Professional Documents

Culture Documents

4 HIRA Format - Sand Blasting Activity

Uploaded by

MD AbdullahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 HIRA Format - Sand Blasting Activity

Uploaded by

MD AbdullahCopyright:

Available Formats

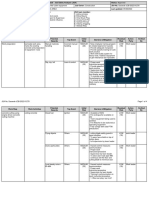

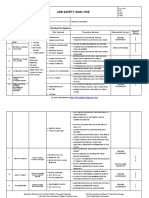

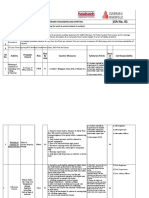

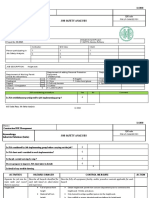

TPL UI / EHS / 2.

3 Rev:0 Date: 01-Oct-17

HAZARD IDENTIFICATION AND RISK ASSESSMENT FORMAT

Project:

Location:

Date: Task – Copper Slag Blasting Activity

Base Residual

Acceptable(NA)

Consequences

Risk Risk

Routine (R)/Non

Acceptable(A)/

Legal concern

Activity

Routine(NR)

Hazard

Sr. No.

(Action By)

Probability

Probability

Control Measures

Non

Remarks

Y/N

Severity

Severity

(OCP, HSMP, PPE etc.)

Risk

Risk

A Blasting R High pressure Bodily Y 3 3 M Ensure good condition of hosepipe. 1 3 L A Sudip C, M/s

Operation injuries Use whip lash arrangement to hold hose A L B, M/s G

Noise pipe M Engineers,

Noise Ensure relief valve in safe working condition M/s Pooja

Induced Ensure TPI for air compressor & hopper Architecure

Deafness Depute trained personnel

(NID) Wear Helmet, Ear Muff, Leather gloves &

coveralls, Mask, Safety shoes, Face shield

to be used by blaster during blasting

operation

Provide washing points so workers can

wash their hands and face routinely

Prohibit eating, drinking in blasting area

R Exposure to Inhalation Y 2 3 M Use exhaust ventilation systems 1 3 L A - Do -

dust (Respirat Do not use compressed air to clean the

ory area

problems Fencing around compressor & blasting

) operations to be ensured.

Green net to be provided

Blaster & his coworker should undergo the

medical checkup.

Conduct TBT and Training

© TATA PROJECTS LIMITED, URBAN INFRASTRUCTURE

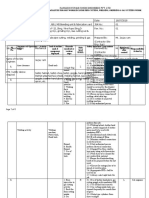

TPL UI / EHS / 2.3 Rev:0 Date: 01-Oct-17

HAZARD IDENTIFICATION AND RISK ASSESSMENT FORMAT

b R Movement of Personal Y 3 3 M Isolate the blasting area from others 1 3 L A - Do -

villagers, injury Ensure co-worker away from the blaster.

small kids No one should be allowed near blasting area.

nearby Strict supervision

c R Health issues Silicosis, Y 2 2 L Mask should be used 1 2 L A - Do -

Eye Ensure washing point

injury Ensure rest at regular interval

B Demob of R High pressure Hit by Y 3 2 M Release pressure before disconnecting hose 1 2 L A - Do -

blasting injection injury flying Conduct TBT and Training

equipment grits Use PPEs

Remainin

g

pressure

C Mixing paints R Fire hazard in the

Fire Y 3 3 M Check and ensure no hot work at the vicinity 1 3 L A - Do -

Explosion hazard No smoking allowed

Splashing due to Barricade and display signboard

hot work No cutting the empty container (paints)

Smoking allowed by gas cutting

Use gloves & safety goggle during mixing

D Spray painting R Fire hazard Fire and Y 3 4 M Check and ensure no incompatible hot work 1 4 L A - Do -

Explosion explosion allowed

Inhalation due to Power connection routed through RCCB

Skin irritation hot work Follow instruction, as given in MSDS

Electrocution Smoking Proper lighting (explosion proof light)

Asphyxiation Inhalation Keep finger or body away from spray gun tip

High pressure of Conduct TBT & training on regular basis

injury harmful Use proper PPE e.g. mask, safety goggle etc

vapor

Defect

ladder

Prepared By: Rajan K S/ Sudip C / A Karthik Approved By – Project Manager

© TATA PROJECTS LIMITED, URBAN INFRASTRUCTURE

You might also like

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Hazard Identification and Risk Assessment for Temporary Structure Erection and DismantlingDocument8 pagesHazard Identification and Risk Assessment for Temporary Structure Erection and DismantlingMD AbdullahNo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument4 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- OEM Connections Sensor +5 Volt Supply #4Document2 pagesOEM Connections Sensor +5 Volt Supply #4ibrahem100% (2)

