Professional Documents

Culture Documents

APFF 1896 Introduction of 750W Motor

Uploaded by

jakaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APFF 1896 Introduction of 750W Motor

Uploaded by

jakaCopyright:

Available Formats

ECB Priority IV

1. General information

Introduction of 750W oil pump motor

ECB Number : ECB APFF 1896

Priority : IV

Applicable to : ZS and ZS+ units

PGC : 48G – 48TA – 48TB - 487

Responsible person : Sergio Pais

2. Document overview

This document describes the following:

1. General information ........................................................................................................................................................ 1

2. Document overview ........................................................................................................................................................ 1

3. Safety first ...................................................................................................................................................................... 2

4. Document Information and History ................................................................................................................................. 2

5. Subject ........................................................................................................................................................................... 3

6. Reason for this ECB ....................................................................................................................................................... 3

7. Description ..................................................................................................................................................................... 3

8. Application ...................................................................................................................................................................... 3

9. Required parts ................................................................................................................................................................ 5

10. Planning ordering parts at ASC ...................................................................................................................................... 6

11. Reimbursement criteria .................................................................................................................................................. 6

12. Reporting ........................................................................................................................................................................ 6

13. Safety precautions .......................................................................................................................................................... 7

27/07/2015 VTF- SP Page 1 of 7

3. Safety first

4. Document Information and History

Edition Date Description Author

00 16/09/2015 First Edition VTF-SP

22/09/2015 VTF - SP Page 2 of 7

5. Subject

This ECB is to inform the field that the oil pump motor can be upgraded from 370 watt (Siemens) to a 750 watt (WEG).

6. Reason for this ECB

We received reports from oil pump motor failures when the unit was working in extreme conditions. Low ambient

temperature (thick oil which resulted in high motor power). Therefore it was decided to enlarge the motor power from 370

watt to 750 watt.

The new oil pump motor has been implemented in airpower production as from serial number APF193939

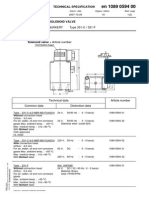

7. Description

The new motor is interchangeable with the previous motor.

8. Application

Applicable for

ZS18-30, ZS37-75, ZS90-160

ZS18-45+VSD

ZS37-75+VSD

ZS90-132+

ZS90-160+VSD

When replacing the motor, the fuses and overload settings have to be adapted according to the below list.

22/09/2015 VTF - SP Page 3 of 7

22/09/2015 VTF - SP Page 4 of 7

9. Required parts

For ZS18-30, ZS37-75, ZS18-45+VSD, ZS37-75+VSD :

Fuse

Hz V Motor part A F15 Fuse pn Quantity Overload pn Oil pump

number Setting number

8L/min

50/60 200 1635 0913 05 3,16/3,58 3.9 1089 9168 62 3 1089 9512 68 1623449800

60 220 1635 0913 05 3.25 3.6 1089 9168 62 3 1089 9512 68 1623449800

50 230 1635 0913 05 2.74 3.0 1089 9168 62 3 1089 9512 68 1623449800

50 400 1635 0913 01 1.58 1.7 1089 9332 55 3 1089 9512 93 1623449800

50 500 1635 0913 03 1.26 1.4 1089 9332 55 3 1089 9512 93 1623449800

50 690 1635 0913 02 0.913 1.0 1089 9332 82 3 1089 9512 93 1623449800

60 380 1635 0913 04 1.65 1.8 1089 9332 55 3 1089 9512 93 1623449800

60 440-460 1635 0913 01 1.4 1.5 1089 9332 55 3 1089 9512 93 1623449800

60 575 1635 0913 03 1.09 1.2 1089 9332 55 3 1089 9512 93 1623449800

For ZS90-160, ZS90-132+, ZS90-160+VSD :

Fuse

Hz V Motor part A F15 Fuse pn Quantity Overload pn Oil pump

Setting number

number

20L/min

50 400 1635 0913 01 1.58 1.7 1089 9332 55 3 1089 9512 93 1623607800

50 500 1635 0913 03 1.26 1.4 1089 9332 55 3 1089 9512 93 1623607800

50 690 1635 0913 02 0.913 1.0 1089 9332 82 3 1089 9512 93 1623607800

60 380 1635 0913 04 1.65 1.8 1089 9332 55 3 1089 9512 93 1623607800

60 440-460 1635 0913 01 1.4 1.5 1089 9332 55 3 1089 9512 93 1623607800

60 575 1635 0913 03 1.09 1.2 1089 9332 55 3 1089 9512 93 1623607800

22/09/2015 VTF - SP Page 5 of 7

For ZS-IB (ZS units where the interface box is installed):

