Professional Documents

Culture Documents

JSA-002 JSA For TCF

Uploaded by

Rafeeq Ur RahmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA-002 JSA For TCF

Uploaded by

Rafeeq Ur RahmanCopyright:

Available Formats

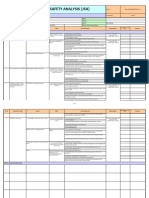

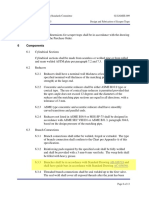

DESCRIPTION OF TASK: Construction of Temporary Construction Facility for Upgrade Water Supply at KGP

WORK LOCATION: Temporary Construction Facility

REFERENCES (if any): REQUIRED SAFETY EQUIPMENT

1. Required to wear proper PPE, Safety shoes, Helmet, Glasses, hand gloves

(where applicable), ear plug/ muffs, high-visibility vest, dust mask.

2. Barricades, Sign Boards, warning sign, fire watch man, standby man, and fire

extinguishers.

Prepared by): Reviewed by : Approved by:

HSE Manager Project Manager PMT

________________________ _______________________ ________________________

Signature Signature Signature

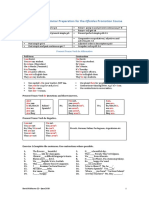

S/N SEQUENCE OF JOB STEPS POTENTIAL HAZARDS HAZARDS CONTROLS ACTION BY

1. Both permit issuer & receiver need to

conduct a joint site inspection to discuss

the hazards & precautions required for

conducting the job safely.

2. Invite other entities with utilities that may

be affected by this activity.

3. Obtain work permit.

4. A toolbox meeting shall be conducted,

provide hard copy of JSA and discussed

Permit Issuer/Receiver

Preliminary Site Inspection 1.Injury/Incident due to falling to all manpower.

1. Site Engineer

Slipping 5. In case of any emergency all activities

Site Supervisor

should be stopped, and all employees

should move to designated safe assembly

area.

6. Non-essential personnel shall be kept

clear of the work area.

7. All the personnel should wear Safety

shoes, safety glass and hard hat and

other needed personal protective

equipment.

2. Mobilization of equipment and 1. Prepare the area and clear obstructions Subcon CM/ Site Engineer

Material to worksite 1. Traffic hazards prior to mobilization of equipment. Permit Receiver

2. Ensure all equipment/tools are properly Supervisor

SHE-JSA-002- Rev.0 Page 1 of 4

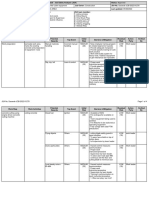

secured on trailers bed. Pre-inspection

checking to be done prior to mobilization.

2. Property damage 3. Lifting devices, electric tools to be

inspected and offload machines

3. Struck by moving /equipment in a secured.

equipment. safe way/away from moving equipment.

4. Assign trained flag man wearing high All Workers

4. Caught in between visibility vest and flag that will guide

mechanical parts. vehicle drivers and control the traffic.

5. Unattended 5. Keep unnecessary personnel away from

reversing/maneuvering equipment/location.

6. Use full time qualified supervision.

1.Trained flag men equipped with safety

vest and flag that will guide vehicle drivers

and control the traffic.

2.Certified operator must be used.

3.Keep only the needed personnel in site.

1.Conduct joint site inspection.

2.Secure a hot work permit.

3.Certified operator must be used.

1. People struck by

equipment. 1.Maintain safe distance between pipe and

Subcon CM/ Site Engineer

2. Live Pipeline struck by equipment position.

Movement and operation of Heavy Permit Receiver

3. equipment if any. 2.Valid equipment sticker / daily operator

Equipment Supervisor

3. Fire inspection check list.

Equipment Operators

4. Oil leak

5. Unqualified operator 1.Use multipurpose (ABC or ABCE) Fire

Extinguishers using dry chemical powder.

2.In case of an emergency evacuation, all

workers should move to designated

assembly area.

1.Daily operator inspection check list.

1.Certified / competent operator must be

used.

4. Backfilling & Compaction 1.Struck by moving 1. Necessary Sign Boards to be placed, Flag Subcon CM/ Site Engineer

equipment. Man to control the traffic. Permit Receiver

2. All equipment /tools shall be inspected by Supervisor

2.Slips, trips and falls a competent person. All Workers

3. A pre-task meeting shall be conducted by

a supervisor prior to start any activity.

