Professional Documents

Culture Documents

Working at Height Risk Assessments

Uploaded by

Rajan GuptaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Working at Height Risk Assessments

Uploaded by

Rajan GuptaCopyright:

Available Formats

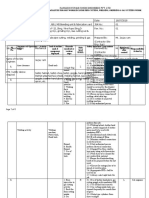

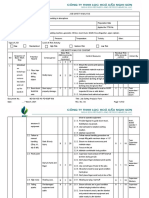

Ref. No.

: GPL F HS 02 Date: 10/20/2020

Rev.No.: 00 Page no. 01 of 01 GPL/HIRA/10

Hazard Identification & Risk Assessment Format

Activity: Working at Height

Risk

Assessment

Non-Significant (NS)

Risk Assessment existing Control Measures additional

Ref. Of WI/ SOP :-

Legal Yes/No

Significant (S) /

Control

Measures

Sr. No. Activity Hazard Issues (Internal/External) Risk ( Probable Outcome) Existing Control Additional Control Measure Opportunities & Action Remark

Probability(P)

Probability(P)

Severity(S)

Severity(S)

Risk Level

Risk Level

(H/M/L) :

(H/M/L) :

1. Scaffolding material should be

1. Carry work under supervision.

Damaged scaffolding material Internal Personal Injury in good condition. P2 S3 M

2. Remove damaged scaffold 2.Strictly follow P2 S3 M Nil

GPL work instruction(SOP).

1. Provide mid rail, top rail to 1. Inspect scaffold as per

Missing of railing Internal Fall from height protect person from fall. P2 S3 M checklist. P2 S3 M Nil

Personal Injury 2. Provide Red Tag to the scaffold 2. Take work permit before start

if found railing missing. of job.

1.anchorage point at height to

anchor harness.

2. Provide anchorage point above

Missing of anchorage point Fall from height shoulder level. 1. Inspect anchorage point to

Internal 3. Provide vertical lifeline with P3 S3 H P2 S3 M Nil

(lifeline) Personal Injury ensure strength.

fall arrester for tower crane.

4. Provided adequate

dia.polypropelene rope as

vertical life line

1. Implement administrative

Scaffolding erected on uneven 1. Compact area. control measure. Follow GPL

Internal Fall of scaffold 2. Scaffolding should be erected on P2 S3 M P2 S3 M Nil

surface base plate. work instruction(SOP)

2. Follow work permit system.

1. Provide edge barricading

Fall of material

2. Wear Safety harness and fix to

Working at open edge Internal anchorage point P2 S4 H 1. Continuous supervision to be P2 S4 M Nil

Fall of person 3. Safety net should be provided provided

4. Take work permit YES S

1 Working at Height

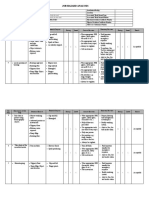

1. Remove all defective ladder

Improper access Internal Fall of person or 1. Inspect ladder before use. P3 S3 H P2 S3 M Nil

material 2. Provide staircase as a means of during inspection from site.

access to all height job.

1. Inspect working platform

1. Follow work permit system.

Insufficient working platform Internal Injury to body part 2. Avoid gap in platform. P3 S4 H P2 S4 M Nil

3. Provide sufficient working

platform.

1. Check safety harness before

use. 1. Remove damaged safety

Damaged harness Internal Fall of Person 2. Conduct training on Safety P2 S3 M P2 S3 M Nil

harness.

harness inspection.

1. Continuous supervision should

Stacking material at Edge Internal Fall of Material 1. Do not keep material at edge P3 S3 H P1 S3 M Nil

be provided.

Fall of Material 1. Avoid loose material keeping 1. Good housekeeping should be

Loose material Internal at height P2 S3 M maintained P1 S3 M Nil

Personal injury 2. Safety Net should be

provided..

