Professional Documents

Culture Documents

Managing Your Silage-Making: What's in This Section?

Uploaded by

Ihsan HarjantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Managing Your Silage-Making: What's in This Section?

Uploaded by

Ihsan HarjantoCopyright:

Available Formats

9 Managing your

silage-making

9 Managing your silage-making

Objective:

• To produce high intake silage with maximum What’s in

this section?

efficiency by reducing field and clamp losses.

Challenge:

• Understanding fermentation

• Ensure your silages have high nutritional value

and a stable lactate fermentation • The importance of grass quality

• Reduce your actual cost of utilised silage DM • Making good quality clamp silage

by 10% this year. • Estimating clamped

silage quantities

Target • Making good quality

baled silage.

Make consistently good quality silage for less than

£109/tonne utilised DM.

Good Silage Time After Time

Experience shows that consistently good silage

Contents

results from attention to detail at all stages of silage The Fermentation Process Page 9:3

making – in the field, ensiling and at feed out. The Importance of Grass Quality Page 9:4

Time invested in producing well preserved silage Making Clamp Silage Page 9:7

has been shown to pay handsome dividends Big Bale Silage Page 9:11

throughout the winter – reducing concentrate

feed requirements by up to 2kg/hd/day.

There is no reason why well made big bale

silage should not be of similar quality and

nutritional value to clamp silage. Bales are not

necessarily more expensive than clamp silage.

Improvement through grassland management 9:1

Action plan

To make consistently good quality silage for less than £109/tonne utilised DM.

1. Make Good Quality Clamp Silage 4. Make Good Quality Big

Bale Silage

Cut and ensile your grass quickly and cleanly

from leafy swards with the best all-round practice Cut, bale and wrap your grass quickly and cleanly

for the greatest value at least cost (Page 9:7). from leafy swards with the best all-round practice

for the greatest value at least cost (Page 9:11).

2. Manage Your Silage Effluent

5. Assess Big Bale Silage Stocks

Store and spread or feed all your silage effluent

effectively to make the most of it while preventing Make good estimates of your actual big bale silage

pollution (Page 9:8). dry matter stocks throughout the season as the basis

for their most efficient management (Page 9:12).

3. Assess Clamped Silage Stocks

Make good estimates of your actual clamp silage

dry matter stocks throughout the season as the basis

for their most efficient management (Page 9:9).

9:2 Improvement through grassland management

The fermentation process

A good understanding of the fermentation process

is essential if you are to produce high quality

silage. The processes of converting fresh forage

into preserved silage involves four main stages

and is the same in bale or clamp (Figure 9.1).

Figure 9.1: The Fermentation Process Under Good Ensiling Techniques

Aerobic • Lasts a few hours

Stage • Oxygen levels are reduced

• Enzymes remain active while pH is 5.5-6.5

Fermentation • Begins when all the oxygen in the silo has been used up (anaerobic)

Stage • Can last several weeks – but the quicker the better

• Lactic acid dominates

• pH drops 3.7-5.0

Storage • Acidic conditions limit microbial activity providing the silo is airtight and a stable

Stage low pH has been achieved

• Micro-organism populations gradually decline

• Some microbes can remain active particularly if pH is not low enough

• Clostridia and bacilli can survive as spores

Feeding • Aerobic spoilage starts on exposure to air

Stage • Yeasts degrade preserving acids

• pH rises and heat is generated

• Moulds begin to grow and can produce harmful mycotoxins

• Aerobic spoilage will be minimised by good clamp management techniques

It is essential when ensiling to exclude as much air as

possible to achieve a strong lactic acid fermentation

– dropping the pH as quickly as possible and

restricting the activity of undesirable bacteria.

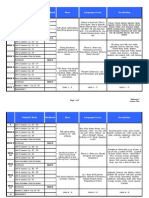

Table 9.1: Maximum pH Required to Produce Well Fermented Silage at Different Ranges of DM

DM range % <18 18-20 20-22 22-24 24-26 26-28 28-30 >30

pH required 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.8

Improvement through grassland management 9:3

The importance of grass quality

Grass Qualities for Good

Fermentation Failing to account for the nitrogen

content in slurry is a frequent cause

The rapid multiplication of lactic acid bacteria which of high nitrate levels in silage.

is needed to drop pH rapidly requires an energy

source – grass sugars. Without a good level of grass

sugars (often termed water soluble carbohydrates or

WSC) fermentation is likely to be slow and poor. Dry matter content – 25-30% in clamp (10%

higher in bales) silage dry matters of 2-3%

A minimum WSC content of 3% in the fresh crop below the above range can be fed but

is required will compromise dry matter intakes.

