Professional Documents

Culture Documents

Cost Reduce in Construction by Using Cut & Cover Method in Sub-Way

Uploaded by

Anil SuryawanshiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cost Reduce in Construction by Using Cut & Cover Method in Sub-Way

Uploaded by

Anil SuryawanshiCopyright:

Available Formats

Cost Reduce in Construction by Using

Cut & Cover Method in Sub-Way

Engineering

VOLUME 2 ISSUE 9

www.ijatser.com

1

Rahul sharma, 2Prof. Kapil Soni

1

M.Tech Scholar, 2HOD

Department of Civil Engineering

University Institute of Technology, AISECT, Bhopal

Abstract- Nearly one-third of the level crossings in the area covered by western Central Railway (WCR) are altered and efforts are on to

make certain that the altered crossings are replaced with limited height subways (LHS) or introduce road diversions. This year, the

WCR is planning to construct 25 LHS in its limits Every year, nearly 15 persons lose their lives in accidents while crossing these altered

crossings and in almost all the cases, these accidents happen as those crossing the railway tracks do not monitor the mandatory safety

measures, railway authorities say. According to a spokesman of the WCR, there are 130 level crossings in WCR area and of these, 0 are

altered level crossings. The WCR’s safety action plan envisages converting all the manned level crossings by 2016 into either manned

crossings or into LHS. So far, 30 such level crossings were converted into LHSs or road diversions were planned, the spokesman

disclosed. In fact, since last couple of years, the number of casualties came down. In 2012-13, four persons died and efforts are onto

ER

ensure zero accidents at these crossings,” says the spokesperson. Limited Height Subways are being constructed every year at possible

locations to make certain safe passage for road users.

The number of collisions at level crossings between trains and road vehicles that end in death and injury. The chart also shows the

number of people killed or injured in those collisions. This data is derived from the New Zealand Transport Agency's crash analysis

system, which holds records of police reported information. Based on rail occurrence reports provided by rail operators. These reports

cover up a wide range of occurrences including both accidents (events that caused death, injury, or significant property harm) and

incidents (events that placed, or could have placed someone or something at risk of death, injury or major property damage). Only a

S

reasonably small number of reported occurrences result in injury. The less serious occurrences are useful for identifying potential

safety issues.

Keywords- Limited Height Subway, Traffic Vehicle Unit, Design and Drawing, Launching, Traffic Block.

AT

I. INTRODUCTION diverting to either existing level crossing, existing bridge or by

construction of new RUB. Earlier work for new RUB is

There are large numbers of level crossing (manned as well as

proposed to be constructed by using push through technique.

altered) on Indian railways. Some of these can be closed by

Then it is proposed to carry out work by cut & cover method

constructing L H S and few manned/unnamed LC’s can be

which has greatly enhanced the economy. This paper deals with

IJ

closed by constructing normal height sub way. This thesis deals

the comparison of these both techniques. Kota division of

different methods for construction of limited subway.

western central railway has taken many steps for the benefit of

Potentials of such level crossings on Kota section have been

general public and passenger. Apart from manning of five

studied and suitable method for construction of subway has

altered level crossing gates, four level crossing gates have been

been also suggested. This paper deals with construction of

©

closed either by providing Limited Height Subways or by

limited height sub way by cut & cover method at manned LC

diverting the road traffic to the nearest manned level crossing

No. 81 in Kota section, WCR. On Indian railways level

gate. This has saved time and enhanced the safety of road users

crossings contributes approx 30% of consequential train

many fold while crossing the railway line as level crossing

accidents whereas in terms of casualties they contribute more

gates are a major source of accidents and human causalities all

than 60% there are 3400 level crossings as on 25.10.2014 on

over the Indian Railways. Limited Height Subways are pre-

Indian railway, out of which only 1600 are manned most of the

constructed and inserted below the railway line within a short

accident takes place on unnamed level crossing .therefore,

span of time by blocking the traffic for 4-5 hours. Limited

altered level crossing are most vulnerable. As per corporate

Height Subways can be provided where the height of railway

safety plan, all the altered level crossing has to be manned. On

line and the underlying embankment is adequate. Alipurduar

manned level crossing when road traffic or rail traffic is more,

Division of N.F.Railway has already commissioned 14 such

it affects the running of train. Best way to deal the problem is

Limited Height Subways during last year. Such initiative for

to have grade separation. On busy level crossing based of

elimination of level crossing by Limited Height Subways

TVUs works of road over bridge are being sanctioned in lieu of

reiterate Indian Railway’s is deep commitment to the safety of

level crossing. However, cost construction of ROB is very high

road users and more numbers of such Limited Height Subways

and also time consuming. At many locations, road traffic

are under construction.

consist of light vehicles, two wheelers etc. which can be

The death of 12 persons in another train accident at an altered

catered by providing subways of limited height which are

rail crossing proves that we still have to improve the system of

economical. Many level crossings are planned to be closed by

Indian railways and the state transport authorities to end this

WWW.IJATSER.COM | ALL RIGHTS RESERVED 21

International Journal of Advanced Technology for Science & Engineering Research. www.ijatser.com, Volume 2, Issue 9,

OCTOBER – NOVEMBRER 2017, Page 21-27

menace once for all. Meanwhile a few hundreds more would Altered level crossings are another problem area for the Indian

needlessly perish each year due to this eminently avoidable Railways, and one of the major causes of accidents. In spite of

situation that the railways have carelessly perpetuated for far various measures taken by the Indian Railways, level crossing

too long. To be sure accidents at levels crossing are almost old accidents have continued to occur, that too frequently.

as the railways. Though efforts are made to reduce such Accidents at Altered Level Crossings are caused mainly due to

accidents to bring down casualties over the years the numbers trespassing by road vehicles across these on Railway tracks.

are still too large for any comfort. Most recent information Railways have the “Right of Way” across altered level

show that the number of such accidents have come down from crossings. The road vehicle drivers are duty bound under

close to a hundred at the turn of the millennium to just a little Section 131 of the Motor Vehicles Act, 1988, to “get down

more than fifty in recent years. However, the number of from the Vehicle, walk up to the crossing to ensure that no train

causalities remains high with as many as 2154 people killed is approaching from either side before crossing the altered level

and 2223 injured at level crossings between April 2000 and crossing” Thus, the primary cause of the accidents at altered

March 2013. And the number of deaths dues to accidents at level crossings is negligence by road vehicle users. There are

crossings have hovered around 300 for almost a decade now. 14896 altered and 17839 manned level crossings on IR as on

