Professional Documents

Culture Documents

TR200 Surface Tester Manual

Uploaded by

prasadjoshi781429Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TR200 Surface Tester Manual

Uploaded by

prasadjoshi781429Copyright:

Available Formats

15

Beijing TIME High Technology Ltd.

www.timeinstrument.com

TR200/220 Standard Delivery

●Main unit

●TS100 standard pickup

1

1

Optional Accessories

●TS110 pickup for curved surface

●TS120 pickup for small holes

●Specimen Ra 1 ●TS130 pickup for deep grooves

SURFACE ROUGHNESS TESTER ●Protection nose 1 ●TS140 right-angled pickup

●Steel support 1 ●Measuring platform TA610/TA620

●Screwdriver 1 ●Leveling table TA630/TA631

●Communication cable 1 ●Magnetic stand

●Instruction Manual 1 ●Steel adapter (Ø8)

●Software 1 ●Steel adapter (L-attachment)

●TIME Certificate 1 ●Printer TA230

●Warranty card 1

Features

●Applicable in production site, laboratory and workshop in factory

●Easy operation menu and large LCD display with backlight

●Li-ion rechargeable battery

●Pickup position indicator

●Conform to ISO standard, compatible with DIN, ANSI and JIS

standard

●Advanced software for TR200 and TR220 is available

●Lots of delicate optional accessories are supplied making user’s

measurement more efficient and much easier

Technical Specification

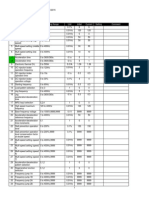

Model TR200 TR220

Ra, Rz, Ry, Rq, Rt, Rp, Rmax, Rv, Ra, Rz, Ry, Rq, Rt, Rp, Rmax, Rv, R3z, RS, RSm,

Roughness parameters

R3z, RS, RSm, RSk, Rmr, RSk, Rmr, Rpc, Rk, Rpk, Rvk, Mr1, Mr2

Roughness profile (R)

Assessed profiles

Primary profile (P)

Measuring system Metric, imperial

Display resolution 0.001 μ m

Data output RS232

Pickup measuring range ±20μ m, ±40μ m, ±80μ m

Cutoff length (L) 0.25mm / 0.8mm / 2.5mm/Auto

Evaluation length 1~5L (selectable)

Tracing length (1~5)L+2L(selectable)

Digital filter RC, PC-RC, Gauss, D-P

Max. tracing length 17.5mm/0.71inch

Min. tracing length 1.3mm/0.051inch

Pick-up Standard pickup TS100, inductive, Diamond stylus radius 5μm, angle of stylus 90°

Accuracy ≤±10%

Repeapility <6%

Power Li-ion battery rechargeable

Dimensions(mm) 141×56 ×48

Weight(g) 480 440

16

Beijing TIME High Technology Ltd.

www.timeinstrument.com

System Diagram

Steel support

Measuring with steel support and

protection nose

Protection nose

Leveling table

TA630/TA631 Printer TA230

Measuring Platform

TA610/TA620 Operation with Magnetic stand Software for TR200/220

Pickups Optionals

Operation with measuring TS100 standard pickup

Steel adapter for

platform for high accuracy With skid for roughness test on plane

connecting to platform

surface, shaft and inner surface of

(L-attachment)

holes with min. diameter of 5mm, max.

depth of 22mm

TS110 pickup for curved surface

Used for roughness testing of curved

Steel adapter (Ø8)

surface with min curvature radius

3mm, working with measuring platform

TS130/131 pickup for deep grooves TA610/620

TS130: Used for roughness testing TS120 pickup for small holes

of deep groove with min. width Used for roughness testing of small

2mm, max. depth 3mm or of step holes with min. 2mm diameter of inner

with max. height 3mm surface, max. depth 9mm

TS131: Used for roughness testing TS140 right-angled pickup

of deep groove with min. width Comprising right-angled pickup and

3mm, max. depth 10mm or of step right-angled transmit rod, used for

with max. height 10mm, working roughness testing of groove and crac

with measuring platform TA610/620 k with min. width 7.5mm~20mm, and

of steps with max. height 2.5mm,

working with TA610/620

17

Beijing TIME High Technology Ltd.

