Professional Documents

Culture Documents

At TC3CN006 18 T1 Ja101

Uploaded by

Dhaneswar SwainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

At TC3CN006 18 T1 Ja101

Uploaded by

Dhaneswar SwainCopyright:

Available Formats

Bolted Connections –

Inspection

AT-TC3CN006-18-T1-JA10

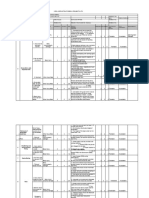

Key Inspection Points for Bolt Tightening Checklist

Below is a checklist of the key inspection points for four different bolt

tightening methods: turn-of-nut, calibrated wrench, direct tension

indicator (DTI), and twist-off bolts.

Note that some specifications described in the following content may not

be the same as the specifications followed by your agency. Always check

with your State agency's standards and specifications when using these

guidelines.

Sections

● Turn-of-nut

● Calibrated Wrench

● Direct Tension Indicator (DTI)

● Twist-off Bolts

Turn-of-nut

Ensure that snug-tight closes all gaps and that uniform hand torque is being

applied (turn-of-nut depends upon on all bolts being equally tight at the

start)

Make sure that installers are holding the bolt head from turning (turn angle

on the nut means nothing if the bolt turns)

Ensure that installers can explain the required turn angle and whether or not

it changes when the bolt grade and length change

Both the beginning and ending angle marks should be visible on the joint and

also be on the nuts

Calibrated Wrench

Ensure that all tools have calibration stickers and that the torque-to-tension

test ratio is known for that specific tool on the R-C lot number of bolt

assemblies being tightened

Published August 2018 1

Bolted Connections –

Inspection

AT-TC3CN006-18-T1-JA10

Make sure that the bolt is not allowed to turn during tightening as false

results can happen

Do not allow any pre-published torque charts to be used

Ensure the same lubrication and bolt conditions as were used during the

torque-tension test

Ensure that hardened flat washers, or beveled washers where required, are

used under the nut and bolt, especially in non-standard holes as frictions will

change

Direct Tension Indicator (DTI)

Ensure that DTIs are properly placed with the bumps away from the joint and

usually not under the turning member (another washer should be on top of

the DTI if the nut is turning on it)

If squirt washers are used, conduct a test in the tension calibrator to verify

the amount of squirt that approximates the desired tension value, and make

sure that the operators are consistent

Have the operators explain the use of the feeler gauge on DTIs

Double check the parallelism of the plies (if the assembly is not square, it can

lead to false results)

Twist-off Bolts

Ensure that lubrication and condition of the bolts is the same as when the

rotational capacity (ROCAP) testing was done—this method measures

torque, not bolt tension directly

Be sensitive to crosstalk issues as bolts may loosen as adjacent bolts are

tightened—re-tightening with a calibrated torque wrench may be necessary

but if the bolt has a button-head that may be impossible

Make sure operators collect the broken bolt ends as they can be a slip hazard

and can fall from height

Published August 2018 2

Bolted Connections –

Inspection

AT-TC3CN006-18-T1-JA10

Ensure that hardened flat washers, beveled washers, or finger shims are

used with these bolts when needed

Published August 2018 3

You might also like

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Pa 1016b Turntable Bearing Bolt Inspection (All Units)Document4 pagesPa 1016b Turntable Bearing Bolt Inspection (All Units)albanNo ratings yet

- Torque Wrench Standard Practices - Full Version.Document7 pagesTorque Wrench Standard Practices - Full Version.Siva SubramaniNo ratings yet

- How It Works - PDF RotaBoltDocument5 pagesHow It Works - PDF RotaBoltaop10468No ratings yet

- Model M ManualsDocument6 pagesModel M ManualsdiegoNo ratings yet

- Alignment: Torque vs. TensionDocument6 pagesAlignment: Torque vs. Tensionfrancesca_bonfanti_1No ratings yet

- Question & AnswerDocument12 pagesQuestion & AnswerbalamuruganNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentKarthik VadlamudiNo ratings yet

