Professional Documents

Culture Documents

QA QC Plan ACL PQP 02 PDF

QA QC Plan ACL PQP 02 PDF

Uploaded by

Ahmed Imtiaz RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QA QC Plan ACL PQP 02 PDF

QA QC Plan ACL PQP 02 PDF

Uploaded by

Ahmed Imtiaz RaoCopyright:

Available Formats

QUALITY ASSURANCE / QUALITY CONTROL PLAN

ATS-QA/QC-PLAN

ACL-PQP-02/01

Rev. Date ATS Contr. Client

01 For presentation

ATS Contractor Client

Signature: Signature: Signature:

Name: Name: Name:

Date: Date: Date:

Page 1 of 7

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1

CONSTRUCTION

QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 2 of 7

CONSTRUCTION QUALITY ASSURANCE / QUALITY COTROL PLAN

One of the main priorities of AKKILA COMPANY LIMITED is to maintain high quality of the works

and to improve continuously the Quality System. The present manual covers all construction

quality assurance and quality control procedures, practices and documentation, as follows:

1. Preparation and updating of Construction QA/QC plan including:

Description of procedures and standard practices,

QA/QC responsibility matrices and document flow,

Inspection report forms,

2. Preparation and qualification of welding procedures.

3. Qualification of welders.

4. Field quality control, including:

Traceability during fabrication and erection works,

Control of compliance with relevant procedures,

Visual inspection,

Radiographic inspection,

Ultrasonic inspection,

Magnetic particle inspection,

Liquid penetrant inspection,

Preparation of welding books and welding inspection reports,

Supervision of pipeline/flow line pigging and gauging,

Supervision of hydrostatic testing,

Completion of the documentation,

PROCEDURES AND STANDARD PRACTICES

In order to provide the assurance of the quality, the following procedures and standard practices

are applied:

Standard practice for visual examination,

Standard practice for radiography,

Standard practice for liquid penetration examination,

Standard practice for magnetic particle inspection,

Standard practice for ultrasonic testing,

Standard practice for bending,

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1

CONSTRUCTION

QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 3 of 7

Hydrotesting procedure,

Standard practice for surface preparation and painting inspection

Standard practice for tank and vessel cleaning;

Standard practice for lowering pipe into trench, trench padding and backfilling,

Standard practice for tank construction & erection

Welding procedures,

All these documents are based on the applicable codes and standards, such as ASME Section V,

ASME Section VIII, ASME Section IX, ANSI/ASME B31.3, B31.4, B31.8, API Standard 1104, etc.,

as well as on the schedules and specifications of Client.

The procedures and standard practices are included in Part I of the Construction QA/QC plan.

RESPONSIBILITY MATRICES AND DOCUMENT FLOW

The responsibility matrices and document flow tables are included in Part II of the Plan.

They are the following:

Pipeline / flowline Responsibility Matrix and Document Flow.

The Responsibility Matrix (Mat 01-PL) shows the responsibilities of the QA/QC staff, pipeline

engineers, foremen, and material men in the quality control process during all stages of

construction, namely: Right of way, Stringing, Bending, Trenching, Welding NDT/NDE, Coating,

Lowering-in, Backfilling, Hydrostatic testing, Reinstatement.

The Document Flow Table (Doc 01-PL) shows the way of preparation, signing, and distribution of

the QA/QC documents, related to the process, namely: visual, dye-pen and radiographic inspection

reports, trench inspection, joint insulation, lowering and backfilling reports, report for welding

defects, orders for repair, pigging and hydrotesting reports.

In-plant piping Responsibility Matrix and Document Flow.

The Responsibility Matrix (Mat 02-in) shows the responsibility of the QA/QC staff, piping

engineers, foremen, and material men in the quality control process during all in-plant piping

fabrication and erection, namely: sorting of materials (material dedication), preparation for

prefabrication, welding, NDT/NDE sandblasting, painting, erection (incl. Field welding), hydrostatic

testing and reinstatement.

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1

CONSTRUCTION

QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 4 of 7

The Document Flow Table (Doc 02-in) shows the way of preparation, signing and distribution of

the following documents related to prefabrication and erection of the plant piping: visual, dye- pen.

and radiographic reports, coating reports, progress reports, welding inspection reports,

hydrotesting reports.