www.timeinstrument.com

TIMESurf for TR200/TR220

TIMESurf for TR200 and TR220 Software works with TIME surface

roughness tester TR200 and TR220 for managing, analyzing, printing and

searching measured data and graphs

MR Curve RK Curve

Database management Online measurement

You might also like

- TR200Document3 pagesTR200DeepakNo ratings yet

- Premature Fatigue Failure of A Spring Due To Quench CracksDocument8 pagesPremature Fatigue Failure of A Spring Due To Quench CracksCamilo Rojas GómezNo ratings yet

- Determination of Static Coefficient of Friction of Test Couples Using An Inclined Plane Testing DeviceDocument5 pagesDetermination of Static Coefficient of Friction of Test Couples Using An Inclined Plane Testing Devicemohamed senoussiNo ratings yet

- Atlas of Stress-Strain Curves: Second EditionDocument5 pagesAtlas of Stress-Strain Curves: Second EditionLucio MárquezNo ratings yet

- A 455 - A 455M - 12a PDFDocument3 pagesA 455 - A 455M - 12a PDFأسامة وحيد الدين رمضانNo ratings yet

- Determining Decarburization and Carburization in Hardened and Tempered Threaded Steel Bolts, Screws and StudsDocument4 pagesDetermining Decarburization and Carburization in Hardened and Tempered Threaded Steel Bolts, Screws and StudscristianNo ratings yet

- As 2900.12-2002 Quantities and Units Characteristic NumbersDocument10 pagesAs 2900.12-2002 Quantities and Units Characteristic NumbersSAI Global - APACNo ratings yet

- Microstructure and Mechanical Properties of Selective Laser Melted Inconel 718 Compared To Forging and CastingDocument4 pagesMicrostructure and Mechanical Properties of Selective Laser Melted Inconel 718 Compared To Forging and CastingRafael CoelhoNo ratings yet

- Chapter 3: Tensile TestingDocument10 pagesChapter 3: Tensile TestingKhairul MuzafarNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- A Comparison of Laboratory Abrasion and Field Wear ResultsDocument11 pagesA Comparison of Laboratory Abrasion and Field Wear ResultschrisnnnNo ratings yet

- D 2511Document2 pagesD 2511Asep TheaNo ratings yet

- 169 PD0192ThreadsStandardReferenceGuiderev4Document21 pages169 PD0192ThreadsStandardReferenceGuiderev4Coman ovidiuNo ratings yet

- STP1353 Eb.1415051 1 PDFDocument257 pagesSTP1353 Eb.1415051 1 PDFpaolaNo ratings yet

- Stress Corrsion Cracking Behavion of Austenitic Stainless Steel PDFDocument5 pagesStress Corrsion Cracking Behavion of Austenitic Stainless Steel PDFJEISON CONTRERAS HOYOSNo ratings yet

- Surfaceb Finish Meterology TutorialDocument162 pagesSurfaceb Finish Meterology TutorialChristian Barnard100% (1)

- As 2900.11-2002 Quantities and Units Mathematical Signs and Symbols For Use in The Physical Sciences and TechDocument10 pagesAs 2900.11-2002 Quantities and Units Mathematical Signs and Symbols For Use in The Physical Sciences and TechSAI Global - APACNo ratings yet

- MS - 003400 - 01 Rev 29Document22 pagesMS - 003400 - 01 Rev 29Arjun PrajapatiNo ratings yet

- STD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXDocument2 pagesSTD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXAkshay KalraNo ratings yet

- G 123 - 00 (2015)Document10 pagesG 123 - 00 (2015)ruben carcamo100% (1)

- Austenitic Chromium-Nickel-Silicon Alloy Steel Seamless and Welded PipeDocument4 pagesAustenitic Chromium-Nickel-Silicon Alloy Steel Seamless and Welded PipeJosé Ramón GutierrezNo ratings yet