WSC levels in grass are highly variable but a

few basic rules can help to maximise levels. The lower the dry matter content

of the forage the more acid is

• High sugars are associated with dry

sunny weather – and are further boosted required to preserve it, so the

by cold night time temperatures lower the pH needs to be.

• Grass sugars peak in the afternoon

• Traditionally tetraploid varieties have had

higher sugar levels than diploids. IGER

have produced high sugar diploids with The higher the dry matter of

superior sugar levels to most tetraploids the forage the harder it is to

consolidate, so the more difficult it

• Legumes are inherently low in sugars.

is to create anaerobic conditions,

Nitrate-nitrogen levels below 0.1% both at ensiling and at feed out.

Although high nitrate levels increase crude protein

content they can also lead to the production of

Dry matter losses are minimised between

ammonia in the silage which is alkaline and so

25 and 30% (see Figure 9.2).

increases pH.

High nitrates indicate that nitrogen taken up by the

sward has not been fully metabolised into plant

protein, usually due to high nitrogen inputs or due

to weather conditions. During a dry period grass

nitrogen uptake often slows, and when rain arrives it

can produce a sudden peak of nitrogen in the sward.

9:4 Improvement through grassland management

Figure 9.2: Typical DM Losses in Silage-making

20

% Original Crop DM Once 50% of the sward has

started to head the D value is

16

likely to be below 67D.

Total

% Loss of DM

12

Field

respiration, leaf shatter, leaching

8

In-Silo As digestibility decreases protein content will also

4 respiration & fermentation

decline, by around 3% a week. Grass protein

Effluent

levels are influenced by nitrogen applications

0

15 20 25 30 35 40 45 as well as stage of maturity. Uptake of nitrogen

Crop DM at Ensiling (%) and protein formation can also be restricted by

Source: J Bax

soil deficiencies in potash (K) and sulphur.

Low DM silage needs very acidic conditions for a It is important to match the heading dates of

stable silage to be produced. Very wet, low pH your grass varieties to suit your cutting dates

silages are not a good base for a winter ration and to maximise quality. Be aware that heading

intakes will be reduced. dates will vary depending on altitude, aspect

and on seasonal weather conditions.

Analysing grass prior to cutting can provide useful

information about the quality of forage and how Recent work at Moorepark has suggested that

you manage it. It may prompt you to consider late perennials are most suited to providing high

delaying harvesting or it could influence the quality silage if the leys are to be included in the

way you handle one particular problem field. grazing rotation in early spring before being shut

out for silage. (Humphreys and O’Keily 2006.)

Grass Qualities for High Early spring grazing will delay heading dates and

subsequent decline in digestibility by around 10 days.

Nutritional Value

Leys with a high ryegrass content (70%+) are

essential to an efficient silage system. Grass For the highest digestibility

weeds and broad leaved weeds like docks silage, swards must be cut early

will compromise both yield and quality. while the grass is still leafy

and before heading starts.

Silage nutritional quality, intake potential and milk

production value are governed primarily by the

digestibility (D Value) of the grass being ensiled.

Early cuts of silage have been associated with

lower DM yields/ha in single cut systems.

A drop of one unit of D represents a

However, research from SAC Crichton Royal Farm

5% decline in animal productivity.

shows that with two silage cuts, yields are similar

but quantity better with earlier cutting (Table 9.2).

Grass digestibility can decline by up to three units/

week with the onset of stem formation and heading.

Improvement through grassland management 9:5

Table 9.2: Cutting Date, Silage Energy Content and Yield

Early Cutting Date Conventional Cutting Date

1st Cut 2nd Cut 1st Cut 2nd Cut

Metabolisable Energy

11.8 11.4 11.1 11.3

(ME) (MJ/kg DM)

Yield (tonnes DM/ha) 4.2 4.1 5.5 2.5

Total yield (tonnes DM/ha) 8.3 8.0

Source: Thomas, Bax and Osman (1998) More Milk from Grass.

