Professional Documents

Culture Documents

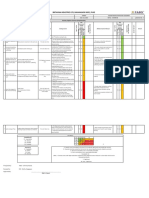

HAZARD IDENTIFICATION & RISK ASSESSMENT

Uploaded by

sinziana ghinetOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HAZARD IDENTIFICATION & RISK ASSESSMENT

Uploaded by

sinziana ghinetCopyright:

Available Formats

FOREMAT HAZARD IDENTIFICATION & RISK ASSESSMENT

Project Name: Godrej Aqua

Date:25.12.2018 Ref No. : GPL/AQUA/ELITE/HIRA/16 Revision No. : R - 00

Activity: Electrical Conducting & Installation work

Risk Risk

Assessment Assessment

Non-Significant (NS)

Non-Significant (NS)

existing existing

Ref. Of WI/ SOP :-

Legal Yes/No

Legal Yes/No

Significant (S) /

Significant (S) /

Control Control

Measure Measure

Sr.

Activity Hazard Risk ( Probable Outcome) Existing Control Additional Control Measure Remark

Probability(P)

Probability(P)

No.

Risk(R) : P*S

Risk(R) : P*S

Severity(S)

Severity(S)

1) Proper accesses as

1. Competent rigger shall be

compact leveled surface shall be

engaged for material shifting &

maintained for movement for F-15.

lifting activity

2) Pre- inspection checklist

2)

shall be ensured before engagement

Deployment of competent operator

1) Wrong approach 2) of F-15

& signalmen

Bad Housekeeping 3) 3) Deployment of competent

3) Mobile phone shall be

Wrong Sling use 4) operator & signalmen

prohibited during operation of

Damage wire rope 5)

1)Tilt of F-15 tower crane and F-15

Material Unauthorized operator & 4) Load chart should be display in to

2) Fall of material 4) Illumination level should be

Shifting by F- Signalmen the cabin of the F-15 & tower crane

1 3) Hit by object Yes P4 S3 A S good Yes P1 S3 D S

15 or Tower 6) Unwanted swing

4) Material damage

crane crane 7) Wrong 5) Valid TPI certificate shall

5)Personal Injury 5) supervision should

siglingiling 8) All be available for tower crane & F- 15 as

be strict

management requirement well as all lifting tools & tackles 6)

6) Medical screening shall be

not full field in F-15 & Tag line should be provided

ensured for all operator &

tower crane.

signalmen.

7) Daily inspection by operator,

7) Use of all required PPE'S

weekly by P&M & fortnightly by

safety Dept.

8) Full fill the all

management requirement.

1) Access should be clear

2) only screened workmen allowed to

1) Illumination should be good , 2)

work

House keeping should be

1) Improper access 3) close the all holes or openings

Martial maintained .

2) Work on height 1) Fall of material 4) Use full body harness safety belt

2 handling & No P3 S3 B NS 3) Proper supervision shall be No P1 S3 D NS

3) Wrong method use for 2) Personal Injury during height work

Shifting by ensured as wearing of safety

material handling. 3) Health problem. 5)Ladder to be provided in proper

Workmen. harness during workmen when

4) Wrong ladder use . slope (1:4 extended 1m above from

engaged at edge and near the

landing level)

shaft opening.

6) Use of all required PPE'S

7) Use of sound ladder .

1. Helper should be present during

wall cutting with grinder

1. check the cutting wheel before use. machine.2.Housekeeping should

1. Damaged cutting wheel

2. Check all time safety guard be maintained .3.Supervision

2.safety guard not 1. Physical injury.

conditions should be strict. 4.

available. 2. Health injury.

3.Use nose mask for control breathing Ensure electrical cable not laying

3 Wall cutting 3. Dust pollution 3. Hearing damage. No P4 S3 A NS

generator dust. on ground. 5. Use of No P1 S3 D NS

with Grinder. 4. Noise pollution. 4.Eye injury

4. Use ear plug all time. industrial plug top

5. Generated flying object. 5. Electrocution.

5.use safety goggles. 6.Proper supervision shall be

6.Electricity

5. Electricity supply through 30 MA ensured as wearing of safety

ELCB/RCCB elec. DB. harness during workmen when

engaged at edge and near the

shaft opening.