4. Unnecessary personnel shall be kept

clear of the work site.

SHE-JSA-002- Rev.0 Page 2 of 4

5. First aid kit shall be available at site.

6. PPE should be worn at all time.

1. Identify tripping hazards; highlight all

which cannot be removed with barrier

tape.

2. PPE should be worn at all time.

1. Do not use defective tools.

2. All equipment /tools shall be inspected by

a competent person. Subcon CM/ Site Engineer

Backfilling & Compaction 3. Vibration and Noise 3. A pre-task meeting shall be conducted by Permit Receiver

5.

(continued…) hazards a supervisor prior to start any activity. Supervisor

4. Ear plugs should be used while working All Workers

near vibrators, compactors and heavy

equipment.

1. Aramco/3rd Party Certified operator and

Rigger with visibility vest only allowed

performing the activity.

2. Operator sound horn while swinging

3. Taglines should be used to control the

load while lifting the load from the trailer

1. Uncontrolled swing of load. truck.

2. Accident due to heavy 1. Wind speed to be monitored while lifting.

wind speed, rain, 2. Lifting works to be stopped if wind speed Subcon CM/ Site Engineer

Erection of the portable cabins by sandstorm and poor exceeds 20 mph or 32 km/h Permit Receiver

6. visibility.

using crane 3. Work to be stopped in case of Heavy Supervisor

3. Crane tipping over, storm or rain All Workers

uneven ground, Failure of 1. Ensure only Aramco/3rd Party approved

equipment Rigger and operators are involved in the

operation.

2. Ensure equipment is approved by SA

and maintain daily checklist.

3. Crane to be positioned on proper

leveled/compacted ground.

4. Use wooden pads below the outriggers.

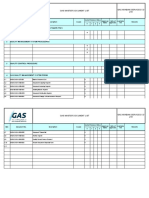

1. Regular disposal of waste, debris and

scrap materials shall be carried out.

2. Metal containers for waste, used paper

cups, scrap and debris shall be provided.

Subcon CM/ Site Engineer

3. Wash, toilets and launch facilities shall be

Permit Receiver

7. House Keeping 1. Health Hazard clean.

Supervisor

4. Drinking containers shall be in good

All Workers

sanitary condition.

5. Provide collection drums for waste

materials and regularly take them to

designated dumping area.

SHE-JSA-002- Rev.0 Page 3 of 4

Recommendations/Notes

Conduct toolbox safety meeting prior to work activities.

Explain to the workers the purpose of this JSA and enforce implementation of content.

If an injury or near miss occurs and investigation suggests, the JSA shall be reviewed to determine whether changes are needed in the job procedures.

SHE-JSA-002- Rev.0 Page 4 of 4

You might also like

- Reeser, Welding CompleteDocument243 pagesReeser, Welding CompleteCarlos GC100% (6)

- JSP For AsphaltDocument8 pagesJSP For Asphaltmohammed tofiqNo ratings yet

- 002 Job Safety Analysis For Excavation, Backfilling and Compaction Activities at SAOO GOSPs Rev 03 PDFDocument8 pages002 Job Safety Analysis For Excavation, Backfilling and Compaction Activities at SAOO GOSPs Rev 03 PDFHaleemUrRashidBangash100% (1)

- Load Test Procedures for Bridges, Gantry and Jib CranesDocument6 pagesLoad Test Procedures for Bridges, Gantry and Jib CranesMeritorious Khan100% (5)

- ARK JSA Manual Excavation A 3Document9 pagesARK JSA Manual Excavation A 3REMYANo ratings yet

- SAND FILLING JSADocument5 pagesSAND FILLING JSAOgunwa Emmanuel0% (1)

- S/N Sequence of Basic Steps Potential Hazards Hazards Control Action byDocument7 pagesS/N Sequence of Basic Steps Potential Hazards Hazards Control Action byjavithNo ratings yet

- Hazard IdentificationDocument16 pagesHazard IdentificationBaluNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadNo ratings yet

- Cross Country ManualDocument52 pagesCross Country Manualpp2076No ratings yet

- JOB SAFETY ANALYSIS FOR CARPENTRY AND WOOD WORKDocument3 pagesJOB SAFETY ANALYSIS FOR CARPENTRY AND WOOD WORKba ratnaparkheNo ratings yet