- Hse Check List For Portable Grinding MachineDocument1 pageHse Check List For Portable Grinding MachineMD AbdullahNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- HAZARD IDENTIFICATION & RISK ASSESSMENTDocument3 pagesHAZARD IDENTIFICATION & RISK ASSESSMENTsinziana ghinet100% (1)

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTNo ratings yet

- Bar Cutting Machine HSE ChecklistDocument2 pagesBar Cutting Machine HSE ChecklistMD Abdullah100% (1)

- Job Safety Practices FirefightingDocument16 pagesJob Safety Practices Firefightingmohammed tofiqNo ratings yet

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Drum Rooller Daily ChecklistDocument1 pageDrum Rooller Daily ChecklistMD AbdullahNo ratings yet

- Sarawak JSA for Concrete CuttingDocument4 pagesSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailNo ratings yet

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatNo ratings yet

- HSE ViolationDocument1 pageHSE ViolationVIKASNo ratings yet

- Job Safety Analysis - Pipeline Bending (38 charactersDocument6 pagesJob Safety Analysis - Pipeline Bending (38 charactersMoaatazz NouisriNo ratings yet

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- JSEA FOR EARTH WORK (Alumina Silo Area)Document13 pagesJSEA FOR EARTH WORK (Alumina Silo Area)MD AbdullahNo ratings yet

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- JSA-002 JSA For TCFDocument4 pagesJSA-002 JSA For TCFRafeeq Ur RahmanNo ratings yet

- HIRADocument6 pagesHIRAvijay kumar singhNo ratings yet

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- Job Safety Analysis: Shaybah NGL Recovery Plant DepartmentDocument4 pagesJob Safety Analysis: Shaybah NGL Recovery Plant DepartmentMadhan KannanNo ratings yet

- Air Compressor Inspection HSE ChecklistDocument1 pageAir Compressor Inspection HSE ChecklistMD Abdullah100% (2)

- JSA For Erection of Precast..Document18 pagesJSA For Erection of Precast..Shafie ZubierNo ratings yet

- Dewatering Pump ChecklistDocument1 pageDewatering Pump ChecklistMD Abdullah100% (1)

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathNo ratings yet

- Risk Assess JSA Bolt Tightening 012Document7 pagesRisk Assess JSA Bolt Tightening 012Abdeldjalil Ferhati100% (2)

- Confine Space at Water TankDocument7 pagesConfine Space at Water TanknaraNo ratings yet

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Job Safety Analysis for Blasting and Painting WorkDocument11 pagesJob Safety Analysis for Blasting and Painting WorkRajuNo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- JSA-For Lifting Activity by CraneDocument3 pagesJSA-For Lifting Activity by CraneEman MantoNo ratings yet

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith s100% (1)

- PROJECT – EPCC 02 MS BLOCK HRRL CAMP INSPECTIONDocument10 pagesPROJECT – EPCC 02 MS BLOCK HRRL CAMP INSPECTIONRaj singhNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- Natural Gas ProcessingDocument41 pagesNatural Gas Processingjomafeba100% (2)

- AIR Modeller 2019-04-05 83Document68 pagesAIR Modeller 2019-04-05 83Tomeu Llompart100% (8)

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- Excavation SafetyDocument11 pagesExcavation SafetyDenease CrummieNo ratings yet

- HIRA For Loading or Unloading ActivityDocument4 pagesHIRA For Loading or Unloading ActivityMD Abdullah100% (2)

- Rock Mass Classification SystemsDocument33 pagesRock Mass Classification Systemsmortaza7094No ratings yet

- Diesel Filling JSADocument6 pagesDiesel Filling JSAMohammed Ali QaziNo ratings yet

- Linux Interview QuestionsDocument4 pagesLinux Interview QuestionsPaaventhan DharmarajanNo ratings yet

- Height Work Safety AnalysisDocument4 pagesHeight Work Safety AnalysisNitesh KumarNo ratings yet

- JSA For Pipe Installation TS 3Document8 pagesJSA For Pipe Installation TS 3Shilpiengg SafetyNo ratings yet

