Professional Documents

Culture Documents

BS 5950-2000 Example 002 PDF

BS 5950-2000 Example 002 PDF

Uploaded by

Eng Hinji RudgeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BS 5950-2000 Example 002 PDF

BS 5950-2000 Example 002 PDF

Uploaded by

Eng Hinji RudgeCopyright:

Available Formats

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

BS 5950-2000 Example 002

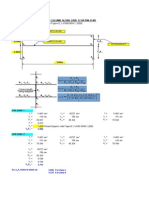

SQUARE TUBE MEMBER UNDER COMPRESSION & BENDING

EXAMPLE DESCRIPTION

The frame object axial and moment strengths are tested in this example.

A continuous column is subjected to factored loads and moments N = 640 kN;

Mx = 10.5 kN-m; My = 0.66 kN-m. The moment on the column is caused by

eccentric beam connections. This example was tested using the BS 5950-2000

steel frame design code. The design capacities are compared with independent

hand calculated results.

GEOMETRY, PROPERTIES AND LOADING

Mx

My

H

A A

Section A-A

H=5m

Material Properties Loading Design Properties

E = 205000 MPa N = 640 kN Ys = 355 MPa

v = 0.3 Mx = 10.5 kN-m

G = 78846.15 MPa My = 0.66 kN-m

TECHNICAL FEATURES TESTED

Section compactness check (compression & bending)

Member compression capacity

Section bending capacity

BS 5950-2000 Example 002 - 1

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

RESULTS COMPARISON

Independent results are taken from Example 15 on page 83 of the SCI Publication

P326, Steelwork Design Guide to BS5950-1:2000 Volume 2: Worked Examples

by M.D. Heywood & J.B. Lim.

Percent

Output Parameter ETABS Independent Difference

Compactness Class 1 Class 1 0.00%

Axial Capacity,

773.2 773.2 0.00%

Nc (kN)

Bending Capacity, 68.3 68.3 0.00%

Mc (kN-m)

COMPUTER FILE: BS 5950-2000 EX002

CONCLUSION

The results show an exact comparison with the independent results.

BS 5950-2000 Example 002 - 2

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

HAND CALCULATION

Properties:

Material:

E = 205000 MPa

G = 78846.15 MPa

Ys = 355 MPa

ρ y = 1.0 • Ys = 355 MPa

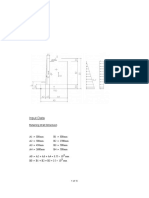

Section: RHS 150x150x6.3:

Ag = 3580 mm2

D = B = 150 mm, T=t = 6.3 mm

b = B − 3 • t = d = D − 3 • T = 150 − 2 • 6.3 = 131.1mm

r33 = 58.4483 mm

Z33 = 163,066.7 mm3

S33 = 192,301.5 mm3

Loadings:

N = 640 kN

Mx = 10.5 kN-m

My = 0.66 kN-m

Fv33 = Mx/H = 10.5 / 5 = 2.1 kN

Section Compactness:

P 640

=r1 = = 0.002183

dt ρ y 131 • 6.3 • 355

275 275

=ε = = 0.880

ρy 355

BS 5950-2000 Example 002 - 3

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

Localized Buckling for Flange:

b 131.1

λ= = = 20.81

T 6.3

d 131.1

λ p= 28 ε < 80ε − = 28 • 0.880 < 80 • 0.880 −

t 6.3

λ=

p 24.6 < 49.6

=λ 20.81 <=

λ p 24.6 , No localized flange buckling

Flange is Compact.

Localized Buckling for Web:

d 131.1

λ= = = 20.81 :

t 6.3

64ε 64 • 0.88

=

λp < 40

= ε < 40 • 0.88

= 56.3 > 35.2

1 + 0.6r1 1 + 0.6 • 0.002183

So λ p =35.2

=λ 20.81 <=

λ p 35.2 , No localized web buckling

Web is compact.

Section is Compact.

