Professional Documents

Culture Documents

California Trimmer: Mower Maintenance Manual

California Trimmer: Mower Maintenance Manual

Uploaded by

ScottOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

California Trimmer: Mower Maintenance Manual

California Trimmer: Mower Maintenance Manual

Uploaded by

ScottCopyright:

Available Formats

CALIFORNIA TRIMMER

MOWER MAINTENANCE MANUAL

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Table of Contents

Section 1: General Information Page

Handle Assembly Instructions 4

Maintenance – All Models 6

Oil Change Procedures – All Models 9

Height Adjustment – All Models 10

Catcher and Bale Adjustment – All Models 12

Section 2: Home Owner Model Page

Clutch Adjustment 14

Reel Adjustment 16

Roller Adjustment 18

Roller Assembly 20

Trouble Shooting

“Reel won’t turn” 22

“Mower won’t propel” 23

Parts List and Mower Schematics 24

Section 3: Commercial Models Page

Clutch 27

Reel Adjustment 30

Roller Adjustment 33

Drive Shaft Disassembly 35

Drive Shaft Assembly 36

Roller Assembly 42

Trouble Shooting

“Reel won’t turn” 46

“Mower won’t propel” 47

Parts List and Mower Schematics 48

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Handle Assembly Instructions

Home Owner Model

Tools Required:

2 1/2” Wrenches

2 7/16” Wrenches

1 3/8” Wrench

1 Flat-Blade Screw Driver

1 Pliers w/cutters

To determine Left or Right, position yourself in the operator’s position behind the mower.

Handle Assembly

Connect the bottom and top section of the handle using (4) each 5/16” bolts, washers

and nylock nuts. Tighten using the two (2) 1/2” wrenches.

Note: The extension forks of the top section should be mounted to the outside of the

bottom handle section. The bolts should go through the handle to the inside and the

washers and nuts go on the inside of the handle.

Clutch Rod Assembly

Remove the shipping plastic and fully thread the coupling nut attached to the

top section of the clutch rod onto the bottom section and tighten jam nuts.

Secure the clutch rod to the clutch lever on the handle with the supplied cotter

pin.

Roller-Lift Straps

The roller-lift straps are connected to the roller-lift lever on the top section of the handle.

Attach the roller-lift straps to the roller-lift toggle using a 1/4” X 1” bolt and nylock nut. The

roller-lift straps should straddle (one on each side of) the roller-lift toggle. Tighten using

the two (2) 7/16” wrenches.

Throttle Cable Assembly

Just below the hand grip on the right-hand side, using the flat-

blade screw driver and 3/8” wrench, remove the two (2) nuts from

their screws. Attach the throttle control lever to the top handle

piece with the two (2) screws and nuts, and tighten. Use the

provided spring clip to secure throttle cable to the handle.

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Handle Assembly Instructions

Heavy Duty & Commercial Models

Tools Required:

2 1/2” Wrenches

1 7/16” Wrenches

1 3/8” Wrench

1 Flat-Blade Screw Driver

1 Pliers w/cutters

To determine Left or Right, position yourself in the operator’s position behind the mower.

Handle Assembly

Connect the bottom and top section of the handle using (4) each 5/16” bolts, washers

and nylock nuts. Tighten using the two (2) 1/2” wrenches.

Note: The extension forks of the top section should be mounted to the outside of the

bottom handle section. The bolts should go through the handle to the inside and the

washers and nuts go on the inside of the handle.

Clutch Rod Assembly

Remove the shipping plastic and fully thread the coupling nut attached to the

top section of the clutch rod onto the bottom section and tighten jam nuts.

Secure the clutch rod to the clutch lever on the handle with the supplied cotter

pin.

Roller-Lift Rod

The roller-lift rod is connected to the roller-lift lever on the top section of the handle.

Insert the bottom end of the roller-lift rod into the roller-lift toggle, secure roller-lift rod to

roller-lift toggle with a cotter pin.

Throttle Cable Assembly

Just below the hand grip on the right-hand side, using the flat-blade

screw driver and 3/8” wrench, remove the two (2) nuts from their

screws. Attach the throttle control lever to the top handle piece with

the two (2) screws and nuts, and tighten. Use the provided spring

clip to secure throttle cable to the handle.

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Mower Maintenance

Heavy Duty & Commercial Models

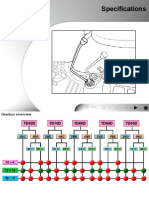

6 4 1 2 4 6

6 3 5 6 3

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Mower Maintenance

Heavy Duty & Commercial Models

Commercial Use – Daily Inspection

1. Check Engine oil level. The oil should be filled to the engine specifications (see engine

owner’s manual)

2. Check air cleaner. Some Honda engines have an oil bath filter. Oil should be added to

maintain optimum level. Inspect sponge filter for debris (dirt, grass etc.). Briggs engines

have a dry filter. Inspect for debris (dirt, grass etc.).

3. Check engine and reel chain tension, adjust if necessary. All chains should have about a

1/4” of play. Loosen chain-tensioner bolt, adjust tensioner setting chain to desired

tension and re-tighten bolt. Check roller chain tension once each week. To tighter roller

chain raise roller aligning the roller shaft parallel to the drive shaft. This puts the roller at

the furthest point of movement.

4. Grease reel grease fittings (zerk fittings).

5. Grease clutch forks. Put grease on shaft between the ends of the forks.

6. Grease zerk fittings on front and rear wheels. Steady rest, center drive shaft support

bracket, should be filled once a month.

7. Lube chain with engine oil. Use a paint brush to apply oil to chain. Momentarily run

machine to spin off excess oil before use.

Non-Commercial Use Only

1. Follow the same procedures listed above after every eight hours of use.

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Notes

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Oil Change Procedure

All models

Preparation for mowers with oil bath air filters.

Note: This method of oil change should be done when the gas tank is low on fuel. If the fuel tank is full,

gas could leak around the gas cap.