Surprisingly the accidents happen not just at altered crossings 1.4.2011. These level crossings contribute to 30 percent of

but also at manned ones. But as expected the number of fatalities in Railway mishap and statistically contribute to about

accidents at altered level crossing far outnumbers that at 40 percent of accidents on IR. Accordingly, Indian Railways

manned crossings. In fact while the accident at manned Vision – 2020 and Railway Budget Speech documents envisage

crossings numbered just 105 during this period that at altered elimination of all altered level crossings. Presently, the altered

crossing were as much as 870 during this period. And while the level crossings are provided with speed breakers and road sign

accidents at manned crossings killed 277 and 323 that at altered boards on either side of the level crossings to warn road users

ER

crossings killed 1927 and 1910. of any approaching trains. Warning sign-boards are also

One reason for the innumerable deaths at level crossings was provided alongside of railway track, at the approach of such

the huge number of such points. There were 30,348 level altered level crossings so that the train driver starts whistling to

crossing over the railway network of which only 18,725 were warn the road users of the approaching trains Indian Railways

manned and as many as 11563 remained altered. Consequently have decided to eliminate all altered level crossings (LCs) in

accidents at level crossings accounted for 43% of all significant next five years as part of Indian Railway Vision 2020. Multi-

S

rail accidents and as much as two third of the fatalities to be

sure accidents at rail crossings are not unique to India but also

pronged strategies have been adopted to achieve this end.

While some of the LCs would be closed by merging them with

happens in developed economies. Numbers for the European the nearby LC by constructing connecting roads, other LCs

AT

Union do in fact show that their railway network had as many would be provided with Road under bridge (RUB) or Limited

as 123,000 level crossings with the number of crossing Height Subway (LHS) and also by manning of qualifying

averaging 5 per 10 kilometres of line. And only 29% of the altered LCs. The position, as it obtains over Indian Railways

crossings were active monitored with barriers and audio or with respect to various steps being undertaken for eliminating

visual warnings. Other had only safety warnings like stop signs. the altered level crossings.

And figures at the turn of the decade show that there were 619 Indian Railways conduct thorough social awareness programs,

IJ

accidents at level crossings which killed 359 people. But unlike on a regular basis, to educate road users. This includes

in India the accidents at rail crossings in EU accounted for a publicity campaigns through various media like newspapers,

much smaller 30% of the total fatalities in railway accidents. TV, Radio etc., distribution of posters, leaflets, various short

However the advanced countries railways have been proactive duration films/advertisements etc. Even the efforts are made in

in ushering in more up to date technologies and educating the local languages by the Zonal Railways for educating the road

©

public on safety at the rail crossings. While some countries like users about the safety measures to be taken while negotiating

Norway has been developing technologies to track rail the altered level crossings. There is a need to educate people at

vibrations and send warnings to road traffic others use global Village Panchayats, schools, weekly markets in rural areas and

positioning systems to detect movement of trains also carry out ambush checks at altered level crossings.

II. RELATED WORK B. Railway’s to Eliminate Level Crossing’s

RDSO department of Indian Railways have decided for gradual As Indian Railways have decided for gradual elimination of all

elimination of all the level crossings for ensuring safety of the the level crossings for ensuring safety of the commuters in the

commuters in the coming years, west Central Railway is too coming years, west Central Railway is too taking steps in this

taking steps in this direction. About 38 railway crossings will direction. About 38 railway crossings will be replaced with the

be replaced with the construction of LHS (Limited Height construction of LHS (Limited Height Subway) in the current

Subway) in the current financial year. Indian Railways has financial year. Indian Railways has targeted to remove all the

targeted to remove all the level crossings on its route as these level crossings on its route as these crossings are not only

crossings are not only causing safety problems but also create causing safety problems but also create operational hindrances.

operational hindrances. The altered crossings will be removed The altered crossings will be removed by constructing LHS.

by constructing LHS. These railway crossings have been spread over the entire area

of west Central Railway incorporating the divisions of west

A. Accident’s at Level Crossing’s

Central Railway has planned to construct 80LHS during the

WWW.IJATSER.COM | ALL RIGHTS RESERVED 22

International Journal of Advanced Technology for Science & Engineering Research. www.ijatser.com, Volume 2, Issue 9,

OCTOBER – NOVEMBRER 2017, Page 21-27

year 2014-15. In addition to this, about 38 LHS will also be construction documents for L H S Projects and to expedite the

constructed in this year. In the west Central Railway region review and approval by the Railroad of design and construction

there are about 130 level crossings. Among them, 130 are submittals. The purpose of review by the Railroad is solely to

manned railway crossings and no are altered. There are five insure compliance with the minimum standards of the Railroad

cattle crossings and 8 canal crossings. Out of the total crossings dealing with particular areas of concern to rail transportation

in WCR region, there are 35 level crossings in Kota division, and not to warrant the general safety of the structure.

55 level crossings in nagda division. In Kota division, many These Guidelines supplement the current (AREMA) Manual

LHB will be constructed replacing the level crossings on the for Railway Engineering, AASHTO and State Railroad

Mathura- Shamgarh section. This includes level crossing Regulatory Body requirements. Where these Guidelines and the

number 81 (Km 748/7-9), 78 (Km 755/19-21), 74(Km 785/1-3) documents referenced in the preceding sentence differ, these

and 73 (Km 787/21-23). The approximate cost for construction Guidelines will govern.

of LHB at these four crossings is about Rs 16 crore. A. Construction Observation

There is the policy to remove all the gates over level crossings. Review cost is a function of the quality of submittals received

Since, 2012, about 15 LHS has been completed but this year, from the Applicant. Regardless, all actual costs incurred by the

there is an ambitious target of completing78 LHS. 30 level Railroad or its consultant during the plan review process and

crossing gates have already been interlocked over WCR. To construction Monitoring phase of the work shall be fully

overcome the problem of boom breakage, crossings have been recoverable from the Applicant.

provided with sliding booms. Design calculations shall be provided for all structures, except

Railways are preparing Master Plan for elimination of altered Overhead Structures, to be constructed as part of the Project.

level crossings by manned level crossings ROB/RUB Design Calculations shall be clear, readable and easy to follow.