• Inoculants – Protect forage quality by ensuring

Cutting 2nd cut silage later will rapid and effective fermentation. Applying

an inoculant with lactic acid bacteria helps

also reduce its digestibility by up

to quickly dominate the fermentation and

to four units, as well as delaying keep more of the soluble proteins and sugars

regrowth for subsequent grazing. available to the animal. Select inoculants which

provide at least 1 million bacteria/gram silage

• Enzymes – Can help to reduce heating and

aerobic spoilage after opening the clamp.

Delaying cutting date by a Particularly suited for high DM silages

week can result in the death which can be at risk from moulding that

of over 2000 tiller/m2. produces toxins which depress intake

• Acid based additives – Formic acid reduces

pH and can improve digestibility, intake and

cattle performance – although is unpleasant

to handle. Generally used in very poor

Additive Use

conditions with wet silages where there is

also a higher risk of soil contamination

Additives are an essential part of • Sugar sources such as molasses supply

silage-making, helping to preserve additional sugars to naturally occurring

bacteria in the silage but give a lower

nutritional quality and improve

fermentation response than formic acid

fermentation quality – but they do not

compensate for poor management. • Sugar beet pulp can help retain effluent,

but provides limited source of sugar

to aid the fermentation process.

9:6 Improvement through grassland management

Making clamp silage

One key objective in silage-making Once cut the grass leaf starts to

must be to cut and ensile grass die and continues to respire, losing

quickly and cleanly with minimal loss water but also dry matter and

of dry matter and feeding value. nutritional value. The longer the

wilting time, the more you lose.

Cutting

Picking-up

Silage quality can best be ensured by:

• Setting the mower to leave the widest Silage quality can best be ensured by:

possible swath to encourage wilting • Setting the pick-up high enough to avoid

• Mowing when the crop is dry to further aid soil contamination

wilting and enhance sugar concentration • Chopping higher DM (25-40%DM) down to

• Leaving 7-8cm stubbles to avoid soil and manure 10-15mm but longer chopping wetter crops to

contamination and encourage fast regrowth 25-35mm to optimise clamp consolidation

• Keeping all operations as clean as • If necessary adjust chop length as the day

possible; particularly when wet. progresses, to ensure good consolidation in

the clamp

Spreading • Keeping all operations as clean and quick as

possible, particularly when wet.

Silage quality can best be ensured by:

• Spreading grass rapidly and evenly within Clamp filling

one hour of cutting to encourage wilting

Silage quality can best be ensured by:

• Not rowing up swaths until immediately before

pick up • Filling clamps as rapidly as possible

• Not leaving rowed-up swaths overnight to • Keeping the clamp apron clean by avoiding

heat up. dirty wheelings where grass will be tipped

• Ensuring good consolidation by even filling

Wilting and regular rolling of thin layers of no more

than 20cm

Silage quality can best be ensured by: • Cross rolling with a second tractor if possible

• Achieving the target 25-30% DM • Not over-consolidating low dry matter silages

content in 12-24hrs where possible

• Filling large bunkers in a wedge shape from

• Cutting, spreading and picking up in the one end.

same day in poor wilting weather.

Improvement through grassland management 9:7

• Keeping the sides of the clamp slightly above • Crops ensiled at 25% DM will produce

the level of the centre so the tractor leans away little effluent

from the walls

• Crops ensiled at 18% DM will produce up to

• Avoiding rolling before the next day’s filling 100 litres effluent/tonne/day at peak flow

(as this will draw air in)

• Crops ensiled at 15% DM will produce up to

• Sealing the clamp after each day’s work only if 200 litres effluent/tonne/day at peak flow

it effectively prevents the entry of air

• Most effluent will be produced in the first

• If silage is of high dry matter consider taking ten days after ensiling. Short chop lengths

the last few acres as direct cut which will will increase early peak flow levels, as

consolidate well and seal the top of the clamp. will the use of acid based additives

• Collected effluent can be spread on to

Clamp sealing land but should be diluted 1:1 with water

to reduce the risks of pollution and sward

Silage quality can best be ensured by: scorch. Aim for a rate of between 25-

30m3/ha (2200-2700gl/acre) and do not

• Making the final seal as soon as consolidation

spread near water courses or boreholes

is complete

• Do not mix effluent with slurry in a confined

• Folding in exposed side sheets first, then

area or in under-shed tanks as it will release

covering the whole area with plastic sheeting

toxic gases harmful to humans and livestock.