- Batching Plant HSE ChecklistDocument2 pagesBatching Plant HSE ChecklistMD AbdullahNo ratings yet

- 4.HIRA Excavation OnlyDocument6 pages4.HIRA Excavation OnlyMD Abdullah100% (1)

- What Is HIPOT Testing (Dielectric Strength Test) - EEPDocument7 pagesWhat Is HIPOT Testing (Dielectric Strength Test) - EEPmahmoud fawzyNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Job Steps Potential Hazards Recommended Safe Job ProceduresDocument3 pagesJob Steps Potential Hazards Recommended Safe Job ProceduresDJadee Anuppur AmlaiNo ratings yet

- JSA-RHI-ARZ-0-021 ASU - Rockwool Installation Rev02 - ArzewDocument8 pagesJSA-RHI-ARZ-0-021 ASU - Rockwool Installation Rev02 - ArzewHSE RHINo ratings yet

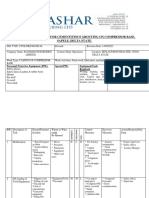

- JHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEDocument8 pagesJHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEaloysius akpanNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- JHA Formation Preparation or Leveling.Document2 pagesJHA Formation Preparation or Leveling.Mark Buendia100% (1)

- FIELD ERECTION OF 15000 BBLs TANK (IK-2545) PROJECT: PAINTING WORK IN CONFINED SPACE JSADocument2 pagesFIELD ERECTION OF 15000 BBLs TANK (IK-2545) PROJECT: PAINTING WORK IN CONFINED SPACE JSAJohnNo ratings yet

- Hira RCC Cement MillDocument2 pagesHira RCC Cement MillRajuNo ratings yet

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- JSA For New EmployeesDocument20 pagesJSA For New EmployeesNilayNo ratings yet

- Shifting of Materials by Double HydraDocument1 pageShifting of Materials by Double HydraShahid RazaNo ratings yet

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocument2 pagesNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Job Safety Analysis: 10.06.2017 Page 1 of 7Document7 pagesJob Safety Analysis: 10.06.2017 Page 1 of 7Raghava RichhuNo ratings yet

- Work at Height Safety AnalysisDocument2 pagesWork at Height Safety AnalysiszebmechNo ratings yet

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- JSA - Dismantling CM ShedDocument4 pagesJSA - Dismantling CM ShedvivekaramanaNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocument2 pagesRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- JSA for Drain Line ReplacementDocument5 pagesJSA for Drain Line ReplacementMadhan KannanNo ratings yet

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- Excavation Risk AssessmentsDocument7 pagesExcavation Risk Assessmentshussein aliNo ratings yet

- 414-KTPA SMELTER EXPANSION MONSOON PLANDocument12 pages414-KTPA SMELTER EXPANSION MONSOON PLANMD Abdullah100% (1)

- Scaffold SWLDocument1 pageScaffold SWLMD AbdullahNo ratings yet

- 5.hira - FPS Pipe RemovalDocument3 pages5.hira - FPS Pipe RemovalMD AbdullahNo ratings yet

- R1 - Work Method Statement ExcavationDocument13 pagesR1 - Work Method Statement ExcavationMD AbdullahNo ratings yet

- Method for Alumina Fluride Storage Foundation WorkDocument5 pagesMethod for Alumina Fluride Storage Foundation WorkMD AbdullahNo ratings yet

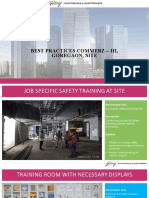

- G&B Good Practices DT.30.06.2022Document17 pagesG&B Good Practices DT.30.06.2022MD AbdullahNo ratings yet

- V5 I 1 Conveyor Belt Operation SafetyDocument7 pagesV5 I 1 Conveyor Belt Operation SafetyMD AbdullahNo ratings yet

- 2.method Statement For Installation of Cable Tray & Cable LayingDocument14 pages2.method Statement For Installation of Cable Tray & Cable LayingMD AbdullahNo ratings yet

- Jsea For Assemble and Disassemble of Hydra EngineDocument14 pagesJsea For Assemble and Disassemble of Hydra EngineMD AbdullahNo ratings yet

- Training On NC & CADocument19 pagesTraining On NC & CAMD AbdullahNo ratings yet

- SOP For Hydra RepairingDocument13 pagesSOP For Hydra RepairingMD AbdullahNo ratings yet

- Chopsaw Cutting Machine HSE ChecklistDocument1 pageChopsaw Cutting Machine HSE ChecklistMD AbdullahNo ratings yet