Government is concerned with number of fatalities at level Computer program generated output or data sheet calculations

ER

crossings. In the Central Road Fund (CRF) Act 2000 (Act no. shall be accompanied by input data information and sample

54 of 2000 para10 (viii) allocation of 12.5% of total of ‘fifty calculations to verify the Accuracy of the computer output.

percent of cess on high speed diesel oil and the entire cess A geotechnical report shall be provided covering all bridges

collected on petrol’ shall be for the construction of road either and retaining walls. The preliminary geotechnical report shall

under or over the railway by means of a bridge and erection of include enough information to support foundation design

safety works at altered rail-road crossings. Funds for the calculations and backfill design requirements. The Final

S

construction of ROBs/RUBs are available. Railways on their

part to expedite construction of ROB and RUB have issued

geotechnical report shall have recommendations consistent

with those used in the final structural design.

guidelines and drawings for standard span of composite girders The necessities of drainage report is require where flow is not

AT

as well as have improved their fund utilization in the last suitable available or change the drainage pattern for the

couple of years. In 2009-2010, UMLC accidents constituted continuous flow in rail road hydraulic criteria is used where it

about 38% (62 out of 162) of the total consequential train is required.

accidents and were responsible for 72% (161 out of 225) of the B. Precast Concrete Box Culvert’s

total fatalities. The vulnerability at level crossings has always Standard designs for precast concrete box culverts are existing

been a cause of concern to Railway Authorities. with spans altering from 3 to 5 meter and rises altering from 3

IJ

All such level crossing (manned or altered) which can be to 4.5 meter. Standard precast concrete box culverts are

eliminated by construction of limited use subway should be typically fabricated in sections; however larger boxes are

identified. However, criteria for selection should be based on fabricated in sections to reduce section weight. The designs

one or more of the followings: utilize concrete strengths between 5 and 6 ksi and are suitable

Safety consideration- accident vulnerable LC locations where

©

for fill heights ranging from less than 2 feet to a maximum of

visibility is poor and elimination of level crossing will increase 25 feet. Box culverts outside of the standard size ranges must

safety. be custom designed.

Reduction in LC numbers- elimination of level crossings will

yield substantial operational benefits.

Site feasibility-embankment height is adequate and will not

allow collection of water under bridge and surrounding water

table is low and approach road is feasible. Minimum bank

height required will be 3M.

TVUs- locations where thus is less but having potential of

getting manned or have already qualify.

III. METHODOLOGY

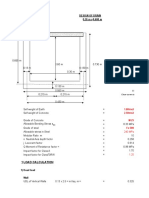

Figure 1: Typical Precast Concrete Box Dimension’s

The purpose of Guidelines is to inform Applicants, Contractors Each culvert size has three or four classes. Each one group has

and other parties concerned with Railroad policies, particular wall and slab thicknesses, reinforcement areas,

requirements and standards for the design and construction of concrete strength, and fill height variety to which it applies.

limited height sub way. Compliance with these Guidelines is Shop drawing submittals for Mendota approval will not be

required to achieve uniformity in the preparation of required when standard culvert sections are used.

WWW.IJATSER.COM | ALL RIGHTS RESERVED 23

International Journal of Advanced Technology for Science & Engineering Research. www.ijatser.com, Volume 2, Issue 9,

OCTOBER – NOVEMBRER 2017, Page 21-27

The standard plan tables are based on welded wire framework The soil-structure dealings factor (Fe) is used to regulate the

reinforcement with yield strength of 65 ksi and a concrete vertical earth load accepted by the culvert. It is intended to

apparent cover of 2 inches. Mendota requires that actual clear approximate the arching effects of some of the overburden soil

cover be between 1.5 inches and 2 inches. Design if to adjacent regions slightly outside the span of the culvert and

conventional rebar is used, the steel area shown on the standard account for installation conditions. Culverts located in channel

plan sheets needs to be increased 8% to account for the situation need to bear less straight up load than those

difference in steel yield strength (65 ksi/60 ksi). Also, crack constructed in embankment conditions, because the

control must be rechecked for the specific bar size and spacing consolidated material in the adjacent trench walls is typically

used. stiffer than new embankment material. Conservatively assume

To prevent corrosion at the ends of welded wire fabric, nylon culverts are installed in embankment conditions.

boots are required on the ends of every fourth longitudinal wire The factor is:

at the bottom of the form. Plastic spacers may be utilized in lieu Fe=1+0.20 H/Bc

of nylon boots when spaced at a maximum of 48 inches. The Where:

highest permissible dimension of reinforcement bars is #6 and H = Depth of backfill (ft)

the highest permissible size of welded wire is W23. A BC = Outside width of culvert (2 sidewall thickness + span) (ft)

maximum of two layers of welded wire fabric can be used for The approximate strip method is used for design with the 1

primary reinforcement. If two layers are used, the layers may axial wide design strip oriented parallel to the span. The design

not be nested. live loads applied to the top slabs of box culverts include the

C. CAST-IN-PLACE CONCRETE BOX CULVERT’S train and tandem loads for box culverts of any span length. For

The major box culverts constructed in Minnesota be complete box culverts through spans of 15 feet or larger way loads are

of cast-in-situ place concrete. The concert of these structures also applied to the top slabs of box culverts.

ER

over the years has been very good. Currently, most box culvert D. LOOSE MATERIAL

installations are precast due to the reduced time required for The L H S in loose material is following-

plan production and construction. Cast-in-place culverts Aggregates

continue to be an allowable option. Sand

Material Properties Steel

Concrete Compressive Strength f’c = 5 ksi or 6 ksi Water

Steel Yield Strength = 60 ksi (rebar)

S

Steel Yield Strength = 65 ksi (welded wire fabric) Steel formwork

E. TEST ON AGGREGATE’S

Reinforced Concrete Unit Weight = 0.150 kcf The aggregate testing helps you ensure that the quality of your

AT

Soil Fill Unit Weight = 0.120 kcf concrete and aggregate complies with compulsory regulations

Culvert Backfill Angle of Internal Friction = 30 degrees and quality control standards. Mostly test of aggregates are

Water Unit Weight = 0.0624 kcf following-

Various methods can be used to model culverts. Based on past 1. Sieve Analysis

experience, Mendota prefers a 2-Dimensional (2D) plane frame 2. Water Absorption

model be used to analyze culverts. This form is supposed to be 3. Aggregate Impact Value

IJ

outwardly supported by a pinned sustain on one base corner 4. Aggregate Crushing Value

and roller support on the other base corner. The stiffness of the With the help of sieve analysis we have to decide the particle

haunch is included in the model. The model is assumed to be in size supply of the coarse and fine aggregates. This is done by

equilibrium so external reactions to loads applied to the sieving the aggregates as per IS: 2386 (Part I) – 1963.