- Proper slinging method to be

adopted. Bridle/choker hitch is used for The boards should not be

handling the boards with Crane as per shifted with rollers by pushing

the manufacturers specification manually.

Improper Material No P3 S2 C NS The boards should be shifted No P1 S2 _ NS

Hit by / struck between objects

Handling - Power distribution boards will be with F-15 with slinging

handled manually with minimum 4 arrangement

people.

- Access is kept free of obstructions

The board is made as per norms

(Check IP 55) with steel. Implement trained wrokmen

Water penetration Short circuiting NO P3 S3 B NS and close supervision required No P1 S2 _ NS

Distribution - Light fittings and boards are placed in all time at work.

boards (SDB, water protected area.

FDB, MCCB &

PDB)

4 installation,

Cable routing

&

FOREMAT HAZARD IDENTIFICATION & RISK ASSESSMENT

Project Name: Godrej Aqua

Date:25.12.2018 Ref No. : GPL/AQUA/ELITE/HIRA/16 Revision No. : R - 00

Activity: Electrical Conducting & Installation work

Risk Risk

Assessment Assessment

Non-Significant (NS)

Non-Significant (NS)

existing existing

Ref. Of WI/ SOP :-

Legal Yes/No

Legal Yes/No

Significant (S) /

Significant (S) /

Control Control

Measure Measure

Sr.

Activity Hazard Risk ( Probable Outcome) Existing Control Additional Control Measure Remark

Probability(P)

Probability(P)

No.

Risk(R) : P*S

Risk(R) : P*S

Severity(S)

Severity(S)

Distribution

boards (SDB,

FDB, MCCB &

PDB)

4 installation,

Cable routing - Bus bars are covered with phylum

& sheet

commissionin

g

Terminals are protected

- Cable insertion with gland Implement trained workmen

- Permit system and LOTO system is and close supervision required

Contact with conductors Electric Flash / Short circuiting NO P3 S4 A NS at site. Training provided to No P1 C3 D NS

followed

workmen.

- Connections are made in such a way

that cable conductors are not visible.

- Armored cable joints are made with

MSeal

- Flexible power cable joints are made

properly with sleeves or by using Male-

Female connectors.

Electricians with B license only are Avoiding lonely working at critical

engaged. areas.

Electricity Electrocution Usage of necessary PPEs like 11kv Yes P2 S4 B S Y P1 S3 D S

Rubber gloves, Safety shoes, Red -Impart basic knowledge in first aid

Safety helmet.

-No loose clothing.

Usage of insulated hand tools

The board is provided with lock & key NO Awareness training provided to

Unauthorized operation Personnel Injury P2 S2 D NS No P1 S3 D NS

system. enganged workmen.

Working with

5 electrical - Minimum two local earthing are

installation provided for the distribution boards

(SDB, FDB & MCCB) apart from body

earth.

- The panel is made of metal as per

norms

- Earth loop is available in all sockets

Implement trained workmen

Leakage of power Electrocution Yes P3 S3 B S and close supervision required Y P1 S3 D S

- All electrical circuits are given with all time at site.

RCCBs. Power and Lighting circuits

are separated.

- Light fittings are provided for

illumination in separate poles isolating

from the formwork components/

scaffoldings

- Double insulated cables are used for

the works- Gland is provided at the

entry point of panel

- Armored cable are routed either

below the ground, above the ground or

inside the building with stable support.

- Armored cables are laid not in open

areas and at building edges.

6 Improper Routing Cable / Route map is plotted and

Cable route

Cable damage

Electrocution - Flexible cable is routed 7’ above the No P3 S4 B NS

displayed for reference

No P1 S4 D NS

ground

- Flexible cable is tied with threads

(insulated wires) instead of GI wires

- Sharp corners of distribution boards

are protected with sleeves/half cut

PVC pipes

FOREMAT HAZARD IDENTIFICATION & RISK ASSESSMENT

Project Name: Godrej Aqua

Date:25.12.2018 Ref No. : GPL/AQUA/ELITE/HIRA/16 Revision No. : R - 00

Activity: Electrical Conducting & Installation work

Risk Risk

Assessment Assessment

Non-Significant (NS)

Non-Significant (NS)

Improper Routing Cable / P3 existing Route map is plotted and P1 existing

Ref. Of WI/ SOP :-

Legal Yes/No

Legal Yes/No

Significant (S) /

Significant (S) /

6 Cable route Electrocution No S4 B NS No S4 D NS

Cable damage Control displayed for reference Control

Measure Measure

Sr.