1. Undo wing nut and remove oil bath filter reservoir, both top and bottom pieces.

Note:

2. Remove carefully, check for the reservoir gasket, which may stick to the bottom section of the oil

reservoir.

3. The GX series engine has two oil plugs, one in the front and one in the back, for draining oil from

the engine. However, the position of the engine on the frame does not offer easy access and can

cause the old oil to pour onto the mower, requiring extra clean-up time. It is easier to remove the

oil-fill plug. Tip the mower forward and pour oil into a can or plastic container.

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Height Adjustment

All models

Two different ranges of height adjustments are available. The higher range is achieved with the “caster

bracket” (no. 1) in the bottom hole (as shown). The lower range is achieved with the “caster bracket” (no.

1) in the top hole.

With the “caster bracket” (no.1) in the lower hole, the “height adjustment lever” (no. 2) will utilize the top 4

to 5 holes of the “quadrant” (no. 3).

With the “caster bracket” (no. 1) in the top hole, the “height adjustment lever” (no. 2) will utilize the bottom

4 to 5 holes of the “quadrant” (no. 3).

In either height range, moving the “height adjustment lever” (no. 2) towards the front of the mower will

raise the height in small increments. Moving the “height adjustment lever” (no. 2) towards the back of the

mower will lower the height in small increments.

1

3 2 4 5 6

To change the range setting, take the “height adjustment lever” (no. 2) out of the holes of the “quadrant”

(no. 3) and move it in the direction of the change. Back if the “caster bracket” (no.1) is being moved to

the top hole or forward if the “caster bracket” (no.1) is being moved to the bottom hole. Loosen the

“caster wheel nut” (no. 6).

Remove the nut on the “tie rod” (no. 4), slide the “tie rod” (no. 4) out, being careful not to lose the washer

between the “adjuster bracket” (no. 5) and the frame (washer not shown). Slide the “tie rod” (no. 4)

through the desired hole of the side plate, “caster bracket” (no. 1), and the other side plate. Place the

washer (not shown) on the “tie rod” (no. 4) between the frame and “adjuster bracket (no. 5). Install the nut

on the “tie rod” (no. 4). Do not over tighten this nut, the height adjuster pivots at this point. Tighten the

“caster wheel nut” (no. 6).

10

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Catcher and Bale Adjustment

All models

The “V” of the catcher bale is offset to one side, making one side shorter than the other. On 20 and 25

commercial mowers the short side goes to the left, as shown. On the Home Owner mower the short side

goes to the right.

The catcher has three “bale” holes on each side to accommodate the bale at various height settings.

After setting mower to the desired height, see height adjustment, put the bale in the holes that positions

the catcher as level to the ground as possible.

Bale holes

Short leg “V”

After determining the best “bale holes”, attach the bale to the catcher using a washer and cotter pin on

each side.

11

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Notes

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

12

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model

Clutch Adjustment

Tools Required:

2 1/2” Wrenches

1 1/8” Allen wrench

CAUTION:

ALL ADJUSTMENT MUST BE MADE WITH THE ENGINE TURNED OFF.

Step 1

With the clutch rod pointing down toward the engine in the engaged position (see above) the tip of

the belt guard is just off the belt.

Adjust by bending the belt guard up or down so that the tip of the belt guard is approximately the

thickness of a dime off the belt in the engaged position. Make sure the belt guard doesn’t ride on the

belt.

13

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model

Clutch Adjustment

BRACKET SWIVEL BEARING BOTTOM PULLEY

Step 2

With the clutch rod pointing up in the disengaged position (see above) make sure the idler bearing does

not ride on the bottom pulley. The idler bearing should be within one quarter (1/4) of an inch from the

bottom pulley. The belt release bracket should be above parallel to the frame, thus creating a slight bend

in the belt.

Adjustments to the idler is made in the engaged position by loosening the set screw in the swivel and

sliding the clutch rod up or down. Reset the set screw in the swivel when adjustment is complete.

Adjustments to the release bracket are done after the belt bearing is positioned correctly. In the

disengaged position, loosen the nut on the bearing and position the belt release bracket above parallel to

the frame. Retighten the nut when adjustment is complete.

14

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model

Cutter Bar to Reel Adjustment

Tools Required:

1 Adjustable Wrench or 1/4” Open-end Wrench

CAUTION:

ALL ADJUSTMENTS MUST BE MADE WITH THE ENGINE TURNED OFF.

The reel on the Home Owner model is fixed and stationary to the frame. The cutter bar is adjusted to the

reel. The cutter bar adjusting screws raise and lower the cutter bar in relation to the reel.

Step 1

Disengage the clutch, as shown below, before adjusting the cutter bar.

Step 2

Turn one adjusting screw in small increments until the cutter bar touches the reel. Turn the reel with one

hand. Rest the palm of one hand on the caster bracket and pull the blade on the reel with the fingers of

that hand. The reel should move about the distance of the space between the blades. As the reel is

turned it will make the sound of metal scraping.

15

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model

Cutter Bar to Reel Adjustment – (Continued)

Step 3

Repeat the above process with the opposite adjusting screw.

Step 4

Slide a piece of thin paper, such as a page from a phone book or newspaper, at small intervals, all the

way across the cutter bar to test for proper adjustment. When adjusted properly the paper will be cut

cleanly and evenly across the entire width of the mower.

16

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model

Roller Adjustment Procedures

Tools Required:

1 5/32” Allen Wrench

1 7/16” Wrench

1 Screw Driver

CAUTION:

ALL ADJUSTMENTS MUST BE MADE WITH THE ENGINE TURNED OFF.

Step 1

Loosen roller “U” Bolts and set screws on both sides of the drive roller. This will loosen the drive roller on

the yoke.

Step 2

Pull the drive roller back, tensioning the chain taut. Make sure the drive roller is in the furthest position

from the drive shaft. If the drive roller is not in the furthest most position, the chain will become relaxed.