©

structure are assumed to act equal and opposite. This section The apparatus used are –

will assume a 2D plane frame model when referring to i) A set of IS Sieves of sizes – 80mm, 63mm, 50mm,

modelling, applied loads, and self-weight. 40mm,31.5mm, 25mm, 20mm, 16mm, 12.5mm, 10mm,

The self-weight of the top slab must be resisted by the top slab. 6.3mm,4.75mm, 3.35mm, 2.36mm, 1.18mm, 600µm, 300µm,

The advantage of axial density from the self-weight of the top 150µm and 75µm.

slab and walls is not integrated in the investigation. The top ii) Balance or scale with an accuracy to measure 0.1 percent of

slab, wall, and all haunch weights are applied to the bottom the weight of the test sample.

slab as an upward reaction from the soil in an equivalent The weight of sample available should not be less than the

uniform pressure. The base slab weight is not useful in the weight given below:-

model because its load is supposed to be openly resisted by the Table I: Size and Weight Balance

soil. Maximum size present in Minimum weight of

The design fill height is measured from the top surface of the substantial proportion’s sample dispatched for

top slab to the top of the roadway or fills. The design fill height (mm) testing (kg)

is denoted by the abbreviations of H or De depending on the 63 100

equation used. Earth upright loads transfer to soil and pathway

loads over the culvert and in nearby regions slightly outside the 50 100

span of the culvert based on the soil-structure dealings factor. 40 50

Culvert walls are assumed to be frictionless, so no vertical

component of the earth horizontal resultant force is considered. 25 50

WWW.IJATSER.COM | ALL RIGHTS RESERVED 24

International Journal of Advanced Technology for Science & Engineering Research. www.ijatser.com, Volume 2, Issue 9,

OCTOBER – NOVEMBRER 2017, Page 21-27

16 25 include any considerable amount of clay balls or pellet and

injurious impurity e.g. iron pyrites, alkalis, salts, coal, mica,

12.5 12

shale or parallel coated materials in such form or in such

10 6 quantities as to cause corrosion of metal or affect adversely the

6.3 3 strength, the durability or the appearance of mortar, plaster or

concrete.

The sample for sieving should be prepared from the larger The sum of the percentages of all deleterious material shall not

sample either by quartering or by means of a sample divider. exceed 5%. Fine aggregate must be checked for organic

Water Absorption of Aggregate’s: These examination helps to impurities such as decayed vegetation humps, coal dust etc.

find out the water absorption of coarse aggregates as per IS: IV. TESTING PROCEDURE

2386 (Part III) – 1963. For this test a sample not less than Before testing measure diameter of the test piece, determine

2000g should be used. The equipment use for this analysis are:- cross-sectional area S0 and original gauge length L0.

Wire basket – perforated, electroplated or plastic coated among

wire hangers for suspend it from the balance, Water-tight Complementary scale shall be marked along the whole test

container for suspending the basket, Dry soft absorbent cloth – piece. The marks could not result in premature fracture. Grip

75cm x 45cm (2 nos.), Shallow tray of minimum 650 sq.cm the test piece in the jaws of the test machine. Make sure that

area, Air-tight container of a capacity similar to the basket and analysis pieces are held in such a way that the force is applied

Oven. as axially as probable. Prepare inscription device for making of

TABLE II: Water Absorption of Coarse Aggregates stress-strain diagram apply load by arranged rate of stressing.

ER

Within the elastic range the rate of stressing shall be within the

S.No Determination No. A B C limits given in. Inside the plastic range the straining time shall

not exceed 0.0025/s for purpose of yield strength and 0,008/s

Weight of saturated

for determination of tensile strength after fracture put down the

1. surface dried 2409 2380 2491

maximum force Fm, measure the final gauge length Lu And

sample g in (A)

minimum diameter after fracture. From stress-strain diagram

2.

Weight of oven

dried sample g in 2404

S 2375 2486

find the force at the point of yield Fy (by the rule of three).

Found tensile strength yield strength % elongation after break

(B)

AT

a least amount cross-sectional area and % reduction of the area

5/240 5/24

Z Rate of stressing. S-1Modulus of elasticity of the material

4*10 5/2375* 86*1

Water absorption = N/mm2 min. max. <150000 2 10 ≥150 000 6 30 Building

3. 0= 100 = 00 =

A-B/B*100 % = Materials 10 Testing Methods Evaluation of Results

0.208 0.210 % 0.20

Determined values of tensile strength yield strength and

% 1%

IJ

ductility (i.e. percentage elongation after fracture) should be

Aggregate Impact Value: This test is done to determine the compared with requirements given In the appropriate

aggregate impact value of coarse aggregates as per IS: 2386 standards. A basic need for ordinary types of steel are given in

(Part IV) – 1963. The apparatus used for determining aggregate Price of the percentage decrease of the area are only

©

impact value of coarse aggregates is Impact testing machine informative and is not given in standards.

conforming to IS: 2386 (Part IV)- 1963,IS Sieves of sizes – A. Fineness of Cement

12.5mm, 10mm and 2.36mm, A cylindrical metal measure of Therefore we need to decide the fineness of cement by dry

75mm dia. and 50mm depth, A tamping rod of 10mm circular sieving as per IS: 4031 (Part 1) – 1996.The standard of this is

cross section and 230mm length, rounded at one end and Oven. that we decide the amount of cement whose grain sizes rage

Aggregate Crushing Value: This analysis helps to establish the than particular mesh size. The equipment used are 90µm IS

aggregate crushing value of coarse aggregates as per IS: 2386 Sieve, Balance able of weighing 10g to the nearest 10 mg, A

(Part IV) – 1963. The apparatus used is cylindrical measure nylon or pure bristle brush, preferably with 25 to 40mm,

and plunger, Compression testing machine, IS Sieves of sizes bristle, for cleaning the sieve.

– 12.5mm, 10mm and 2.36mm. B. Soundness of Cement

Aggregate most of which pass through 4.75 mm IS sieve is Soundness of cement is determined by Le-Chatelier method as

known as fine aggregate. Fine aggregate shall consists of per IS: 4031 (Part 3) – 1988.Equipment – The equipment for

normal sand, crushed stone sand, crushed gravel sand stone conducting the Le-Chatelier analysis should conform to IS:

dust or arable dust, fly ash and broken brick (burnt clay). It 5514–1969 stability, whose permissible difference at a load of

shall be hard, durable, chemically inert, clean and free from 1000g should be +1.0g and Water bath.

adherent coatings, organic matter etc. as well as shall not C. Consistency of Cement

WWW.IJATSER.COM | ALL RIGHTS RESERVED 25

International Journal of Advanced Technology for Science & Engineering Research. www.ijatser.com, Volume 2, Issue 9,

OCTOBER – NOVEMBRER 2017, Page 21-27

The fundamental plan is to discover out the water content The slumped concrete takes different shapes, and according to

necessary to produce a cement paste of standard consistency as the shape of slumped concrete, the slump is termed as true

specified by the IS: 4031 (Part 4) – 1988. The principle is that slump, shear slump or collapse slump. But a shear or collapse

pattern consistency of cement is that consistency at which the slump is achieved, a fresh sample should be taken and the test

Vicat plunger penetrates to a point 5-7mm from the bottom of repeated. A collapse slump is an indication of too wet a mix.