Activity Hazard Risk ( Probable Outcome) Existing Control Additional Control Measure Remark

Probability(P)

Probability(P)

No.

Risk(R) : P*S

Risk(R) : P*S

Severity(S)

Severity(S)

- Permit system and LOTO procedure

is followed

- Correct rated Metal clad plug tops

are used for taking power supply

- Only electrician gives the power

supply to the equipment

- Light posts, Hand tools etc are

allowed to shift only after the removal

of power plug

Power - Every plant and machinery is Pass system need to be followed

7 Leakage of power Electrocution No P2 S4 B NS No P1 S4 D NS

distribution inspected by the PEC person and HSE for deploying any equipment

person before deployment

- Electrician will take the advise from

PEC person for charging the

equipment

- All high powered equipment are

provided with local earthing.

- Junction boxes / light fittings are not

allowed to be kept on floors

1. Implement trained

worker.2.Provided full body 1. Avoid lone worker. 2.

1. Physical injury.

8 Working at 1. Person fall. harness.3.Material doesn’t store edge No P2 S3 C NS Supervison should be No P1 S2 __ NS

2.Person Fatal

Height. 2. Material fall of opening.2.safe working platform strick.3.Maintaing proper

3.Porperties damaged.

used.4.material storage with safe housekeeping working area.

order.

- Regular disposal of wiped cloth

- Flammable materials are removed

Accumulated

9 Fire Fire regularly No P3 S3 B NS 1. Supervision should be strictly. No P1 S3 _ _ NS

wastage.

- Fire Extinguisher & fire bucket is

provided

Probability (P) P/S S1 S2 S3 S4

P1: Improbable P1 - - D C

P2 : Remote P2 - D C B

P3 : Possible P3 D C B A

P4 : Probable P4 D B A A

Severity (s) A : Hazards must be avoided (or the level of risk reduced significantly and reliable by controls)

S1 : Negligible B : Hazards should be avoided (or the level of risk reduced significantly and reliable by controls)

S2 : Minor C : Risk to be controlled as far as reasonably practicable

S3 : Sever D : Risk is controlled as far as reasonably practicable .

S4 : Extreme -- : Acceptable risk

LEGAL : If activity come under legal implecation (significant) than additional control

measures is to be taken and has to be reviewed periodically.

S : Significant

NS : Non - Significant.

Preapared By : HIRA Team ____________________________________________________________________________________

_________________________ _________________________ _____________________________

Reviewd By :

Contractor Project Manager : PMC Project Manager : Regional Safety Manager:

Approved By:

________________________________________________

GPL Project Manager

You might also like

- M01 00101-15 LPDocument34 pagesM01 00101-15 LPMacelevi Darevi100% (3)

- The Apprentice Doctor® Control Bleeding CourseDocument68 pagesThe Apprentice Doctor® Control Bleeding CourseAnton Scheepers100% (2)

- The Hazard Identification and Risk Assessment for the Pacaltsdorp Substation Fence Installation ProjectDocument10 pagesThe Hazard Identification and Risk Assessment for the Pacaltsdorp Substation Fence Installation ProjectemmyNo ratings yet

- Risk Assessment For Elevator Shaft Slab Demolition (C01, S10)Document1 pageRisk Assessment For Elevator Shaft Slab Demolition (C01, S10)ray100% (1)

- Risk assessment for 300MW Masinloc coal-fired power plant plumbing worksDocument8 pagesRisk assessment for 300MW Masinloc coal-fired power plant plumbing worksResearcherNo ratings yet

- Al Door&WindowDocument1 pageAl Door&WindowChandruNo ratings yet

- Job HazardDocument2 pagesJob HazardBre WirabumiNo ratings yet

- Working at Height Risk AssessmentsDocument1 pageWorking at Height Risk AssessmentsRajan GuptaNo ratings yet

