Professional Documents

Culture Documents

EHS-SWI-037 - 0 Loadbank Testing - Draft

Uploaded by

Chris Bonnington100%(1)100% found this document useful (1 vote)

162 views2 pagesThis document provides safety instructions for load bank testing. It outlines qualifications and training required, safety checks of equipment and documentation, use of personal protective equipment, lockout/tagout procedures, and monitoring during energization and testing. Personnel must be qualified and trained. They must inspect equipment and documentation daily. During dead testing, adequate communication and defined work sequences must be followed. For live testing, at least two electrically skilled persons and a safety supervisor are required, and proper arc flash PPE must be worn. Status of the system and work area is monitored during and after testing.

Original Description:

Original Title

EHS-SWI-037_0 Loadbank Testing - Draft

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides safety instructions for load bank testing. It outlines qualifications and training required, safety checks of equipment and documentation, use of personal protective equipment, lockout/tagout procedures, and monitoring during energization and testing. Personnel must be qualified and trained. They must inspect equipment and documentation daily. During dead testing, adequate communication and defined work sequences must be followed. For live testing, at least two electrically skilled persons and a safety supervisor are required, and proper arc flash PPE must be worn. Status of the system and work area is monitored during and after testing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

162 views2 pagesEHS-SWI-037 - 0 Loadbank Testing - Draft

Uploaded by

Chris BonningtonThis document provides safety instructions for load bank testing. It outlines qualifications and training required, safety checks of equipment and documentation, use of personal protective equipment, lockout/tagout procedures, and monitoring during energization and testing. Personnel must be qualified and trained. They must inspect equipment and documentation daily. During dead testing, adequate communication and defined work sequences must be followed. For live testing, at least two electrically skilled persons and a safety supervisor are required, and proper arc flash PPE must be worn. Status of the system and work area is monitored during and after testing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

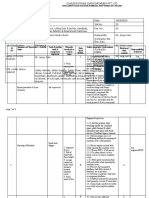

SAFE WORK INSTRUCTION

Load bank Testing

EHS-SWI-037_0

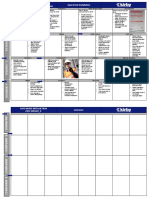

Qualifications / Training Safety Check Safety Devices Check Documentation

Personnel performing Daily & Before Daily & Before Before commencing the

testing must be commencing the shift: commencing the shift: shift:

competent and Ensure that all Check all testing Completed or signed

1. PREPARE

qualified to perform the persons involved in equipment’s and onto STA

task in full accordance task are informed of ensure that is Work permits to be in

with specified safety the days site testing calibrated and leads place. (Inspection and

procedures. activities and risks fitted for purpose Testing permit, Dead

Trade certificate (tested electrical Use calibrated working, Live

installations identified, Proving units to Working)

SFS 6002 Training

drawings, sources of ensure proof of Make sure all

First Aid training for energy) personnel read,

isolation verified

Electric Shock understand and sign

Visual inspect work against a calibrated

Arc Flash training area prior to unit. the RAMs

Approved Electrical commencing any Ensure and check

Safety supervisor (live) testing. communication

Personal Protective Gear (Dead Testing) Personal Protective Gear (Live Testing) Safety Controls Work Area

Kirby requires personnel Kirby requires Implement LOTO Barrier off work area

to wear: personnel to wear and apply personal and ensure suitable

2. ASSESS

Safety Footwear Arc Resistant PPE locks signage is in place.

Safety Glasses Proving unit Where equipment is Ensure that work

Safety Gloves Voltage indicator supplied from more area is clear and

than one source, place load bank unit

Safety Helmet

equipment must be cables in a safe way

High Visibility Vest labelled - user is fully Use adequate

Proving unit aware that dual protection against

Voltage indicator source exists direct or indirect

Ensure shepherd contact (PPE, rubber

hook and Fire mats)

extinguisher (Live

Testing)

Prior to testing Dead Testing After Dead Testing After Dead Testing

Check connection Maintain adequate All flash guards are Documentation to be

3. CONTROL

pins in cable communication then re-installed on completed and

Visually inspect all during testing boards / cubicles. submitted to the

elements of cabling, Follow defined Re-inspect the panel Commissioning

protective device, working sequence and ensure no Team

cable colours and Where 3 pole debris / swarf is

cable terminations breakers are used present, once KGE

(where applicable) neutral connection Electrical Tester

and prove dead will be disconnected checks are complete

Ensure site is in safe to carry out insulated and is satisfied the

condition for Power resistance test then equipment may

On (refer to procedure terminated and proceed to

OP-36) torqued. energisation.

