Professional Documents

Culture Documents

WI - Hoist Duty Classification: Lootah Lemmens LLC

Uploaded by

Nguyen Chuyen0 ratings0% found this document useful (0 votes)

15 views1 pageThe duty classification of a hoist unit is based on its load spectrum, average operating hours per day, hoisting speeds, and environment. The load spectrum can be light, medium, heavy, or very heavy. The classification also considers average operating hours per day and is categorized from M3 to M8, with higher numbers indicating heavier use. The classification system aims to determine the appropriate duty for electric hoists based on their intended application and operating conditions.

Original Description:

hoist

Original Title

hoist

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe duty classification of a hoist unit is based on its load spectrum, average operating hours per day, hoisting speeds, and environment. The load spectrum can be light, medium, heavy, or very heavy. The classification also considers average operating hours per day and is categorized from M3 to M8, with higher numbers indicating heavier use. The classification system aims to determine the appropriate duty for electric hoists based on their intended application and operating conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageWI - Hoist Duty Classification: Lootah Lemmens LLC

Uploaded by

Nguyen ChuyenThe duty classification of a hoist unit is based on its load spectrum, average operating hours per day, hoisting speeds, and environment. The load spectrum can be light, medium, heavy, or very heavy. The classification also considers average operating hours per day and is categorized from M3 to M8, with higher numbers indicating heavier use. The classification system aims to determine the appropriate duty for electric hoists based on their intended application and operating conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

WI - Hoist Duty Classification

The duty classification of hoist unit is based on following:

1. loadspectrum

2. Average operating Hours per working day.

3. Hoisting Speeds

4. Environement

1). Loadspectrum

Light Medium Heavy Very Heavy

Load

Working Hours

COMPANY Average Operating Hours/day

HOIST DUTY CLASSIFICATION Electric Installation

Daily Load Spectrum

Typical Area of Application FEM % ED

Working ISO ASME GOST

Not Very

Valid Any Start / Stop Electric Light Medium Heavy

Hours European American Russian

More Motor Heavy

With Idle Powerhouse & utilities. Infrequent handling. Hoists used

Time 1-6 prima11y to install & service heavy equipment. Where loads M3 H1 1M 1 Bm 75 25 1-2 0.5-1 0.25-0.5 0.1-0.25

Months infrequently approach rated load.

Light machine shop, fabricating service, and maintenance.

4 Hours Loads and utilization randomly distributed. Rated loads M4 H2 2M 1Am 75 30 2-4 1-2 0.5-1 0.25-0.5

infrequently handled.

General machine shop, fabricating, assembly, storage, and

8 Hours warehousing. Loads and utilization randomly distributed. M5 H3 3M 2m 150 40 4-8 2-4 1-2 0.5-1

Total running time not over 25% of the work period.

High volume handling of heavy loads, frequently near rated

load in steel warehousing, machine and fabricating shops,

16 Hours M6 H4 4M 3m 300 50 8-16 4-8 2-4 1-2

mills, and foundries, with total running time not over 50%.

Of the work period.

Bulk handling of material in combination with buckets.

Magnets or other heavy attachments. Equipment often cab M7 H5 5M 4m 600 100 16-24 8-16 4-8 2-4

operated. Duty cycles approaching

24 Hours

continuous operation are frequently necessary. User must

specify exact details of operation, Including weight of

attachments.

M8 6M 5m ∞ 100 24 16-24 8-16 2-5

Lootah Lemmens LLC

PO BOX 7648, UAQ, UAE www.lootahlemmens.com

Tel. 00971 6 767 22 88 info@lootahlemmens.com

Fax. 00971 6 767 23 22

You might also like

- Reading A02wout AnsDocument4 pagesReading A02wout AnsTavi Nicolae67% (3)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Operator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesFrom EverandOperator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesRating: 5 out of 5 stars5/5 (3)

- Application Engineering BulletinDocument2 pagesApplication Engineering BulletinCesar G.No ratings yet

- MIT Hoist Catalogue PDFDocument12 pagesMIT Hoist Catalogue PDFSaúl Santamaría GutiérrezNo ratings yet

- Qualititative Test of Lipids and Preparation of Carboxylic Acid Salt From LipidsDocument6 pagesQualititative Test of Lipids and Preparation of Carboxylic Acid Salt From LipidsNurul Farhana NasirNo ratings yet

- Electric Wire Rope Hoists "MH" and "MHM" TypesDocument8 pagesElectric Wire Rope Hoists "MH" and "MHM" TypesKovács EndreNo ratings yet

- Duty RatingDocument2 pagesDuty RatingJuan Manuel RuedaNo ratings yet

- Cataloge Hoists 2009Document26 pagesCataloge Hoists 2009Erc Nunez VNo ratings yet