Member Compression Capacity:

l K l 1.0 • 5000

λ 22 =λ 33 =e 33 = 33 33 = =85.546

r33 r33 58.4483

=λ max {λ 22 , λ=

33 } 85.546

π2 E π2 • 205000

=λ o 0.2= 0.2 = 15.1

ρy 355

Robertson Constant: a = 2.0 (from Table VIII-3 for Rolled Box Section in CSI

code documentation)

=

Perry Factor: η 0.001a ( λ −=

λ 0 ) 0.001 • 2 ( 85.546 − 15.1

= ) 0.141

BS 5950-2000 Example 002 - 4

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

π2 E π2 • 205000

Euler Strength: ρ= = = 276.5 MPa

λ2

E

85.5462

ρ y + ( η + 1) ρ E 355 + ( 0.141 + 1) • 276.5

=φ = = 355.215 MPa

2 2

ρE ρ y 276.5 • 355

=ρc = = 215.967 MPa

φ + φ2 − ρ E ρ y 335.215 + 335.2152 − 276.5 • 355

= g ρc

N c A= 3580 • 215.967

N c = 773.2 kN

Section Shear Capacity:

ρ y = 1.0 • Ys = 275 MPa

D 150

Av =

Ag =3580 • =1790 mm 2

D + B 150 + 150

Pv = 0.6 ρ y Av 2 = 0.6 • 355 • 1790

Pv = 381.3kN

Section Bending Capacity:

With Shear Reduction

0.6=

• Pv 228.8 kN=

> Fv 2.1kN

So no shear reduction is needed in calculating the bending capacity.

Mc =

ρ y S33 ≤ 1.2ρ y Z 33 =

355 • 192,301.5 ≤ 1.2 • 355 • 163, 066.7

=M c 68.3kN-m ≤ 69.5 kN-m

M c = 68.3kN-m

With LTB Reduction

Not considered since the section is square.

BS 5950-2000 Example 002 - 5

You might also like

- CSA S16-09 Example 002Document6 pagesCSA S16-09 Example 002Anitha Hassan KabeerNo ratings yet

- Best Stochastic Trading StrategyDocument5 pagesBest Stochastic Trading StrategyBadrun Ibrahim67% (3)

- BS 5950-2000 Example 001Document5 pagesBS 5950-2000 Example 001Anitha Hassan KabeerNo ratings yet

- 16 Selection of Concrete Filled Steel Pipe Columns 23052014Document1 page16 Selection of Concrete Filled Steel Pipe Columns 23052014Ahmad Badsha QuadriNo ratings yet

- Chapter 36 WexDocument30 pagesChapter 36 WexCaesarAbdullahNo ratings yet

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocument6 pagesStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresNo ratings yet

- Pile Cap Design - 4columnsDocument2 pagesPile Cap Design - 4columnstheunknown076No ratings yet

- Beam On Elastic Foundation AnalysisDocument5 pagesBeam On Elastic Foundation AnalysisMagdy BakryNo ratings yet

- Ec9 Ex61 Shear No StiffenersDocument3 pagesEc9 Ex61 Shear No StiffenersimotalpNo ratings yet

- Design Example-Beam Compact SectionDocument13 pagesDesign Example-Beam Compact SectionManoj RautNo ratings yet

- Vertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisDocument10 pagesVertical Loads On Building Frames: Assumptions For The Analysis of Girders Using Approximate AnalysisNeven Ahmed HassanNo ratings yet

- Precast Column - Stability CalculationDocument1 pagePrecast Column - Stability Calculationarif_rubinNo ratings yet

- Cruciform Sections + NSCApril06 - TechDocument3 pagesCruciform Sections + NSCApril06 - TechIho1No ratings yet

- Tubular Profiles For Telecom Structures PDFDocument8 pagesTubular Profiles For Telecom Structures PDFJitendraNo ratings yet

- Beam Columns Example - Is 800Document7 pagesBeam Columns Example - Is 800anil97232No ratings yet