REPORT FORMS

The report forms are included in Part III of the plan, divided into 5 topics:

Welding, NDT, Hydrotest.

Pipeline / Flowing / In-Plant.

Mechanical.

Civil.

Instrumentation.

The forms were prepared on the grounds of the recommendations given by related codes and

standards, and in compliance with the good field practice.

PREPARATION AND QUALIFICATION OF WELDING PROCEDURES

The preparation and qualification of the welding procedures is carried out by

Welding /NDE (Non-Destructive Evaluation) Group (see fig.1) in accordance with the requirements

of ASME IX, API Standard 1104, ANSI/ASME B31.3, B31.4, B31.8, AWS D1.1, etc.

There are 10 welding procedures covering most of the pipeline and in-plant piping construction

activities. These procedures are prepared by AKKILA COMPANY LIMITED QA/QC engineers and

qualified under the supervision of RWTUV. They are included in Part I of the Plan.

Any further qualification of a procedure that may appear necessary for a job will be prepared by

experienced welding engineers and submitted to the Client for approval. After being approved by

the Client, the procedure will be carried out in the fabrication yard by experienced welders under

the supervision of welding inspectors from both AKKILA COMPANY LIMITED QA/QC Department

and the Client, Certified materials and consumables shall be used. The mechanical testing will take

place in authorized laboratory, approved by the Client.

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1

CONSTRUCTION

QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 5 of 7

QUALIFICATION OF WELDERS

The welder’s testing and qualification is carried out by the Welding/ NDE Group (see fig.1). The

qualification of welders under the qualified welding procedures is carried out according to the

requirements of ASME IX API Standard 1104, ANSI/ASME B31.3, B31.4, B31.8, AWS D1.1, etc

The testing takes place in the fabrication yard under the supervision of welding inspectors from

both AKKILA COMPANY LIMITED Group and the Client. Certified materials and consumables are

used. Welder’s Performance Test Record is prepared and signed for the successful welders. The

welders are provided with ID cards for the duration of the works.

FIELD QUALITY CONTROL

The field quality control is carried out by the Field Inspection Group (see fig.1). The following

activities take place:

Preparation and updating of welding maps.

Tracing prefabrication, blasting, priming, and painting.

Visual inspection of welding, blasting, priming, and painting.

Checking paint thickness.

Monitoring work compliance with the relevant procedures.

Checking skid assembly.

Checking vessels.

Checking rotating equipment.

Checking earthworks.

Concrete pour checking.

Grouting checking.

Checking instrument installation.

Preparation of mechanical, civil, electrical and instrumentation checklists.

The following documents are related to the field quality control:

Visual Inspection Report

Workshop/Erection Welding Report

Trench Inspection Report

Joint Insulation Inspection Report

Lowering and Backfilling Report

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1

CONSTRUCTION

QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 6 of 7

In-plant Piping Coating Report

Skid Assembly Report

Vessel Inspection and Closing Report

Rotating Equipment Report

Mechanical Equipment Checklist

Mechanical Completion Checklist

Earthwork checklist

Backfilling checklist

Concrete Pour Checklist

Instrument Installation Record

RADIOGRAPHY AND OTHER NON-DESTRUCTIVE METHODS

The non-destructive testing is carried out by NDT Group (see fig.1).

Appropriate NDT equipment and materials are provided:

Gamma-ray sources,

Films and chemicals,

Image quality indicators,

Viewers and pentameters,

Photo-laboratory equipment,

MOI equipment,

Ultrasonic equipment,

Dye penetration testing chemicals,

Field hardness testing equipment (if necessary).

The evaluation of the results is performed by Welding/NDE Group (see fig.1). The staff is properly

qualified. The minimum qualification required is Level II.

The following documents are related to the NDT/NDE:

Liquid Penetration test Report

Radiographic Examination Report

Magnetic Particle Test Record

Ultrasonic Test Record

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1

CONSTRUCTION

QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 7 of 7

PREPARATION OF WELDING BOOKS AND WELDING INSPECTION REPORTS

The welding book (W008) for the pipelines, and the welding inspection report (W005) for the in

plant piping, are final documents summarizing all welding and NDT carried out. They contain

welding history and reference to all reports related to the welding of a pipeline or in-plant piping

element. The preparation of these documents is a continuous processes during the execution the

words. The completion of such document takes place after the line or spool obtains status of “NDT

clear”. The welding book/welding inspection report, together with all related inspection reports,

form the Test Package, which is to be completed before the hydrostatic testing.