- Sarawak JSA for Concrete CuttingDocument4 pagesSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailNo ratings yet

- JSA For HDPE Liner Fusion Welding2Document6 pagesJSA For HDPE Liner Fusion Welding2Mohammed Minhaj100% (8)

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- JSA For Concrete PouringDocument1 pageJSA For Concrete PouringHSE fahadNo ratings yet

- Exavation Works PipercksDocument4 pagesExavation Works PipercksHRTYR100% (1)

- EPC-3 Gasoline package Assembly & Erection JSADocument3 pagesEPC-3 Gasoline package Assembly & Erection JSAFrancis Vinoj100% (1)

- ARK-JSA - Installation of Form Works, Rebars & Concrete PouringDocument7 pagesARK-JSA - Installation of Form Works, Rebars & Concrete PouringREMYA100% (3)

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- Tank Modification and Repair Work Safety AnalysisDocument12 pagesTank Modification and Repair Work Safety Analysisbagas prakoso100% (1)

- JSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Document10 pagesJSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Zubair Khan100% (1)

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- JSA - CABLE TERMINATION TITLEDocument4 pagesJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- Job Safety Analysis Work SheetDocument7 pagesJob Safety Analysis Work SheetTomNo ratings yet

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiNo ratings yet

- JSA Road Routine MaintenanceDocument3 pagesJSA Road Routine MaintenanceBen Hammadi Rym100% (2)

- Sharon Olds On The Subway EssayDocument2 pagesSharon Olds On The Subway EssaymyfairlibbyNo ratings yet

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDocument1 pageJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNo ratings yet

- Job Safety Analysis: Shaybah NGL Recovery Plant DepartmentDocument4 pagesJob Safety Analysis: Shaybah NGL Recovery Plant DepartmentMadhan KannanNo ratings yet

- 3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseDocument5 pages3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar Gondal100% (1)

- Risk Assess JSA Bolt Tightening 012Document7 pagesRisk Assess JSA Bolt Tightening 012Abdeldjalil Ferhati100% (2)

- Job Safety Analysis for Brick Work, Tile and Glass RemovalDocument4 pagesJob Safety Analysis for Brick Work, Tile and Glass RemovalSushil Kumar YadavNo ratings yet

- New Pta Complex: Jsa For Reinforcing Steel BarsDocument12 pagesNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNo ratings yet

- JSA Manual Excavation and Cable LayingDocument3 pagesJSA Manual Excavation and Cable Layingimran100% (1)

- 4 HIRA Format - Sand Blasting ActivityDocument2 pages4 HIRA Format - Sand Blasting ActivityMD Abdullah100% (1)

- JSA - CivilDocument5 pagesJSA - CivilRajuNo ratings yet

- Project Plan Template: Project Conception and InitiationDocument5 pagesProject Plan Template: Project Conception and InitiationAnonymous 4eQB3WZNo ratings yet

- J-76-1 IKS Wellhead Installation and Operation ManualDocument72 pagesJ-76-1 IKS Wellhead Installation and Operation Manualmam100% (1)

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- Concrete Pouring JSaDocument12 pagesConcrete Pouring JSaTheo Vidallon BautistaNo ratings yet

- Diesel Filling JSADocument6 pagesDiesel Filling JSAMohammed Ali QaziNo ratings yet

- DIY Armor ZineDocument8 pagesDIY Armor Zinesnidely_whiplash0% (1)

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- Plant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerDocument6 pagesPlant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerJoypee MacasamponNo ratings yet

- VE055622-038 Construction Scope of WorkDocument38 pagesVE055622-038 Construction Scope of WorkRafeeq Ur RahmanNo ratings yet

- Installation JSADocument4 pagesInstallation JSAMohammed Minhaj100% (1)

- Risk Assessment For Anti Termite WorksDocument7 pagesRisk Assessment For Anti Termite WorksSaeed Ahmad100% (1)

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (1)

- Nike CSR Case StudyDocument6 pagesNike CSR Case Studyshrutiagarwal9229100% (3)

- Bricks Messonary Work Job Hazard AnalysisDocument2 pagesBricks Messonary Work Job Hazard AnalysisMc Evans Magallanes100% (1)

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- JSA For Bobcat OperationDocument2 pagesJSA For Bobcat Operationwahyu nugrohoNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDocument4 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohn100% (1)