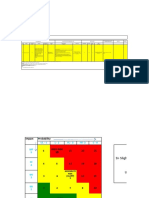

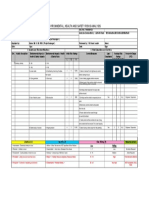

RISK Calculation / Evaluatio

Probability (P) P/S S1 S2 S3 S4

P1: Improbable P1 L L M M

P2 : Remote P2 L M M H

P3 : Possible P3 M M H H

P4 : Probable P4 M H H H

A : Hazards must be avoided (or the level of risk reduced significantly and reliable by controls)

Severity (s)

B : Hazards should be avoided (or the level of risk reduced significantly and reliable by controls)

S1 : Negligible

C : Risk to be controlled as far as reasonably practicable

S2 : Minor

D : Risk is controlled as far as reasonably practicable .

S3 : Sever

-- : Acceptable risk

S4 : Extreme

LEGAL : If activity come under legal implecation (significant) than additional control measures is to be taken and has to be reviewed periodically.

S : Significant

NS : Non - Significant.

PREPARED BY KEC PROJECT MANAGER PMC SAFETY MANAGER

PMC PROJECT MANAGER GPL SAFETY MANAGER GPL PROJECT MANAGER

You might also like

- HIRA For Electrical Hand Tools - 12Document1 pageHIRA For Electrical Hand Tools - 12Devendra BrilltechNo ratings yet

- Risk Assesment For Electrical Conducting & Installation WorkDocument3 pagesRisk Assesment For Electrical Conducting & Installation Worksinziana ghinet100% (1)

- Barricading Work Risk AssessmentsDocument1 pageBarricading Work Risk AssessmentsHSE1 SHAMNETNo ratings yet

- Cable Tray Fixing - HiraDocument175 pagesCable Tray Fixing - HiraVENKATESAN MNo ratings yet

- Concreting Risk AssessmentsDocument2 pagesConcreting Risk AssessmentsHSE1 SHAMNET0% (1)

- Electrical HiraDocument114 pagesElectrical HiraVENKATESAN M100% (1)

- Storage of Chemical Risk AssessmentsDocument1 pageStorage of Chemical Risk AssessmentsMohammed Amer PashaNo ratings yet

- Labor Camp - Erection & Operation Risk AssessmentsDocument2 pagesLabor Camp - Erection & Operation Risk Assessmentshussein aliNo ratings yet

- Fire - HiraDocument142 pagesFire - HiraVENKATESAN M100% (1)

- HTG Engineering Pvt. Ltd. 2 800 MW Adani Power Jharkhand LTD Hira RegisterDocument7 pagesHTG Engineering Pvt. Ltd. 2 800 MW Adani Power Jharkhand LTD Hira Registeruttam mishra0% (1)

- HIRADocument7 pagesHIRAmadhur chavanNo ratings yet

- HIRA - Height WorkDocument3 pagesHIRA - Height WorkHiralal Pattanayak100% (2)

- HiraDocument4 pagesHiraArshad KhanNo ratings yet

- Hira Carpentry WorkDocument2 pagesHira Carpentry WorkAtiq ShaikhNo ratings yet

- Chipping Work by MCDocument1 pageChipping Work by MCChandruNo ratings yet

- Hoist Erection Operation & Maintenance Work - R0 - 30.09.2017Document6 pagesHoist Erection Operation & Maintenance Work - R0 - 30.09.2017Nikhil ManjrekarNo ratings yet

- Risk Assessment Scaffolding, Painting, Stone Cutting & Fixing and Working at Height Work ISO 45001Document7 pagesRisk Assessment Scaffolding, Painting, Stone Cutting & Fixing and Working at Height Work ISO 45001123shripad100% (1)

- HIRADocument6 pagesHIRAvijay kumar singhNo ratings yet

- Jsa For Mechanical Activity: H/M/L H/M/LDocument1 pageJsa For Mechanical Activity: H/M/L H/M/Ljithin shankarNo ratings yet

- HIRA - Hydro TestDocument3 pagesHIRA - Hydro TestHiralal PattanayakNo ratings yet

- Iaslc Ra 013 Working Under Direct Sun LightDocument4 pagesIaslc Ra 013 Working Under Direct Sun LightJoe PsNo ratings yet

- Risk Assessment All Activities TLT HIRADocument50 pagesRisk Assessment All Activities TLT HIRAvijay100% (2)

- Insulation of Ducting and PipingDocument1 pageInsulation of Ducting and PipingKrishna Patil100% (1)