• Using two sheets; a new sheet covered with

last year’s sheet to reduce the risk of puncture

Managing feed out

• Covering the whole sheeted surface with straw

bales, tyres or special heavy silage clamp covers Minimising aerobic spoilage and protecting silage

• Ensuring the sheeting is not punctured, quality once the clamp is open can best be

protecting it from birds with netting achieved by:

and repairing any damage • Pulling back the top sheet to expose only

• Ensuring that unroofed clamps shed rainwater the silage that is needed on a daily basis

freely so it does not seep into the clamp. • Using narrow clamps to limit the area of the

exposed face and to ensure that you move

through and across the clamp quickly

Managing Silage Effluent

• Taking the clamp face back at least 2m a

week and aim to get across the face between

• Silage effluent is highly polluting and should

three and seven days, the importance of this

not reach field drains, watercourses or water

speed across the clamp will vary depending

supplies. As little as one litre of silage effluent

on consolidation, dry matter, fermentation,

can lower the oxygen content of over 10,000

residual sugars and climatic conditions, the

litres of water to below a critical level for fish

key point is to avoid secondary fermentation

• Silos should have an effluent storage capacity

• Keeping a tight clamp face – use a shear grab

of at least two days at peak flow rate, which

and sharpen regularly.

increases rapidly with declining DM levels

9:8 Improvement through grassland management

Assessing Clamped Silage Stocks monitored. Be aware that even in a clamp the silage

is likely to be variable and rationing will need to

Be prepared to review both your assessment of silage be adjusted to take account of that variability.

stocks and its quality throughout the feeding period.

The amount of silage clamped can be calculated

Dry matter losses, clamp wastage, animal rejection easily for budgeting purposes from clamp

and animal performance all need to be continually dimensions and silage DM (Example 9.1).

Example 9.1: Calculating Silage Stocks

Clamp Silage Fresh

Clamp Clamp Clamp Silage Silage DM

Capacity Density* Silage

Length (m) Width (m) Height (m) DM (%) (tonnes)

(m3) (kg/m3) (tonnes)

F=DxE

A B C D=AxBxC E G H=FxG

÷1000

20 12 3 720 650 468 26 121.68

* From Table 9.4

Improvement through grassland management 9:9

Table 9.5: Silage Stocks Ready Reckoner (tonnes)

Worksheet 12 provides a pro forma to

calculate the quantity of silage in Clamp Size (m3) Grass Silage (% DM)

individual clamps.

20 25 30

Table 9.4: Silage Density 200 145 132 123

400 290 264 246

Fresh Weight

Silage DM (%)

Density (kg/m3) 600 435 396 369

16 800 800 580 528 492

18 760 1000 725 660 615

20 730 A good estimate of stocks made throughout the

22 695 season will allow forage supplies to be matched to

livestock requirements as precisely as possible

24 675 (Section 8).

26 650

Identifying a shortfall of conserved forage at first

28 633 cut, for instance, enables greater provision to be

30 615 made for silage-making later in the season.

Alternatively, a quick assessment of silage stocks can Alternatively, grazing can be extended later into

be made from estimates of clamp size and silage autumn to reduce conserved forage needs (Section

DM (Table 9.5). 7) or early provision can be made for purchasing

bulk feeds such as brewers’ grains or pressed pulp,

or sowing alternative forage crops (Section 6).

9:10 Improvement through grassland management

Big bale silage

Making Good Quality Big

Big bale silage is a flexible and Bale Silage

economic way of conserving grass

Good quality big bale silage-making demands

that can be used as a positive aid

essentially the same criteria as good quality silage

to maintaining grass quality.

in the field and swath.

The higher DM of big bale silage, generally 35-40%,

means a more restricted fermentation, making it

Big bale silage costs about the same as clamp especially important to guard against aerobic spoilage.

silage per tonne of utilised DM (Section 2).

It is particularly vital to avoid soil contamination

Where smaller areas are to be harvested which can introduce potentially damaging listeria and

or three or four cuts are required, big bale botulinum micro-organisms into the bale.

silage may work out cheaper than clamp

silage and it is also more saleable. Cutting

Silage quality can best be ensured by:

The quality of big bale silage can • Mowing when the crop is dry to aid wilting

be similar to clamp silage and and enhance sugar concentration

fermentation losses are generally • Leaving a 7-8cm stubble to avoid soil and

half of those reported in clamps. manure contamination and to encourage

fast re-growth

• Using a mower conditioner to promote

There can be benefits to integrating bale silage with rapid wilting

clamp silage: • Matching the swath to the baler width.

