Professional Documents

Culture Documents

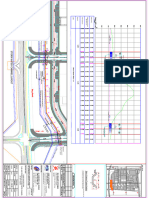

FTA157 Piping Plan Poster PDF

Uploaded by

Anatoli KarpobOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FTA157 Piping Plan Poster PDF

Uploaded by

Anatoli KarpobCopyright:

Available Formats

Mechanical Seal Piping Plans www.flowserve.

com

Plan 02 Single Seals Plan 03 Plan 11 Plan 13 Plan 14

What What What outlet

What What

Dead-ended seal chamber with Circulation created by the design inlet Seal flush from pump discharge Recirculation from seal chamber outlet Seal flush from pump discharge and

no flush. of the seal chamber. through orifice. to pump suction through orifice. recirculation to pump suction with orifices.

seal Why seal

Why Default single seal flush plan. seal Standard flush plan on vertical pumps. Combination of Plan 11 and Plan 13.

seal seal

end view No fluid recirculation needed. end view No external fluid recirculation end view Why end view end view Why

Where needed. Seal chamber heat removal. Why Continuous seal chamber venting

Cooling jacket seal chambers in high Solids removal from seal chamber. Seal chamber venting on horizontal Continuous seal chamber venting on vertical pumps.

temperature services. on vertical pumps. inlet

Where pumps. Seal chamber heat removal.

Clean fluids. Large bore/open throat seal Increase seal chamber pressure and Seal chamber heat removal. Increase seal chamber pressure

chambers. orifice orifice orifices

Top-entry mixers/agitators with dry fluid vapor margin. and fluid vapor margin.

seals. Dirty or contaminated fluids. Where Where Where

tapered bore seal chamber shown

Heating jacket seal chambers in fluids General applications with clean fluids. Vertical pumps. Vertical pumps.

that solidify at low temperatures. Clean, non-polymerizing fluids. Clean, non-polymerizing fluids

Seal chamber pressure is greater

than suction pressure. at moderate temperatures.

Moderate temperature fluids with

moderate solids.

Non-polymerizing fluids.

Plan 21 Single Seals Plan 23 Plan 31 Plan 32 Plan 41

vents, What What What inlet What vents, What

inlet normally closed Seal flush from pump discharge vent, normally closed Seal flush from internal pumping inlet Seal flush from pump discharge inlet normally closed Seal flush from pump discharge through

outlet Seal flush from an external clean

through orifice and cooler. device through cooler. through cyclone separator. source. cyclone separator and cooler.

cooling out cooling out cooling out

seal Cooler added to Plan 11 flush seal

Standard flush plan in hot water seal Centrifuged solids are returned seal Why seal Combination of Plan 21 and Plan 31.

end view increases heat removal. end view services. end view to pump suction. end view Seal chamber heat removal. end view Why

Why Why Why Process and solids removal from seal Seal cooling.

Seal cooling. inlet cooling coils Efficient seal cooling with low cooler Seal chamber heat removal. pressure flow control chamber.

cooler

valve cooling coils Solids removal from flush and seal chamber.

cooler cooling coils duty. Solids removal from flush and seal indicator Increase seal chamber pressure and cooler

Reduce fluid temperature to increase cyclone separator Where

fluid vapor margin. Increase fluid vapor margin. chamber. fluid vapor margin. High temperature service, typically less

cyclone

Reduce coking.

temperature Improve water lubricity. Where temperature flow Where separator than 177°C (350°F).

indicator Dirty or contaminated fluids, water indicator indicator strainer Dirty or contaminated fluids, paper

cooling in Where (optional) Dirty or contaminated fluids, water with sand

orifice cooling in Where with sand or pipe slag. (opitonal) pulp. cooling in

temperature High temperature service, hot temperature or pipe slag.

High temperature service, typically

indicator hydrocarbons. Non-polymerizing fluids. check valve from clean source, High temperature service. indicator Non-polymerizing fluids.

less than 177°C (350°F).