Examples are shown in part IV:

Test package example

Hydrotesting documentation example

Welding book

The examples represent real cases taken from the field practice of AKKILA COMPANY LIMITED.

Attachments:

Pipeline/Flowline Responsibility Matrix

In-Plant Piping Responsibility Matrix

Pipeline/Flowline Document Flow

In-Plant Piping Document Flow

Construction QA/QC Plan Fig.01

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

Quality Assurance / Quality Control

PIPELINE / FLOWLINE

RESPONSIBILITY MATRIX

Unit Material Pipeline QA/QC

Foreman

JOB Man Engineer Unit

Complete Complete

R. O. W

check check

Check truck Complete

Loads check Complete

Stringing

Collect Mill check

Certificates

Complete check

Draw scheme Gauging

Bending

For Welding (Roundness check)

Book

Complete check Complete check

Trenching

Prepare L001 Issue L001

Measure pipe 100%

length inspection,

Check

Welding Write on pipes Issue W001

Consumables

Length, pipe # Fill in W008

Weld # Issue W010

Radiography

Dye Pen

Check Evaluate

NDT

Consumables Radiographs

Issue W002. W003

Order repair(W017)

Check Complete check

Complete

consumables Prepare L002

Coating Check

Collect

Issue L002

certificates

Lowering-in / Complete check Complete check

Backfilling Prepare L003 Issue L003

Issue W008

Collect

Test Pack Related

Preparation documents

Complete

Test pack

Complete Collect Documents

Check Issue L004

Hydrotest

Prepare L004 Issue W004

Complete Test pack

Complete Complete

Reinstatement

Check Check

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

MAT01 – PL. xls

Quality Assurance / Quality Control

IN-PLANT PIPING

PESPONSIBILITY MATRIX

Unit Material Pipeline QA/QC

Foreman

JOB Man Engineer Unit

Storage piping, Complete check

fittings, Collect mill Complete check

flanges certificates

Check classes,

Sort materials List of Complete

Dimensions, Complete check

As per isometrics discrepancies check

schedules

Schedule

Issue materials

Preparation for Check Issue Preparation as

As per

Prefabrication Requisitions requisitions Per test pack

requisitions

priorities

Prefabrication – fitting Complete Complete

And tack welding check check

100% visual

Complete Mark weld #,

Welding Issue W011 inspection,

check Welder #

Issue W001

Radiography

Dye pen,

Issue W002

Check Evaluate

NDT

consumables radiographs

Issue W009

Issue W010

Order repair (W017)