Vicat mould. Equipment – Vicat apparatus meeting the No more than an accurate slump is of any use in the test. An

requirements to IS: 5513 – 1976, Balance, whose permissible end slump will generally mean that the mix is too wet or that it

difference at a load of 1000g should be +1.0g, Gauging trowel is a high workability mix, for which slump test is not

meeting the requirements to IS: 10086 – 1982. appropriate. extremely dry mixes have slump 0–25 mm are use

D. Concrete Slump Test in road construction, low workability mixes; having slump 10

The concrete slump test is an empirical test that measures the – 40 mm are used for foundations with light reinforcement,

workability of fresh concrete medium workability mixes; 50 - 90 for normal reinforced

More exclusively, it measures the uniformity of the concrete in concrete placed with vibration, high workability concrete; >

that exact batch. This experiment is performed to check the 100 mm.

consistency of freshly made concrete. Consistency is a term F. Tensile Testing and Compression Testing on Reinforced

very closely related to workability. It is a term which describes Material

the state of fresh concrete. It refers to the simplicity by means Tensile tests can be carried out on the Ferro cement in order to

of which the concrete flows. It is used to indicate the degree of establish the relationship between tensile stress and elongation.

ER

wetness. Workability of concrete is mostly affect by G. Tensile Testing on Unreinforced Specimen’s

consistency i.e. wetter mixes resolve be more workable than The tensile strength is found by a split 'cylinder' experiment

drier mixes, except concrete of the same consistency may using similar equipment as in the compression test. Still, the

differ in workability. It is also used to establish consistency true tensile strength resolve lie between 50 and 70% of the

between individual batches. splitting 'tensile strength'.

This investigation is popular due to the ease of apparatus used

S

and simple procedure. Regrettably, the simplicity of the test

H. Bending Test with Reinforced Material

Bending tests can be carried out on the Ferro cement in order

often allows a wide unpredictability in the manner that the test to establish the relationship between bending moment, tensile

AT

is performed. The slump test is used to ensure standardization bending stresses and elongation.

for different batches of similar concrete under field conditions, I. Bending Fatigue Test

and to ascertain the effects of plasticizers on their introduction. Bending fatigue tests can also be carried out on test specimens

In India this experiment is conduct as per Indian standard of the hull construction.

specification. The slump test effect is a slump of the behaviour J. Impact Test

IJ

of a dense inverted cone of concrete under the action of An impact test can be performed on representative reinforced

gravity. It processes that the consistency or the wetness of panels by using a drop weight. Failure occurs when the test

concrete. panel develops a leak.

Metal mould, in the shape of the frustum of a cone, open at K. RCC BOX

©

both ends, and provided by the handle, top inside dia 4 in (102 Clear span 4 m

mm), and base internal dia 8 in (203 mm) with a height of 1 ft Clear height 4.5 m

(305 mm). A 2 ft (610 mm) long shot nosed metal rod, 5/8 in Top slab thickness 0.45 m

(16 mm) in diameter. Bottom slab thickness 0.45 m

The test is carried out using a mould known as a slump cone or Side wall thickness 0.45 m

Abram’s cone. The cone is placed on a hard non-absorbent Unit weight of concrete 24 KN/m3

surface. This cone is full with fresh concrete in three stages, Unit weight of earth 18 KN/m3

every time it is tamped with a rod of standard size. At the end Unit weight of water 10 KN/m3

of the third stage, concrete is struck off wash out to the top of Co-efficient of earth pressure at rest 0.5

the mould. The mould is cautiously lifted vertically up, so as Total cushion on top 0.0 m

not to disturb the concrete cone. Concrete subsides. This Thickness of wearing coat 0.15 m

subsidence is termed as slump, and is measured in to the Concrete grade M40 = 40 Mpa Steel grade Fe 415 = 415 Mpa

nearest 5 mm if the slump is <100 mm and measured to the БSc (Concrete) 8.33 Mpa

nearest 10 mm if the slump is >100 mm. Est. (Steel) 200 Mpa

E. Result Modular ratio 10

n (for depth of neutral axis) 0.294

WWW.IJATSER.COM | ALL RIGHTS RESERVED 26

International Journal of Advanced Technology for Science & Engineering Research. www.ijatser.com, Volume 2, Issue 9,

OCTOBER – NOVEMBRER 2017, Page 21-27

j (for effective depth) 0.902 one core is very less as compared to fully fledged ROB’s cost,

k (for moment of resistance) 1.105 M pa which will be in the range of 10 to 20 cores. The benefit of

All dimensions are in meter unless subways is fast and immediate. Cut & cover method is more

economical for single line work. The same may be used in

Mentioned otherwise.

double line section in electric traction which will cost Rs. 75

All moments are in KN/m and shear force divided in KN lakhs for closing existing level crossing as against sanction up

unless mentioned otherwise. to 1.5 Cr for which proposal are being sanctioned in RUB level.

Box pushing technique gives less joints in embankment and do

L. Execution Methodology not require traffic blocks. But may cost more. If longer barrel

There are various methods of construction of limited height length cost of box pushing gets lesser and may become

subway depends on the location of level crossing bank height comparable with cut & cover method which may be worked

out. “I’m not against infrastructure. I am against the idea of we

and traffic density. Described as under-

have to push the money out the door because we promised that

Cut and cover method we would spend it.” According to the problem that in what

RH girder method scope can subway engineering influence the prices of

Box pushing peripheral real estate, this paper summarized the problems in

Box pulling similar research presented, and put forward that the influence is

In-situ construction of box after inserting RH girder. The LC s taken by factors of person, and the influence can be studied by

where bank height is more than 3 m are identified and grouped the probability of choosing subway. Different from other

similar research, based on the analysis of the factors which can

together for calling of tender duly deciding the methodology.

influence people choose subway or not, this paper constructs

ER

M. Cement Concrete Pavement the logistic model. Testing the model by using the research

Cement concrete is a combination of coarse and fine data of India, this document get the list on which we know in

aggregates, cement and water in appropriate proportions. what scope can subway engineering influence the surrounding

Sometimes admixtures are also additional to get specific real estate prices by adjusting the logistic model variable X4?

behaviour property of the material. Finally, discussed the model applicability and in different cities

to application.

V. RESULT ANALYSIS

S REFERENCES

I am currently working with a construction company which is [1] IS: 460 (Part-1)-1978 (second revision), Test sieves, Bureau of Indian

AT

right now making Road under Bridge (RUB) and Road over standard, New Delhi.

Bridge (ROB) for Indian railways at various locations in [2] IS: 4926 Indian Standard specification for ready mixed concrete.

[3] Indian Railway Standard Codes and Specification’s (IRS).

Madhya Pradesh and I found the same thing. Firstly ROB is

[4] Indian railway –Engineering Code

most costly and does not face any problems like water [5] Indian Railway Bridges, Specifying the load’s for Design of super

drainage, during floods etc and thus rendering the road every structure and sub structure of bridges and chapter -8 for the rule for the

IJ

day. Secondly ROB is long term solution and RUB is short opening of railway adopted in 1941-Revised –August 1982.