17

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model

Roller Adjustment Procedures – (Continued)

To Check

Move the drive roller up, past the furthest most position and the drive chain will become slack on top.

Move the drive roller down, past the furthest most position and the chain will become slack on the bottom.

Make sure the bolt heads on the sprocket clear the yoke when it spins. Tighten the “U” Bolt and set

screw on the right side.

Step 3

With the chain taught, in the furthest most position from the drive shaft, make sure the drive roller is

parallel to the back cross piece of the yoke. Tighten the left “U” Bolt and set screw on the clamp.

18

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model

Roller Assembly Procedures

Tools Required:

1 1/2” Wrench

One end plate of the roller has three (3) holes and the other end plate has six (6) holes.

Step 1

Starting with the end that has three (3) holes, bolt the bearing holder and bearing, using the bolts, lock

washers and washers. Do not tighten. Repeat on the other end.

Step 2

Slide the roller shaft into the roller from the six (6) hole side. This will align the bearing holders. Tighten

the bearing holders on both end plates.

19

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model

Roller Assembly Procedures – (Continued)

Step 3

Place the sprocket spacers over the remaining three (3) holes.

Install a “30 Tooth” sprocket using the bolts, lock washers and washers. Try to center the sprocket as

much as possible.

Make sure the roller spins freely. If prior to installation of the “30 Tooth” sprocket the roller spun freely,

but now does not, add a washer under each of the spacers.

20

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model – Trouble Shooting

“Reel doesn’t turn”

TURN OFF ENGINE

DISENGAGE

CLUTCH

DOES REEL TURN ADJUST REEL SEE

FREELY BY HAND NO INSTRUCTIONS

YES

REMOVE CHAIN

GUARDS

START ENGINE &

ENGAGE CLUTCH

REPLACE SET

IS ENGINE PULLEY

NO SCREWS AND/OR

TURNING?

KEY. SEE NOTE 2

YES

REPLACE BELT

IS BELT TURNING? NO AND/OR PULLEY.

SEE NOTE 2

YES

REPLACE SET

IS BOTTOM PULLEY

NO SCREWS OR PULLEY.

TURNING?

SEE NOTE 2

YES

IS THE 8 TOOTH

SPROCKET ON REPLACE SET

JACKSHAFT NO SCREWS. SEE

TURNING? NOTE 2

21

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model – Trouble Shooting

“Reel doesn’t turn” – (Continued)

YES

REPLACE 8 TOOTH

IS THE CHAIN

NO SPROCKET. SEE

TURNING?

NOTE 2

YES

IS DRIVESHAFT REPLACE

TURNING? SEE NO DRIVESHAFT. SEE

NOTE 1 NOTE 2

YES

IS 17 TOOTH REPLACE SET

SPROCKETS NO SCREWS. SEE

TURNING? NOTE 2

YES

REPLACE 17

IS CHAIN TURNING? NO TOOTH SPROCKET.

SEE NOTE 2

YES

IS FRONT SPROCKET REPLACE SET

SPINNING ON REEL YES SCREWS. SEE

SHAFT? NOTE 2

NO

CALL CALIFORNIA TRIMMER

OR VISIT

WWW.CALTRIMMER.COM

NOTE 1: LOOK AT SHAFT INSIDE 17 TOOTH OUSIDE SPROCKET.

NOTE 2: SHUT OFF ENGINE BEFORE ADJUSTING.

22

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model – Trouble Shooting

“Mower won’t propel itself”

TURN OFF ENGINE

DISENGAGE

CLUTCH

DOES REEL TURN ADJUST REEL SEE

FREELY BY HAND NO INSTRUCTIONS

YES

REMOVE CHAIN

GUARDS

START ENGINE &

ENGAGE CLUTCH

REPLACE SET

IS ENGINE PULLEY

NO SCREWS AND/OR

TURNING?

KEY. SEE NOTE 2

YES

REPLACE BELT

IS BELT TURNING? NO AND/OR PULLEY.

SEE NOTE 2

YES

REPLACE SET

IS BOTTOM PULLEY

NO SCREWS OR PULLEY.

TURNING?

SEE NOTE 2

YES

IS THE 8 TOOTH

SPROCKET ON REPLACE SET

JACKSHAFT NO SCREWS. SEE

TURNING? NOTE 2

23

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Home Owner Model – Trouble Shooting

“Mower won’t propel itself” – (Continued)

REPLACE 8 TOOTH

IS THE CHAIN

NO SPROCKET. SEE

TURNING?

NOTE 2

YES

IS DRIVESHAFT REPLACE

TURNING? SEE NO DRIVESHAFT. SEE

NOTE 1 NOTE 2

YES

IS 8 TOOTH REPLACE SET

SPROCKET NO SCREWS. SEE

TURNING? NOTE 2

YES

REPLACE 8 TOOTH

IS CHAIN TURNING? NO SPROCKET. SEE

NOTE 2

YES

DISASSEMBLE ROLLER

IS ROLLER SPINNING NO TO DETERMINE

PROBLEM. SEE NOTE 2

YES

ADJUST ROLLER LIFT

CHAIN. SEE NOTE 2

NOTE 1: LOOK AT SHAFT INSIDE 17 TOOTH OUSIDE SPROCKET.

NOTE 2: SHUT OFF ENGINE BEFORE ADJUSTING.

24

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Clutch Adjustment

Tools Required:

2 1/2” Wrenches

Pre-Adjustment Preparation

The air filters on some engines have an oil bath air filter and must be removed prior to tipping the mover

forward to adjust the clutch forks.

Step 1

Tip the mower forward up onto the front part of the frame so that the handle is resting on a table or work

bench. Or support the fuel tank with a block of wood or stand like pictured below.

25

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Clutch Adjustment – (Continued)

Clutch Adjustment Bolt

Part # 25321

The clutch spring is held in place by two clutch forks that are connected by the clutch adjustment bolt.