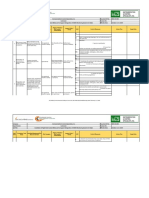

Energisation – Live testing Energisation – Live testing After Live Testing After Live Testing

The AP or Electrical Live testing shall be Once all testing is Warning & Danger

4. MONITOR

Tester shall check to done by a working complete VOLTAGE signs will

ensure the system is group that have at MCCB/ACB can be installed on each

complete, fully least two electrically remain closed or source end panel /

connected free of skilled persons alternatively KGE AP cubicle once tested.

any residual debris / having training in live will re-apply LOTO, For final circuits the

swarf and once all working and one AP will update site circuit designation

pre- requisitions are person acting as the MIMIC board where will be applied to

in place the AP can electrical safety applicable. each field device.

energise the isolator supervisor. Always maintain a

in question. Ensure that correct clean & tidy work

ARC Flash PPE is area.

xxxxxxxx

worn

SAFE WORK INSTRUCTION

EHS-SWI-037_0

5. WARNING ! 6. WARNING ! 7. WARNING ! 8. WARNING !

You might also like

- EHS-SWI-019 - 0 Lifting Operations For Teleporter - DraftDocument2 pagesEHS-SWI-019 - 0 Lifting Operations For Teleporter - DraftChris BonningtonNo ratings yet

- 7.electrical LOTO Check List InspectionDocument1 page7.electrical LOTO Check List Inspectionfitri widyaNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: DG OperationDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: DG Operationba ratnaparkheNo ratings yet

- MEWP: Pre-Use Inspection Checklist: Inspection Item Pass Fail CommentsDocument1 pageMEWP: Pre-Use Inspection Checklist: Inspection Item Pass Fail CommentsObodoruku StanleyNo ratings yet

- Ladders, Hop Ups Risk AssessmentDocument8 pagesLadders, Hop Ups Risk AssessmentRebecca Winter100% (1)

- JSA-Installation of Electronic Access Control & Physical Security Devices at Main Entrance Gate-1 HADEEDDocument8 pagesJSA-Installation of Electronic Access Control & Physical Security Devices at Main Entrance Gate-1 HADEEDMuhammad Umar GondalNo ratings yet

- HSE 14 Lockout and TagoutDocument1 pageHSE 14 Lockout and TagoutBa N Nhim100% (1)

- Jsa Ground Grid MocksvilleDocument2 pagesJsa Ground Grid MocksvilleChristopher NewbyNo ratings yet

- CAT-HSI-064-A Human Machine InterfaceDocument10 pagesCAT-HSI-064-A Human Machine Interfacemohamamd shahid100% (1)

- Fatigue Management Procedure Sew39Document13 pagesFatigue Management Procedure Sew39Viem Abdul HalimNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnounNo ratings yet

- JSA E&I 4.earthing Bonding InstallationDocument3 pagesJSA E&I 4.earthing Bonding InstallationAmyNo ratings yet

- Bar Bending MachineDocument1 pageBar Bending Machinesaurav royNo ratings yet

- JSA-RSS-HSE-005 Bristle Blasting, Needle Gun and Painting ActivityDocument7 pagesJSA-RSS-HSE-005 Bristle Blasting, Needle Gun and Painting ActivityRaditya PramudyaNo ratings yet

- Job Safety Analysis (Jsa) : Damage and Personal InjuryDocument2 pagesJob Safety Analysis (Jsa) : Damage and Personal InjuryReda Bouali100% (1)

- Fall Protection Survey of RIG 40Document3 pagesFall Protection Survey of RIG 40Kevin Josh Bonales100% (1)

- Gi-0006 011Document2 pagesGi-0006 011malika_00No ratings yet

- JsaDocument5 pagesJsaMohd AzrinNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Scissor Lift - HseDocument4 pagesScissor Lift - HserassdriverNo ratings yet

- SHE 68 - 9589 - Elevator Work PermitDocument2 pagesSHE 68 - 9589 - Elevator Work PermitciupcicNo ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- TFU-Risk Assessment RA-11 - Use of Grooving & Threading MachinesDocument1 pageTFU-Risk Assessment RA-11 - Use of Grooving & Threading Machinesarshin wildanNo ratings yet

- Risk Assessment GRP Tank InstallationDocument19 pagesRisk Assessment GRP Tank Installationanwer.ahmadNo ratings yet

- JSA-Replacement of GD, FD & MCP - Rev.00Document7 pagesJSA-Replacement of GD, FD & MCP - Rev.00Muhammad Umar GondalNo ratings yet

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 pagesJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNo ratings yet

- Job Safety Analysis WorksheetDocument7 pagesJob Safety Analysis WorksheetMohamedSaidNo ratings yet