Boiler feed water and hot water normally open Polymerizing and/or oxidizing fluids. drain,

drain, Hot water over 80°C (180°F). drain,

normally normally over 80°C (180°F). normally

closed Clean, non-polymerizing fluids. closed closed

Clean, non-polymerizing fluids.

Plan 52 Dual Seals Plan 53A Plan 53B Plan 53C Plan 54 & 55

vent, pressure source, level

normally What What What level indicator transmitter What What

pressure normally open vent, pressure

open Unpressurized buffer fluid circulation outlet Pressurized barrier fluid circulation outlet Pressurized barrier fluid circulation outlet vent, normally closed Pressurized barrier fluid circulation outlet Pressurized barrier fluid circulation

outlet transmitter normally closed transmitter

through reservoir. through reservoir. with bladder accumulator. with piston accumulator. by external system.

pressure

seal

orifice

Fluid is circulated by a pumping ring seal

orifice

transmitter Fluid is circulated by a pumping ring in pressure source,

Fluid is circulated by a pumping ring

differential pressure

Fluid is circulated by a pumping ring seal

Plan 54 Why

seal normally closed in the dual seal assembly. seal transmitter Isolate process fluid.

end view in the dual seal assembly. end view the dual seal assembly. end view end view liquid fill, in the dual seal assembly. end view

finned

reservoir Why Why temperature Why normally Why Zero process emissions.

reservoir pipe

inlet liquid fill, Outboard seal acts as a safety backup liquid fill, Isolate process fluid. transmitter closed Isolate process fluid. Where

inlet (alternative Isolate process fluid. cooler

normally closed normally closed inlet inlet

to the primary seal. Zero process emissions. reservoir) Zero process emissions. inlet Zero process emissions. Used with pressurized dual seals.

level indicator level Zero to very low process emissions. level indicator level bladder piston

transmitter transmitter Where Higher pressure than Plan 53A. Higher pressure than Plan 53A.

accumulator accumulator

No process contamination is allowed. Used with dual pressurized seals. Where Dynamic tracking of system pressure. from/to external

temperature

Where High vapor pressure fluids, light Used with dual pressurized seals. barrier/buffer What

cooling coils cooling coils

indicator

drain, normally closed Where circulating system

Used with dual unpressurized seals. hydrocarbons. liquid fill, Used with dual pressurized seals. Unpressurized buffer fluid circulation

High vapor pressure fluids, light

normally closed by external system.

cooling out cooling in High vapor pressure fluids, light cooling out cooling in Hazardous/toxic fluids. hydrocarbons. High vapor pressure fluids, light

hydrocarbons. Heat transfer fluids. drain, Hazardous/toxic fluids. temperature hydrocarbons. Plan 55 Why

Hazardous/toxic fluids. indicator Outboard seal acts as a safety

drain, drain, Dirty/abrasive or polymerizing fluids. normally Heat transfer fluids. Hazardous/toxic fluids.

(optional) backup to the primary seal.

normally Heat transfer fluids. normally closed

Mixers/agitators and vacuum service. Dirty/abrasive or polymerizing fluids. Heat transfer fluids. Zero to very low process emissions.

closed closed

No process contamination is allowed.

Where

Used with unpressurized dual seals.

Plan 62 Quench Seals Plan 65A Plan 65B Plan 66A Plan 66B

What What What What

What

External quench on atmospheric side External drain with leakage detection Leakage detection on atmospheric side Leakage detection on atmospheric side

External drain with leakage detection

of seal. on atmospheric side of seal. of seal utilizing two throttle bushings in of seal utilizing a throttle bushing and

inlet level on atmospheric side of seal. PIT

Quench fluids typically steam, nitrogen, level PIT pressure series. pressure orifice plug.