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- Skidmore Instructions Model MS ManualsDocument15 pagesSkidmore Instructions Model MS ManualsbwbrockNo ratings yet

- Assembly and Tensioning of High Strength Bolts andDocument14 pagesAssembly and Tensioning of High Strength Bolts andKirtichandraKomarrajuNo ratings yet

- Click Wrench RepairDocument31 pagesClick Wrench RepairTu PhamNo ratings yet

- A325-Twist of BoltDocument6 pagesA325-Twist of BoltPham NhatNo ratings yet

- Er 063 2Document4 pagesEr 063 2ariel.garayNo ratings yet

- General Information: Torque SpecificationsDocument3 pagesGeneral Information: Torque SpecificationsLuis TepezanoNo ratings yet

- Specifications TorqueDocument20 pagesSpecifications Torquethoma111s100% (2)

- HSFG Bolts British MetricDocument24 pagesHSFG Bolts British MetricAlastair BrownNo ratings yet

- 70.00.00 Standard Practices - Maintenance ProceduresDocument21 pages70.00.00 Standard Practices - Maintenance ProceduresTimoteo Molina RomeroNo ratings yet

- CAT Torque Specifications General InformationDocument2 pagesCAT Torque Specifications General InformationSergeyNo ratings yet

- Setting Obc KTA 19Document6 pagesSetting Obc KTA 19ariy yuli styawan100% (1)

- Rota BoltDocument5 pagesRota Boltgst ajahNo ratings yet

- General InformationDocument7 pagesGeneral InformationRobert SantiagoNo ratings yet

- Operational Performance Test / Engine Test: Valve Clearance AdjustmentDocument5 pagesOperational Performance Test / Engine Test: Valve Clearance AdjustmentArdi Heineken PradaNo ratings yet

- 5fb10-30 Repair Manual Ce308Document262 pages5fb10-30 Repair Manual Ce308Сергей Сергей100% (1)

- AAX Tong MaintenanceDocument7 pagesAAX Tong MaintenanceBahman Matouri100% (1)

- SM-TOYOTA 5FB10 30-5FB10 5FB14 30-5FB14 5FB15 30-5FB15 5FB18 30-5FB18 5FB20 30-5FB20 - AaaDocument47 pagesSM-TOYOTA 5FB10 30-5FB10 5FB14 30-5FB14 5FB15 30-5FB15 5FB18 30-5FB18 5FB20 30-5FB20 - AaaHushanji100% (2)

- Toyota 5FBE10-18 - Service ManualDocument441 pagesToyota 5FBE10-18 - Service ManualjonathanrioscNo ratings yet

- Study of Contact - RetentionDocument10 pagesStudy of Contact - RetentionvkmsNo ratings yet

- C11 and C13 On-Highway Engines-Parte1Document69 pagesC11 and C13 On-Highway Engines-Parte1yeferson mora guerreroNo ratings yet

- Bolt TensionDocument2 pagesBolt TensionJayaram GowdaNo ratings yet

- Assembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62Document12 pagesAssembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62rajuajiNo ratings yet

- Flange Joint and Flange ManagementDocument20 pagesFlange Joint and Flange Managementsiraphat.bmNo ratings yet

- Assembly Removal and Installation: Remove and Install The Parts, As Shown BelowDocument5 pagesAssembly Removal and Installation: Remove and Install The Parts, As Shown BelowHugoE.TorresNo ratings yet

- True Bore Alignment System: User GuideDocument12 pagesTrue Bore Alignment System: User GuideDenis BenderNo ratings yet

- Bolt Torque & Bolt Tap TestDocument20 pagesBolt Torque & Bolt Tap Testbudymood100% (3)

- 99 AX Booster Assembly ManualDocument34 pages99 AX Booster Assembly ManualFernando NunezNo ratings yet

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

- Metastream TSC Coupling IOMDocument4 pagesMetastream TSC Coupling IOMthanhphamNo ratings yet