The clutch adjusting bolt has two nuts set together that hold the clutch forks and spring in position once it

has been adjusted to the proper tension. The inner nut is for adjusting the tension of the spring and the

outer jam nut, when tightened against the inner nut, secures the desired tension of the spring.

Adjusting the Clutch Spring Tension

Step 1

Disengage the clutch. This will allow the drive sprocket to move slightly to the right and to the left on the

drive shaft.

Step 2

Use one 1/2” wrench to hold the inner nut and the second 1/2” wrench to loosen the outer jam nut. Once

the outer jam nut is loosened, the inner nut can be turned clockwise to; compress the clutch spring,

widening the gap between the clutch pad and sprocket but decreasing the tension on the clutch, or

counter clockwise to; lessen the tension on the spring, decreasing the gap between the clutch pad and

sprocket and increase the tension on the clutch.

26

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Clutch Adjustment – (Continued)

The proper spacing for the clutch is about the thickness or a nickel or quarter. Press the drive sprocket

over toward the large fork. The proper spacing can be gauged between the clutch lining and the drive

sprocket.

Step 3

When proper clearance has been achieved retighten outer jam nut.

27

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Reel Adjustment

Tools Required:

1 Hammer

1 Screw Driver or Metal Rod/Punch, approx. 12” long

2 7/16” Wrenches

To determine Left or Right, position yourself in the operator’s position behind the mower.

The reel bearing holders are off centered and mounted to the side plates of the frame with the reel-shaft

hole toward the front to the mower at the 10 o’clock position on the left-hand side and the 2 o’clock

position on the right-hand side or the mower.

Step 1

Three bolts and the clamp ring secure the reel bearing holders to the frame. To make adjustments, first

loosen all the bolts approximately 1/4 of a turn. The left-side clamp ring has three threaded holes. Only

the bolts are loosened on the left side. On the right-side the unthreaded clamp ring is secured with three

sets of bolts and nuts.

28

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Reel Adjustment – (Continued)

Step 2

There two shoulders or “notch” studs on each reel bearing holder. Place the screw driver or metal punch

on the notch stud and using the hammer tap the studs down in the front on one side, then the other. This

moves the reel bearing holder, moving the reel blades down toward the cutter bar. The blades passing

over the cutter bar will make a whooshing or metal-to-metal scraping sound. If the reel blades are too

close to the cutter bar, and the reel will not spin, place the screw driver or metal on the “notch” studs on

the back side of the bearing holder closest to the grass shield, and using a hammer tap the bearing

holders up and then repeat the process to lower to desired position. This may take several attempts to

get the reel into the desired position.

29

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Reel Adjustment – (Continued)

Step 3

Take a piece of thin paper, such as from a phone book or newspaper. Place a small part of the paper

between the cutter bar and blade. Carefully turn the reel downward. If the blade and cutter bar are

aligned properly, the paper will be cut evenly, across the length or the cutter bar.

Step 4

Caution: Do not completely tighten nuts and bolts. This could cause the cutter bar and reel to come out

of adjustment.

When the reel is set in the desired position, begin tightening all nuts and bolts. Do not completely

tighten the nuts and bolts as this could cause the reel and cutter bar to come out of adjustment. Start

by snuggly securing all nuts and bolts, in a consecutive manor, gradually tighten each nut and bolt in

successive rotation until all are tight, securing reel gearing holders in the desired positions.

Step 5

After all nuts and bolts have been tightened, recheck the setting with a piece of thin paper as described

above. Sometimes during the tightening process, the reel can be shifted up, down or away from the

cutter bar. If necessary repeat the process.

30

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Roller Adjustment Procedures

Tools Required:

1 1/8” Allen Wrench

1 Screw Driver

2 7/16” Wrenches

CAUTION:

ALL ADJUSTMENTS MUST BE MADE WITH THE ENGINE TURNED OFF.

Step 1

Loosen roller “U” Bolts and set screws on both sides of the drive roller. This will loosen the drive roller on

the yoke.

Step 2

Pull the drive roller back, tensioning the chain taut. Make sure the drive roller is in the furthest position

from the drive shaft. If the drive roller is not in the furthest most position, the chain will become relaxed.

31

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Roller Adjustment Procedures – (Continued)

To Check

Move the drive roller up, past the furthest most position and the chain will become slack on top. Move the

drive roller down, past the furthest most position and the chain will become slack on the bottom. Make

sure the bolt heads on the sprocket clear the yoke when it spins. Tighten the “U” Bolt and set screw on

the right side.

Step 3

With the chain taught, in the furthest most position from the drive shaft, make sure the drive roller is

parallel to the back cross piece of the yoke. Tighten the left “U” Bolt and set screw on the clamp.

32

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Drive Shaft Disassembly

Tools Required:

1 5/32” Allen Wrench 1 Pulley Puller

1 Needle Nose Pliers 1 Hammer

2 1/2” Wrenches 1 Spring Compression Tool

Unbolt both chain guards and remove.

Remove all three (3) chains by removing their master links.

Remove the two (2) roller springs.

Disconnect the clutch rod from the clutch fork.

Remove the two (2) clutch forks and clutch adjustment bolt.

Unbolt the steady rest.

Remove the two (2) set screws from the 17 tooth outer sprocket.

Unbolt the bearing holders from the frame on both sides.

Remove the drive shaft assembly from the mower frame.

Using a pulley Puller, remove the bearing holder from the right side.

NOTE: Do not pull the bearing holder by it’s’ “ears”. This may cause them to break off.

Remove the wheel(s) and spacer(s).

Using a Pulley Puller, remove the bearing holder from the other side.

NOTE: Do not pull the bearing holder by the “ears”. This may cause them to break off.

Remove the wheel(s) and spacer(s).

Remove the set screws from the wheel set collar.