[6] IIT/Kanpur –RDSO guideline’s on seismic design of railway bridges.

term solution .ROB can handle much more traffic than RUB

[7] Specifications for road and bridges works issued by ministry of road

can. But Presently RUB is built at level crossings which are transport & highways (MORTH).

in or around really small villages which have minimal traffic. [8] Hand Book for Estimation of Design Discharge for Railway Bridges.

[9] www.ptv.vic.gov.au/getting-around/travelling-safely/railway-crossing-

©

ROBs are built at major towns and cities which already have

safety-awareness/

lots of traffic and thus RUB would not be of much use there.

[10] vic.childsafetyhub.com.au/street-smart-rail-crossing-safety awareness/

Finally these RUBs are constructed would someday become [11] www.wheels24.co.za/News/Guides_and_Lists/if-there-is-a-track-expect-

ROBs maybe in next 10-20-30 years. But eventually all a-train-what-drivers-should-do-at-level-crossings-in-sa-20170726.

RUBs will be eliminated and those present only in really [12] www.up.com/cs/groups/public/documents/document/pdf_rr_grade_sep_p

rojects.pdf

small villages and remote places or where ROB is no longer

[13] ftp.dot.state.tx.us/pub/txdot-

constructible would remain. RUB are also a traffic bottle info/library/pubs/bus/bridge/uprr_bnsf_guidelines.pdf

neck. Whereas you just glide through on Road over bridges. [14] paperzz.com/doc/855067/joint-bnsf-uprr-guidelines-for-railroad-grade---

Also I show here a cost estimate. We are building 1 ROB at union-pac.

[15] blogs.timesofindia.indiatimes.co

total cost of x we are building 9 RUBs at TOTAL cost of 2x

[16] www.scribd.com/document/21529182

We would never invest in something so heavily if a cheaper [17] www.scribd.com/document/27947081

option was available. [18] Report. No. RDSO/2007/GE: 0011: Guidelines for blanket layer

provision on track formation with emphasis on heavy axle load train

VI. CONCLUSION operations.

The construction of limited height subways is a right step in

right direction to eliminate the LHS and increase the safety

standards of Railways as well of the road users. The cost Rs

WWW.IJATSER.COM | ALL RIGHTS RESERVED 27

You might also like

- Construction and Analysis of Flyover by BRTSDocument7 pagesConstruction and Analysis of Flyover by BRTSEditor IJTSRDNo ratings yet

- Field Training ReportDocument36 pagesField Training ReportashoknrNo ratings yet

- BPT !Document17 pagesBPT !Dilip D SNo ratings yet

- High Speed Trains, Smart Railway Station and Dedicated Freight CorridorDocument36 pagesHigh Speed Trains, Smart Railway Station and Dedicated Freight CorridorAbhishek SinghNo ratings yet

- Sky Bus: A Paradigm Shift in Urban TransportationDocument15 pagesSky Bus: A Paradigm Shift in Urban TransportationShilpaNo ratings yet

- Railway Gate ControlDocument6 pagesRailway Gate Controlsakshi pawarNo ratings yet

- Design and Analysis of Pre Cast Box Segment Using Limit State Method Manually and StaadproDocument3 pagesDesign and Analysis of Pre Cast Box Segment Using Limit State Method Manually and StaadproResearch ParkNo ratings yet

- Lectura Modelos de ServicioDocument13 pagesLectura Modelos de ServicioLeidy Johana Tovar CupaNo ratings yet

- Indian Highways Editorial AugustDocument2 pagesIndian Highways Editorial AugustBalaji AmarNo ratings yet

- SkybusDocument25 pagesSkybusDharmik Dobariya100% (3)

- Analysis and Design of Pre Cast Box For Road Under Bridge RUB and Road Over Bridge ROB by Using STAAD Pro. and Box Pushing TechniqueDocument6 pagesAnalysis and Design of Pre Cast Box For Road Under Bridge RUB and Road Over Bridge ROB by Using STAAD Pro. and Box Pushing TechniqueEditor IJTSRDNo ratings yet

- Sky Bus Metro Presentation by B RajaramDocument10 pagesSky Bus Metro Presentation by B RajaramtalkmanNo ratings yet

- Railway EngineeringDocument9 pagesRailway Engineeringsezgin icaNo ratings yet

- Dubai-Metro-Case-Study 2020Document4 pagesDubai-Metro-Case-Study 2020Anurag Singal100% (1)

- Improving Traffic Flow at Intersections with FlyoversDocument11 pagesImproving Traffic Flow at Intersections with FlyoversSuvamNo ratings yet

- Railway EngineeringDocument18 pagesRailway EngineeringAngelica GicomNo ratings yet

- Double Decker Corrected WriteupDocument8 pagesDouble Decker Corrected WriteupVYOMESH VERMA100% (1)

- Sky Bus: A Greener Way for Mass TransitDocument59 pagesSky Bus: A Greener Way for Mass TransitSesha ReddyNo ratings yet

- The Study of Skybustechnology On Mass Transportation: Jyoti Meena & Dr. Om PrakashDocument3 pagesThe Study of Skybustechnology On Mass Transportation: Jyoti Meena & Dr. Om PrakashVaibhav SharmaNo ratings yet

- Sky Bus Metro Rail Linking Cities in Himalaya Region: AbstractDocument3 pagesSky Bus Metro Rail Linking Cities in Himalaya Region: AbstractdivyamNo ratings yet

- Special Topic Report by Sadiq MerchantDocument26 pagesSpecial Topic Report by Sadiq MerchantMuhammad Sadiq MerchantNo ratings yet

- Impact of COVID-19 On Construction IndustryDocument3 pagesImpact of COVID-19 On Construction IndustryVamsi BasavaNo ratings yet

- Planning and Design of Downtown Line Stage 2Document8 pagesPlanning and Design of Downtown Line Stage 2gnnivlaNo ratings yet

- Pertemuan 6 - Jalan Rel Dan Kereta ApiDocument30 pagesPertemuan 6 - Jalan Rel Dan Kereta ApiMaya MitchellNo ratings yet

- 188 - Downs, ChrisDocument10 pages188 - Downs, ChrisrockmanqhNo ratings yet

- Railway Engineering (CL-410) : 1 ReferenceDocument49 pagesRailway Engineering (CL-410) : 1 Referencearpit_089No ratings yet

- Sky BusDocument14 pagesSky BusRahul GharateNo ratings yet

- Railways, Harbour, Tunneling and Airports PDFDocument102 pagesRailways, Harbour, Tunneling and Airports PDFRanjitha SR RanjuNo ratings yet

- "Raising of Road Over Bridge On Western Railway": SynopsisDocument6 pages"Raising of Road Over Bridge On Western Railway": SynopsisDurgesh GovilNo ratings yet