Check Complete check Complete check

Sandblasting, consumables

Priming, Painting Collect Prepare L005 Issue L005

certificates

All NDT Activities for field welding

Erection Issue W009

Issue W011

Issue W010

Issue W009

Prepare W004

Collect related

Test Pack

documents

Complete

pack

Complete check

Complete

Hydrotest Issue W004

check

Complete Test Pack

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

Complete Complete

Reinstatement

check check

MAT 02 – IN. xls

Quality Assurance / Quality Control

PIPELINE / FLOWLINE

DOCUMENT FLOW

Index Description Prepared by Signed by Copies Distribution

QA / AC Client

W001 Visual inspection Report QA / AC 2

Client Inspector QA / QC

QA / AC Client

W002 Liquid Penetration Test Report QA / QC 2

Client Inspector QA / QC

Client

Radiographic Examination QA / AC QA / QC

W003 QA / QC 4

Report Client Inspector Pipeline Engineer

Welding Foreman

Client

QA / QC

W010 Defective Welding Rate QA / QC QA / QC 4 Pipeline engineer

Construction

Manager

Client

P/L Engineer QA / QC

L001 Trench Inspection Report 3 QA / QC

QA / QC Client Inspector

Pipeline Engineer

Client

P/L Engineer QA / QC

L002 Coating Inspection Report 3 QA / QC

QA / QC Client Inspector

Pipeline Engineer

Client

P/L Engineer QA / QC

L003 Lowering-in & Backfilling Report 3 QA / QC

QA / QC Client Inspector

Pipeline Engineer

Client

P/L Engineer QA / QC

L004 Pigging Report 3 QA / QC

QA / QC Client Inspector

Pipeline Engineer

Client

QA / QC

W008 Welding Book QA / QC 3 QA / QC

Client

Pipeline Engineer

Client

P/L Engineer QA / QC

Hydrotest Report QA / QC

QA / QC Client

Pipeline Engineer

Client

Pipe and Fitting Mill Certificate Vendor Vendor 3 QA / QC

Material Man

Client

Coating Certificate Vendor Vendor 3 QA / QC

Material Man

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

DOC 01 – IN. xls

Quality Assurance / Quality Control

IN-PLANT PIPING

DOCUMENT FLOW

Index Description Prepared by Signed by Copies Distribution

QA / AC Client

W001 Visual inspection Report QA / AC 2

Client Inspector QA / QC

Construction

Workshop/ Erection Welding Piping Piping Manager

W011 3

Report Engineer Engineer QA / QC

Piping Engineer

Client

QA / QC

W012 Order For X - ray QA / QC QA / AC 3

Piping Engineer

Welding Foreman

QA / AC Client

W002 Liquid Penetration Test Report QA / QC 2

Client Inspector QA / QC

Client

Radiographic Examination QA / AC

W003 QA / QC 4 QA / QC

Report Client Inspector

Piping Engineer

Client

QA / QC

In-Plant Welding Progress

W009 QA / QC QA / QC Piping Engineer

Report

Construction

Manager

Piping Client

QA / QC

L005 In-plant Piping Coating Report Engineer 3 QA / QC

Client Inspector

QA / QC Piping Engineer

Client

W005 Welding Inspection Report QA / QC QA / QC 2

QA / QC

QA / QC Client

Hydrotest Report QA / QC 2

Client Inspector QA / QC

Client

Pipe and Fitting Mill Certificate Vendor Vendor 3 QA / QC

Material Man

Client

Coating Certificate Vendor Vendor 3 QA / QC

Material Man

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

DOC 02 – IN.xls

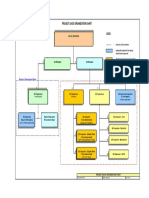

CONSTRUCTION QA/QC PLAN

FIGURE 1

QUALITY ASSURANCE/QUALITY CONTROL ORGANIZATION

QA/QC MANAGER

Field Inspection Group Construction / Welding Group

Material Compliance Welding procedures

Pipelines Welder’s qualification

In-Plant Piping Fabrication & Rolling

Civil Tank Erection / Construction

Mechanical/Vessels NDT Planning

Instrumentation/Electrical Evaluation NDT results

Hydrotesting

Repair planning & control

Precommissioning

NDT Group

Radiography

Ultrasonic

MPI

Liquid

Penetration

P.O. Box 54711, Abu Dhabi, United Arab Emirates

Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

You might also like

- Control of Calibrated Equipment ProcedureDocument8 pagesControl of Calibrated Equipment ProcedureFaisalNo ratings yet

- Weld Cleaning MethodsDocument7 pagesWeld Cleaning MethodsTrần Thùy LinhNo ratings yet

- 88 Numerical Series BASED TECHNOLOGY AWARENESS Grigory GRABOVOIJADocument5 pages88 Numerical Series BASED TECHNOLOGY AWARENESS Grigory GRABOVOIJAStellaEstel93% (15)

- VECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0Document10 pagesVECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0hymerchmidtNo ratings yet

- SAIC-W-2077 Weld Joint Identification SystemDocument1 pageSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNo ratings yet

- Inspection Test Plan: Grinding, Build Up & ResurfaceDocument3 pagesInspection Test Plan: Grinding, Build Up & Resurfacemohd as shahiddin jafriNo ratings yet

- QAQC Organization ChartDocument1 pageQAQC Organization Chartteto100% (1)

- Material Receiving Inspection ReportDocument2 pagesMaterial Receiving Inspection Reporttuan mai vanNo ratings yet