- Cherry Picker Boom Lift HSE ChecklistDocument2 pagesCherry Picker Boom Lift HSE ChecklistMD AbdullahNo ratings yet

- Daily Scaffold Inspection ChecklistDocument1 pageDaily Scaffold Inspection ChecklistMD AbdullahNo ratings yet

- Bipl, Ranjangaon, Projects - 2015: Checklist For HydraDocument1 pageBipl, Ranjangaon, Projects - 2015: Checklist For HydraMD AbdullahNo ratings yet

- Diesel Scissor Lift Daily ChecklistDocument2 pagesDiesel Scissor Lift Daily ChecklistMD AbdullahNo ratings yet

- Cherry Picker Boom Lift HSE ChecklistDocument2 pagesCherry Picker Boom Lift HSE ChecklistMD AbdullahNo ratings yet

- SOP-Covid - 19Document6 pagesSOP-Covid - 19MD AbdullahNo ratings yet

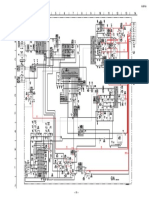

- 2SK2663Document1 page2SK2663hectorsevillaNo ratings yet

- An Overview of Aluminum Foam Production MethodsDocument8 pagesAn Overview of Aluminum Foam Production Methodsgouhua yuanNo ratings yet

- All 31 9amDocument134 pagesAll 31 9amSikha KaushikNo ratings yet

- DBMS Lab ManualDocument199 pagesDBMS Lab ManualMoulika Chowdary100% (1)

- Naukri RohinLohat (10y 0m) PDFDocument5 pagesNaukri RohinLohat (10y 0m) PDFayesha siddiquiNo ratings yet

- Green Mark Manager 6 May 2019Document1 pageGreen Mark Manager 6 May 2019Haider Tyebally TyeballyNo ratings yet

- Experiment #8 - Slender MemberDocument4 pagesExperiment #8 - Slender MemberLuís Alberto Tang YorisNo ratings yet

- Configure Switching FeaturesDocument28 pagesConfigure Switching FeaturesCinco PredragNo ratings yet

- AVImark ReadMe Enhancements 2009.0.0Document33 pagesAVImark ReadMe Enhancements 2009.0.0William OglesbyNo ratings yet

- Eromobil Er230 Manual1Document14 pagesEromobil Er230 Manual1Станислав НиколовNo ratings yet

- TP ConductionDocument25 pagesTP Conductionizham shukeriNo ratings yet

- BOQ For PWN-Actual 8-03-2020Document48 pagesBOQ For PWN-Actual 8-03-2020Ihd ConsultancyNo ratings yet

- Design and Analysis of Gas Turbine Combustion Chamber For Producer Gas AsDocument5 pagesDesign and Analysis of Gas Turbine Combustion Chamber For Producer Gas AsPhạm Công ÁnhNo ratings yet

- EcgDocument29 pagesEcgSouvikDattaNo ratings yet

- Steel Reinforcement For WallsDocument7 pagesSteel Reinforcement For WallsSurinderPalSinghGillNo ratings yet

- C3 - WO9 - Steel Structure Works - Internal Schedule (Metal Building Factory) PDFDocument1 pageC3 - WO9 - Steel Structure Works - Internal Schedule (Metal Building Factory) PDFAdel MorsyNo ratings yet

- 95 8576 9.2 - X3302 PDFDocument37 pages95 8576 9.2 - X3302 PDFSalik SiddiquiNo ratings yet

- Aquini: 3 Decades of ExcellenceDocument13 pagesAquini: 3 Decades of ExcellenceAnuj AggarwalNo ratings yet

- HT Processes GuideDocument16 pagesHT Processes GuideHukam ChandNo ratings yet

- Renovate Galvanized SteelDocument1 pageRenovate Galvanized SteelSam SamuelsonNo ratings yet

- Report on Materials and SuppliersDocument4 pagesReport on Materials and SuppliersVivek S SurendranNo ratings yet

- Medical Equipment MaintenanceDocument6 pagesMedical Equipment Maintenancever_at_workNo ratings yet

- Panasonic Sa-Ak350pl SMDocument103 pagesPanasonic Sa-Ak350pl SMEder Espinoza BajoneroNo ratings yet

- P16NF06FP STMicroelectronicsDocument9 pagesP16NF06FP STMicroelectronicsSoniaNo ratings yet