- Kumsan CatalogueDocument72 pagesKumsan Catalogueakın ersöz100% (1)

- Cmaa Fem HmiDocument3 pagesCmaa Fem HmiEric SalgadoNo ratings yet

- Open Winch: For Process Cranes and High CapacitiesDocument12 pagesOpen Winch: For Process Cranes and High CapacitiesFiroz PawaskarNo ratings yet

- V4000R43X保养规范Document52 pagesV4000R43X保养规范Amin GuiNo ratings yet

- Hoist & Endcarriage Selection Charts Selection ChartDocument67 pagesHoist & Endcarriage Selection Charts Selection ChartJDN Monocrane100% (1)

- Lecture 2Document11 pagesLecture 2Mostafa GadelrabNo ratings yet

- R-Type Hoist - Guide - EDocument8 pagesR-Type Hoist - Guide - EsmailialeeNo ratings yet

- HM I Hoist Duty ClassificationsDocument1 pageHM I Hoist Duty ClassificationsCesar NietoNo ratings yet

- NHP - Liquid Resitance Starters - M350 - LRS - OVERVIEWDocument5 pagesNHP - Liquid Resitance Starters - M350 - LRS - OVERVIEWRon BentleyNo ratings yet

- Gearmotor REMIDocument21 pagesGearmotor REMIManojNo ratings yet

- CM20170619 43609 08733Document26 pagesCM20170619 43609 08733Jonas CrixelNo ratings yet

- MS50096 - 07E - Maintenance ScheduleDocument52 pagesMS50096 - 07E - Maintenance ScheduleSladjanNo ratings yet

- Uzetne DizaliceDocument12 pagesUzetne DizaliceGogyNo ratings yet

- Power System ProtectionDocument12 pagesPower System ProtectionAkbarul KausarNo ratings yet

- EmucarshedghaziabadDocument34 pagesEmucarshedghaziabadShubham GuptaNo ratings yet

- Structures and Mechanisms ClassificationsDocument1 pageStructures and Mechanisms ClassificationsminakirolosNo ratings yet

- SANY ECH Brochure-112315Document18 pagesSANY ECH Brochure-112315李文鈞No ratings yet

- T7 BSI3 V 30Document24 pagesT7 BSI3 V 30ArabyAbdel Hamed SadekNo ratings yet

- Load Shedding Benefits SavingsDocument3 pagesLoad Shedding Benefits SavingsJoeDabidNo ratings yet

- 08 - LM6000 Gas Turbine MaintenanceDocument24 pages08 - LM6000 Gas Turbine MaintenanceMohamed Bin IerousNo ratings yet

- Obata - Grab Bucket Type Ship UnloaderDocument20 pagesObata - Grab Bucket Type Ship Unloadertrungnq_ktd97No ratings yet

- Aluminum Worm Gear Reducer IOM Manual PDFDocument10 pagesAluminum Worm Gear Reducer IOM Manual PDFkasparob25No ratings yet

- Hydraulic Pressure GaugeDocument1 pageHydraulic Pressure GaugeBob ForeverNo ratings yet

- Marine Engine Genset Product Guide PDFDocument104 pagesMarine Engine Genset Product Guide PDFHendriyana RizkyNo ratings yet

- Marine Engine Genset Product Guide PDFDocument104 pagesMarine Engine Genset Product Guide PDFRezha Maulana Kusuma A100% (1)

- Operation Manual Operation Manual Operation Manual Operation Manual &Document63 pagesOperation Manual Operation Manual Operation Manual Operation Manual &migueljesusmNo ratings yet

- Uncompromisingly Cost-Effective: Demag DC-Com Special Chain HoistDocument4 pagesUncompromisingly Cost-Effective: Demag DC-Com Special Chain HoistsarochimNo ratings yet

- PM Clinic WA500-6Document3 pagesPM Clinic WA500-6Naughty VongNo ratings yet

- Gar PPT PDFDocument18 pagesGar PPT PDFGilberto MejiaNo ratings yet

- ER2 Large Capacity Operator's ManualDocument48 pagesER2 Large Capacity Operator's ManualKito Canada100% (1)

- MS50095 - 08E ScheduleDocument33 pagesMS50095 - 08E Scheduletrainingcenter eurasiancmNo ratings yet

- Manual Tecle Electrico de Cadena TXKDocument38 pagesManual Tecle Electrico de Cadena TXKChristian Moreno Alvarez100% (2)

- Crane and Hoists ClassificationsDocument5 pagesCrane and Hoists ClassificationsAnonymous E0ZpSSA5No ratings yet

- SSD1Document88 pagesSSD1gabriel santhosh kumar gNo ratings yet

- Hydraulic TMT Bar BenderDocument2 pagesHydraulic TMT Bar BenderNikesh MoreNo ratings yet