Slide the set collar off. You may need to tap the set collar with a hammer to remove it. Be careful not to

hit the drive shaft, this may cause damage to the drive shaft.

Remove the set screws from the roller drive sprocket and remove. Like the set collar you may need to

tap the sprocket with a hammer to remove it. Be careful not to hit the drive shaft, this may cause damage

to the drive shaft.

Slide the steady rest and small hard washer off.

Slide the spring compression tool on the shaft until it is touching the set collar in its extended length and

tighten it in place. Now loosen the set screws on the set collar and relieve t ension on the spring.

Remove the remaining parts.

33

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Drive Shaft Assembly

Tools Required:

1 5/32” Allen Wrench 1 Bearing Setting Tool

1 Needle Nose Pliers 1 Hammer

2 1/2” Wrenches 1 Spring Compression Tool

Secure the drive shaft, either by inserting the short end of the drive shaft into a hole in your work bench or

secure in a vice. Take care not to dent or mar the surface of the drive shaft.

Step 1

Make sure the drive shaft clutch plate is clean and dry.

The clutch lining has a solid black rubber side and a belted side.

Step 2

Place the lining with the solid black rubber side facing down, on the clutch plate of the drive shaft, and the

belted side facing up.

34

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Drive Shaft Assembly – (Continued)

Step 3

Install the 39 tooth sprocket. Make sure that it is clean and dry prior to installation. The 39 tooth sprocket

should spin freely on the drive shaft. You may need to install a small amount of grease to the inside of

the oilite bushing. If you do add grease to the bushing make sure that excess does not get on the clutch

lining.

If the 39 tooth sprocket does not spin freely, check the drive shaft and the bushing for galling, or

roughness.

Step 4

Install one small hard washer, the clutch spacer and the large hard washer. The large hard washer has a

rounded outer edge on one side and a square outer edge on the other. Be sure to put the rounded

edge towards the 39 tooth sprocket to avoid excessive wear to the clutch fork.

35

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Drive Shaft Assembly – (Continued)

Step 5

Install the clutch spring and set collar. Place the drive shaft in a vise, making sure to place a rag or

cloth between the jaws of the vice and the drive shaft in order to prevent marring or scratching the

surface of the drive shaft.

Step 6

Using a spring compression tool, compress the spring until it measures 4 3/8” in length, the 4 3/8” should

be the dimension of the compressed spring only.

36

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Drive Shaft Assembly – (Continued)

To compress, slide the spring compression tool, in it’s contracted length, onto the drive shaft and tighten

its two (2) set screws. Turn the bottom part of the spring compression tool until the desired measurement

of the spring is achieved. Tighten the two (2) set screws on the set collar. Be sure to use a liquid

thread lock on the set screws. Slowly loosen the tension on the spring compression tool by turning the

bottom, making sure the collar is holding securely in place. Loosen the set screws on the spring

compression tool and remove from drive shaft. Lightly file the two (2) indentations on the drive shaft, left

by the set screws, if needed. Check the length of the spring to make sure the collar stayed in place.

Step 7

On the shaft closest to the plate, install one wheel with the zerk fitting in the up position and grease the

wheel. Install two (2) wheel spacers. Install the second wheel with the zerk fitting in the up position. Lay

the bearing and holder on the wheel against the shaft. If the shaft protrudes higher than the bearing, add

additional shims until the top of the shaft is flush with the top on the bearing.

Install the bearing and holder with a driver. Make sure that the inner face of the bearing is not damaged

during installation. The bearing and wheels should spin freely.

37

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Drive Shaft Assembly – (Continued)

Step 8

Install the second small hard washer, steady rest, sprocket and set collar, as shown, on the other side of

the shaft. Put the rounded edge of the hard washer towards the steady rest. Leave the two (2) set

screws on the sprocket loose in order to align the sprocket with the roller sprocket after the drive shaft

assembly has been installed in the mower.

Leave the two (2) set screws on the set collar loose until after the wheels have been installed.

Install the steady rest as shown (grease zerk facing down)

Step 9

Install the first wheel on this side with the zerk fitting facing the spring. Install as many wheel spacers or

shims as you did during the installation of the first set of wheels on the other side to ensure even

placement of the wheels.

Install the second wheel with the zerk fitting facing the end of the drive shaft. Install the second bearing

and holder with a driver as before, making sure not to damage the bearing.

Step 10

Grease the remaining three (3) wheels and steady rest.

38

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Drive Shaft Assembly – (Continued)

Step 11

Install the assembled drive shaft into the mower frame.

Bolt the bearing holder to the frame, on the left-side, or the clutch side of the drive shaft.

Bolt the bearing holder to the frame on the other side.

Tap the end of the drive shaft to ensure it is seated completely in the left-side bearing holder.

Slide both wheels and set collar over, against the bearing holder and tighten the two (2) set screws.

Align the roller drive sprocket with the roller sprocket and tighten the two (2) set screws, be sure that one

of the set screws is tightening on the flat surface on the drive shaft. Install the roller chain and

roller springs.

Install the 17 tooth sprocket and tighten the two (2) set screws, be sure that one of the set screws is

tightening into the dimple on the drive shaft. Install chain and chain guard.

Install the engine chain and chain guard.

Install the two (2) clutch forks and clutch adjustment bolt.

Attach the clutch rod to the clutch fork.

Adjust the clutch. (See Clutch Adjustment on Page 28)

39

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Roller Assembly

Tools Required:

1 Bearing Driver

1 Hammer

1 1/2” Wrenches

Step 1

Install one bearing holder with the bearing on one side of the roller shaft.

One end plate on the roller is set deeper inside the roller than the other.

Step 2

Install roller shaft with the bearing holder on the plate that is set deeper. Use bolts, locks washers and

washers. Do not tighten at this time.

Step 3

Install a bearing holder with bearing on opposite end of the roller.

40

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial

Roller Assembly – (Continued)

Step 4

Install bolts, lock washers and washers. Tighten the bolts on both ends at this time.