- Torque Screwdriver RepairDocument16 pagesTorque Screwdriver RepairFrancisco Ros AlvaradoNo ratings yet

- Tabla Tension Correas GatesDocument4 pagesTabla Tension Correas Gatesvibrador0% (1)

- Instruction Manual High-Strength Structural Bolting AssembliesDocument30 pagesInstruction Manual High-Strength Structural Bolting AssembliesRaul Becerra FalomirNo ratings yet

- 4M41Document10 pages4M41Guadalupe GuerreroNo ratings yet

- TX Dot RocapDocument9 pagesTX Dot RocapIFIdocsNo ratings yet

- TDS Encoder Belt Tension and Pulley Alignment ProcedureDocument1 pageTDS Encoder Belt Tension and Pulley Alignment ProcedureCarelNo ratings yet

- Direct Tension Indicator: Instruction ManualDocument5 pagesDirect Tension Indicator: Instruction ManualKemal HanogluNo ratings yet

- Rev00-Gasket Installation & Bolt Torquing ProcedureDocument24 pagesRev00-Gasket Installation & Bolt Torquing ProcedureHansel FrancisNo ratings yet

- Manual ToyotaDocument37 pagesManual ToyotaBastian Tapia LopezNo ratings yet

- Instruction Manual For Installing High-Strength Bolts: With Direct Tension Indicators (ASTM F959M) Metric Series EditionDocument24 pagesInstruction Manual For Installing High-Strength Bolts: With Direct Tension Indicators (ASTM F959M) Metric Series EditionHendri Arief SetyawanNo ratings yet

- Manual de Torques CaterpillarDocument48 pagesManual de Torques CaterpillarJohn Calfuan Alfaro50% (2)

- Sebf 8054 Обмеры и Правка КвDocument33 pagesSebf 8054 Обмеры и Правка КванджелаNo ratings yet

- Procedures For Rotational Capacity Testing For High Strength BoltsDocument12 pagesProcedures For Rotational Capacity Testing For High Strength BoltsAGnes Stephani MuntheNo ratings yet

- Pretension Ing With DTI SquirtersDocument2 pagesPretension Ing With DTI SquirtersmrgishiNo ratings yet

- Model MS ManualsDocument15 pagesModel MS ManualsbarrettshawnNo ratings yet

- GPT Installation Instructions - LoresDocument7 pagesGPT Installation Instructions - LoresEWheelerFKNo ratings yet

- TC-FJ Running Manual 2021 Rev. DDocument9 pagesTC-FJ Running Manual 2021 Rev. DGouldNo ratings yet

- TCBC-TS Running Manual 2021 Rev ADocument10 pagesTCBC-TS Running Manual 2021 Rev AGouldNo ratings yet

- 7.0 Reference: 7.1 Engine Room LayoutDocument3 pages7.0 Reference: 7.1 Engine Room LayoutCarlos MenaNo ratings yet

- TCBC-HT Running Manual 2021 Rev BDocument9 pagesTCBC-HT Running Manual 2021 Rev BGould100% (3)

- Presentation On Torqueing Tension IngDocument13 pagesPresentation On Torqueing Tension IngudayalNo ratings yet

- Concrete Mixer Inspection ChecklistDocument1 pageConcrete Mixer Inspection ChecklistDhaneswar SwainNo ratings yet

- Powerpoint Heat SafetyDocument11 pagesPowerpoint Heat SafetyDhaneswar SwainNo ratings yet

- TF-Chimney & VFD-16.04.15Document9 pagesTF-Chimney & VFD-16.04.15Dhaneswar SwainNo ratings yet

- The Importance of EffectiveDocument6 pagesThe Importance of EffectiveDhaneswar SwainNo ratings yet

- TrainingDocument16 pagesTrainingDhaneswar SwainNo ratings yet

- Ladder Inspection Checklist 10-2017Document2 pagesLadder Inspection Checklist 10-2017Dhaneswar SwainNo ratings yet

- Gas Cutting & WeldingDocument37 pagesGas Cutting & WeldingDhaneswar SwainNo ratings yet

