Professional Documents

Culture Documents

Fuel Propulsion System

Uploaded by

Red CrazyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Propulsion System

Uploaded by

Red CrazyCopyright:

Available Formats

*Fuel System*

PAGLAUM is equipped with a well-sealed 350ml fuel storage tank with outlet

shut-off valve. With the shut-off valve opened, fuel passes from the tank into the inlet

junction of the mechanical fuel injection pump. In the mechanical fuel injection pump

there is a solenoid valve, it is an electromechanical device which uses electric current

to generate a magnetic field and operate a mechanism which regulates the flow of the

fuel pass. As the fuel gets past the valve it enters the mechanical fuel injection pump,

where it is pressurized to the right level before it is sprayed inside the cylinder by the

fuel injector at the right timing to produce complete combustion. A return line hose is

also available at the fuel injector for recovery of excess pressure, which leads back

into solenoid valve junction before the pump inlet for it to be utilized again. With this

cyclic flow and combustion, energy from the fuel is transformed into useful work to

propel PAGLAUM forward.

*Propulsion System*

The propulsion system of the PAGLAUM starts from the engine, where the

power is generated. From the engine, the power will be transmitted by means of a

centrifugal clutch. This type of clutch was used to allow the engagement to happen

only at a high rotational speed. When a certain high rotational speed of the engine is

attained, the centrifugal clutch will allow the transmission of power to the chain drive

reduction. The chain drive reduction is used to reduce the rotational speed of the

engine’s output to match the required rotational speed needed to drive the wheels.

Lastly, after having a rotational speed reduction from the chain drives, power will be

transmitted to the wheels, a one-way cam clutch is used on each shaft of the wheels.

This clutch was used, so that (higher or better) freewheeling will be achieved.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Group 4 (Toledo, Toring, Valencerina) Materials Testing (4-7)Document44 pagesGroup 4 (Toledo, Toring, Valencerina) Materials Testing (4-7)Red CrazyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Fuels and CombustionDocument28 pagesFuels and CombustionDrupad PatelNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- CEE 111 CORROSION PREVENTION AND CONTROL YAP FinalDocument8 pagesCEE 111 CORROSION PREVENTION AND CONTROL YAP FinalRed CrazyNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Boilers, Steam Generators, Dryers, and Process HeatersDocument2 pagesBoilers, Steam Generators, Dryers, and Process HeatersRed CrazyNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Heat Transfer ProblemsDocument5 pagesHeat Transfer ProblemsRed CrazyNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Assignment2 Answer-KeyDocument11 pagesAssignment2 Answer-KeyRed Crazy0% (1)

- Calculator Techniques (Pass無し 131119Document172 pagesCalculator Techniques (Pass無し 131119Tricia Ann Destura100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- GeometryDocument214 pagesGeometryRed CrazyNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- PhysicsDocument22 pagesPhysicsRed Crazy0% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

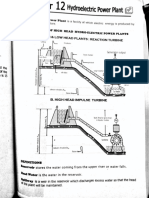

- Hydro PlantDocument15 pagesHydro PlantRed CrazyNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Heat TransferDocument19 pagesHeat TransferRed CrazyNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- AlgebraDocument263 pagesAlgebraeric salesNo ratings yet

- CatalogueBuilding2015 AdnotatDocument708 pagesCatalogueBuilding2015 AdnotatOctavian GrigoreNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Determination of Hardness of Water (Step-By-Step Plan)Document6 pagesDetermination of Hardness of Water (Step-By-Step Plan)ravenheart90No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 3-Cable U-Ftp Cat 6a 4p X 23awg Lszh-3 500mts BARPADocument3 pages3-Cable U-Ftp Cat 6a 4p X 23awg Lszh-3 500mts BARPAMarco Antonio RubinaNo ratings yet

- EG110 (Spring 2021) Exam #2 Pelayo MartinezDocument6 pagesEG110 (Spring 2021) Exam #2 Pelayo MartinezPelayo MartinezNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Analisis de La Susmpension Con AdamsDocument18 pagesAnalisis de La Susmpension Con AdamscorsasportNo ratings yet

- SHPP GL Ch3.FullDocument417 pagesSHPP GL Ch3.FullLuis Faustino Rodriguez LopezNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- ReadMe NetDocument2 pagesReadMe NetMariano MartinezNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Final Revision Jurnal NCIE - Feby Sanna SibaraniDocument9 pagesFinal Revision Jurnal NCIE - Feby Sanna Sibaranifeby sannaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- TCDS E4ea PT6 PDFDocument22 pagesTCDS E4ea PT6 PDFGabriielLoopez100% (2)

- Despiece SUSP. DEL 930EDocument2 pagesDespiece SUSP. DEL 930EAndersson Campos VásquezNo ratings yet

- BSC6900 GSM V900R012 DimensioningDocument88 pagesBSC6900 GSM V900R012 Dimensioningginiskid301086No ratings yet

- Dti Oil and Gas Industry White PaperDocument36 pagesDti Oil and Gas Industry White PaperSoniya AgnihotriNo ratings yet

- M and J Slab Gate ValveDocument12 pagesM and J Slab Gate Valvetxlucky80No ratings yet

- ATA51Document213 pagesATA51Challa AmarsrinuNo ratings yet

- 525d Manual Instalare Detector Paradox Cu MicroundeDocument2 pages525d Manual Instalare Detector Paradox Cu MicroundeGheorghiescu AndreiNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- HTTP Freecircuitdiagram - Com 2009-05-18 Wailing-Alarm-sirenDocument4 pagesHTTP Freecircuitdiagram - Com 2009-05-18 Wailing-Alarm-sirenmahmud ibrahimNo ratings yet

- BS 6840-10 PDFDocument28 pagesBS 6840-10 PDFJeff Anderson CollinsNo ratings yet

- Mokveld-Product Sheet Angle ChokeDocument2 pagesMokveld-Product Sheet Angle Chokeyulianus_sr100% (1)

- Cooper Nova Manual S280421 Part1Document14 pagesCooper Nova Manual S280421 Part1Arliel John GarboNo ratings yet

- Demountable Flares DatasheetDocument2 pagesDemountable Flares Datasheetmanojeil1No ratings yet

- 5Document22 pages5juan carlos zavalaNo ratings yet

- D3 Tips and Tricks PDFDocument482 pagesD3 Tips and Tricks PDFaitheljarNo ratings yet

- 315 MVA Trafo PDFDocument12 pages315 MVA Trafo PDFzeeshanyg100% (2)

- Pds 62-Sin Ds En-MeggerDocument2 pagesPds 62-Sin Ds En-MeggerAdhy PrastyoNo ratings yet

- AutoCAD Structural Reinforcement Detailing Manual Eng 2010Document222 pagesAutoCAD Structural Reinforcement Detailing Manual Eng 2010Payincash100% (1)

- In-Display Fingerprint SensorDocument20 pagesIn-Display Fingerprint SensorPrakhil SethiNo ratings yet

- Table 1 CostDocument1 pageTable 1 CostqualitylifearchitectureNo ratings yet

- Hydrogen Peroxide Gas GeneratorsDocument17 pagesHydrogen Peroxide Gas GeneratorsCliff ThriveNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Types of RAMDocument2 pagesTypes of RAMCerina Avergonzado BuendiaNo ratings yet

- Method Statement FOR Pipe LayingDocument5 pagesMethod Statement FOR Pipe LayingburereyNo ratings yet