Hz V Motor part A F15 Setting Overload pn

number

50/60 200 1635 0913 05 3,16/3,58 3.9 1089 9551 17

60 220 1635 0913 05 3.25 3.6 1089 9551 17

50 230 1635 0913 05 2.74 3.0 1089 9551 17

50 400 1635 0913 01 1.58 1.7 1089 9551 16

50 500 1635 0913 03 1.26 1.4 1089 9551 34

50 690 1635 0913 02 0.913 1.0 1089 9551 34

60 380 1635 0913 04 1.65 1.8 1089 9551 16

60 440-460 1635 0913 01 1.4 1.5 1089 9551 16

60 575 1635 0913 03 1.09 1.2 1089 9551 34

50/60 200 1635 0913 05 3,16/3,58 3.9 1089 9551 17

10. Planning ordering parts at ASC

Parts are available in ASC

11. Reimbursement criteria

Following costs can be claimed through normal monthly warranty reporting within the normal warranty period.

1. The price of the motor, fuses and overload relay (at transfer price)

2. 1,5 hours of labour

12. Reporting

All units subject to this ECB must be reported in WAnT system mentioning ECB APFF 1896

22/09/2015 VTF - SP Page 6 of 7

13. Safety precautions

The operator must employ safe working practices and observe all related local work safety requirements and regulations.

• Maintenance must only be performed by authorised, trained and specialised personnel.

• Before maintenance, repair work, adjustment or any other non-routine checks, stop the compressor, switch off the

voltage, press the emergency button and depressurise the compressor. In addition, the power insolating switch must

be opened and locked.

• Use only the correct tools for maintenance and repair work.

• All maintenance work shall only be undertaken when the machine has cooled down.

• A warning sign bearing a legend such as ‘Work in progress; do not start’ shall be attached to the starting equipment.

• Persons switching on remotely controlled machines shall take adequate precautions to ensure that there is no one

checking or working on the machine. To this end, a suitable notice shall be affixed to the remote start equipment.

• Close the compressor air outlet valve before connecting or disconnecting a pipe.

• Before removing any pressurized component, effectively isolate the machine from all sources of pressure and relieve

the entire system of pressure.

• Scrupulously observe cleanliness during maintenance and repair. Keep dirt away by covering the parts and exposed

openings with a clean cloth, paper or tape.

• Make sure that no tools, loose parts or rags are left in or on the machine.

• All regulating and safety devices shall be maintained with due care to ensure that they function properly. They may

not be put out of action.

• Always wear the following personal protective equipment: Work clothing, safety shoes, safety goggles, ear protection

and safety gloves when there is a cutting risk or a risk for a heat injury.

The safety guidelines are described in the instruction “Risk Assessment ZS55+ maintenance” with publication nr 2946 9098

01 (available on the Business Portal in the section Safety, Quality and Environment/Safety/Safety Risk Assessment).

22/09/2015 VTF - SP Page 7 of 7

You might also like

- BD520 Aif129092Document40 pagesBD520 Aif129092Nikolay VelchevNo ratings yet

- ZT275Document199 pagesZT275ricardo100% (1)

- User Interface 2946 1044 00Document27 pagesUser Interface 2946 1044 00gak66No ratings yet

- 9845000020-01 - Installation of ER Kit On GA 90-180 (&VSD)Document10 pages9845000020-01 - Installation of ER Kit On GA 90-180 (&VSD)BRUNO MARDEGANNo ratings yet

- ECB Priority III: Oil Carry Over From Air Filter On GA7-37VSD+Document6 pagesECB Priority III: Oil Carry Over From Air Filter On GA7-37VSD+Yurdan HakimNo ratings yet

- TI Overhaul - Transient Load Valve 2946 0797 00Document14 pagesTI Overhaul - Transient Load Valve 2946 0797 00khanh khanhNo ratings yet

- ESM 15-22 Sparepart Recom 1984Document1 pageESM 15-22 Sparepart Recom 1984влад камрNo ratings yet

- Elgi NH 170 Air Compressor Parts Manualsv PowerDocument46 pagesElgi NH 170 Air Compressor Parts Manualsv Powerchallapalli_bhaskarNo ratings yet

- Air-Dryer Atlas ASL 2007 03Document22 pagesAir-Dryer Atlas ASL 2007 03Ronaz1981No ratings yet

- The 4 S's of Success in 40 CharactersDocument794 pagesThe 4 S's of Success in 40 CharactersМихайло ЗахаркоNo ratings yet

- GA 160! - AssemblyDocument7 pagesGA 160! - Assemblymohamed100% (1)

- Atlas Copco: Stationary Air CompressorsDocument631 pagesAtlas Copco: Stationary Air CompressorsAbodi Aliraqi100% (1)

- Atlas Copco: Stationary Air CompressorsDocument100 pagesAtlas Copco: Stationary Air CompressorsJavier LópezNo ratings yet

- Invoice CompetentDocument1 pageInvoice CompetentNaveen ChauhanNo ratings yet

- ATLAS Z KitsDocument13 pagesATLAS Z KitsRoberto ZevallosNo ratings yet

- Compressor Spare Parts ListDocument32 pagesCompressor Spare Parts ListUbanAirlanggaNo ratings yet