• Baling a small acreage a few days ahead

of the main clamp silage will provide high Wilting

quality forage and mean a quicker return

of one or two paddocks to the grazing Silage quality can best be ensured by:

rotation ahead of the main aftermath area

• Wilting to 35-40%DM and an absolute

• Having a stock of bales to buffer feed minimum of 25% to avoid bale

cows at grass will remove the need to distortion which leads to air ingress

open a clamp and expose a slow moving

clamp face to aerobic spoilage • Employing vigorous swath treatment

to promote rapid moisture loss

• Bales of different quality can be made

to target small groups of cattle. • Using inoculants designed for high

DM silages where required.

Improvement through grassland management 9:11

Baling Storage

Silage quality can best be ensured by: Silage quality can best be ensured by:

• Gathering several swaths into a windrow • Storing bales on a hard standing within

for improved baler performance 24hrs of baling and covering immediately

• Producing uniform box shaped windrows • Not moving bales once stacked or leaving

that match the baler’s pick up capacity them for at least three weeks before moving

• Making firm well shaped bales that are easier • Avoiding spear type equipment to move bales

to enclose and store since taping rarely produces a good seal

• Bale chopping increases the density of the • Storing low dry matter bales (25-35%DM) only

bales (fewer bales/ha so reducing costs) one high

• Chopping also reduces the air in each • Stacking higher DM bales to a maximum of

bale and releases sugars; both of which three high

improve speed of fermentation.

• Controlling pests, especially rats and repairing

any damage to bale wrap promptly

Wrapping • Cover with netting to keep away birds and also

farm cats

Silage quality can best be ensured by:

• Identifying bales of different quality to feed to

• Wrapping promptly, within 2-4hrs of baling

different classes of stock.

• Wrapping close to the stack rather than

transporting wrapped bales from the field

to reduce chance of physical damage (this Assessing Big Bale Silage Stocks

also prevents soil compaction in the field)

The weight of big bales can vary quite widely

• Using six layers of wrap to improve sealing

(400-800kg), so for an accurate assessment of

and also protect from physical damage. IGER

quantities it is important to weigh more than just

research has identified big increases in lysteria

a few. Weights will be affected from field to

associated with inadequate wrapping

field depending on dry matter and baler speed

• Using green or white wrap has been shown to and settings.

reduce the temperatures of stored bales and to

subsequently reduce the amount of moulding. Factor in that between weighing an unwrapped

bale in the field to feedout it is likely that each bale

will lose at least 5%DM in fermentation losses.

Wet bales maybe even 10% with effluent losses.

9:12 Improvement through grassland management

Summary

• Failing to account for the nitrogen content in • Cutting 2nd cut silage later will also reduce

slurry is a frequent cause of high nitrate its digestibility by up to four units, as well as

levels in silage delaying regrowth for subsequent grazing

• The lower the dry matter content of the • Delaying cutting date by a week can

forage the more acid is required to preserve result in the death of over 2000 tiller/m2

it, so the lower the pH needs to be

• Additives are an essential part of silage-

• The higher the dry matter of the forage making helping to preserve nutritional quality

the harder it is to consolidate, so the and improve fermentation quality – but they

more difficult it is to create anaerobic do not compensate for poor management

conditions, both at ensiling and at feed out

• One key objective in silage making must

• A drop of one unit of D represents a be to cut and ensile grass quickly and

5% decline in animal productivity cleanly with minimal loss of dry matter

and feeding value

• Once 50% of the sward has started to head

the D value is likely to be below 67D • Big bale silage is a flexible and economic

way of conserving grass that can be used as

• For the highest digestibility silage, swards

a positive aid to maintaining grass quality

must be cut early while the grass is

still leafy and before heading starts • The quality of big bale silage can be similar

to clamp silage and fermentation losses are

generally half of those reported in clamps.

See also...

Section 2: Calculating the Cost of Your Feeds

Section 6: Supplementing Grazing

Section 7: Shortening Your Winter Feeding

Section 8: Planning Your Silage-making

Section 15: Factsheet 12: Herbage Analysis

Section 16: Worksheet 12: Clamped Silage Quantity

Refer to Factsheet 17 on interpreting

silage analysis.