- Geared Motor Catalogue-2018-19Document20 pagesGeared Motor Catalogue-2018-19velhankar.pushNo ratings yet

- Mumtaz Abbas: ContactDocument5 pagesMumtaz Abbas: ContactMuhammad Hamza NaveedNo ratings yet

- MV Circuit Breaker or Vacuum Contactor Part 1Document2 pagesMV Circuit Breaker or Vacuum Contactor Part 1hashimelecNo ratings yet

- Modec Case StudiesDocument15 pagesModec Case Studiessamah eskanderNo ratings yet

- Operation Manual &: Part ListDocument33 pagesOperation Manual &: Part ListMiguel Alfonso Ruiz MendezNo ratings yet

- ACCOLIFT CLH Electric Chain Hoists Installation Operation Maintenance and Parts ManualDocument98 pagesACCOLIFT CLH Electric Chain Hoists Installation Operation Maintenance and Parts ManualMiguel Alfonso Ruiz Mendez100% (1)

- Guascor F SF 180 Diesel EnginesDocument10 pagesGuascor F SF 180 Diesel EnginesXmenxs XmenxsNo ratings yet

- Guascor Marine Diesel Engines and SystemsDocument9 pagesGuascor Marine Diesel Engines and SystemsYans BalNo ratings yet

- Guascor F SF 360 Diesel EnginesDocument9 pagesGuascor F SF 360 Diesel EnginesØussåma SaidNo ratings yet

- Guascor F SF 480 Diesel Engines - 2Document9 pagesGuascor F SF 480 Diesel Engines - 2Xmenxs XmenxsNo ratings yet

- PM Clinic Wa500-6Document2 pagesPM Clinic Wa500-6Jose Miguel Oyola CoronadoNo ratings yet

- Yaleelectrictrolleymodel VTEFDocument7 pagesYaleelectrictrolleymodel VTEFSergio Hurtado AvellaNo ratings yet

- Caracteristicas Del Tecle TecleelectricoDocument32 pagesCaracteristicas Del Tecle TecleelectricoEdgar Julio Sara TairoNo ratings yet

- Choice (Or) Selection of Electrical Drives: Unit - I - Electric Drives Lecture-2Document3 pagesChoice (Or) Selection of Electrical Drives: Unit - I - Electric Drives Lecture-2Anup NaskarNo ratings yet

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Pump PerformanceDocument25 pagesPump PerformanceNguyen ChuyenNo ratings yet

- Sound Pressure: Pa (20 Micro Pascal, 0.02 Mpa)Document3 pagesSound Pressure: Pa (20 Micro Pascal, 0.02 Mpa)Nguyen ChuyenNo ratings yet

- Practices For Lurbricating Bearing in APIDocument6 pagesPractices For Lurbricating Bearing in APINguyen ChuyenNo ratings yet

- Motor Data For 55798Document1 pageMotor Data For 55798Nguyen ChuyenNo ratings yet

- LGLT 2: Grease SelectionDocument4 pagesLGLT 2: Grease SelectionNguyen ChuyenNo ratings yet

- You Can Use The Following Formula For Determining Stiffening Frame SizeDocument1 pageYou Can Use The Following Formula For Determining Stiffening Frame SizeNguyen ChuyenNo ratings yet

- DEMISTERDocument6 pagesDEMISTERNguyen ChuyenNo ratings yet

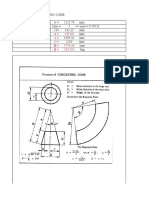

- Khai Trien Hinh ConeDocument4 pagesKhai Trien Hinh ConeNguyen ChuyenNo ratings yet

- 1,4-Butanediol: From Wikipedia, The Free EncyclopediaDocument11 pages1,4-Butanediol: From Wikipedia, The Free EncyclopediaNguyen ChuyenNo ratings yet

- Specific Heat Capacities of AirDocument13 pagesSpecific Heat Capacities of AirNguyen ChuyenNo ratings yet

- Dynamic, Absolute and Kinematic ViscosityDocument8 pagesDynamic, Absolute and Kinematic ViscosityNguyen ChuyenNo ratings yet

- External Pressure: 1 - The Basics - Failure MechanismsDocument18 pagesExternal Pressure: 1 - The Basics - Failure MechanismsNguyen ChuyenNo ratings yet

- 650-645 Design Requirements For Self-Supporting Roofs 9/24/07Document5 pages650-645 Design Requirements For Self-Supporting Roofs 9/24/07Nguyen ChuyenNo ratings yet

- Driving SystemDocument8 pagesDriving SystemNguyen ChuyenNo ratings yet

- Catalog - Extrusion Piston Pump PDFDocument76 pagesCatalog - Extrusion Piston Pump PDFNguyen ChuyenNo ratings yet