seal seal transmitter overflow Why seal

transmitter Why seal seal

end view or water. end view end view overflow

Leakage collection to detect for

end view indicator Why end view indicator Why

chamber Safety indicator for primary seal block chamber

Drain connection to be larger than inlet block

process leakage. transmitter Safety indicator for primary seal to transmitter Safety indicator for primary seal detects

detects failure. valve,

connection. valve, (PIT) detect failure. (PIT) failure.

drain normally Where drain normally Safety indicator to detect seal failure. drain drain

drain Why Minimize leakage from seal gland in Where

open May be used alone or with Plan 62 open Continuous monitoring of leakage case of seal failure. May be used alone or with Plan 65A

for proper orientation

Prevent solids buildup on atmospheric quench.

for proper orientation

Drain - see end view

rates to atmosphere.

Drain - see end view

quench, side of seal. Where or Plan 65B.

normally open Used with close clearance throttle bypass Where

check

Prevent icing.

bypass May be used alone or with Plan 65A Used with close clearance throttle

bushing. line Used with close clearance throttle

valve line drain, see end view or Plan 65B. drain, see end view bushing.

drain, see end view Where Useful with single seals in remote bushing. for proper orientation

Used with single seals. orifice drain valve, for proper orientation Used with flashing or non-flashing Used with flashing or non-flashing fluids.

for proper orientation locations and critical services. Used with non-flashing, condensing

normally closed fluids. Useful when adding atmospheric side

Oxidizing fluids or fluids that coke, hot fluids.

hydrocarbons. Useful with single seals in remote loca- leakage detection to an existing seal.

Useful with seals in remote locations tions and critical services.

Crystallizing fluids or fluids that salt and critical services. Useful with single seals in remote

drain, orifice

out. drain Used with close clearance throttle locations and critical services.

normally plug

bushings.

Caustic. open

Cold fluids less than 0°C (32°F).

Plan 72 Gas Seals Plan 74 Plan 75 Plan 76 Good Piping Practices

What What What What Minimize line losses Use long radius bends

vent Plan 53A Plan 23

vent Unpressurized buffer gas control Pressurized barrier gas control pressure Drain from containment seal cavity Vent from containment seal cavity

transmitter vent, Use large diameter Minimize component losses

system. flow coalescing system. vent, to liquid collector and vapor recovery. to vapor recovery. example example

normally open tubing Optimize for thermosyphon

transmitter filter test isolation normally

flow transmitter coalescing Containment seal support typically Gas seal support typically with seal Why seal Why Only upward sloping

seal seal connection valve open Check rotation direction

end view regulator filter with nitrogen buffer gas. end view check regulator nitrogen barrier gas. end view Leakage collection for zero to very low end view Leakage collection for zero to very low high point vent

inlet lines. Slope shall be

check valve Why inlet valve Why process emissions. process emissions. Test for leaks

level orifice orifice 40 mm/m (0.5 in/ft).

Zero to very low process emissions. Isolate process fluid. indicator Safety indicator for primary seal. drain Safety indicator for primary seal.

drain drain drain pressure

gas inlet, Safety backup to primary seal. gas inlet, Zero process emissions. Where Where

transmitter

for proper orientation

May be used alone or with Plan 72 drain, May be used alone or with Plan 72

Drain - see end view

vent normally open Where drain, normally open Where

Used with dual unpressurized normally Used with dual pressurized gas seals. on containment seals. normally on containment seals.

filter drain, containment seals. closed Fluids that condense at ambient closed Fluids that do not condense at ambient

filter drain, High vapor pressure fluids, light level

drain normally closed temperature. temperature.