- PurlinDocument8 pagesPurlinRafaArdiSyahrezaNo ratings yet

- Raft DesignDocument8 pagesRaft Designomolewa joshuaNo ratings yet

- Lintel Beam (When Height Less)Document30 pagesLintel Beam (When Height Less)Kartik MehtaNo ratings yet

- Meever India Brochure FinalDocument44 pagesMeever India Brochure FinalSrinu NaikNo ratings yet

- BalustradeDocument10 pagesBalustradeTerry CheukNo ratings yet

- Column-Footing Size 3Document8 pagesColumn-Footing Size 3Anonymous HJ7hmihhNo ratings yet

- Dimensional Solutions Mat3DDocument69 pagesDimensional Solutions Mat3DTimothy HancockNo ratings yet

- Assignment On Structural Design Lab - 2 Submitted by PRADYUT ANAND/ MT/CE/10016/19Document15 pagesAssignment On Structural Design Lab - 2 Submitted by PRADYUT ANAND/ MT/CE/10016/19Pradyut AnandNo ratings yet

- 8224 Grating No HeaderDocument69 pages8224 Grating No HeadervishalnalwarNo ratings yet

- Splice Connection 200Document19 pagesSplice Connection 200Gheorghe IonicaNo ratings yet

- Section Properties:-: Try With Section Ixx Iyy ZXX Zyy A R R T TDocument4 pagesSection Properties:-: Try With Section Ixx Iyy ZXX Zyy A R R T TbuildconNo ratings yet

- Purlin Design CalculationDocument3 pagesPurlin Design Calculationmsiddiq1No ratings yet

- Design of Concrete & Masonry Structures: Dr. Ye Lu Lecture #7-2 (Week 7)Document20 pagesDesign of Concrete & Masonry Structures: Dr. Ye Lu Lecture #7-2 (Week 7)tien2506onlineNo ratings yet

- Add An Extra DL and Revise - 0.15 PSFDocument1 pageAdd An Extra DL and Revise - 0.15 PSFsharif uddinNo ratings yet

- Punching Calculation With ExceletabsDocument3 pagesPunching Calculation With Exceletabssengar007No ratings yet

- Concreto Aci 318-051Document20 pagesConcreto Aci 318-051Freddy Gallo SanchezNo ratings yet

- Lecture Three - Welded ConnectionsDocument30 pagesLecture Three - Welded ConnectionsAhmedNo ratings yet

- Estimating Deadloads On Timber CanopiesDocument1 pageEstimating Deadloads On Timber CanopiesConrad HarrisonNo ratings yet

- Extended LECTUREDocument21 pagesExtended LECTUREbaraka100% (1)

- Chap 7 Foundation DesignDocument36 pagesChap 7 Foundation DesignZulhasri WahapNo ratings yet

- Sections: Universal Columns (UC) EurocodeDocument2 pagesSections: Universal Columns (UC) EurocodeRajesh RNo ratings yet

- Lashing Lug Round Bar Design: 1. GeneralDocument3 pagesLashing Lug Round Bar Design: 1. GeneralinnovativekarthiNo ratings yet

- Quiz 2Document4 pagesQuiz 2Jerome M. GuetaNo ratings yet

- Difference Beetween Is 800-2007 & Is 800-1984Document96 pagesDifference Beetween Is 800-2007 & Is 800-1984ayazmadNo ratings yet

- JassimDocument29 pagesJassimZain Communication0% (1)

- Thermal Stress ExamplesDocument10 pagesThermal Stress ExamplesVishal V BhagwatNo ratings yet

- Beam-Column Using Double Angle CleatDocument7 pagesBeam-Column Using Double Angle CleatNur Syahira100% (1)

- Precast Concrete PilesDocument4 pagesPrecast Concrete PilesnanamallowNo ratings yet

- Steel Fiber Reinforced Concrete For Pavement: A Case Study in The PhilippinesDocument4 pagesSteel Fiber Reinforced Concrete For Pavement: A Case Study in The PhilippinesMarlon MatusalemNo ratings yet

- Software Verification: AISC-360-16 Example 002Document3 pagesSoftware Verification: AISC-360-16 Example 002alejandro mantillaNo ratings yet