- Electrical HiraDocument114 pagesElectrical HiraVENKATESAN M100% (1)

- Storage of Chemical Risk AssessmentsDocument1 pageStorage of Chemical Risk AssessmentsMohammed Amer PashaNo ratings yet

- Fire - HiraDocument142 pagesFire - HiraVENKATESAN M100% (1)

- Barricading Work Risk AssessmentsDocument1 pageBarricading Work Risk AssessmentsHSE1 SHAMNETNo ratings yet

- HIRA For Electrical Hand Tools - 12Document1 pageHIRA For Electrical Hand Tools - 12Devendra BrilltechNo ratings yet

- BOCW and SafetyDocument31 pagesBOCW and Safetydreamboy87No ratings yet

- Chipping Work by MCDocument1 pageChipping Work by MCChandruNo ratings yet

- Risk Assessment For Production and ErectionDocument14 pagesRisk Assessment For Production and ErectionFurqan FarrukhNo ratings yet

- Appendix 1 Job Safety Analysis IBS Components Installation Rev.0 RSKUSCVDocument21 pagesAppendix 1 Job Safety Analysis IBS Components Installation Rev.0 RSKUSCVkimura takuyaNo ratings yet

- GroutingDocument1 pageGroutingraphael damanikNo ratings yet

- Risk Assessment For Mechanical: Preparation WorkDocument3 pagesRisk Assessment For Mechanical: Preparation Workahmedalderbi801No ratings yet

- Risk Assessment for Corian at Mozoon Towers ProjectDocument12 pagesRisk Assessment for Corian at Mozoon Towers Projectadeoye AdeyemiNo ratings yet

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- Risk Assessment For Installation of Diesel Generator111111Document8 pagesRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- Tower Crane Work Permit ChecklistDocument1 pageTower Crane Work Permit Checklistfaisal nadeemNo ratings yet

- HSE-F-314 Passenger-Material Hoist Monthly ChecklistDocument1 pageHSE-F-314 Passenger-Material Hoist Monthly ChecklistAhmad RazaNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Aftab QadirNo ratings yet

- Discharge Rod 11kv 3phaseDocument1 pageDischarge Rod 11kv 3phasewaytobhushan100% (1)

- Skillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayingDocument6 pagesSkillbuild Risk Assessment: Competition Organising Partner: Citb /skillbuild Competition Skills: BricklayinguknandiNo ratings yet

- BMR - Safety PPT Apr-2023Document17 pagesBMR - Safety PPT Apr-2023shamshad ahamedNo ratings yet

- RA (Working at Height)Document4 pagesRA (Working at Height)Yan Naing HtooNo ratings yet

- Block Work MSDocument19 pagesBlock Work MSjonesNo ratings yet

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 pagesJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNo ratings yet

- RA - Concrete PouringDocument1 pageRA - Concrete PouringعمروNo ratings yet

- Al Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentDocument9 pagesAl Musairie Trading & Contracting Co. Qatar WLL: Hazard Identification & Risk AssessmentSujan AugustinNo ratings yet

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- Risk-Assessment Ducts & AccessoriesDocument13 pagesRisk-Assessment Ducts & AccessoriesMohammed Amer PashaNo ratings yet

- Grass Cutting Risk AssessmentDocument4 pagesGrass Cutting Risk AssessmentKaiser Carlo100% (1)

- Hazrd Identification & Risk Assessment: Mmf100 Nov 2009 - Pm/105/01 © Mott Macdonald 2009Document2 pagesHazrd Identification & Risk Assessment: Mmf100 Nov 2009 - Pm/105/01 © Mott Macdonald 2009SuperuserAsadhussainNo ratings yet

- 18A - FO - Permit To Work LogDocument2 pages18A - FO - Permit To Work Lograjesh_rathNo ratings yet

- Tools / Equipment:: Job Safety Analysis (Jsa)Document5 pagesTools / Equipment:: Job Safety Analysis (Jsa)Sameer AlmahboubNo ratings yet