High vapor pressure fluids, light normally closed hydrocarbons. transmitter

drain,

pressure hydrocarbons. Hazardous/toxic fluids.

reservoir located High vapor pressure fluids, light High vapor pressure fluids, light

orifice normally closed

transmitter Hazardous/toxic fluids. below seal drain port hydrocarbons. hydrocarbons.

pressure Services that do not tolerate liquid

Clean, non-polymerizing, barrier seals. Hazardous/toxic fluids. Hazardous/toxic fluids.

transmitter drain,

non-oxidizing fluids. Clean, non-polymerizing fluids. normally Clean, non-polymerizing, non-oxidizing Clean, non-polymerizing, non-oxidizing

Used in combination with Plan 75 closed fluids. fluids. 0.91 m (3 ft)

Moderate temperature fluids. 0.45 - 0.60 m

and/or Plan 76. normal liquid level

(1.5 - 2 ft)

seal end view

FTA157eng REV 12-14

Experience in Motion © 2014 Flowserve Corporation

low point drain

1.2 m (4 ft) max

low point drain

0.9 m (3 ft) max

You might also like

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- g3616 A4 Lehw0198 FinalDocument4 pagesg3616 A4 Lehw0198 FinalVictor NunezNo ratings yet

- Gabbioneta RDocument6 pagesGabbioneta Rvrider81No ratings yet

- API 618 Compressors1 PDFDocument0 pagesAPI 618 Compressors1 PDFAnonymous ffje1rpaNo ratings yet

- Gas Engine - MountingDocument22 pagesGas Engine - MountingMauro DiazNo ratings yet

- Waukesha Knock Index Power CurveDocument1 pageWaukesha Knock Index Power CurveparathasiNo ratings yet

- Single-Stage Steam TurbinesDocument8 pagesSingle-Stage Steam Turbinesfouzi gherNo ratings yet

- L7042GDocument2 pagesL7042GRose MarieNo ratings yet

- Ficha Técnica - ElectricaDocument8 pagesFicha Técnica - ElectricainspeccionestecnicasnfpaNo ratings yet

- AJI20024 Ajax Integral Engine Compressor DPC 2804 r0 WebDocument2 pagesAJI20024 Ajax Integral Engine Compressor DPC 2804 r0 WebfsajnmasNo ratings yet

- Rod ReversalDocument21 pagesRod ReversalandresNo ratings yet

- UPA Type Series BookletDocument122 pagesUPA Type Series BookletRicardo BarrosNo ratings yet

- API 692 Seal Gas Filters & SeparatorsDocument4 pagesAPI 692 Seal Gas Filters & SeparatorsTasawwur Tahir100% (1)

- NIC 13.20 Rev.01Document15 pagesNIC 13.20 Rev.01Mahmoud Ahmed100% (1)

- Ariel Compressor InfoDocument439 pagesAriel Compressor InfojimeneajNo ratings yet

- Case Study SentinelDocument2 pagesCase Study Sentinelashumishra007No ratings yet

- Plunger PumpDocument8 pagesPlunger Pumpmember1000No ratings yet

- 04-Unit - Force Feed Lubrication SystemDocument38 pages04-Unit - Force Feed Lubrication SystemKavi BhandariNo ratings yet

- Sehs8984 01Document11 pagesSehs8984 01NimNo ratings yet

- API 676 Datasheet PDFDocument6 pagesAPI 676 Datasheet PDFPierre Norris0% (1)

- LM6000 Sampling Procedure With SpecificationsDocument18 pagesLM6000 Sampling Procedure With SpecificationsDario100% (1)

- ES9-414 Leveling Install - CDocument29 pagesES9-414 Leveling Install - CIfran Sierra100% (1)

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- PumpsDocument19 pagesPumpsIon_Riswan100% (1)

- Ariel Air CompressorDocument4 pagesAriel Air CompressorCelso FernandesNo ratings yet

- 2652 Duplex Piston Pump Mud PumpDocument2 pages2652 Duplex Piston Pump Mud Pumpalfonsoar447370100% (1)

- Roto JetDocument0 pagesRoto JetHernan GirautNo ratings yet

- S-8B1 8B1TDocument6 pagesS-8B1 8B1TbryandownNo ratings yet

- New Cardrige Design - BRXsealDocument15 pagesNew Cardrige Design - BRXsealobumuyaemesi100% (1)