- Effective Length For Moment FrameDocument5 pagesEffective Length For Moment FramenhulugallaNo ratings yet

- MathCAD - Retaining Wall FoundationDocument6 pagesMathCAD - Retaining Wall FoundationValentinNo ratings yet

- Wind Load Calculation For Multiple Framed Open Structures Design Wind PressureDocument2 pagesWind Load Calculation For Multiple Framed Open Structures Design Wind Pressurechirag01020% (1)

- UB5 Steel Beam Analysis & Design (BS5950Document4 pagesUB5 Steel Beam Analysis & Design (BS5950yambalaoingjrNo ratings yet

- Type 1 New Jersey' Style Median Barrier: Product No: 7-0070Document17 pagesType 1 New Jersey' Style Median Barrier: Product No: 7-0070EiflaRamosStaRitaNo ratings yet

- Calculation of Effective LengthDocument3 pagesCalculation of Effective Lengthbuildcon100% (1)

- CE6686 - Design of RCC and Composite StructuresDocument12 pagesCE6686 - Design of RCC and Composite StructuresSabarinath MuruganNo ratings yet

- BS 5950-2000 Example 002Document5 pagesBS 5950-2000 Example 002Ulasi IfeanyiNo ratings yet

- BS 5950-2000 Example 001Document5 pagesBS 5950-2000 Example 001thanzawtun1981No ratings yet

- IS 800-2007 Example 003 PDFDocument12 pagesIS 800-2007 Example 003 PDFwillowdoNo ratings yet

- CSA S16-09 Example 002Document6 pagesCSA S16-09 Example 002Bùi Văn HợpNo ratings yet

- CSA S16-01 Example 001Document7 pagesCSA S16-01 Example 001Bùi Văn HợpNo ratings yet

- CISC 95 Example 002Document6 pagesCISC 95 Example 002Bùi Văn HợpNo ratings yet

- NTC 2008 Example 002Document14 pagesNTC 2008 Example 002Anitha Hassan KabeerNo ratings yet

- NTC 2008 Example 001Document6 pagesNTC 2008 Example 001Anitha Hassan KabeerNo ratings yet

- Long Span PrattDocument36 pagesLong Span PrattCarmel Buniel SabadoNo ratings yet

- Surveying1 DoneDocument63 pagesSurveying1 DoneAnitha Hassan Kabeer100% (1)

- 8sem Civil Structural Engineering Design-1 DineshChandra AssignmentsDocument10 pages8sem Civil Structural Engineering Design-1 DineshChandra AssignmentsAnitha Hassan KabeerNo ratings yet

- Architects & Engineers Association: Application Form For MembershipDocument1 pageArchitects & Engineers Association: Application Form For MembershipAnitha Hassan KabeerNo ratings yet

- Naveed Anwar CVDocument22 pagesNaveed Anwar CVAnitha Hassan Kabeer100% (1)

- E TN SWD General 003Document4 pagesE TN SWD General 003Anitha Hassan KabeerNo ratings yet

- RS3 Pile Raft ModelingDocument11 pagesRS3 Pile Raft ModelingAlberto EscalanteNo ratings yet

- E TN SWD General 005Document6 pagesE TN SWD General 005Anitha Hassan KabeerNo ratings yet

- E TN SWD General 001Document15 pagesE TN SWD General 001Anitha Hassan KabeerNo ratings yet

- UnitII HSNDocument68 pagesUnitII HSNAnitha Hassan KabeerNo ratings yet

- E TN SWD General 008Document4 pagesE TN SWD General 008Anitha Hassan KabeerNo ratings yet

- NTC 2008 Example 001Document6 pagesNTC 2008 Example 001Anitha Hassan KabeerNo ratings yet

- NTC 2008 Example 002Document14 pagesNTC 2008 Example 002Anitha Hassan KabeerNo ratings yet

- Biological Stain Analysis: DNA: Fourth EditionDocument88 pagesBiological Stain Analysis: DNA: Fourth Editionccondeiu1No ratings yet