- JSA FOR Concerate PlacementDocument1 pageJSA FOR Concerate Placementwahyu nugrohoNo ratings yet

- Job Steps Potential Hazards Recommended Safe Job ProceduresDocument3 pagesJob Steps Potential Hazards Recommended Safe Job ProceduresDJadee Anuppur AmlaiNo ratings yet

- JSA-RHI-ARZ-0-021 ASU - Rockwool Installation Rev02 - ArzewDocument8 pagesJSA-RHI-ARZ-0-021 ASU - Rockwool Installation Rev02 - ArzewHSE RHINo ratings yet

- Sa VZ58 Operators ManualDocument42 pagesSa VZ58 Operators ManualWilliam James AbercrombieNo ratings yet

- Rotary Kiln Handbook NEWDocument44 pagesRotary Kiln Handbook NEWkosmc123No ratings yet

- JSA 02-03 Vertical Borehole and Anode Bed InstallationDocument5 pagesJSA 02-03 Vertical Borehole and Anode Bed InstallationHaleemUrRashidBangash50% (2)

- JHA Formation Preparation or Leveling.Document2 pagesJHA Formation Preparation or Leveling.Mark Buendia100% (1)

- JSA - Dismantling CM ShedDocument4 pagesJSA - Dismantling CM ShedvivekaramanaNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnNo ratings yet

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- JSA Hot Work Indospace RajpuraDocument2 pagesJSA Hot Work Indospace RajpuraGuri PreetNo ratings yet

- JSA - Cast in Place Reinforced Concrete ChamberDocument8 pagesJSA - Cast in Place Reinforced Concrete ChamberSkinhead TvNo ratings yet

- Saes H 201Document13 pagesSaes H 201Rafeeq Ur RahmanNo ratings yet

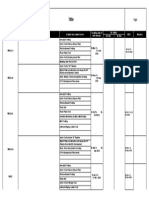

- Gas Master Document List: Quality Management System Manual (Project Quality Plan)Document2 pagesGas Master Document List: Quality Management System Manual (Project Quality Plan)Rafeeq Ur RahmanNo ratings yet

- Documented Information "Incoming / Outgoing" Master Log: Action Required DistributionDocument1 pageDocumented Information "Incoming / Outgoing" Master Log: Action Required DistributionRafeeq Ur RahmanNo ratings yet

- Risk Management PPT BECHTELDocument19 pagesRisk Management PPT BECHTELRafeeq Ur RahmanNo ratings yet

- SAUDI ARAMCO ID/PID - WELD SUMMARY AND TRACKING SYSTEMDocument9 pagesSAUDI ARAMCO ID/PID - WELD SUMMARY AND TRACKING SYSTEMRafeeq Ur RahmanNo ratings yet

- MCC Plan StatusDocument1 pageMCC Plan StatusRafeeq Ur RahmanNo ratings yet

- 1 List of Electrical ProcedureDocument1 page1 List of Electrical ProcedureRafeeq Ur RahmanNo ratings yet

- Safety Orientation Enrollment Form SkypeDocument1 pageSafety Orientation Enrollment Form SkypeRafeeq Ur RahmanNo ratings yet

- The Story of CricketDocument14 pagesThe Story of CricketsamsungloverNo ratings yet

- Safety Orientation Enrollment Form SkypeDocument1 pageSafety Orientation Enrollment Form SkypeRafeeq Ur RahmanNo ratings yet

- Certificate Milestone CompletedDocument1 pageCertificate Milestone CompletedRafeeq Ur RahmanNo ratings yet

- Milestone Cerificate DraftDocument1 pageMilestone Cerificate DraftRafeeq Ur RahmanNo ratings yet

- Notes - For - Teacher Unit 8 To 10 PDFDocument3 pagesNotes - For - Teacher Unit 8 To 10 PDFRafeeq Ur RahmanNo ratings yet

- CDC UP Interface Control TemplateDocument9 pagesCDC UP Interface Control TemplateSyed AliNo ratings yet

- Quality PDFDocument14 pagesQuality PDFi AM TechnicalNo ratings yet

- Pages From SAES-M-100Document1 pagePages From SAES-M-100Rafeeq Ur RahmanNo ratings yet

- A Gift of Chappals: Before You ReadDocument18 pagesA Gift of Chappals: Before You ReadDr Linda Mary SimonNo ratings yet