- Ajax Cause & EffectDocument3 pagesAjax Cause & EffectgustavoespinosamNo ratings yet

- Aftercooler Parts For Qsk60 Gas EngineDocument3 pagesAftercooler Parts For Qsk60 Gas EngineMuhammad IshfaqNo ratings yet

- Ariel Calculation MethodDocument6 pagesAriel Calculation MethodSubrata Mukherjee100% (1)

- Flowserve Mechanical Seal PlanDocument56 pagesFlowserve Mechanical Seal PlanAnonymous 1XHScfCINo ratings yet

- Special Edition Tensioner JuneDocument3 pagesSpecial Edition Tensioner JuneDjebali MouradNo ratings yet

- Force Feed Lubrication Sysytem ImprovementsDocument8 pagesForce Feed Lubrication Sysytem Improvementsdiego yecid millan mendozaNo ratings yet

- KCDocument3 pagesKCSandheepKumarNo ratings yet

- Technical Manual For Models JGZ and JGU PDFDocument211 pagesTechnical Manual For Models JGZ and JGU PDFjudarangoca100% (2)

- 03 Product OverviewDocument44 pages03 Product OverviewMamdouh ElhanafyNo ratings yet

- BorsigDocument37 pagesBorsigChup AlaNo ratings yet

- 20 RR NOV 300Q-5 Technical Data SheetsDocument2 pages20 RR NOV 300Q-5 Technical Data SheetsJorge SoriaNo ratings yet

- Hoer CT Valve 2Document5 pagesHoer CT Valve 2Tu PhamNo ratings yet

- Hi-T Pigalert IOM ManualDocument14 pagesHi-T Pigalert IOM ManualRaghNo ratings yet

- Training CompresorDocument18 pagesTraining Compresorpatrask0% (1)

- VOITH Vorecon Variable Speed Panetary GearDocument8 pagesVOITH Vorecon Variable Speed Panetary GearFrank PuchiNo ratings yet

- Guascor SFGLD 480 Lean Burn Gas Engine: DimensionsDocument2 pagesGuascor SFGLD 480 Lean Burn Gas Engine: DimensionsEdu Lopez GarciaNo ratings yet

- Compresor GasDocument16 pagesCompresor GasvallenatoNo ratings yet

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDocument8 pagesMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaNo ratings yet

- 10418AE0026-30 - Rev - 0 Rev CCDocument43 pages10418AE0026-30 - Rev - 0 Rev CCcecilNo ratings yet

- PIL140 Dry Gas Face Seals Rev 12aDocument13 pagesPIL140 Dry Gas Face Seals Rev 12ampiumettiNo ratings yet

- Dry Gas Seal, Final PresentationDocument20 pagesDry Gas Seal, Final Presentationwaqas pirachaNo ratings yet

- DN DN: Main Switchboard Aft 4000x500x1800Document1 pageDN DN: Main Switchboard Aft 4000x500x1800Costel Ava ConstantinNo ratings yet

- Form Development: Design 3: Library ProjectDocument1 pageForm Development: Design 3: Library Projectأحمد العراقيNo ratings yet

- Report On Issues Observed in Waterproofing Apllication at B6 L07 Cleaning Room and Disable BathroomDocument4 pagesReport On Issues Observed in Waterproofing Apllication at B6 L07 Cleaning Room and Disable BathroomYasith AbeywickramaNo ratings yet

- Ac17 Pen SetsDocument1 pageAc17 Pen SetsMoezart JsNo ratings yet

- Sayy Road Open ChannelDocument1 pageSayy Road Open Channelparanidharan KaliyamurthyNo ratings yet