- HiraDocument4 pagesHiraArshad KhanNo ratings yet

- Safety Observation & Non-Compliances Report For R-8A (14102022)Document6 pagesSafety Observation & Non-Compliances Report For R-8A (14102022)Myo Lwin100% (1)

- Boom Lift - Working FromDocument5 pagesBoom Lift - Working Fromwahyu nugrohoNo ratings yet

- Hira Carpentry WorkDocument2 pagesHira Carpentry WorkAtiq ShaikhNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- RISK ASESSMENT For SKYLIGHTDocument23 pagesRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- Isolation Work PermitDocument2 pagesIsolation Work PermitVijayakumar KarunanidhiNo ratings yet

- Installation of GlassDocument6 pagesInstallation of GlassVilky VargheseNo ratings yet

- Hiradc Merentang KabelDocument3 pagesHiradc Merentang KabeladelenaNo ratings yet

- AL AIN MALL WORK PERMITDocument1 pageAL AIN MALL WORK PERMITVeterano 1968No ratings yet

- Iaslc Ra 013 Working Under Direct Sun LightDocument4 pagesIaslc Ra 013 Working Under Direct Sun LightJoe PsNo ratings yet

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh100% (1)

- Job Safety & Environment Analysis: Revision NoDocument3 pagesJob Safety & Environment Analysis: Revision NonishanthNo ratings yet

- App-16.2 - Risk Assessment For Vermeer Axis WorksDocument13 pagesApp-16.2 - Risk Assessment For Vermeer Axis Worksloveson709No ratings yet

- Risk Assessment For Stone WorkDocument17 pagesRisk Assessment For Stone WorkKhuda BukshNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- Cutting, Griding, WeldingDocument6 pagesCutting, Griding, WeldingAli SalihNo ratings yet

- False CeilingDocument1 pageFalse CeilingGyanendra Narayan Nayak100% (1)

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- HIRADC - 001 - Installation of Earthing SystemDocument3 pagesHIRADC - 001 - Installation of Earthing SystemZhafri SyazwiNo ratings yet

- Risk Assesment For Lighting Protection SystemDocument2 pagesRisk Assesment For Lighting Protection SystemAsfand AyazNo ratings yet

- Risk Assesment For Electrical Conducting & Installation WorkDocument2 pagesRisk Assesment For Electrical Conducting & Installation WorkAjay kumarNo ratings yet

- SID-WRA-06 - Pipeline Erection & HydrotestingDocument2 pagesSID-WRA-06 - Pipeline Erection & Hydrotestingcnanda89No ratings yet

- Japanese Words LeanDocument32 pagesJapanese Words Leansinziana ghinetNo ratings yet

- Who Wants To Be A Millionaire - Template by SlideLizardDocument52 pagesWho Wants To Be A Millionaire - Template by SlideLizardPedro popNo ratings yet

- LeanGlossary 01 08Document10 pagesLeanGlossary 01 08jayakumargjNo ratings yet

- Amount:: Mybrd Mobile Transfer DetailsDocument1 pageAmount:: Mybrd Mobile Transfer Detailssinziana ghinetNo ratings yet

- Liebenberg 1990 The Art of TrackingDocument188 pagesLiebenberg 1990 The Art of Trackingsinziana ghinetNo ratings yet

- Japanese Words LeanDocument32 pagesJapanese Words Leansinziana ghinetNo ratings yet

- Base Line Risk Assessment Corporate OfficeDocument13 pagesBase Line Risk Assessment Corporate Officesinziana ghinetNo ratings yet

- Base Line Risk Assessment Corporate OfficeDocument13 pagesBase Line Risk Assessment Corporate Officesinziana ghinetNo ratings yet

- HAZARD IDENTIFICATION & RISK ASSESSMENTDocument3 pagesHAZARD IDENTIFICATION & RISK ASSESSMENTsinziana ghinet100% (1)

- Fire Risk Assessment ReportDocument10 pagesFire Risk Assessment Reportsinziana ghinetNo ratings yet

- Logic PPT MaximsDocument37 pagesLogic PPT MaximsPalak Bhagat100% (1)

- Date: TimeDocument2 pagesDate: Timeryn calasagsagNo ratings yet

- Lesson 1 Touching The Void ExtractDocument2 pagesLesson 1 Touching The Void Extractlight LawlietNo ratings yet