- Design For MaintainabilityDocument2 pagesDesign For MaintainabilityJulianna BakerNo ratings yet

- PMP3670B QSG - 20130306Document96 pagesPMP3670B QSG - 20130306doru nastaseNo ratings yet

- Tib Amx AdministrationDocument384 pagesTib Amx AdministrationTaher HarrouchiNo ratings yet

- (Gkmojo) Recent Major Government Schemes: Memorise The Objective of Each SchemeDocument16 pages(Gkmojo) Recent Major Government Schemes: Memorise The Objective of Each SchemeUrvashi SahNo ratings yet

- Application For Leave: DepedDocument21 pagesApplication For Leave: Depedarnulyn.garciaNo ratings yet

- AP Poetry PromptsDocument53 pagesAP Poetry PromptsSeth Adler100% (1)

- Test Global WarmingDocument3 pagesTest Global Warminghocine91No ratings yet

- Cert - of Expenses Not Requiring ReceiptsDocument2 pagesCert - of Expenses Not Requiring ReceiptsMarven SindayNo ratings yet

- Parker SSD 650 Easy Start GuideDocument17 pagesParker SSD 650 Easy Start GuideDarren RisleyNo ratings yet

- DV4Document4 pagesDV4Karim El GazzarNo ratings yet

- MASTERY CLASS IN AUDITING PROBLEMS Part 2 Prob 10 15Document34 pagesMASTERY CLASS IN AUDITING PROBLEMS Part 2 Prob 10 15Makoy BixenmanNo ratings yet

- Guide To Install Mac Os XDocument5 pagesGuide To Install Mac Os XMdnor RahimNo ratings yet

- Module 5: Environmental EducationDocument61 pagesModule 5: Environmental EducationChristlly LamyananNo ratings yet

- A4 Cross SectionDocument24 pagesA4 Cross SectionarkabbotNo ratings yet

- Formative Assessment 2 Dance AnalysisDocument2 pagesFormative Assessment 2 Dance AnalysisRj ReyesNo ratings yet

- Sartorius Cata Integrated Lab Equipment S 0300 eDocument430 pagesSartorius Cata Integrated Lab Equipment S 0300 eedal_108No ratings yet

- Export PunjabDocument440 pagesExport PunjabHimanshu MittalNo ratings yet

- Academic Text Reading Skills of Senior High School Students of Batangas CityDocument9 pagesAcademic Text Reading Skills of Senior High School Students of Batangas CityElkissa Joy Lumbres Yutuc100% (1)

- Functions of Banking Sectors in Bangladesh.Document2 pagesFunctions of Banking Sectors in Bangladesh.Omar FarukNo ratings yet

- Student Guide 2015Document13 pagesStudent Guide 2015api-295463484No ratings yet

- 9245 Single Channel On-Line Sodium Analyzer-Operator ManualDocument130 pages9245 Single Channel On-Line Sodium Analyzer-Operator Manualdenios09No ratings yet

- UNIT 10 Extra Gram ExerciseDocument6 pagesUNIT 10 Extra Gram ExerciseFernando BenitezNo ratings yet

- Financial Statement Analysis: - FocusDocument12 pagesFinancial Statement Analysis: - FocuspfeNo ratings yet

- MM-Syllabus of Strategic Management-2021Document6 pagesMM-Syllabus of Strategic Management-2021Tiffani AnnisaNo ratings yet

- VM Sludgemaster Rev1222Document15 pagesVM Sludgemaster Rev1222Pkk Siam Rayong co-saleNo ratings yet

- Volmary Catalogue 2024Document398 pagesVolmary Catalogue 2024Vikash TrivediNo ratings yet

- JSPL Investor PresentationDocument60 pagesJSPL Investor PresentationRatish Kumar mishra100% (1)

- Quality Control of Construction Testing of Concrete CubesDocument20 pagesQuality Control of Construction Testing of Concrete Cubesgaurav522chdNo ratings yet