Professional Documents

Culture Documents

Load Angle of Synchronous Generator

Load Angle of Synchronous Generator

Uploaded by

raviOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Load Angle of Synchronous Generator

Load Angle of Synchronous Generator

Uploaded by

raviCopyright:

Available Formats

https://www.ebah.com.

br/content/ABAAAgT5AAB/transmission-and-

distribution-of-electrical-engineering?part=2

In the most fundamental terms: the electromagnetic torque inside a synchronous machine (air-gap

torque) is developed by the interaction of two magnetic fields: one created by dc current applied to the

field winding, and another one created by the positive-sequence components of the stator currents.

The flux created by the currents in the stator is "rotating" at the frequency of the ac currents (relax for a

moment and consider a 2-pole machine only). The flux created by the field winding is rotating at the

mechanical speed of the shaft.

These two fluxes are stationary with respect to each other only when the mechanical speed matches the

frequency of the ac currents, therefore the name "synchronous machine".

If you have two magnetic fluxes, the torque between them will be proportional to the magnitude of

each flux and the sine of the angle between these fluxes. That angle, the angle between the rotor flux

and the stator flux, is called the load angle. You have to increase the angle to get more torque (or

power).

Because the torque follows a sine curve, its maximum occurs at 90 degrees. Exceed 90 degrees and

you'd have a pole slip and, in general, protection would trip the machine.

In practical terms, due to stability and all, synchronous machines do not operate anywhere near that 90

degrees threshold.

Note that the load angle and the torque is related to active power. Reactive power has some impact (via

demagnetizing effects) but it is a secondary effect. The load angle between the internal fluxes of the

machine can be understood (at least as a first approximation) as dependent exclusively on active power.

The flux produced by the field winding leads the flux produced by the stator winding during operation as

a generator (i.e., power conversion from the mechanical side, turbine, to the electrical output of the

machine). You can visualize it as the field flux "pulling" the stator flux. Or the stator flux being the

"load", the drag trying to slow down the speed.

The flux produced by the stator windings will lead the flux produced by the stator winding during

operation as a motor.

Speaking in practical terms, load angle is kept at 30 degrees electrical and as the Mega Watt load on the

machine increases, load angle also increases, machine delivering more power and this goes on upto 90

degrees electrical.

If the load angle is increased beyond 90 degrees, machine looses synchronism and falls out of step from

other machines and will no more operate as synchronous machine

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ALFA Romeo 147 OEM CodesDocument108 pagesALFA Romeo 147 OEM CodesDragos Valentin StefanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bengt Broms - Foundation EngineeringDocument262 pagesBengt Broms - Foundation EngineeringAnonymous lMTMFfmPl80% (10)

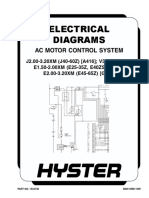

- Hyster 1534738 11 03 srm1059Document46 pagesHyster 1534738 11 03 srm1059Martin Israel Cordero Castillo100% (4)

- The Eective Number of Cycles of Earthquake Ground Motion: Jonathan Hancock and Julian J. BommerDocument28 pagesThe Eective Number of Cycles of Earthquake Ground Motion: Jonathan Hancock and Julian J. Bommerjuan muneraNo ratings yet

- Sk210lc-9 Na-Eu Shop ManualDocument1,610 pagesSk210lc-9 Na-Eu Shop ManualNguyen van luong100% (9)

- 10M134 AIC Assignment 1 & 2 PDFDocument14 pages10M134 AIC Assignment 1 & 2 PDFChandannnn92No ratings yet

- Miscible Displacement ProcessesDocument24 pagesMiscible Displacement ProcessesrarahahaNo ratings yet

- AISI 1018 Carbon Steel (UNS G10180) : Topics CoveredDocument4 pagesAISI 1018 Carbon Steel (UNS G10180) : Topics CoveredPablo MenendezNo ratings yet

- Hitachibebiconaircompressor PDFDocument2 pagesHitachibebiconaircompressor PDFRizky Adi FirdausNo ratings yet

- SC-1060U DatasheetDocument2 pagesSC-1060U DatasheetAgus IrawanNo ratings yet

- CHH LVL Portal Frame Design Example - Sept 2008Document92 pagesCHH LVL Portal Frame Design Example - Sept 2008podderickNo ratings yet

- Process Instrumentation 2Document8 pagesProcess Instrumentation 2Aditya RasalNo ratings yet

- Transport PhenomenonDocument29 pagesTransport PhenomenonSidharthNo ratings yet

- FEA Model PAperDocument6 pagesFEA Model PApersmg26thmayNo ratings yet

- Hole-Drilling Method For Measuring Residual Stresses-V1 PDFDocument188 pagesHole-Drilling Method For Measuring Residual Stresses-V1 PDFsumatrablackcoffee453100% (1)

- MTU Series 10V1600 ESN 6601002253 PDFDocument154 pagesMTU Series 10V1600 ESN 6601002253 PDFRath Asypaden100% (1)

- Coefficient of Rolling Friction - Lab ExperimentDocument3 pagesCoefficient of Rolling Friction - Lab ExperimentRyan RafaelNo ratings yet

- Agitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDocument1 pageAgitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDeepikaNo ratings yet

- Saturation Nucleate Pool Boiling - A Simple CorrelationDocument9 pagesSaturation Nucleate Pool Boiling - A Simple CorrelationForcus on100% (1)

- Hydraulics PDFDocument37 pagesHydraulics PDFaktk1234No ratings yet

- PSV-Scrapper TrapDocument1 pagePSV-Scrapper TrapUmer KhanNo ratings yet

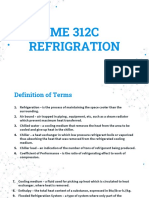

- Definition of Terms - RefrigerationDocument32 pagesDefinition of Terms - RefrigerationNiño Gerard JabagatNo ratings yet

- Basics of Industrial Maintenance (Schoolcraft Publishing)Document7 pagesBasics of Industrial Maintenance (Schoolcraft Publishing)rfgerfgNo ratings yet

- Vacuum PumpDocument4 pagesVacuum PumpJohnNo ratings yet

- Tires and WheelsDocument54 pagesTires and WheelsSandip Jawre100% (1)

- 3.CFDLV11 N2 P32 41Document11 pages3.CFDLV11 N2 P32 41For YoutubeNo ratings yet

- CH 5 DrillingDocument39 pagesCH 5 DrillingMANJEET KUMARNo ratings yet

- Rak-50 3149 L. l12 - Hardening Soil Model PDFDocument111 pagesRak-50 3149 L. l12 - Hardening Soil Model PDFMinhLêNo ratings yet

- NK 50-200-210 - 98318043 - Genoa PlasticDocument4 pagesNK 50-200-210 - 98318043 - Genoa PlasticSajidNo ratings yet