- Civil 0042 CHECKLIST FOR CIVIL WORKSDocument30 pagesCivil 0042 CHECKLIST FOR CIVIL WORKSDhaneswar SwainNo ratings yet

- Training Title: Confined Space Entry (Especially Rescue) Location: Jebel Ali Terminal Dubai Trainer Name: Syed Neyaz AhmadDocument27 pagesTraining Title: Confined Space Entry (Especially Rescue) Location: Jebel Ali Terminal Dubai Trainer Name: Syed Neyaz AhmadDhaneswar SwainNo ratings yet

- Sample HIRADocument18 pagesSample HIRADhaneswar SwainNo ratings yet

- EMP PlanDocument8 pagesEMP PlanDhaneswar SwainNo ratings yet

- Safety Quiz - Office Safety Answer KeyDocument2 pagesSafety Quiz - Office Safety Answer KeyDhaneswar SwainNo ratings yet

- Confined Space PermitDocument3 pagesConfined Space PermitDhaneswar SwainNo ratings yet

- Safety Quiz - Electrical Safety-1: DirectionsDocument2 pagesSafety Quiz - Electrical Safety-1: DirectionsshreyasNo ratings yet

- Safety Quiz - Electrical Answer KeyDocument2 pagesSafety Quiz - Electrical Answer KeyDhaneswar SwainNo ratings yet

- Authorization Letter For New WorkersDocument2 pagesAuthorization Letter For New WorkersDhaneswar SwainNo ratings yet

- Viviid Renewables PVT - LTDDocument37 pagesViviid Renewables PVT - LTDDhaneswar SwainNo ratings yet

- 02 - Accident ReportDocument6 pages02 - Accident ReportDhaneswar SwainNo ratings yet

- HIRA - Erection by Crane - PannelDocument5 pagesHIRA - Erection by Crane - PannelDhaneswar SwainNo ratings yet

- NTPC Solapur - Main Plant - 19.06.2014Document1 pageNTPC Solapur - Main Plant - 19.06.2014Dhaneswar SwainNo ratings yet

- Hira - For Shot Blasting & Upto 2nd Coat of PaintingDocument15 pagesHira - For Shot Blasting & Upto 2nd Coat of PaintingDhaneswar SwainNo ratings yet

- Work PermitDocument2 pagesWork PermitDhaneswar Swain100% (1)

- Methodlogy of Blasting For ICHSDocument10 pagesMethodlogy of Blasting For ICHSDhaneswar SwainNo ratings yet

- Work at Height Training SheetDocument1 pageWork at Height Training SheetDhaneswar SwainNo ratings yet

- SHE Induction RegisterDocument2 pagesSHE Induction RegisterDhaneswar SwainNo ratings yet

- Winch Machine Safety PrecautionDocument2 pagesWinch Machine Safety PrecautionDhaneswar SwainNo ratings yet

- r7 13-Ehs Req PofDocument9 pagesr7 13-Ehs Req PofDhaneswar SwainNo ratings yet

- Hira BCN 22aDocument33 pagesHira BCN 22aDhaneswar SwainNo ratings yet

- Final Jsa & Method StatmentDocument11 pagesFinal Jsa & Method StatmentDhaneswar SwainNo ratings yet

- Cable Laying - Docx4Document2 pagesCable Laying - Docx4Dhaneswar SwainNo ratings yet

- Nov23 Design 01 06 Nov. 2023Document19 pagesNov23 Design 01 06 Nov. 2023Jayson MariNo ratings yet

- RC Cantilever Retaining Wall FinalDocument36 pagesRC Cantilever Retaining Wall FinalKrishna DixitNo ratings yet

- Compatible Puller Stud and Hydraulic Cylinder Capacity Chart (0599, 7000, 7562)Document5 pagesCompatible Puller Stud and Hydraulic Cylinder Capacity Chart (0599, 7000, 7562)Odai AlsaafinNo ratings yet