- Cuplocks Scaffolding JSA UtilityDocument4 pagesCuplocks Scaffolding JSA UtilitysoubhagyaNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- JSA For Scissor Lift, Rev-6Document2 pagesJSA For Scissor Lift, Rev-6Mahamudul HasanNo ratings yet

- AFA HIRA - Electrical Control PanelDocument30 pagesAFA HIRA - Electrical Control PaneljavedNo ratings yet

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Job Hazard Analysis: How To Use This FormDocument4 pagesJob Hazard Analysis: How To Use This FormZul Atfi100% (1)

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- 09.00AM to11.00PM Clear: TCE EffwaDocument3 pages09.00AM to11.00PM Clear: TCE EffwaAjayNo ratings yet

- Sand FillingDocument1 pageSand FillingGyanendra Narayan NayakNo ratings yet

- Al Door&WindowDocument1 pageAl Door&WindowChandruNo ratings yet

- Grinding ActivityDocument1 pageGrinding ActivityKrishna Patil100% (2)

- JSA For Erection of Precast..Document18 pagesJSA For Erection of Precast..Shafie ZubierNo ratings yet

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGDocument2 pagesJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioNo ratings yet

- Hira RCC Cement MillDocument2 pagesHira RCC Cement MillRajuNo ratings yet

- Final HIRA - GBLDocument49 pagesFinal HIRA - GBLAbdul Rasheed MangrioNo ratings yet

- RA - Plumbing Works Rev. BDocument8 pagesRA - Plumbing Works Rev. BResearcherNo ratings yet

- Job Hazard Analysis PermitDocument1 pageJob Hazard Analysis PermitKhorchnoi Abaja CalimlimNo ratings yet

- Peb HiraDocument2 pagesPeb HiraRANJEET SINGH100% (1)

- All HiraDocument40 pagesAll Hirarameese muhammed100% (1)

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- HIRA For TATA Project - Tool RoomDocument124 pagesHIRA For TATA Project - Tool Roomvivek vjNo ratings yet

- HIRA NewDocument107 pagesHIRA NewPrabhakaran Gurunathan100% (1)

- F 5.3 C Star-Safety-Inspection-JULYDocument4 pagesF 5.3 C Star-Safety-Inspection-JULYSn Ahsan100% (1)

- Hira DineshDocument11 pagesHira DineshDurai GunasekaranNo ratings yet

- 44 Safety Observation Report. 380 KV OHTL - Qiddyia Area 02-11-2021Document4 pages44 Safety Observation Report. 380 KV OHTL - Qiddyia Area 02-11-2021Shafie ZubierNo ratings yet

- Risk Assessment For Erection of Steel GirderDocument11 pagesRisk Assessment For Erection of Steel GirderNirajan MarwaitNo ratings yet

- Weekly HSE Inspection Closeout Report - 01Document2 pagesWeekly HSE Inspection Closeout Report - 01niyas100% (1)

- RCC at Height HiraDocument1 pageRCC at Height Hiraskfahimuddin100% (1)

- Safety Observtion Register FarhadDocument2 pagesSafety Observtion Register Farhadalla malikNo ratings yet

- HIRA For DPP-2 Project in I BlockDocument20 pagesHIRA For DPP-2 Project in I BlockSiddharth PNo ratings yet

- 4 HIRA Format - Sand Blasting ActivityDocument2 pages4 HIRA Format - Sand Blasting ActivityMD Abdullah100% (1)

- Drilling Work by MCDocument1 pageDrilling Work by MCChandruNo ratings yet

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- HIRA - Fixed Scaffold and Wall BreakingDocument6 pagesHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- Hira - RCC Road ActivityDocument3 pagesHira - RCC Road Activitytariq1987100% (1)

- Survey Work HSE Risk AssessmentsDocument2 pagesSurvey Work HSE Risk AssessmentsDeepak DasNo ratings yet

- DG Unloading and Installation Risk AssessmentsDocument3 pagesDG Unloading and Installation Risk AssessmentsMontadhar HaithamNo ratings yet

- Revised MS For WaterproofingDocument9 pagesRevised MS For WaterproofingChamux skalNo ratings yet

- LMS Power Cable Handbook Vol 2 PDFDocument182 pagesLMS Power Cable Handbook Vol 2 PDFReaksmey Bin100% (3)