- OSH-18 (PTW) Permit To Work System ProcedureDocument3 pagesOSH-18 (PTW) Permit To Work System Procedurerizal azizanNo ratings yet

- JSP For Electrical and HV TestingDocument4 pagesJSP For Electrical and HV TestingmohammedNo ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Jsa Psa & GisDocument3 pagesJsa Psa & GisMohammed NouzalNo ratings yet

- 30.0 - Lone Working and or in Remote Locations v3.0 EnglishDocument14 pages30.0 - Lone Working and or in Remote Locations v3.0 Englishjbdejhiuhw100% (1)

- Petrofac Limited Hsseia StandardDocument15 pagesPetrofac Limited Hsseia Standardrodman823No ratings yet

- 5 - Equipment's Master ChecklistDocument5 pages5 - Equipment's Master ChecklistSaboor KabierNo ratings yet

- Risk Assessment - Tower DecommissioningDocument5 pagesRisk Assessment - Tower DecommissioningJeffery Mulei100% (1)

- 5.2 - Isolation of Energy SourcesDocument16 pages5.2 - Isolation of Energy SourcesarunNo ratings yet

- 024 - Mobile Scaffold Inspection ChecklistDocument1 page024 - Mobile Scaffold Inspection ChecklistFaiez AripiNo ratings yet

- 07.01 Risk Assessment For Fire Alarm SystemDocument15 pages07.01 Risk Assessment For Fire Alarm SystemShah MuzzamilNo ratings yet

- External Safety Audit Check-List For Onshore Drilling RigsDocument30 pagesExternal Safety Audit Check-List For Onshore Drilling RigsSiddhartha ChakradharNo ratings yet

- Jsa - Cable Termination PDFDocument4 pagesJsa - Cable Termination PDFD FiransyahNo ratings yet

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- Risk A For Fabrication, Welding, Cutting and GrindingDocument3 pagesRisk A For Fabrication, Welding, Cutting and GrindingSaravanaNo ratings yet

- SOP For Pole Erection With All Hard WireDocument7 pagesSOP For Pole Erection With All Hard WireVIKAS SINGH BAGHELNo ratings yet

- Revised JHA HDDDocument12 pagesRevised JHA HDDHariharan RajaramanNo ratings yet

- Lock Out Tag Out Program Log BookDocument1 pageLock Out Tag Out Program Log BookwaytobhushanNo ratings yet

- Safety Commitment: Nothing Is More Important Than Health and SafetyDocument1 pageSafety Commitment: Nothing Is More Important Than Health and SafetyReynaldo GrantNo ratings yet

- Buku IstighfarDocument1 pageBuku IstighfarAfif MudzakkirNo ratings yet

- Appendix A-Job Safety Analysis FormDocument3 pagesAppendix A-Job Safety Analysis Formjiks_i4uNo ratings yet

- Lockout Tagout ProcedureDocument7 pagesLockout Tagout ProcedureKadesh Hanah McCarthyNo ratings yet

- HDPE Plastic PIPE FUSION WELDING WORK METHOD STATEMENT 01 PDFDocument11 pagesHDPE Plastic PIPE FUSION WELDING WORK METHOD STATEMENT 01 PDFSuryakant Suraj100% (1)

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- HSE InductionDocument8 pagesHSE InductionEsamKhalilAlQadi100% (1)

- Data Logger Discovery Risk Assessment 1Document1 pageData Logger Discovery Risk Assessment 1Coin DozerNo ratings yet

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- CMS For Cad WeldingDocument9 pagesCMS For Cad WeldingarockiyathassNo ratings yet

- Safety Harness ChecklistDocument1 pageSafety Harness Checklistagung100% (1)

- Mobile Scaffold SafetyDocument1 pageMobile Scaffold SafetyDhiraj ThukralNo ratings yet

- 125 - Hse Inspection Checklist - Boom Struck (Haib)Document1 page125 - Hse Inspection Checklist - Boom Struck (Haib)Er AjenkNo ratings yet

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- HSF-PR-0063 Work at HeightDocument32 pagesHSF-PR-0063 Work at HeightChris Bonnington0% (1)

- EHS-SWI-037 - 0 Loadbank Testing - DraftDocument2 pagesEHS-SWI-037 - 0 Loadbank Testing - DraftChris Bonnington100% (1)

- EHS-SWI-012 - 0 Span Deck Installation - DraftDocument2 pagesEHS-SWI-012 - 0 Span Deck Installation - DraftChris BonningtonNo ratings yet

- Personal Protective Gear Pre-Operational Inspection Safety Device Checks DocumentationDocument2 pagesPersonal Protective Gear Pre-Operational Inspection Safety Device Checks DocumentationChris BonningtonNo ratings yet