- A203Grf, A203 GR.F, A203 GR F, Steel Plate - SteelmaterialDocument2 pagesA203Grf, A203 GR.F, A203 GR F, Steel Plate - SteelmaterialNguyen ChuyenNo ratings yet

- Compact Exchangers For Demanding ApplicationsDocument4 pagesCompact Exchangers For Demanding ApplicationsNguyen ChuyenNo ratings yet

- PumpDocument9 pagesPumpNguyen ChuyenNo ratings yet

- Demister (Vapor)Document6 pagesDemister (Vapor)Nguyen ChuyenNo ratings yet

- Machines Application Notes Ask Application Submit Case HistoryDocument7 pagesMachines Application Notes Ask Application Submit Case HistoryNguyen ChuyenNo ratings yet

- Biological Monitoring: Pt. Indo TrainingDocument12 pagesBiological Monitoring: Pt. Indo TrainingnursusiartiNo ratings yet

- Tuning Solution V16.0.3.0Document16 pagesTuning Solution V16.0.3.0Amine HerbacheNo ratings yet

- E38 Closed Circuit Current TestDocument4 pagesE38 Closed Circuit Current TestCezaryCezasNo ratings yet

- Master Thesis In-Depth InterviewsDocument5 pagesMaster Thesis In-Depth Interviewsrqopqlvcf100% (1)

- Tom MCQ UNIT 2Document14 pagesTom MCQ UNIT 2Kumar PachareNo ratings yet

- Hicc CasestudyDocument19 pagesHicc CasestudyB-05 ISHA PATEL0% (1)

- AkbarDocument13 pagesAkbarNihar HarinkhedeNo ratings yet

- Seward Stomacher 400Document2 pagesSeward Stomacher 400ugomiesterNo ratings yet

- Roxas Claire B. Science Technology and Society 09 Activity 1Document1 pageRoxas Claire B. Science Technology and Society 09 Activity 1Eldrick Neil Reyes100% (1)

- Development LetterDocument3 pagesDevelopment Lettertan balanNo ratings yet

- Josef Suk-BagatellaDocument6 pagesJosef Suk-BagatellaAlessandro CaspaniNo ratings yet

- An Introduction To Mount EverestDocument4 pagesAn Introduction To Mount EverestJihad HasanNo ratings yet

- Autonomy of Art or Dignity of The Artwork? - Agnes HellerDocument20 pagesAutonomy of Art or Dignity of The Artwork? - Agnes HellerProfrFer100% (1)

- Abe Tos 2023Document28 pagesAbe Tos 2023DelenayNo ratings yet

- Sky SurfingDocument10 pagesSky SurfingCamila Soledad Aguilera PizarroNo ratings yet

- Critical Thinking and EBPDocument31 pagesCritical Thinking and EBPEni SukmawatiNo ratings yet

- 2.2 Crime Scene Investigation andDocument1 page2.2 Crime Scene Investigation andFatima Sarpina HinayNo ratings yet

- C2-Forecasting Demand & SupplyDocument31 pagesC2-Forecasting Demand & SupplyPRITHIVI KUMAR A R 1522554No ratings yet

- The Fashion SystemDocument8 pagesThe Fashion SystemPrincess Baik HatiNo ratings yet

- Crochet Pattern "Doll-Chamomile": TanaticrochetDocument9 pagesCrochet Pattern "Doll-Chamomile": TanaticrochetElene Lomidze100% (1)

- DLL - July 15 - Idiomatic ExpressionsDocument2 pagesDLL - July 15 - Idiomatic ExpressionsLenlen Santos Catinoy100% (1)

- OpenScapeBusiness V1 R2.1.0 Release Note V1.2.10 ExternDocument14 pagesOpenScapeBusiness V1 R2.1.0 Release Note V1.2.10 Externjan2No ratings yet

- EMPOWERMENT TECHNOLOGIES QUARTER 1 MODULE 3 Final 2 PDFDocument13 pagesEMPOWERMENT TECHNOLOGIES QUARTER 1 MODULE 3 Final 2 PDFJason GullaNo ratings yet

- Basic Survival Skills Training For Survival GroupsDocument5 pagesBasic Survival Skills Training For Survival GroupsevrazianNo ratings yet

- Material No 982981Document23 pagesMaterial No 982981Yelena ObyazovaNo ratings yet

- GSE580Document132 pagesGSE580Anonymous g4wR41qNeNo ratings yet

- Monet Brooks CV PDFDocument2 pagesMonet Brooks CV PDFMonet BrooksNo ratings yet

- Subject: SRE (Software Requirement Engineering) Topic: SRS Document of Project. Project: Medical Store Management. Group MembersDocument9 pagesSubject: SRE (Software Requirement Engineering) Topic: SRS Document of Project. Project: Medical Store Management. Group Membersabdullah amjadNo ratings yet