- Design loads for bridges on high-speed rail routes of 250-350 km/hDocument30 pagesDesign loads for bridges on high-speed rail routes of 250-350 km/hJc WongNo ratings yet

- Ijsrp p1834 PDFDocument3 pagesIjsrp p1834 PDFXYZNo ratings yet

- M.E Project Ms WordDocument25 pagesM.E Project Ms WordMuhammad Sadiq MerchantNo ratings yet

- A Study On The Calculation of Platform Sizes of Urban Rail Hub StationsDocument14 pagesA Study On The Calculation of Platform Sizes of Urban Rail Hub StationsDipayan SarkarNo ratings yet

- Paper MMRC GC-TCPL MML3 FinalFormat-working-tcplDocument10 pagesPaper MMRC GC-TCPL MML3 FinalFormat-working-tcplASHISH SRIVASTAVANo ratings yet

- 41 Ijmtst0703117Document8 pages41 Ijmtst0703117Myo Htet AungNo ratings yet

- Padma BridgeDocument14 pagesPadma BridgeRisat RahmanNo ratings yet

- RoadwaysDocument3 pagesRoadwaysViswanatham MarellaNo ratings yet

- Ijscet Review Assignment 13474 Article+Text 65096 (Reviewed)Document11 pagesIjscet Review Assignment 13474 Article+Text 65096 (Reviewed)Ibnu AmbakNo ratings yet

- Pedestrian Subways For East Tsim Sha Tsui StationDocument7 pagesPedestrian Subways For East Tsim Sha Tsui StationSomesh SiddharthNo ratings yet

- Ropeways in Urban TransportDocument20 pagesRopeways in Urban TransportbbkbkukbNo ratings yet

- Design of The Padma Road and Rail Bridge PDFDocument12 pagesDesign of The Padma Road and Rail Bridge PDFTaiCheong LeeNo ratings yet

- Articulos VibracionesDocument12 pagesArticulos VibracionesJosé Manuel SoriaNo ratings yet

- Solutions For Increasing The Capacities of Cable Cars: Sergej Težak, Marjan LepDocument7 pagesSolutions For Increasing The Capacities of Cable Cars: Sergej Težak, Marjan LepNipNipNo ratings yet

- Railway Underpass RemakeDocument18 pagesRailway Underpass RemakeRahul ReddyNo ratings yet

- Implementation of Shallow Underpasses atDocument8 pagesImplementation of Shallow Underpasses atSHANLEY JADE ILANONo ratings yet

- Skybusppt 170420025455Document23 pagesSkybusppt 170420025455Yash YadavNo ratings yet

- Final ProposalDocument4 pagesFinal ProposalRama Krishna YalamatiNo ratings yet

- Railway EngineeringDocument7 pagesRailway Engineeringmehmal malikNo ratings yet

- Advanced Underground Subway Katraj PuneDocument10 pagesAdvanced Underground Subway Katraj PuneAishwarya VarhadeNo ratings yet

- Railway Construction PDFDocument12 pagesRailway Construction PDFyesuf abdulhakimNo ratings yet

- Rub Construction To Ease Traffic CongestionDocument3 pagesRub Construction To Ease Traffic CongestionYash SinghNo ratings yet

- Pengembangan Perlintasan Tidak Sebidang Untuk Mewujudkan Perkeretaapian Yang Andal, Selamat, Efisien Dan Nyaman Sesuai Kondisi LingkunganDocument26 pagesPengembangan Perlintasan Tidak Sebidang Untuk Mewujudkan Perkeretaapian Yang Andal, Selamat, Efisien Dan Nyaman Sesuai Kondisi LingkunganNur Syam ASNo ratings yet

- The Design of Padma Multipurpose Bridge - Challenges and Solutions.Document10 pagesThe Design of Padma Multipurpose Bridge - Challenges and Solutions.Jahidul IslamNo ratings yet

- Box Pushing Paper - 1Document5 pagesBox Pushing Paper - 1Naresh KumarNo ratings yet

- Design, Analysis and Prototype Development of Railway Wagons On Different Loading Conditions PDFDocument9 pagesDesign, Analysis and Prototype Development of Railway Wagons On Different Loading Conditions PDFravi_entertainfoNo ratings yet

- GSM-based track monitoring system protects bridges during floodsDocument26 pagesGSM-based track monitoring system protects bridges during floodsabdmohNo ratings yet

- The Design of Light-Rail Track in Pavement Needs RevisionDocument7 pagesThe Design of Light-Rail Track in Pavement Needs RevisionF Javier Morales MNo ratings yet

- Jammu-Udhampur-Srinagar-Baramulla Railway Link: World's Highest Railway Bridge in India (Kashmir)Document39 pagesJammu-Udhampur-Srinagar-Baramulla Railway Link: World's Highest Railway Bridge in India (Kashmir)Sathish RoyalrajaNo ratings yet

- OHL Railway Infrastructure Projects Around The WorldDocument20 pagesOHL Railway Infrastructure Projects Around The WorldМаксим ИсаевNo ratings yet

- Irc 105 2019Document36 pagesIrc 105 2019Anil SuryawanshiNo ratings yet

- Ffirkm: S (RFFDocument12 pagesFfirkm: S (RFFAnil SuryawanshiNo ratings yet

- Irc 129 2019Document40 pagesIrc 129 2019Madabhushi MadhusudanNo ratings yet

- Cost Estimate of WarehouseDocument16 pagesCost Estimate of WarehouseAnil SuryawanshiNo ratings yet

- Irc 108 2014Document37 pagesIrc 108 2014Anil SuryawanshiNo ratings yet

- Irc - Gov.in.086.2018 Geometric Design Standards For Roads and StreetsDocument52 pagesIrc - Gov.in.086.2018 Geometric Design Standards For Roads and StreetsMeenu TomsonNo ratings yet

- Irc 121 2017Document37 pagesIrc 121 2017Anil SuryawanshiNo ratings yet

- Irc 128 2019Document44 pagesIrc 128 2019Madabhushi Madhusudan100% (1)

- Irc - Gov.in.086.2018 Geometric Design Standards For Roads and StreetsDocument52 pagesIrc - Gov.in.086.2018 Geometric Design Standards For Roads and StreetsMeenu TomsonNo ratings yet

- MSRIP Phase 2 EnvDocument26 pagesMSRIP Phase 2 EnvAnil SuryawanshiNo ratings yet

- One Stop Solution For Streetlight Poles ....Document20 pagesOne Stop Solution For Streetlight Poles ....Sambit MohapatraNo ratings yet

- Box Truss and Cantilever Sign FoundationDocument27 pagesBox Truss and Cantilever Sign FoundationUros LukovacNo ratings yet

- 4.structure Est (07.07.2016)Document43 pages4.structure Est (07.07.2016)Anil SuryawanshiNo ratings yet