Make sure the roller spins freely. If the roller does not spin freely one or both of the bearings may be

“locked” up on the shoulder of the roller shaft. Using a hammer, tap one or both sides of the roller shaft

until the roller spins freely.

Step 5

Place the sprocket spacer over the remaining three holes.

Step 6

Install the 30 tooth sprocket using bolts, lock washer and washers. Try the center the sprocket as much

as possible.

41

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Notes

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

42

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial – Trouble Shooting

“Reel doesn’t turn”

TURN OFF ENGINE

DISENGAGE

CLUTCH

DOES REEL TURN ADJUST REEL SEE

FREELY BY HAND NO INSTRUCTIONS

YES

REMOVE CHAIN

GUARDS

START ENGINE &

ENGAGE CLUTCH

IS ENGINE REPLACE SET

SPROCKET NO SCREWS. SEE

TURNING? NOTE 2

YES

REPLACE ENGINE

IS CHAIN TURNING? NO SPROCKET. SEE

NOTE 2

YES

IS BOTTOM 39 REPLACE

TOOTH SPROCKET NO SPROCKET. SEE

TURNING? NOTE 2

YES

ADJUST CLUTCH.

SEE INSTRUCTIONS

IS THE DRIVE NO #1

SHAFT TURNING?

SEE NOTE 1.

NO #2 DISASSEMBLE THE DRIVE

SHAFT TO DETERMINE THE 43

PROBLEM

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial – Trouble Shooting

“Reel doesn’t turn” – (Continued)

YES

IS THE 17 TOOTH REPLACE SET

SPROCKET NO SCREWS. SEE

TURNING? NOTE 2

YES

REPLACE 17

IS CHAIN TURNING? NO TOOTH SPROCKET.

SEE NOTE 2

YES

IS FRONT SPROCKET REPLACE SET

SPINNING ON REEL YES SCREWS. SEE

SHAFT? NOTE 2

NO

CALL CALIFORNIA TRIMMER

OR VISIT

WWW.CALTRIMMER.COM

NOTE 1: LOOK AT SHAFT INSIDE 17 TOOTH OUSIDE SPROCKET.

NOTE 2: SHUT OFF ENGINE BEFORE ADJUSTING.

44

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial – Trouble Shooting

“Mower won’t propel itself”

TURN OFF ENGINE

DISENGAGE

CLUTCH

DOES REEL TURN ADJUST REEL SEE

FREELY BY HAND NO INSTRUCTIONS

YES

REMOVE CHAIN

GUARDS

START ENGINE &

ENGAGE CLUTCH

IS ENGINE SPROCKET REPLACE SET

TURNING? NO SCREWS. SEE NOTE 2

YES

REPLACE ENGINE

IS CHAIN TURNING? NO SPROCKET. SEE

NOTE 2

YES

REPLACE

IS BOTTOM 39 TOOTH

NO SPROCKET. SEE

SPROCKET TURNING?

NOTE 2

YES

ADJUST CLUTCH.

SEE INSTRUCTIONS

IS THE DRIVE NO #1

SHAFT TURNING?

SEE NOTE 1. NO #2 DISASSEMBLE THE DRIVE

SHAFT TO DETERMINE THE

PROBLEM

45

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Heavy Duty & Commercial – Trouble Shooting

“Reel doesn’t turn” – (Continued)

YES

IS THE 17 TOOTH REPLACE SET

SPROCKET NO SCREWS. SEE

TURNING? NOTE 2

YES

REPLACE 17

IS CHAIN TURNING? NO TOOTH SPROCKET.

SEE NOTE 2

YES

IS FRONT SPROCKET REPLACE SET

SPINNING ON REEL YES SCREWS. SEE

SHAFT? NOTE 2

NO

CALL CALIFORNIA TRIMMER

OR VISIT

WWW.CALTRIMMER.COM

NOTE 1: LOOK AT SHAFT INSIDE 17 TOOTH OUSIDE SPROCKET.

NOTE 2: SHUT OFF ENGINE BEFORE ADJUSTING.

46

Downloaded from www.Manualslib.com manuals search engine

California Trimmer Mower

Maintenance Manual

Notes

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

47

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Husqvarna L 65 and L77 User Manual - 1978Document11 pagesHusqvarna L 65 and L77 User Manual - 1978lupusnoirNo ratings yet

- Pfaff 1029 Sewing Machine Instruction ManualDocument40 pagesPfaff 1029 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Koehring ManualDocument56 pagesKoehring ManualKyle A. Nolan100% (3)

- 3412 Test SpecDocument3 pages3412 Test SpecsxturboNo ratings yet

- Kent USA ML 1740 2080 Lathe ManualDocument106 pagesKent USA ML 1740 2080 Lathe Manualgohil abhijitNo ratings yet

- 3000 ManualDocument24 pages3000 ManualHotnCrispy CrispyNo ratings yet

- Session 11 - Optimisation of Roller Press SystemDocument58 pagesSession 11 - Optimisation of Roller Press Systemmahendra sen100% (4)

- Hawkjaw Jr. Manual 65K-950JR Serial Numbers 72 To 223Document155 pagesHawkjaw Jr. Manual 65K-950JR Serial Numbers 72 To 223MASAGUS MANGKU GAMANo ratings yet

- HDF 2.5 Owners Manual PDFDocument57 pagesHDF 2.5 Owners Manual PDFLara BarradoNo ratings yet

- Husqvarna SB Designer 1Document67 pagesHusqvarna SB Designer 1Anonymous OLRWS80% (1)

- Experiment 5 Flow Over Broad Crested WeirDocument5 pagesExperiment 5 Flow Over Broad Crested WeirKelly Obrien75% (4)

- L555D AL346V Lathe 11-1-16Document81 pagesL555D AL346V Lathe 11-1-16Ghodke ParmeshwarNo ratings yet