- Transverse Rupture Strength of Metal Powder Specimens: Standard Test Method ForDocument4 pagesTransverse Rupture Strength of Metal Powder Specimens: Standard Test Method FormaldopinNo ratings yet

- Understanding Surface Quality Beyond Average Roughness RaDocument20 pagesUnderstanding Surface Quality Beyond Average Roughness RaStefan NikolićNo ratings yet

- Measuring and Characterizing Surface TopographyDocument58 pagesMeasuring and Characterizing Surface TopographyPradeepa KNo ratings yet

- Astm B 328Document4 pagesAstm B 328martin andolini100% (1)

- STP 480-1970Document281 pagesSTP 480-1970Tưởng Ngô TiếnNo ratings yet

- 1800J High Speed Drop Weight TesterDocument10 pages1800J High Speed Drop Weight TesterJeyalalNo ratings yet

- As 4863.1-2000 Particle Size Analysis - Laser Diffraction Methods General PrinciplesDocument10 pagesAs 4863.1-2000 Particle Size Analysis - Laser Diffraction Methods General PrinciplesSAI Global - APACNo ratings yet

- As 2900.0-2002 Quantities and Units General PrinciplesDocument8 pagesAs 2900.0-2002 Quantities and Units General PrinciplesSAI Global - APACNo ratings yet

- 1980 France-Lanord Ancient Metals 9444 LightDocument72 pages1980 France-Lanord Ancient Metals 9444 LightDavid StrongNo ratings yet

- Nitriding 4340 ADocument8 pagesNitriding 4340 AyanuarNo ratings yet

- Specification For Solid Surfacing Welding Rods and ElectrodesDocument23 pagesSpecification For Solid Surfacing Welding Rods and ElectrodesDmitriyNo ratings yet

- Precipitation Hardening in Metals - T GladmanDocument7 pagesPrecipitation Hardening in Metals - T GladmanSouryatanu SahaNo ratings yet

- Astm E562-19Document7 pagesAstm E562-19Abdeslam EL KAABOUNINo ratings yet

- Preparing and Evaluating Specimens For Automatic Inclusion Assessment of SteelDocument5 pagesPreparing and Evaluating Specimens For Automatic Inclusion Assessment of SteelWaqas RajaNo ratings yet

- A488 13208-2Document18 pagesA488 13208-2DeepakRajurkarNo ratings yet

- Astm B 611 Ed. 85Document2 pagesAstm B 611 Ed. 85Ruben Dario Mamani ArellanoNo ratings yet

- Circumferential Notched Tensile Testing For Correlation of The Stress Intensity Factor (KI) and Stress Corrosion Crack Growth RateDocument5 pagesCircumferential Notched Tensile Testing For Correlation of The Stress Intensity Factor (KI) and Stress Corrosion Crack Growth RateSinan ChenNo ratings yet

- Lecture On Diffusion in SolidsDocument31 pagesLecture On Diffusion in SolidsSiva Kumar RajuNo ratings yet

- SSAB - 912 en Bending of High Strength Steel PDFDocument8 pagesSSAB - 912 en Bending of High Strength Steel PDFchristos032No ratings yet

- The Stregth, Fracture Toughnees and Low Cycle 17-4PH PDFDocument11 pagesThe Stregth, Fracture Toughnees and Low Cycle 17-4PH PDFLarissaNo ratings yet

- Mil STD 3021 - CHG 2Document23 pagesMil STD 3021 - CHG 2Robert VoyleNo ratings yet

- FAQ Processes For Surface Hardening of Stainless Steels Bodycote S3PDocument4 pagesFAQ Processes For Surface Hardening of Stainless Steels Bodycote S3PSinan YıldızNo ratings yet

- A597 Standard Specification For Cast Tool Steel1Document2 pagesA597 Standard Specification For Cast Tool Steel1tsliaNo ratings yet

- NEA Catalog 2014 PDFDocument56 pagesNEA Catalog 2014 PDFmshameliNo ratings yet

- B 177 - 93 - Qje3ny05mw - PDFDocument4 pagesB 177 - 93 - Qje3ny05mw - PDFSamuelNo ratings yet