Improvement through grassland management 9:13

You might also like

- Improve Silage Quality With MolassesDocument2 pagesImprove Silage Quality With MolassesLohith NANo ratings yet

- Chapter 20Document1 pageChapter 20MinethegroundNo ratings yet

- Baled Silage ProductionDocument8 pagesBaled Silage Productionadnan mohammedNo ratings yet

- Silage 2012 16 JAN 2012###Document4 pagesSilage 2012 16 JAN 2012###darran_wardNo ratings yet

- Chemistry ProjectDocument20 pagesChemistry ProjectVigneshNo ratings yet

- Chemistry ProjectDocument20 pagesChemistry ProjectVigneshNo ratings yet

- Mushroom CompostDocument17 pagesMushroom CompostAlirazaNo ratings yet

- Sludge Info From GoogleDocument76 pagesSludge Info From GoogleAMTRIS0% (1)

- MaltingDocument20 pagesMaltingSagar ShahNo ratings yet

- Postharvest HandlingDocument33 pagesPostharvest HandlingMerera TesfayeNo ratings yet

- CR Key Check 6 - FINALdraftDocument26 pagesCR Key Check 6 - FINALdraftRomally Antonette Tagnipez0% (1)

- 31-514-FIBEL BON Gras GB RGB 170706Document15 pages31-514-FIBEL BON Gras GB RGB 170706alexandre miguel teixeiraNo ratings yet

- Chapter 3Document21 pagesChapter 3Getu TolossaNo ratings yet

- Kenya Market Led Aquaculture Programme Business Cases CompressedDocument18 pagesKenya Market Led Aquaculture Programme Business Cases CompressedMkulima HodariNo ratings yet

- Sweetcorn Production Guideline 2019Document5 pagesSweetcorn Production Guideline 2019Murad NəsirliNo ratings yet

- BLO Edward Dec 6 XDocument53 pagesBLO Edward Dec 6 XChris YbanezNo ratings yet

- Sugar RecoveryDocument8 pagesSugar RecoveryGunasridharan LakshmananNo ratings yet

- Agriculture PP1 MSDocument237 pagesAgriculture PP1 MSPurpose EnterpriseNo ratings yet

- Integrated Aquaculture Aquaculture ProjectDocument56 pagesIntegrated Aquaculture Aquaculture ProjectAdams S. Bol-NabaNo ratings yet

- HYDROPONICSDocument30 pagesHYDROPONICSamyra SreenathNo ratings yet

- Production of Citric AcidDocument5 pagesProduction of Citric AcidSonam SharmaNo ratings yet

- Fodder ProcessingDocument57 pagesFodder ProcessingMurali Vet100% (2)

- Code of Practice For The Reduction of Hydrocyanic Acid (HCN) in Cassava and Cassava Products (CAC/RCP 73-2013)Document14 pagesCode of Practice For The Reduction of Hydrocyanic Acid (HCN) in Cassava and Cassava Products (CAC/RCP 73-2013)kustNo ratings yet

- Chapter 1 Sugare Production ProcessDocument51 pagesChapter 1 Sugare Production ProcessAddis WelelawNo ratings yet

- How Can Communities Get Ready To Face The Challenge of Climate ChangeDocument41 pagesHow Can Communities Get Ready To Face The Challenge of Climate ChangeRamanjaneyulu GVNo ratings yet

- Rivulis Blueberries English Metric 20190506 WebDocument12 pagesRivulis Blueberries English Metric 20190506 WebMehdi BassouNo ratings yet

- Blueberries: Growing Beyond Production ChallengesDocument12 pagesBlueberries: Growing Beyond Production ChallengesMehdi BassouNo ratings yet

- Lucern Booklet EnglishDocument28 pagesLucern Booklet EnglishThabo SewelaNo ratings yet

- GineersNow HVACR Leaders Magazine Issue 001, Johnson ControlsDocument78 pagesGineersNow HVACR Leaders Magazine Issue 001, Johnson ControlsGineersNowNo ratings yet

- Beverage Technology - Chapter Two - 2Document67 pagesBeverage Technology - Chapter Two - 2teklitNo ratings yet

- 1965 - Alexander - Uses For Excess andDocument5 pages1965 - Alexander - Uses For Excess andfernandofrenkelNo ratings yet

- Corn Silage: Foraging Ahead For A Greener TomorrowDocument8 pagesCorn Silage: Foraging Ahead For A Greener Tomorrowanthonius70No ratings yet