- G3406 Specifications (4FD, 5NW) SENR3863-01 (Oct 2000)Document39 pagesG3406 Specifications (4FD, 5NW) SENR3863-01 (Oct 2000)caterpillar etNo ratings yet

- Hawkjaw Jr. Manual 65K-ALS Serial Numbers 4 To 9 PDFDocument139 pagesHawkjaw Jr. Manual 65K-ALS Serial Numbers 4 To 9 PDFAnibal Jose Cruz LarezNo ratings yet

- Assetsfilespdfshawkjaw Sr. Manual ALS Serial Numbers 1 To 100.PDF 4Document159 pagesAssetsfilespdfshawkjaw Sr. Manual ALS Serial Numbers 1 To 100.PDF 4Luis Alfredo Mean LaraNo ratings yet

- Combine Harvesters MaintenanceDocument18 pagesCombine Harvesters MaintenanceSanjay v.r v.rNo ratings yet

- Pfaff 418, 438, 838 Service ManualDocument52 pagesPfaff 418, 438, 838 Service ManualTavi BoglutNo ratings yet

- Hawkjaw Sr. Manual M100K-2GSR Serial Numbers 201 To 370Document215 pagesHawkjaw Sr. Manual M100K-2GSR Serial Numbers 201 To 370sitaNo ratings yet

- Downloaded From Manuals Search EngineDocument30 pagesDownloaded From Manuals Search EngineSavery SaveryNo ratings yet

- Toro WheelHorse 48" Plow Blade 79253Document20 pagesToro WheelHorse 48" Plow Blade 79253Kevins Small Engine and Tractor ServiceNo ratings yet

- 2UVR-C Op ManualDocument10 pages2UVR-C Op Manualdanbeaman0% (1)

- DSR Ex 125Document120 pagesDSR Ex 125hugocalero4No ratings yet

- DTR Tokarka 330x600-800Document36 pagesDTR Tokarka 330x600-800riegerautoNo ratings yet

- Chery-QQ S11 Transmisión Parte 4Document17 pagesChery-QQ S11 Transmisión Parte 4limadacarlos100% (1)

- White 1766 Sewing Machine Instruction ManualDocument33 pagesWhite 1766 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Manual de Instalação WarnerDocument8 pagesManual de Instalação WarnerЭлектроника EletroeletrônicaNo ratings yet

- Hawkjaw Iron Roughneck 65K-950JR Operations Maintenance Parts ManualDocument155 pagesHawkjaw Iron Roughneck 65K-950JR Operations Maintenance Parts ManualFranklin Jose Almera AcostaNo ratings yet

- Disc Brake Installation & Service Manual: UK Head Office and Manufacturing USA SalesDocument16 pagesDisc Brake Installation & Service Manual: UK Head Office and Manufacturing USA SalesOrestis AgathokleousNo ratings yet

- Transpol 2Document46 pagesTranspol 2MarcusrezendejuniorNo ratings yet

- Hein Warner 10 10hd 12h SPM 9308130 Parts BookDocument4 pagesHein Warner 10 10hd 12h SPM 9308130 Parts Bookamy100% (43)

- Timberwolf TW 190TVGTR Wood Chipper Instruction ManualDocument56 pagesTimberwolf TW 190TVGTR Wood Chipper Instruction ManualthuanNo ratings yet

- LV14 - Manual Transmission Systems (1) - Issue 1 PDFDocument57 pagesLV14 - Manual Transmission Systems (1) - Issue 1 PDFĐức HòangNo ratings yet

- Standard FRN6 SRN9x Service ManualDocument67 pagesStandard FRN6 SRN9x Service ManualZorig IshdoNo ratings yet

- 175 PDFDocument44 pages175 PDFMichel L. TessierNo ratings yet

- Levas Luv DmaxDocument5 pagesLevas Luv DmaxSamuel da SilvaNo ratings yet

- Juki DLN6390Document52 pagesJuki DLN6390Raza SmartNo ratings yet

- 'M Im SM SM NM S: Section IndexDocument33 pages'M Im SM SM NM S: Section Indexsombra1970 gonzalezNo ratings yet

- WheelHorse Mid Mount 50 Inch Grader Blade 79351Document12 pagesWheelHorse Mid Mount 50 Inch Grader Blade 79351Kevins Small Engine and Tractor Service100% (1)

- Pfaff Hobby 340-751 Sewing Machine Instruction ManualDocument71 pagesPfaff Hobby 340-751 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- RTS TG M78Document9 pagesRTS TG M78woosah1234No ratings yet

- 185Document56 pages185NNo ratings yet

- Hawkjaw Sr. Manual 100K-2GSR Serial Numbers 101 To 120Document165 pagesHawkjaw Sr. Manual 100K-2GSR Serial Numbers 101 To 120ahnafNo ratings yet

- TR 14 01 30PMSDocument3 pagesTR 14 01 30PMSOliver JamesNo ratings yet

- 100K-2GSR - M100K HAWKJAW SR MANUAL Rev D PDFDocument217 pages100K-2GSR - M100K HAWKJAW SR MANUAL Rev D PDFNestor MorenoNo ratings yet

- 2016 Owners ManualDocument95 pages2016 Owners ManualBass is heavyNo ratings yet

- Manual XQ29-1.8 Power Tong - MotDocument27 pagesManual XQ29-1.8 Power Tong - MotPedro GilNo ratings yet

- AP Dynamometer ServiceDocument24 pagesAP Dynamometer ServiceAntonio DimaculanganNo ratings yet

- 2014+Gear+Up Patrol T ManualDocument95 pages2014+Gear+Up Patrol T ManualBass is heavyNo ratings yet

- BT49QT-9 - : User Manual, Service Schedule & HistoryDocument26 pagesBT49QT-9 - : User Manual, Service Schedule & Historysanja721No ratings yet