- Plano Electrico 777fDocument4 pagesPlano Electrico 777fTERONo ratings yet

- Model Jockey Pump Controller:JP3: Wiring SchematicDocument2 pagesModel Jockey Pump Controller:JP3: Wiring SchematicUmair BaBer100% (1)

- Q17017 0100D PK4b (Ii) A TD GN MI 801 1OF1 REV00Document1 pageQ17017 0100D PK4b (Ii) A TD GN MI 801 1OF1 REV00Elektrikal InhinyeroNo ratings yet

- Castle in The Sky - PartsDocument3 pagesCastle in The Sky - PartsLucaNo ratings yet

- CHP 55Document26 pagesCHP 55Gloria HamiltonNo ratings yet

- Guidelines For Entry Travel Pass Applications To Enter Brunei DarussalamDocument2 pagesGuidelines For Entry Travel Pass Applications To Enter Brunei DarussalamGloria HamiltonNo ratings yet

- Megger Testing 3-Phase MotorsDocument2 pagesMegger Testing 3-Phase MotorsGloria Hamilton100% (1)

- Immersible Thermal Gas Mass Flow Meter: FeaturesDocument8 pagesImmersible Thermal Gas Mass Flow Meter: FeaturesGloria HamiltonNo ratings yet

- Flameproof Motors: Aluminium 56-180Document32 pagesFlameproof Motors: Aluminium 56-180Gloria Hamilton100% (1)

- 67 - Interface Switching Cabling PDFDocument142 pages67 - Interface Switching Cabling PDFGloria HamiltonNo ratings yet

- Interlock Logic Diagram NH3Document1 pageInterlock Logic Diagram NH3Gloria HamiltonNo ratings yet

- 6400t Rev-BDocument4 pages6400t Rev-BGloria HamiltonNo ratings yet

- IM10A (Globe Valves For LP&MP Service Ammonia)Document118 pagesIM10A (Globe Valves For LP&MP Service Ammonia)Gloria HamiltonNo ratings yet

- Masoneilan 80000 Data SheetDocument24 pagesMasoneilan 80000 Data SheetGloria HamiltonNo ratings yet

- Compressor Station (Specification 98A)Document2 pagesCompressor Station (Specification 98A)Gloria HamiltonNo ratings yet

- Centum VP Engineerinig Training ReportDocument11 pagesCentum VP Engineerinig Training ReportGloria HamiltonNo ratings yet

- Bap - Bwro SystemDocument55 pagesBap - Bwro SystemGloria HamiltonNo ratings yet

- 4-20 Ma To Current Converter: P/N: IC-DR-XX and AX130300Document3 pages4-20 Ma To Current Converter: P/N: IC-DR-XX and AX130300Gloria HamiltonNo ratings yet

- Arya General Cata 2016Document12 pagesArya General Cata 2016Gloria HamiltonNo ratings yet

- APPENDIX I: UF Operation Timing Chart: Description Tag No. Type of Valve Filtration (Normal)Document3 pagesAPPENDIX I: UF Operation Timing Chart: Description Tag No. Type of Valve Filtration (Normal)Gloria HamiltonNo ratings yet

- 07 - Engine Safety ModuleDocument36 pages07 - Engine Safety ModuleGloria Hamilton75% (4)

- Bap - Uf SystemDocument88 pagesBap - Uf SystemGloria HamiltonNo ratings yet

- Bap - MBP SystemDocument93 pagesBap - MBP SystemGloria HamiltonNo ratings yet

- System DescriptionDocument28 pagesSystem DescriptionGloria HamiltonNo ratings yet

- Bap - Swro SystemDocument104 pagesBap - Swro SystemGloria Hamilton100% (1)

- 08 Unic C3Document49 pages08 Unic C3Gloria HamiltonNo ratings yet

- Control Loops For BoilerDocument23 pagesControl Loops For BoilerGloria HamiltonNo ratings yet

- Shaping Machine & Its OperationsDocument25 pagesShaping Machine & Its OperationsvineethNo ratings yet