- 7 English NCERT ChapterDocument18 pages7 English NCERT ChapterudswainNo ratings yet

- Class7 English1 Unit07 NCERT TextBook EnglishEditionDocument12 pagesClass7 English1 Unit07 NCERT TextBook EnglishEditionSarvepalli Uday KiranNo ratings yet

- Gopal and The Hilsa-Fish: Before You ReadDocument14 pagesGopal and The Hilsa-Fish: Before You ReadRafeeq Ur RahmanNo ratings yet

- Three QuestionsDocument11 pagesThree QuestionschandnkrajNo ratings yet

- Pages From IBC - CH21-2Document1 pagePages From IBC - CH21-2Rafeeq Ur RahmanNo ratings yet

- Masonry 2103.3 - TABLE 2103.7 (1) : A C D BDocument2 pagesMasonry 2103.3 - TABLE 2103.7 (1) : A C D BRafeeq Ur RahmanNo ratings yet

- Pages From 02-SAMSS-009Document1 pagePages From 02-SAMSS-009Rafeeq Ur RahmanNo ratings yet

- Pages From SAES-T-928Document1 pagePages From SAES-T-928Rafeeq Ur RahmanNo ratings yet

- Tips To Dress Well For MenDocument1 pageTips To Dress Well For MensurefashionNo ratings yet

- Model D-C2 Manual FinalDocument399 pagesModel D-C2 Manual Finalemerich007No ratings yet

- Peacissimo Precamp 2 Final - 20110302Document19 pagesPeacissimo Precamp 2 Final - 20110302Michael James WarrenNo ratings yet

- Hosseini 2Document8 pagesHosseini 2Babyblue SonyaNo ratings yet

- My Clothing Habits Reading Comprehension Exercises 88934Document2 pagesMy Clothing Habits Reading Comprehension Exercises 88934Katheryn Yoana Garcia MerloNo ratings yet

- Howiarrivedathatterarrivedathatter Mackenzie DerryDocument6 pagesHowiarrivedathatterarrivedathatter Mackenzie Derryapi-302647075No ratings yet

- QMS 2Document89 pagesQMS 2Oki SyahrialNo ratings yet

- A) Put in Who / Which: 1. I Met A Woman Who .. Can Speak Six LanguagesDocument3 pagesA) Put in Who / Which: 1. I Met A Woman Who .. Can Speak Six LanguagesmervetiryakiNo ratings yet

- Division YES Camp GuidelinesDocument3 pagesDivision YES Camp Guidelinestindog9No ratings yet

- Grammar For Oficial Course 2022Document16 pagesGrammar For Oficial Course 2022Víctor MaesoNo ratings yet

- EnEnEn DDocument98 pagesEnEnEn Dhashamraza74No ratings yet

- UnderstatementDocument4 pagesUnderstatementhappiness1234No ratings yet

- Invoice of Sample RR Inc. 4600 14.05.2016Document1 pageInvoice of Sample RR Inc. 4600 14.05.2016Samiul BariNo ratings yet

- Introduction To LinguisticsDocument8 pagesIntroduction To LinguisticsFelyn Garbe YapNo ratings yet

- A Soldier's Home Full TextDocument8 pagesA Soldier's Home Full Textjmc008No ratings yet

- Rssay: EssayDocument50 pagesRssay: EssayJack HarresNo ratings yet

- Hi Tech Engineering JHADocument3 pagesHi Tech Engineering JHAPHH9834No ratings yet

- Gundam TutorialDocument53 pagesGundam TutorialJeg B. Israel Jr.No ratings yet

- KhadiDocument28 pagesKhadiDeepika Singh100% (1)

- 5 de Thi Hoc Ki 1 Tieng Anh 7 English Discovery Co Dap An Va Loi Giai Chi Tiet 1671174104 27 29Document3 pages5 de Thi Hoc Ki 1 Tieng Anh 7 English Discovery Co Dap An Va Loi Giai Chi Tiet 1671174104 27 29Trang TrầnNo ratings yet

- OK! First For Celebrity News - July 26, 2016 UK PDFDocument116 pagesOK! First For Celebrity News - July 26, 2016 UK PDFSabina FloreaNo ratings yet

- Title Method Statement For Remove Slab On Grade. 4. Work ProcedureDocument2 pagesTitle Method Statement For Remove Slab On Grade. 4. Work ProcedureWaseem HamadNo ratings yet