- Husqvarna Viking 1200Document61 pagesHusqvarna Viking 1200NletNo ratings yet

- XR843-B-Ops-Man-24980-000-C MANUAL OPERARIODocument82 pagesXR843-B-Ops-Man-24980-000-C MANUAL OPERARIOfercho_50No ratings yet

- Pfaff Tiptronic 1029Document40 pagesPfaff Tiptronic 1029Juhász MariannNo ratings yet

- Yanmar GMHMWorkshopManualDocument240 pagesYanmar GMHMWorkshopManualMarius Circeie100% (1)

- Mecanismo Reach RMD PDFDocument22 pagesMecanismo Reach RMD PDFfran reyNo ratings yet

- Lowlander MK4 Manure Spreader - Bunning Owners Manual PDFDocument120 pagesLowlander MK4 Manure Spreader - Bunning Owners Manual PDFДима ЧернеевNo ratings yet

- Specifications: Sec. 21.1 - Pg. 1/28Document18 pagesSpecifications: Sec. 21.1 - Pg. 1/28Petre LacatusuNo ratings yet

- Sprint 3000 Bookletmaker Service ManualDocument32 pagesSprint 3000 Bookletmaker Service ManualCaroline DanielNo ratings yet

- Pfaff 418, 438, 838 Service ManualDocument52 pagesPfaff 418, 438, 838 Service Manualrita.kulcsar.1990No ratings yet

- Pfaff Synchtronic 1229 Sewing Machine Instruction ManualDocument38 pagesPfaff Synchtronic 1229 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Iron Rougneck Hawkjaw SR 100K-2GSRREV01.BDocument155 pagesIron Rougneck Hawkjaw SR 100K-2GSRREV01.BTri CahyadiNo ratings yet

- Transmission ReportDocument22 pagesTransmission ReportKhánh Nguyên LêNo ratings yet

- BM 100Document11 pagesBM 100kaswade BrianNo ratings yet

- Control Valve CharacteristicsDocument5 pagesControl Valve CharacteristicsFarhan HazeeqNo ratings yet

- Article June 2023 Edition of World Pipelines Magazine 1692894876Document4 pagesArticle June 2023 Edition of World Pipelines Magazine 1692894876fahid masoodNo ratings yet

- HOS - PG1028E Mar2003Document164 pagesHOS - PG1028E Mar2003David QuijanoNo ratings yet

- Clause Out of Z662 For AttachmentsDocument1 pageClause Out of Z662 For AttachmentsRandy SauderNo ratings yet

- Circular Slabs - PpsDocument19 pagesCircular Slabs - PpssrivaruniNo ratings yet

- WSM 0000868 01Document59 pagesWSM 0000868 01Hariyanto oknesNo ratings yet

- FPT PBDocument18 pagesFPT PBBilly ZununNo ratings yet

- Metals: An Analysis of Creep Phenomena in The Power Boiler SuperheatersDocument12 pagesMetals: An Analysis of Creep Phenomena in The Power Boiler Superheatersbastian orellanaNo ratings yet

- A State-Of-The-Art Review On Fatigue Life Predicti PDFDocument15 pagesA State-Of-The-Art Review On Fatigue Life Predicti PDFAdnen LaamouriNo ratings yet

- Mechanism and Machine Theory: Roland Mathis, Yves RemondDocument13 pagesMechanism and Machine Theory: Roland Mathis, Yves RemondStefan IlicNo ratings yet

- HYDRAUL-EXPT#6 BDocument5 pagesHYDRAUL-EXPT#6 BJessicaTicse0% (1)

- Replacement: Power Steering Vane Pump (2Jz Ge)Document1 pageReplacement: Power Steering Vane Pump (2Jz Ge)Moh DeBrNo ratings yet

- Final - Me Lab 2 Lab ManualDocument58 pagesFinal - Me Lab 2 Lab ManualAdam MirandaNo ratings yet

- 1987 Book MathematicalAndComputationalAsDocument601 pages1987 Book MathematicalAndComputationalAsUnknown WKNo ratings yet

- PHYS 203: PHYSICS Department Faculty of Science King Abdulaziz UniversityDocument36 pagesPHYS 203: PHYSICS Department Faculty of Science King Abdulaziz Universitynouf AldosareNo ratings yet

- Principal Stress - Definition, Equation, Example, ExplainedDocument14 pagesPrincipal Stress - Definition, Equation, Example, ExplainedayetowodavidNo ratings yet

- The Basics of Lubricants For KunriDocument60 pagesThe Basics of Lubricants For KunriwaleedtanvirNo ratings yet

- Aqualung Micra Adj Service ManualDocument25 pagesAqualung Micra Adj Service ManualEUROTANK MARITIMENo ratings yet

- Brochure QAS Range English 4Document12 pagesBrochure QAS Range English 4ArturNo ratings yet

- Itp MechanicalDocument840 pagesItp MechanicalErwin SambasNo ratings yet

- Fluid Mechanics-Fluid Dynamics PDFDocument3 pagesFluid Mechanics-Fluid Dynamics PDFCristian OmacNo ratings yet

- Shell Omala HD: High Performance Synthetic Industrial Gear and Bearing OilsDocument2 pagesShell Omala HD: High Performance Synthetic Industrial Gear and Bearing Oilsabdul ahhadNo ratings yet

- ARCA Fly ReglerInstr GBDocument6 pagesARCA Fly ReglerInstr GBChanNo ratings yet

- 41 ThermoDynamics ThermoDynamics PDFDocument5 pages41 ThermoDynamics ThermoDynamics PDFmozam haqNo ratings yet

- Tutorial 9 Solutions PDFDocument20 pagesTutorial 9 Solutions PDFBharat SaiNo ratings yet

- Body-mounting-Manual HINODocument217 pagesBody-mounting-Manual HINOAlex Consuegra Medina100% (1)

- Exercise 1Document6 pagesExercise 1Ahmed EidNo ratings yet