- ISO 898-6-1994, OCR Mechanical Properties of Fasteners-2nd EdDocument12 pagesISO 898-6-1994, OCR Mechanical Properties of Fasteners-2nd EdRenatoGolinNo ratings yet

- ASTM E2884 13e1Document7 pagesASTM E2884 13e1tkNo ratings yet

- ASTM D429 Rubber To Metal Adhesion Test EquipmentDocument4 pagesASTM D429 Rubber To Metal Adhesion Test EquipmentLimNo ratings yet

- Galling Resistance of Materials: Standard Test Method ForDocument4 pagesGalling Resistance of Materials: Standard Test Method ForKarin Soldatelli Borsato100% (1)

- Institute of Technology & Management: Unconventional Machining ProcessDocument28 pagesInstitute of Technology & Management: Unconventional Machining ProcessAkash TripathiNo ratings yet

- A554-15a Standard Specification For Welded Stainless Steel Mechanical TubingDocument5 pagesA554-15a Standard Specification For Welded Stainless Steel Mechanical TubingChuthaNo ratings yet

- Datasheet TR-200Document10 pagesDatasheet TR-200Dicky Pratama PutraNo ratings yet

- Surface Roughness Tester TR200, 220Document2 pagesSurface Roughness Tester TR200, 220NGuga Van OnesusNo ratings yet

- Surface Roughness TesterDocument6 pagesSurface Roughness TesterLingga SetiawanNo ratings yet

- TR210Document2 pagesTR210DeepakNo ratings yet

- Ultrasonic Thickness TT100, TT110, TT120, TT130,140Document1 pageUltrasonic Thickness TT100, TT110, TT120, TT130,140Bad ManNo ratings yet

- Surface Preparation - RoughnessDocument2 pagesSurface Preparation - RoughnessBudi SulistyaNo ratings yet

- 147-7061 SL PDFDocument2 pages147-7061 SL PDFBudi SulistyaNo ratings yet

- B. Brosur - SUNCENT-X8 Product Brochure S Ver1 0 2021Document5 pagesB. Brosur - SUNCENT-X8 Product Brochure S Ver1 0 2021Muhammad Rizki SetiawanNo ratings yet

- Recommended Standard Operations Procedure ForDocument12 pagesRecommended Standard Operations Procedure Forprasadjoshi781429No ratings yet

- Ba Threads SpecDocument1 pageBa Threads Specprasadjoshi781429No ratings yet

- Iso - Cie - 19476 eDocument1 pageIso - Cie - 19476 eprasadjoshi781429No ratings yet

- MetrologyDocument20 pagesMetrologyprasadjoshi781429No ratings yet

- Is-919-Part2-1993-Fits and Tolerences For Holes and ShaftsDocument49 pagesIs-919-Part2-1993-Fits and Tolerences For Holes and ShaftsvijaykumarnNo ratings yet

- NISTIR 6969 - Good Laboratory Practice For The Quality Assurance of The Measurement Process (March 2003)Document160 pagesNISTIR 6969 - Good Laboratory Practice For The Quality Assurance of The Measurement Process (March 2003)prasadjoshi781429No ratings yet

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)prasadjoshi781429No ratings yet

- Iso 2431-1996Document15 pagesIso 2431-1996prasadjoshi781429No ratings yet

- Guideline For 17025 Testing Lab PDFDocument23 pagesGuideline For 17025 Testing Lab PDFprasadjoshi781429No ratings yet

- Is 15575.1.2005 Electroacoustics - Level MetersDocument42 pagesIs 15575.1.2005 Electroacoustics - Level Metersprasadjoshi781429No ratings yet

- Is 6311 - 1978 Specification For Iso Metric Screw Thread Measuring CylindersDocument4 pagesIs 6311 - 1978 Specification For Iso Metric Screw Thread Measuring Cylindersprasadjoshi781429No ratings yet

- Nabl 122-08 Push Pull Gauge WebDocument16 pagesNabl 122-08 Push Pull Gauge Webprasadjoshi781429No ratings yet

- 7 QC Tools - StratificationDocument3 pages7 QC Tools - Stratificationraja100% (1)

