31SMontecarloNo ratings yet

- Advanced Digital VLSI Design (ECE 521) (Makeup) PDFDocument2 pagesAdvanced Digital VLSI Design (ECE 521) (Makeup) PDFRahul PinnamaneniNo ratings yet

- SuSD.1.F.008-Electrical Data SheetDocument6 pagesSuSD.1.F.008-Electrical Data SheetHonnie Mae PaduaNo ratings yet

- Lifebook E733Document32 pagesLifebook E733Saša Š.No ratings yet

- EE 330 HW 1 Solutions Fall 2011Document3 pagesEE 330 HW 1 Solutions Fall 2011murphy111No ratings yet

- Jlo Engines Rockwell L-227 L-230 L-252-l Jp-7710 IplDocument8 pagesJlo Engines Rockwell L-227 L-230 L-252-l Jp-7710 Ipljim1961No ratings yet

- "2005" Seminar Information: Jeep With 2.5 or 4.0 Liter Engines & Aw4 TransmissionDocument2 pages"2005" Seminar Information: Jeep With 2.5 or 4.0 Liter Engines & Aw4 TransmissionRoman NavaNo ratings yet

- MSE6-E2M 2014-04 8037121g1Document136 pagesMSE6-E2M 2014-04 8037121g1SAABNo ratings yet

- Alignment of Vertical Shaft HydrounitsDocument50 pagesAlignment of Vertical Shaft HydrounitsAlexander Gotte100% (3)

- GPL 12260Document2 pagesGPL 12260cozocNo ratings yet