- 4 - Perception & Coordination Alterations RVDocument391 pages4 - Perception & Coordination Alterations RVgeng gengNo ratings yet

- DKX Documents SD01763DEN - 0217Document40 pagesDKX Documents SD01763DEN - 0217Ivan DuranNo ratings yet

- Knee Cartilage and MeniscalDocument4 pagesKnee Cartilage and MeniscalKapil LakhwaraNo ratings yet

- Every Rose Has Its ThornDocument2 pagesEvery Rose Has Its ThornPetra100% (1)

- Motor SysDocument72 pagesMotor SysLeoNo ratings yet

- 08 Sugiratan vs. People (Villasenor)Document1 page08 Sugiratan vs. People (Villasenor)resjudicataNo ratings yet

- Civil Unrest in Eswatini. Commission On Human Rights 2021Document15 pagesCivil Unrest in Eswatini. Commission On Human Rights 2021Richard RooneyNo ratings yet

- Rule 1050 Notification and Keeping Records of Accident and or Occupational IllnessesDocument14 pagesRule 1050 Notification and Keeping Records of Accident and or Occupational Illnesseskimytac20No ratings yet

- Lumbar Spine Range of Movement Exercise Program: Coastal West SussexDocument10 pagesLumbar Spine Range of Movement Exercise Program: Coastal West SussexXavierNo ratings yet

- Rapid Medical AssessmentDocument2 pagesRapid Medical AssessmentJan MitchelleNo ratings yet

- Goat Joint Anatomy GuideDocument3 pagesGoat Joint Anatomy GuideAshley Tanya GilbertNo ratings yet

- Facial Nerve Disorders: An Overview of Facial Nerve Anatomy and Common Facial Nerve ConditionsDocument8 pagesFacial Nerve Disorders: An Overview of Facial Nerve Anatomy and Common Facial Nerve ConditionsJOSHI RAJUNo ratings yet

- Anesthetics MedicationDocument3 pagesAnesthetics MedicationJulianna Rheaven JoreNo ratings yet

- Snake bite PosterDocument1 pageSnake bite PosterNecklal SoniNo ratings yet

- Flaps and Grafts in Dermatologic Surgery by Thomas E. Rohrer, Jonathan L. Cook, Andrew J. Kaufman - PDF - WDocument50 pagesFlaps and Grafts in Dermatologic Surgery by Thomas E. Rohrer, Jonathan L. Cook, Andrew J. Kaufman - PDF - WNicolas Tapia RivasNo ratings yet

- Nerves in rope bondage: risks and preventionDocument1 pageNerves in rope bondage: risks and preventionGabrielaNo ratings yet

- General Motors Truck Kodiak Topkick Wiring Diagrams 1995Document23 pagesGeneral Motors Truck Kodiak Topkick Wiring Diagrams 1995emilycollins260586owp99% (134)

- Pilates For ScoliosisDocument13 pagesPilates For ScoliosisIoan-Alexandru CodarceaNo ratings yet

- Intentional Injuries: Types, Causes and EffectsDocument4 pagesIntentional Injuries: Types, Causes and EffectsDaphne Gesto SiaresNo ratings yet

- Hand Tool Safety SWPDocument7 pagesHand Tool Safety SWPSamundeswaran SatiwasilanNo ratings yet

- Muscle Page Upper Trapezius 1Document2 pagesMuscle Page Upper Trapezius 1Yuleidy LopezNo ratings yet

- Sensors - Editorial Sensor Fusion-2020Document3 pagesSensors - Editorial Sensor Fusion-2020SamuelsonNo ratings yet

- Unintentional Injury Prevention, Safety and First Aid: Health Education 9 3 Grading PeriodDocument42 pagesUnintentional Injury Prevention, Safety and First Aid: Health Education 9 3 Grading Periodsophia luNo ratings yet

- MySims - Manual - WIIDocument6 pagesMySims - Manual - WIIasdasdNo ratings yet

- BPSC MCQ 4 PDFDocument10 pagesBPSC MCQ 4 PDFZee khanNo ratings yet