- DFT Workshop TU WienDocument90 pagesDFT Workshop TU WienRavindra KempaiahNo ratings yet

- WI1 3E RelayDocument30 pagesWI1 3E RelayJordan JohnsNo ratings yet

- Gas-Insulated Switchgear ELK-14: The Modular System For GIS, 245 KVDocument20 pagesGas-Insulated Switchgear ELK-14: The Modular System For GIS, 245 KVmaruf048No ratings yet

- Straight Line Sheet (NVSIR)Document20 pagesStraight Line Sheet (NVSIR)vigesa6945No ratings yet

- Osiris MAP FeaturesDocument45 pagesOsiris MAP FeaturesNdèye Fatou SYNo ratings yet

- Geometry Class 6 Final ExamDocument4 pagesGeometry Class 6 Final ExamTanzimNo ratings yet

- Gases and Other Properties: Lesson 5Document7 pagesGases and Other Properties: Lesson 5lucifer angelNo ratings yet

- Final Step-A Answer KeyDocument7 pagesFinal Step-A Answer KeyVansh Jain100% (1)

- HR260 Series High Frequency Radar Level Gauge Instructions-HolykellDocument24 pagesHR260 Series High Frequency Radar Level Gauge Instructions-HolykellJanuar RamadhanNo ratings yet

- FIGL BI ExtractionDocument3 pagesFIGL BI ExtractionDurgesh Singh67% (3)

- First PagesDocument11 pagesFirst PagesEswar KarriNo ratings yet

- Physical ChemistryDocument11 pagesPhysical ChemistryAmaan B EydreesNo ratings yet

- Titanium Book From Org PDFDocument45 pagesTitanium Book From Org PDFSuthirak SumranNo ratings yet

- Intro To CFD Course DetailsDocument1 pageIntro To CFD Course Detailsmaheshj90No ratings yet

- Caixa ClaraDocument3 pagesCaixa ClaraDarioeNo ratings yet

- TV Mas en 3Document23 pagesTV Mas en 3Rendra ArdyantoNo ratings yet

- A Proposed Model For Creep Relaxation of Soft Gaskets in Bolted Joints at Room TemperatureDocument6 pagesA Proposed Model For Creep Relaxation of Soft Gaskets in Bolted Joints at Room TemperatureSubhadip SadhukhanNo ratings yet

- Rhino ScriptDocument73 pagesRhino Scriptwadorno100% (1)

- Time Travel EssayDocument5 pagesTime Travel Essayafabggede100% (1)

- (Maths) Tutorial MaximaDocument1,048 pages(Maths) Tutorial MaximaAntonio GadaletaNo ratings yet

- 13003br PDFDocument3 pages13003br PDFFikri Syahir BachmidNo ratings yet

- Lenox TS Serie 6 - 20 TonDocument36 pagesLenox TS Serie 6 - 20 Tonjose antonioNo ratings yet

- Alcatel 2033 2063 Users Instruction ManualDocument30 pagesAlcatel 2033 2063 Users Instruction ManualpizandolaNo ratings yet

- To Find Condition For Two Quadratic Equations To Have One Root CommonDocument1 pageTo Find Condition For Two Quadratic Equations To Have One Root CommonevilsadduckNo ratings yet

- Geochemist S Workbench Dongle Crack PDFDocument3 pagesGeochemist S Workbench Dongle Crack PDFJohnNo ratings yet

- Annex-4-JDVP-Certificate-of-Learners-Mastery Jimley CSS - MasteredDocument17 pagesAnnex-4-JDVP-Certificate-of-Learners-Mastery Jimley CSS - MasteredJimley CanillaNo ratings yet

- Fluid Mech May 2021Document5 pagesFluid Mech May 2021Naigell SolomonNo ratings yet

- Melsoft FR Configurator Sw3 Vf1Document8 pagesMelsoft FR Configurator Sw3 Vf1mo_be81No ratings yet

- Lecture 07 NormalizationDocument50 pagesLecture 07 NormalizationMunira Akter LataNo ratings yet