- AbhinekDocument21 pagesAbhinekAnup panditNo ratings yet

- Oh1030 Osmocote A90554 (19-6-12) (8-9M) Osm - Udsc39Document2 pagesOh1030 Osmocote A90554 (19-6-12) (8-9M) Osm - Udsc39Jesus Vargas JimenezNo ratings yet

- Evaluation of Cocoyam Corms Processing and Storage in NigeriaDocument5 pagesEvaluation of Cocoyam Corms Processing and Storage in NigeriaOsemwengie OsahonNo ratings yet

- Asella Malt FactoryDocument23 pagesAsella Malt FactoryAbay100% (6)

- Mod 5Document35 pagesMod 5Krishna MoorthyNo ratings yet

- Quality Parameters &: Analysis of Compost and CasingDocument27 pagesQuality Parameters &: Analysis of Compost and CasingShivendra SinghNo ratings yet

- Guide To Choosing and Using Silage Additives - Farmers WeeklyDocument6 pagesGuide To Choosing and Using Silage Additives - Farmers WeeklyΧΡΗΣΤΟΣ ΜΠΑΡΤΖΟΣNo ratings yet

- Calibre BMR Forage SorghumDocument3 pagesCalibre BMR Forage SorghumJethro Briza GaneloNo ratings yet

- Tof Magazine January 2021 IssueDocument8 pagesTof Magazine January 2021 Issuemohamed adamNo ratings yet

- White Corn Production Guidelines: Drying and StorageDocument2 pagesWhite Corn Production Guidelines: Drying and StorageMay an CarbonelNo ratings yet

- Beef Manual 6Document58 pagesBeef Manual 6cosminspataruNo ratings yet

- Citric Acid Production From Pineapple Waste Through Solid-State FermentationDocument6 pagesCitric Acid Production From Pineapple Waste Through Solid-State FermentationCiara DevelosNo ratings yet

- Media For Industrial: FermentationDocument32 pagesMedia For Industrial: FermentationAnonymous 0QJLNvseHNo ratings yet

- Production of Paper Pulp From Groundnut ShellDocument16 pagesProduction of Paper Pulp From Groundnut ShellRajapriya M100% (1)

- Catalog TAM Cocopeat FixDocument8 pagesCatalog TAM Cocopeat Fixtritunggalatha megaNo ratings yet

- Dosing Organic MycroNutrient ChecklistDocument4 pagesDosing Organic MycroNutrient ChecklistDeepak SharmaNo ratings yet

- Chapter 3 - Pond Preparation - PinciplesDocument37 pagesChapter 3 - Pond Preparation - PinciplesPette CoscosNo ratings yet

- 1 Biomass Energy 4Document13 pages1 Biomass Energy 4Kamran HameedNo ratings yet

- Baringo 2016 Agr p1 ANSDocument6 pagesBaringo 2016 Agr p1 ANSedwardNo ratings yet

- Peat and Alternative Material For Mushroom CasingDocument6 pagesPeat and Alternative Material For Mushroom CasingAmirJabriNo ratings yet

- Windsor PDFDocument2 pagesWindsor PDFHomeroNo ratings yet

- Sweet PotatoDocument11 pagesSweet PotatoRaymund AlegriaNo ratings yet

- Plastic Bag Optimization For Algae GrowthDocument7 pagesPlastic Bag Optimization For Algae GrowthNisrin RazaliNo ratings yet

- Principles of SizingDocument24 pagesPrinciples of SizingraghunathNo ratings yet

- Sustainable Oil Palm GAP UnileverDocument20 pagesSustainable Oil Palm GAP UnileverIrfanImadNo ratings yet

- Chemistry PPT UpdatedDocument30 pagesChemistry PPT UpdatedNamraNo ratings yet

- Greenhouse Crop Production in Cocopeat - Myriad IntDocument61 pagesGreenhouse Crop Production in Cocopeat - Myriad IntsurangaNo ratings yet

- Ohi Case Study Powerpoint Presentation 220a - Savanna BeddoesDocument18 pagesOhi Case Study Powerpoint Presentation 220a - Savanna Beddoesapi-307780636No ratings yet

- Business Plan EconomicsDocument3 pagesBusiness Plan EconomicsKen UrielNo ratings yet

- Winter 2010 Homeless Garden Project NewsletterDocument6 pagesWinter 2010 Homeless Garden Project Newslettercalderdavid35No ratings yet