- Minisub ManualDocument12 pagesMinisub ManualCarlos CastilloNo ratings yet

- Operating Principles of Narkomed Anaesthesia Systems - DrägerDocument189 pagesOperating Principles of Narkomed Anaesthesia Systems - DrägerSergio MontesNo ratings yet

- DESIGN GUIDE For Midas Civil PDFDocument178 pagesDESIGN GUIDE For Midas Civil PDFHamidullah HassanzadaNo ratings yet

- Report 2021Document59 pagesReport 2021Bhushan LoharNo ratings yet

- 0008 Residential Tinsmithry 00Document2 pages0008 Residential Tinsmithry 00Jet ToledoNo ratings yet

- Trane Heat Pump XE1000Document32 pagesTrane Heat Pump XE1000jwyatt415560% (5)

- Ina Fag Pillow Block Housing CatalogDocument8 pagesIna Fag Pillow Block Housing Catalogjjcadena2000No ratings yet

- Lock Shield Valve: FeaturesDocument1 pageLock Shield Valve: FeaturesAymen AyedNo ratings yet

- RGA22 Scale Applicator Installation GuideDocument7 pagesRGA22 Scale Applicator Installation GuideKaya Eralp AsanNo ratings yet

- Replacement of Chiller SystemDocument71 pagesReplacement of Chiller Systemmoejamal80No ratings yet

- (Dieselyturbos2) - (26-09-2018) : Parts ListDocument6 pages(Dieselyturbos2) - (26-09-2018) : Parts ListEdinson Ariel Chavarro QuinteroNo ratings yet

- Sir AquinoDocument529 pagesSir AquinoJat Bacsafra0% (2)

- Face-to-Face Dimensions For Integral Flanged Globe-Style Control Valve Bodies (ANSI Classes 125, 150, 250, 300, and 600)Document14 pagesFace-to-Face Dimensions For Integral Flanged Globe-Style Control Valve Bodies (ANSI Classes 125, 150, 250, 300, and 600)Anant Rubade100% (1)

- Ba'Ck To Basics ... : DevelopmentDocument10 pagesBa'Ck To Basics ... : DevelopmentAlaa MaherNo ratings yet

- c5 - Basic Hydraulic CircuitDocument30 pagesc5 - Basic Hydraulic CircuitRaymond LeoNo ratings yet

- MW V.11 Full Line Global Catalog EnglishDocument38 pagesMW V.11 Full Line Global Catalog EnglishZélia OrnelasNo ratings yet

- Guidewires and Micro CathetersDocument34 pagesGuidewires and Micro CathetersDivyeshNo ratings yet

- Ervice AND Arts AnualDocument78 pagesErvice AND Arts AnualMelanie GerdesNo ratings yet

- DBM-400 Instruction PDFDocument80 pagesDBM-400 Instruction PDFZorig IshdoNo ratings yet

- BF Adpters Back Up Rings OnlyDocument1 pageBF Adpters Back Up Rings OnlyHomayraCarranzaNo ratings yet

- Chiller MCQDocument3 pagesChiller MCQHibaNo ratings yet

- AEROI F2B-Parts 0930-038201Document22 pagesAEROI F2B-Parts 0930-038201Jonah RagleNo ratings yet

- Series: Masoneilan High Temperature High Pressure Globe Cage Valves Instruction ManualDocument14 pagesSeries: Masoneilan High Temperature High Pressure Globe Cage Valves Instruction ManualelglockNo ratings yet

- Engine ThesisDocument8 pagesEngine Thesisjessicafinsonmanchester100% (1)

- CNC PaperDocument2 pagesCNC Paperfahadfadi48No ratings yet

- Pcs Fca140 Leaflet Interactiveonline enDocument4 pagesPcs Fca140 Leaflet Interactiveonline enLyonelNo ratings yet

- Concrete Column Design Based On ACI 318-19: Input Data & Design SummaryDocument3 pagesConcrete Column Design Based On ACI 318-19: Input Data & Design Summaryجميل عبد الله الحماطيNo ratings yet