- Robit Rocktools: Casing SystemsDocument16 pagesRobit Rocktools: Casing SystemsGabriel AmorimNo ratings yet

- SAG - Electrical Installation and Maintenance NC IIDocument4 pagesSAG - Electrical Installation and Maintenance NC IIMark MarasiganNo ratings yet

- Instructions For Replacing The Engage - Disengage GearsDocument5 pagesInstructions For Replacing The Engage - Disengage GearsAndi PrengaNo ratings yet

- UL 1693-1999 Electric Radiant Heating Panels and Heating Panel SetsDocument50 pagesUL 1693-1999 Electric Radiant Heating Panels and Heating Panel Setsking leeNo ratings yet

- Asphalt Mix Design MethodDocument12 pagesAsphalt Mix Design MethodHuda MahdiNo ratings yet

- BBC Tech Associates: E-MailDocument1 pageBBC Tech Associates: E-MailRajuNo ratings yet

- CIVIL 3811 - Lecture Slides - Week 7Document58 pagesCIVIL 3811 - Lecture Slides - Week 7hadaNo ratings yet

- Architectural StructureDocument6 pagesArchitectural StructureJohn Aaron BlancoNo ratings yet

- 027 - Section 3C Precast Concrete GrilleDocument2 pages027 - Section 3C Precast Concrete GrilleMark Roger II HuberitNo ratings yet

- Church PlanDocument1 pageChurch PlanJOHN KEMBOINo ratings yet

- Design of Flexible and Rigid PavementDocument29 pagesDesign of Flexible and Rigid Pavementrodge macaraegNo ratings yet

- Geranioc GB1 PDFDocument4 pagesGeranioc GB1 PDFmaksimilNo ratings yet

- Anchor Bolt DetailsDocument1 pageAnchor Bolt Detailsk sulekhNo ratings yet

- Cec 203 ScheduleDocument5 pagesCec 203 ScheduleSky Kush67% (6)

- Project HSE Kickoff Meeting Minutes Template 1661784319Document4 pagesProject HSE Kickoff Meeting Minutes Template 1661784319richardNo ratings yet

- Multifamily Project Final Presentation-CompressedDocument16 pagesMultifamily Project Final Presentation-Compressedapi-458732339No ratings yet

- Private CompaniesDocument7 pagesPrivate CompaniesMoh AchourNo ratings yet

- Prensas y Otros StanleyDocument7 pagesPrensas y Otros StanleyjohangomezruizNo ratings yet

- Building Permission Undertakings - Greater Hyderabad Municipal ...Document15 pagesBuilding Permission Undertakings - Greater Hyderabad Municipal ...scribdasrar100% (1)

- VIII. Tinned Copper Fuse Wire: Table A-8.1Document1 pageVIII. Tinned Copper Fuse Wire: Table A-8.1Rohit choudharyNo ratings yet

- Case Study: Villa 31: The Urban Slum As A Model For Sustainable DevelopmentDocument49 pagesCase Study: Villa 31: The Urban Slum As A Model For Sustainable DevelopmentShravani AmateNo ratings yet

- Disain Campuran Beton Rev.1Document19 pagesDisain Campuran Beton Rev.1yudhiNo ratings yet

- A Review of N. J. Habraken's 'Supports: An Alternative To Mass Housing'Document1 pageA Review of N. J. Habraken's 'Supports: An Alternative To Mass Housing'Abhinav JayantiNo ratings yet

- Tiny House Design and Construction Guide SampleDocument12 pagesTiny House Design and Construction Guide SampleInamotosan54% (26)

- 15.0 Colgrout Masonry Works HandbookDocument48 pages15.0 Colgrout Masonry Works HandbookShabbir LokhandwalaNo ratings yet

- Resort Desktop Study PDFDocument12 pagesResort Desktop Study PDFdumpa hanishaNo ratings yet

- SpecificationsDocument10 pagesSpecificationsAnton_Young_1962No ratings yet

- Table - 7 Storage Load Factors Solar Heat Gain Thru Glass With Internal Shade PDFDocument1 pageTable - 7 Storage Load Factors Solar Heat Gain Thru Glass With Internal Shade PDFkiran raghukiranNo ratings yet