- Double Bus and Transfer Bus SystemDocument46 pagesDouble Bus and Transfer Bus Systemgkpalepu92% (25)

- Basic Electrical Engineering Practice ProblemsDocument26 pagesBasic Electrical Engineering Practice ProblemsChris Thel May60% (5)

- LG 42pj350 Training Manual (ET)Document132 pagesLG 42pj350 Training Manual (ET)RomelyGery Martinez89% (9)

- Micro-Stepping For Stepper MotorsDocument3 pagesMicro-Stepping For Stepper MotorsTanvir S. ShakilNo ratings yet

- Design & Construction of 220 V Voltage StabilizerDocument46 pagesDesign & Construction of 220 V Voltage StabilizerNitin VermaNo ratings yet

- LM150/LM350A/LM350 3-Amp Adjustable Regulators: FeaturesDocument21 pagesLM150/LM350A/LM350 3-Amp Adjustable Regulators: FeaturesJeshua MacedoNo ratings yet

- Solucionario Capitulo 21 Física Serway and FaughnDocument13 pagesSolucionario Capitulo 21 Física Serway and FaughnRafael ColindresNo ratings yet

- 1 s2.0 S0378775314002572 MainDocument19 pages1 s2.0 S0378775314002572 MainChiliveri VinodNo ratings yet

- ATW Pricelist 2021Document14 pagesATW Pricelist 2021Erlangga Bayu100% (1)

- S60-ch3 Ddeciv PDFDocument184 pagesS60-ch3 Ddeciv PDFAlex BravoNo ratings yet

- Technical Specification FOR Current Transformers: II: - 132 KV CTDocument152 pagesTechnical Specification FOR Current Transformers: II: - 132 KV CTKean PagnaNo ratings yet

- EC-101 Electrical Sciences Electrical Sciences 3-1-0-8: Course InstructorsDocument13 pagesEC-101 Electrical Sciences Electrical Sciences 3-1-0-8: Course InstructorsMd ArifNo ratings yet

- CM8870/70C CMOS Integrated DTMF Receiver: California Micro DevicesDocument8 pagesCM8870/70C CMOS Integrated DTMF Receiver: California Micro DevicesEdwinBeNo ratings yet

- Xerox Phaser+7400+Options+Parts+Service+ManualDocument1,102 pagesXerox Phaser+7400+Options+Parts+Service+ManualMarshall Holzderber100% (1)

- Engr: Kamran Soomro MCAT/ECAT-2016Document4 pagesEngr: Kamran Soomro MCAT/ECAT-2016Kamran AliNo ratings yet

- Ulp-05 Er35c2dme7crDocument6 pagesUlp-05 Er35c2dme7crojvp18No ratings yet

- DNR-DNRW DataSheet A05-0422Document4 pagesDNR-DNRW DataSheet A05-0422HAMDYNo ratings yet

- BC-CR708 Operating ManualsDocument31 pagesBC-CR708 Operating ManualsCV. HAKA JAYANo ratings yet

- RS Pro Catalog (VN) (NGUYEN XUONG - RS PRO Catalogue Vietnam) PDFDocument464 pagesRS Pro Catalog (VN) (NGUYEN XUONG - RS PRO Catalogue Vietnam) PDFTom SNo ratings yet

- Summary Faraday's LawDocument4 pagesSummary Faraday's LawReg TbNo ratings yet

- Chapter Two (Instrumentation)Document26 pagesChapter Two (Instrumentation)tsehay girmaNo ratings yet

- ZVP2110A ZVP2110C: P-Channel Enhancement Mode Vertical Dmos Fet P-Channel Enhancement Mode Vertical Dmos FetDocument3 pagesZVP2110A ZVP2110C: P-Channel Enhancement Mode Vertical Dmos Fet P-Channel Enhancement Mode Vertical Dmos Fet19aldo97No ratings yet

- Projects Type FormatDocument10 pagesProjects Type FormatBryan AvilaNo ratings yet

- Inspection Gaz. NotificationDocument21 pagesInspection Gaz. NotificationKatuNo ratings yet

- v90 Operating InstructionsDocument349 pagesv90 Operating InstructionsTodor NakovNo ratings yet

- Experiment #2: Parallel Plate Capacitors and Dielectric ConstantsDocument2 pagesExperiment #2: Parallel Plate Capacitors and Dielectric ConstantsMari KuljanishviliNo ratings yet

- Scilab - Ece ProgramsDocument5 pagesScilab - Ece ProgramsYash PatelNo ratings yet

- AESO Measurement System Standard1Document59 pagesAESO Measurement System Standard1Mufasa 7762No ratings yet