- Inspection and Test Plan For Epc Gas Pipeline Project-X70mDocument15 pagesInspection and Test Plan For Epc Gas Pipeline Project-X70mFolarin Ayodeji100% (1)

- Manual Ateme Kyrion DR5000Document143 pagesManual Ateme Kyrion DR5000Ramiro100% (1)

- Inspection Test Plan ITP v3Document22 pagesInspection Test Plan ITP v3Luis Gabriel Bautista100% (1)

- Proposed Quality Control PlanDocument3 pagesProposed Quality Control PlanMohamad Rafik50% (2)

- Rexroth and Atos Valve CompareDocument7 pagesRexroth and Atos Valve Compareback1949No ratings yet

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Documented Information ProcedureDocument14 pagesDocumented Information ProcedureAnkurNo ratings yet

- Saudi Technical LTD: Qa / QC Department Organization ChartDocument1 pageSaudi Technical LTD: Qa / QC Department Organization Chartzahid_497No ratings yet

- Iso 14001 Certification: Bureau Veritas Certification ServicesDocument2 pagesIso 14001 Certification: Bureau Veritas Certification Servicesibrail5No ratings yet

- Welder Qualification Register 01Document3 pagesWelder Qualification Register 01Andrei UrsacheNo ratings yet

- Pressure Classes: Ductile Iron PipeDocument4 pagesPressure Classes: Ductile Iron PipesmithNo ratings yet

- Qa-Qc Quality PDFDocument60 pagesQa-Qc Quality PDFNaveed Ahmed Get-InfoNo ratings yet

- 1 SATIP-B-019-01 Portable Fire Protection Equip-Rev 1Document2 pages1 SATIP-B-019-01 Portable Fire Protection Equip-Rev 1JithuJohnNo ratings yet

- Quality Control PlanDocument8 pagesQuality Control PlanBharat jangirNo ratings yet

- 2082-PM-CQP-7011 Rev.0 - Constructin Quality PlanDocument22 pages2082-PM-CQP-7011 Rev.0 - Constructin Quality PlanAmarKumarNo ratings yet

- Distribution System Grounding FundamentalsDocument17 pagesDistribution System Grounding FundamentalsJose Alberto RodriguezNo ratings yet

- Contact No: - Contact Address: - C/ODocument5 pagesContact No: - Contact Address: - C/Ovishal bailur100% (1)

- 30a100dbqb23010 - Exde06 - 77 Project Quality PlanDocument81 pages30a100dbqb23010 - Exde06 - 77 Project Quality Plansamuel madisonNo ratings yet

- 11-Qa - QC ProcedureDocument18 pages11-Qa - QC Procedureerwin hidayat100% (1)

- QAQC Procedure For FabricationDocument7 pagesQAQC Procedure For FabricationRajesh K Pillai100% (6)

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- Quality Manual: ISO/TS 16949:2009 Quality Management SystemDocument47 pagesQuality Manual: ISO/TS 16949:2009 Quality Management Systemluismi081300No ratings yet

- Example Progress CalculationsDocument18 pagesExample Progress CalculationsAli HajirassoulihaNo ratings yet

- Loto Policy SampleDocument6 pagesLoto Policy Sampleyemi adelakunNo ratings yet

- PQP Rev. 001Document60 pagesPQP Rev. 001rkssNo ratings yet

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Preservation Proceedure (SAMPLE)Document29 pagesPreservation Proceedure (SAMPLE)Hasann Maawia100% (1)

- Curriculum Vitae - Paul Joseph Sebastian..Document4 pagesCurriculum Vitae - Paul Joseph Sebastian..Abdullah AnsariNo ratings yet

- Quality Control Procedure Index) - Rev.2Document3 pagesQuality Control Procedure Index) - Rev.2valent aviolandaNo ratings yet

- SUF PR 14 Quality AuditingDocument8 pagesSUF PR 14 Quality Auditingscriptd_ozd3nNo ratings yet

- NG-018-XX-PNL-431203 - Rev07 NDT MatricesDocument20 pagesNG-018-XX-PNL-431203 - Rev07 NDT MatricesFolarin Ayodeji100% (1)

- Contractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationDocument5 pagesContractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationSergey KichenkoNo ratings yet