- Road EstmateDocument27 pagesRoad EstmateAnil SuryawanshiNo ratings yet

- Deterministic shallow foundation design using SPT dataDocument4 pagesDeterministic shallow foundation design using SPT dataZahira HeloNo ratings yet

- Cost estimate for road drainage structuresDocument45 pagesCost estimate for road drainage structuresAnil SuryawanshiNo ratings yet

- Items To Be Considered in Structure WorkDocument1 pageItems To Be Considered in Structure WorkAnil SuryawanshiNo ratings yet

- Maintanance Circular of NHAI - FA 1Document1 pageMaintanance Circular of NHAI - FA 1Anil SuryawanshiNo ratings yet

- Upto Date Status of Feasibility Study Under: PKG-2 AS ON 14.07.2020Document1 pageUpto Date Status of Feasibility Study Under: PKG-2 AS ON 14.07.2020Anil SuryawanshiNo ratings yet

- Irc SP 114 2018 PDFDocument144 pagesIrc SP 114 2018 PDFAnil SuryawanshiNo ratings yet

- SE Calculations ExcleDocument4 pagesSE Calculations ExcleAnil SuryawanshiNo ratings yet

- Irc - Gov.in.080.1981pickup Bus StopsDocument14 pagesIrc - Gov.in.080.1981pickup Bus StopsAnonymous ESjaOhiNo ratings yet

- IRC Highway Research Journal January-June 2018 PDFDocument60 pagesIRC Highway Research Journal January-June 2018 PDFAnil SuryawanshiNo ratings yet

- Drain Design Analysis and Reinforcement DetailsDocument68 pagesDrain Design Analysis and Reinforcement DetailsAnil SuryawanshiNo ratings yet

- Building Design PDFDocument71 pagesBuilding Design PDFAnil SuryawanshiNo ratings yet

- Indian Highways Vol.47 6 June 19Document68 pagesIndian Highways Vol.47 6 June 19harnishtanna212No ratings yet

- 09 Stabilization of Slope PDFDocument43 pages09 Stabilization of Slope PDFAnil SuryawanshiNo ratings yet

- Compiled Office Manual-IIIDocument157 pagesCompiled Office Manual-IIIShazaman SaiyedNo ratings yet

- Procedure of Inserting RH Girder Method in RUB PDFDocument4 pagesProcedure of Inserting RH Girder Method in RUB PDFAnil SuryawanshiNo ratings yet

- Indian Standard: Methods of Sampling and Analysis of ConcreteDocument46 pagesIndian Standard: Methods of Sampling and Analysis of Concretehari6krishnanNo ratings yet

- CV1013 - Concrete - 6 Fresh Concrete - S2 19-20Document24 pagesCV1013 - Concrete - 6 Fresh Concrete - S2 19-20Ash KongNo ratings yet

- Introduction to Daduru Oya Reservoir Project Training ReportDocument13 pagesIntroduction to Daduru Oya Reservoir Project Training ReportpooNo ratings yet

- Fig. 1.2 BRICKSDocument53 pagesFig. 1.2 BRICKSDishant ChandraNo ratings yet

- 10 STRUCTURAL Summary 12 23 21Document16 pages10 STRUCTURAL Summary 12 23 21Leonardo Rivero DurianNo ratings yet

- Silos Construction ReportDocument56 pagesSilos Construction Reportsamwel79% (14)

- Concrete TechnologyDocument39 pagesConcrete Technologyazimkhtr@gmail.com100% (4)

- Advance Cement Concrete M Tech LabDocument36 pagesAdvance Cement Concrete M Tech LabDr Sanjay GuptaNo ratings yet

- Slump Test C 143Document7 pagesSlump Test C 143Favio FloresNo ratings yet

- Cement & ConcreteDocument12 pagesCement & ConcretePatricia PalmerNo ratings yet

- Sans 5862-1Document9 pagesSans 5862-1Sergio VianaNo ratings yet

- Workability of Fresh Concrete by Slump TestDocument2 pagesWorkability of Fresh Concrete by Slump TestlearnafrenNo ratings yet

- Properties of Fresh Concrete PresentationDocument38 pagesProperties of Fresh Concrete PresentationKannan KandappanNo ratings yet

- CIVIL-Concrete-Defects & Quality ControlDocument11 pagesCIVIL-Concrete-Defects & Quality ControlNeeraj VermaNo ratings yet

- Concrete Slump Tests - Measuring The Workability of Concrete - Total ConcreteDocument7 pagesConcrete Slump Tests - Measuring The Workability of Concrete - Total ConcreteMOHAMED ELMASLAMANYNo ratings yet

- Concrete Slump Test WikiDocument4 pagesConcrete Slump Test WikiAprizal AzisNo ratings yet

- Specifications For Excavation and EarthworkDocument78 pagesSpecifications For Excavation and EarthworkAjay Singh100% (2)

- Concrete Mix DesignDocument13 pagesConcrete Mix Designjesus_vitangcolNo ratings yet

- Engineering DiaryDocument146 pagesEngineering Diarynicmarsode100% (1)

- ELT-01-EC-TS-0006 - Specification For Concrete Works - R1Document30 pagesELT-01-EC-TS-0006 - Specification For Concrete Works - R1jorgekarlosprNo ratings yet

- Assignment 1 FinalDocument13 pagesAssignment 1 Finalaljr_2801No ratings yet

- Concrete Slump TestDocument20 pagesConcrete Slump TestJared EstesNo ratings yet

- LDCE Notes/Solution of LDCE/Solution of Question Paper of LDCE 2006Document21 pagesLDCE Notes/Solution of LDCE/Solution of Question Paper of LDCE 2006R Sathish KumarNo ratings yet

- Site Lab Checklist1Document4 pagesSite Lab Checklist1layaljamal2No ratings yet

- Projectmodified Mix Design For ConcreteDocument32 pagesProjectmodified Mix Design For ConcreteSagarNo ratings yet

- Concrete Mix Design and TestingDocument20 pagesConcrete Mix Design and TestingNurin Adlina100% (1)

- Concrete Strength with Glass PowderDocument57 pagesConcrete Strength with Glass PowderGLOBAL INFO-TECH KUMBAKONAMNo ratings yet

- ASTM Test Methods SCCDocument2 pagesASTM Test Methods SCCMohiddin MohammadNo ratings yet

- Aashto t119 - Slump TestDocument4 pagesAashto t119 - Slump Testbill_lee_242No ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaFrom EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNo ratings yet

- Transportation Engineering: Theory, Practice, and ModelingFrom EverandTransportation Engineering: Theory, Practice, and ModelingNo ratings yet

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureFrom EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureRating: 4.5 out of 5 stars4.5/5 (11)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionFrom EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNo ratings yet