- Fat Metabolism During ExerciseDocument8 pagesFat Metabolism During ExercisealmaformaNo ratings yet

- Celiac Disease ComputerDocument13 pagesCeliac Disease ComputerShenghohNo ratings yet

- Article On ButterflyDocument1 pageArticle On ButterflyLalaijuhNo ratings yet

- RDO No. 80 - Mandaue City, CebuDocument1,113 pagesRDO No. 80 - Mandaue City, CebuArnold DrilonNo ratings yet

- Who NMH NHD 18.8 EngDocument38 pagesWho NMH NHD 18.8 EngyulissaNo ratings yet

- My Cook BookDocument66 pagesMy Cook BookAkshay KumariNo ratings yet

- 14 - (159-166) PCSIR Brief - Detail For PEC29-09-2012Document9 pages14 - (159-166) PCSIR Brief - Detail For PEC29-09-2012Sana Elli KhanNo ratings yet

- Winter Detox Moroccan Sweet Potato Lentil Soup (Slow Cooker) - Little Spice JarDocument2 pagesWinter Detox Moroccan Sweet Potato Lentil Soup (Slow Cooker) - Little Spice JarConsultorio Ibette ChinchillaNo ratings yet

- Pengaruh Jenis Mulsa Dan Intensitas Naungan Terhadap Perkembangan Penyakit Antraknosa Dan HASIL CABAI (Capsicum Annum)Document7 pagesPengaruh Jenis Mulsa Dan Intensitas Naungan Terhadap Perkembangan Penyakit Antraknosa Dan HASIL CABAI (Capsicum Annum)Dilla Oka PraditaNo ratings yet

- Feasibility Study of Concentrate Feed Final ReportDocument45 pagesFeasibility Study of Concentrate Feed Final ReportIjaaraa SabaaNo ratings yet

- Emotional Intelligence, Staff Management Skills and Job SatisfactionDocument39 pagesEmotional Intelligence, Staff Management Skills and Job SatisfactionShania Jane MontañezNo ratings yet

- Best Bet Dinner Menu July 2023Document2 pagesBest Bet Dinner Menu July 2023MatthewKangNo ratings yet

- Customer Satisfaction Survey - Comparative Study (Final Report)Document32 pagesCustomer Satisfaction Survey - Comparative Study (Final Report)Shreya GuptaNo ratings yet

- 프렌즈 Season04 ScriptDocument242 pages프렌즈 Season04 ScriptbyeoljjiNo ratings yet

- Solved Paper 2020Document13 pagesSolved Paper 2020anuragak2346No ratings yet

- Backyard Aquaponics Magazine 1Document36 pagesBackyard Aquaponics Magazine 1Anonymous zvbJbW5Wg1No ratings yet

- The Importance of Safe Food Handling Practices and Proper Safety Etiquette Among The Grade 12 Cookery Students in DarssthsDocument34 pagesThe Importance of Safe Food Handling Practices and Proper Safety Etiquette Among The Grade 12 Cookery Students in DarssthsLloyd Martin PascualNo ratings yet

- Common Fragrance and Flavor Materials Preparation Properties and Uses PDFDocument2 pagesCommon Fragrance and Flavor Materials Preparation Properties and Uses PDFSummer0% (1)

- F & B Cost Control: Professional Chefs AssociationDocument9 pagesF & B Cost Control: Professional Chefs AssociationOtpor Stoko100% (1)

- Sample Guest HouseDocument33 pagesSample Guest HouseSiddhartha100% (1)

- Programa Welcome 2Document6 pagesPrograma Welcome 2Aleksandra Krstovska0% (1)

- Tle ScrapbookDocument7 pagesTle ScrapbookPurpleNo ratings yet

- Enzyme PacketDocument3 pagesEnzyme PacketBelinda RodriguezNo ratings yet

- Provence CW 7 3 Feb 1 Effects of Industrial Rev DBQDocument8 pagesProvence CW 7 3 Feb 1 Effects of Industrial Rev DBQPaul ProvenceNo ratings yet

- Chemistry Project CBSEDocument23 pagesChemistry Project CBSEH0% (2)

- Prepare and Cook Meat and SeafoodDocument6 pagesPrepare and Cook Meat and SeafoodKemathi McnishNo ratings yet

- 1000 English Collocations in 10 Minutes A DayDocument128 pages1000 English Collocations in 10 Minutes A DayKaksak VisagieNo ratings yet