- M Beam Details1Document5 pagesM Beam Details1AATVIK SHRIVASTAVANo ratings yet

- 2 ShaftsDocument24 pages2 Shaftsrdksj100% (1)

- FADS Local Materials (Additional For FAAST, Intrinsic Safe Detector)Document2 pagesFADS Local Materials (Additional For FAAST, Intrinsic Safe Detector)Faruk HossainNo ratings yet

- Basic Equipment in Material TestingDocument2 pagesBasic Equipment in Material TestingGian Aizel JavierNo ratings yet

- Accessories: Tip and Volume Extraction AccessoriesDocument2 pagesAccessories: Tip and Volume Extraction AccessoriesYing Kei ChanNo ratings yet

- 11111111Document12 pages11111111hari prasadNo ratings yet

- One Touch Fittings PDFDocument11 pagesOne Touch Fittings PDFMohan ShanmugamNo ratings yet

- Section 2 QuestionsDocument2 pagesSection 2 QuestionsSameer MohammadNo ratings yet

- Navigator v17Document60 pagesNavigator v17Carlos CapeloNo ratings yet

- Sample Submission Cover Sheet: Q Q Q Q Q Q Q Q QDocument5 pagesSample Submission Cover Sheet: Q Q Q Q Q Q Q Q QMURALIDHRANo ratings yet

- Sumner Welding CatalogDocument44 pagesSumner Welding CatalogbetokarNo ratings yet

- KCX English Jan 18 FinalDocument8 pagesKCX English Jan 18 FinalDaniel WijayaNo ratings yet

- Built in - SP - Bi B (E) 07cDocument4 pagesBuilt in - SP - Bi B (E) 07cpc100xohmNo ratings yet

- Material Handling Study Report For Removable Tube BundleDocument9 pagesMaterial Handling Study Report For Removable Tube BundleMohamed FarisNo ratings yet

- 021c99s2c06 PDFDocument36 pages021c99s2c06 PDFkamaveriyanNo ratings yet

- RTJ Gasket Catalogue Rev3Document9 pagesRTJ Gasket Catalogue Rev3MJ MagdyNo ratings yet

- Bolts and Nuts-BasicDocument12 pagesBolts and Nuts-BasicGaming channelNo ratings yet

- PDF Soal Pas PBSM Kunci Jawaban Final - CompressDocument6 pagesPDF Soal Pas PBSM Kunci Jawaban Final - Compressnajmudin12No ratings yet

- Worksheet On Pneumatic CircuitDocument2 pagesWorksheet On Pneumatic CircuitSamuel WozabNo ratings yet

- Sem 656DDocument2 pagesSem 656DwaslimNo ratings yet

- Slab, Coloumn Check ListDocument8 pagesSlab, Coloumn Check ListsuniljhilmilNo ratings yet

- Client: Public Authority For Water (PAW), OmanDocument50 pagesClient: Public Authority For Water (PAW), OmanKoshy Thankachen100% (1)

- Heat Balance DiagramDocument10 pagesHeat Balance DiagramJitendra Bhatia100% (3)

- Specification of StrainerDocument3 pagesSpecification of StrainermishtinilNo ratings yet

- MSTE DIAGNOSTIC EXAM (Civil Engineering)Document10 pagesMSTE DIAGNOSTIC EXAM (Civil Engineering)Christian Kerr Dela CernaNo ratings yet

- Breathtester PiecesDocument5 pagesBreathtester PiecesPKMNo ratings yet

- Rotary Vane: Maintenance and Service ManualDocument12 pagesRotary Vane: Maintenance and Service Manualjorge lopez100% (1)

- Swimming Pool E-01Document1 pageSwimming Pool E-01Madelo, Allysa Mae, M.No ratings yet

- Scope of Work & Detailed Technical SpecificationDocument9 pagesScope of Work & Detailed Technical SpecificationBoson FreelancerNo ratings yet