- LTE Signaling TracingDocument19 pagesLTE Signaling TracingSemihOzer100% (2)

- Certification To Iso 3834 For Fabrication IndustryDocument9 pagesCertification To Iso 3834 For Fabrication IndustryvilukNo ratings yet

- MAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1Document9 pagesMAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1IT Support - FernanNo ratings yet

- Quality Record Control ProcedureDocument5 pagesQuality Record Control ProcedureGomathyselviNo ratings yet

- Gse Ms Ag 002 Rev 1 - Method Statement For Above Ground PipingDocument17 pagesGse Ms Ag 002 Rev 1 - Method Statement For Above Ground PipingsugumarNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- Tepng Onshore Const Itt Project Quality PlanDocument45 pagesTepng Onshore Const Itt Project Quality PlanTrustEmmaNo ratings yet

- N-00-PQ-5011-PR - R0A (Material Receiving Procedure) PDFDocument10 pagesN-00-PQ-5011-PR - R0A (Material Receiving Procedure) PDFRaziKhanNo ratings yet

- CV 2023Document5 pagesCV 2023AmitNo ratings yet

- Surface Preparation and PaintingDocument4 pagesSurface Preparation and PaintingSimbu ArasanNo ratings yet

- Monitoring and Measurement of QmsDocument3 pagesMonitoring and Measurement of QmsamoNo ratings yet

- 3900 Series Multi-Mode Base Station Technical Description (V100R002 - 03)Document58 pages3900 Series Multi-Mode Base Station Technical Description (V100R002 - 03)Rashid Mahmood SajidNo ratings yet

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- QP-018, Quality Manual Procedure For Coupon and Probes MonitoringDocument12 pagesQP-018, Quality Manual Procedure For Coupon and Probes MonitoringIksan Adityo MulyoNo ratings yet

- Inar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaDocument14 pagesInar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaSreedhar Patnaik.MNo ratings yet

- Method Statement For Erection of Water TankDocument62 pagesMethod Statement For Erection of Water TankAli HajirassoulihaNo ratings yet

- SAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FDocument2 pagesSAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FAnonymous S9qBDVky100% (1)

- Pressure Testing Methods DVGW G 469Document14 pagesPressure Testing Methods DVGW G 469Ali HajirassoulihaNo ratings yet

- 2.2.16 - QPR-RHE-002 RLC Waste Management 2 (220205)Document30 pages2.2.16 - QPR-RHE-002 RLC Waste Management 2 (220205)Lyle KorytarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistZia ur RehmanNo ratings yet

- 3.2 Develop The Material Control PlanDocument9 pages3.2 Develop The Material Control Planjesus_bs100% (1)

- Iraq Gates Contracting Company: Kaz 12.2 Rehabilitation ProjectDocument8 pagesIraq Gates Contracting Company: Kaz 12.2 Rehabilitation ProjectAhmedNo ratings yet

- O - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlDocument8 pagesO - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlMDhana SekarNo ratings yet

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- Hose Test Method StatementDocument6 pagesHose Test Method StatementRavi ValiyaNo ratings yet

- ASME B31.3 Process Piping: 13. Inspection, Examination & TestingDocument37 pagesASME B31.3 Process Piping: 13. Inspection, Examination & TestingMohamed Al-OdatNo ratings yet

- Annexure C3.23 - Quality Management PlanDocument23 pagesAnnexure C3.23 - Quality Management Planifansusanto100% (1)

- 00 Saip 72Document6 pages00 Saip 72aamirtec301No ratings yet

- Qa-Qc Plan For Sharq R-0aDocument163 pagesQa-Qc Plan For Sharq R-0akbldamNo ratings yet

- Calibration ListDocument2 pagesCalibration ListCemang AmeNo ratings yet

- Coded Marking Procedure - CM-01Document7 pagesCoded Marking Procedure - CM-01carlosNo ratings yet

- MES - Construction Quality Manual - Rev - 0Document55 pagesMES - Construction Quality Manual - Rev - 0Ishaan ThakerNo ratings yet

- Risk Assessment FormDocument25 pagesRisk Assessment FormAli HajirassoulihaNo ratings yet

- NEED SolarshortDocument25 pagesNEED SolarshortAli HajirassoulihaNo ratings yet

- Inance Ontract: Credit TermsDocument2 pagesInance Ontract: Credit TermsAli HajirassoulihaNo ratings yet

- Construction Safety Inspection Checklist: Housekeeping and SanitationDocument8 pagesConstruction Safety Inspection Checklist: Housekeeping and SanitationAli HajirassoulihaNo ratings yet

- Sales Units Jan Feb Mar Apr May Jun: Cash Budget - TemplateDocument4 pagesSales Units Jan Feb Mar Apr May Jun: Cash Budget - TemplateAli HajirassoulihaNo ratings yet

- NEED SolarshortDocument25 pagesNEED SolarshortAli HajirassoulihaNo ratings yet

- Face The FutureDocument68 pagesFace The FutureAli HajirassoulihaNo ratings yet

- Tap Project: Acs02 & Acs03: Piping Works FlowchartDocument1 pageTap Project: Acs02 & Acs03: Piping Works FlowchartAli HajirassoulihaNo ratings yet

- Requisition: Quantity Description Estimated CostDocument1 pageRequisition: Quantity Description Estimated CostAli HajirassoulihaNo ratings yet

- En 12732 (Welding Steel Pipework Requirements) Gas Supply SystemDocument1 pageEn 12732 (Welding Steel Pipework Requirements) Gas Supply SystemAli HajirassoulihaNo ratings yet

- Expence Claim For Service OrderDocument1 pageExpence Claim For Service OrderAli HajirassoulihaNo ratings yet

- ReferDocument189 pagesReferrameshNo ratings yet

- Okonite Instrument CableDocument2 pagesOkonite Instrument CableAnonymous Wu6FDjbNo ratings yet

- How To Use Switch in Gns3Document21 pagesHow To Use Switch in Gns3hem777No ratings yet

- All Sap LinksDocument9 pagesAll Sap Linksapi-3746151100% (2)

- Toshiba m86-m Quanta Bd3 Rev1a SCHDocument13 pagesToshiba m86-m Quanta Bd3 Rev1a SCHВиола БорисовскаяNo ratings yet

- Olympus Cx31Document20 pagesOlympus Cx31RichardAncengNo ratings yet

- VHDL TD - CorrigéDocument6 pagesVHDL TD - CorrigéSahsah AbdeslamNo ratings yet

- R119 PilotDocument4 pagesR119 PilotxavicojmNo ratings yet

- Compaq EPDocument24 pagesCompaq EPmmlozanoNo ratings yet

- Instruction Manual (B) : STP Series Turbomolecular Pumps STP-XA2703/XA3203 Series Pump Specific InformationDocument27 pagesInstruction Manual (B) : STP Series Turbomolecular Pumps STP-XA2703/XA3203 Series Pump Specific InformationJoe JoeNo ratings yet

- LuminaireDocument14 pagesLuminaireKhaled SalemNo ratings yet

- SPEECHDocument1 pageSPEECHJasper Jade MartinNo ratings yet

- 67 FRDocument8 pages67 FRFabian De Jesus Aragon GomezNo ratings yet

- Unit-I: Introduction To J2EEDocument29 pagesUnit-I: Introduction To J2EEsurakshaNo ratings yet

- M10 Laying MasonryDocument187 pagesM10 Laying Masonrymustied mohammedNo ratings yet

- Quick Start Guide: 32-Port 100G Ethernet Switch Package ContentsDocument5 pagesQuick Start Guide: 32-Port 100G Ethernet Switch Package ContentsAlexNo ratings yet

- t38 Fax RelayDocument20 pagest38 Fax RelayCanhCuaCàMuốiNo ratings yet

- CorePower AVR Users Guide July 2013Document2 pagesCorePower AVR Users Guide July 2013Wilbert T. LimNo ratings yet

- AKPS SVL Brochure PDFDocument4 pagesAKPS SVL Brochure PDFGeorge O.No ratings yet

- Unit Two Review - SPR 18 - KEYDocument7 pagesUnit Two Review - SPR 18 - KEYVivek RajanNo ratings yet

- Maki MakiDocument4 pagesMaki MakiMarijana VuckovicNo ratings yet