- CPVS 200 Spare Parts CatalogDocument52 pagesCPVS 200 Spare Parts CatalogFranNo ratings yet

- 2946 1223 00 - Overhaul Inter Cooler - After CoolerDocument12 pages2946 1223 00 - Overhaul Inter Cooler - After CoolerMax JohnNo ratings yet

- Ir Ac Parts ManualDocument83 pagesIr Ac Parts Manualmphammad akhtar khan0% (1)

- Curtis E50 Pump Parts ListDocument8 pagesCurtis E50 Pump Parts ListrobertNo ratings yet

- New Screw Compressor ElementDocument5 pagesNew Screw Compressor ElementNoufou DarankoumNo ratings yet

- Customer Service Report: Parameters Actuals ResponseDocument2 pagesCustomer Service Report: Parameters Actuals ResponseMASU BRAKE PADS QANo ratings yet

- Atlas Copco GA 15 To GA 30 Part List 20 21Document2 pagesAtlas Copco GA 15 To GA 30 Part List 20 21RICHARDNo ratings yet

- Rotary CompressorsDocument52 pagesRotary Compressorsmikeincognito100% (1)

- ZR 315 VSDDocument154 pagesZR 315 VSDLIDAIRNo ratings yet

- 10 6x7 PHE7 BA1 NLDocument8 pages10 6x7 PHE7 BA1 NLRavi KantNo ratings yet

- Blower RBS 145Document83 pagesBlower RBS 145salah ghazalNo ratings yet

- TG Filter 2015 PDFDocument154 pagesTG Filter 2015 PDFSergNo ratings yet

- 2946 1087 00 SPM-VDI Measurement GA 90-160Document3 pages2946 1087 00 SPM-VDI Measurement GA 90-160Tony Humberto GutierrezNo ratings yet

- SB Priority IV APP 2848 ACCIPX v3.14 Updated in CAT and Mercedes Driven Compressors PDFDocument3 pagesSB Priority IV APP 2848 ACCIPX v3.14 Updated in CAT and Mercedes Driven Compressors PDFNoufou DarankoumNo ratings yet

- SL-E Air End Service Manual Compressor ScrollDocument35 pagesSL-E Air End Service Manual Compressor ScrollLucky Karunia Setyawan PratamaNo ratings yet

- QGD55 75风冷外形图Document1 pageQGD55 75风冷外形图RUN GONo ratings yet

- Instruction Books GX2-11 20705403 PDFDocument78 pagesInstruction Books GX2-11 20705403 PDFmoises100% (1)

- XAS 67 DD (G) 2955 2260 00 ASL BookDocument224 pagesXAS 67 DD (G) 2955 2260 00 ASL BookFedor GrigorievNo ratings yet

- GHH Product Brochure enDocument16 pagesGHH Product Brochure entomescu_sorinNo ratings yet

- Apd Catalog PDFDocument28 pagesApd Catalog PDFsoo RenNo ratings yet

- Bürkert Type 331-C / 331-F: Technical SpecificationDocument2 pagesBürkert Type 331-C / 331-F: Technical SpecificationEvgeny TumalevNo ratings yet

- 647 (r01)Document58 pages647 (r01)Aarón HdezNo ratings yet

- RENNER screw compressors: 3.0-75 kW motor powerDocument5 pagesRENNER screw compressors: 3.0-75 kW motor powertitiNo ratings yet

- ServicecontractproposalDocument6 pagesServicecontractproposalNoufou DarankoumNo ratings yet

- Parts List - 17309089Document23 pagesParts List - 17309089Ramon SanhuezaNo ratings yet

- Compresor GX 5 AII 652233Document38 pagesCompresor GX 5 AII 652233victor enrique lopez pedrzaNo ratings yet

- Ga - 110 LincunaDocument554 pagesGa - 110 LincunaFloydMG Tecnomin100% (1)

- USOIL FREE Oil FreeScrewComps 07 2017 Tcm9 1089882Document28 pagesUSOIL FREE Oil FreeScrewComps 07 2017 Tcm9 1089882RyanNo ratings yet

- Compressors Parts List BookDocument12 pagesCompressors Parts List BookRafael Ribeiro De DavidNo ratings yet

- Evo3-Nk: Compact UnitDocument2 pagesEvo3-Nk: Compact Unitoussama100% (1)

- Hitachi Osp-11m5arnDocument1 pageHitachi Osp-11m5arnUbanAirlanggaNo ratings yet

- GA7-15 AII-145-420 Inst 2920-1471-01Document40 pagesGA7-15 AII-145-420 Inst 2920-1471-01JoeNo ratings yet

- CPB-RD IVR Part ListDocument28 pagesCPB-RD IVR Part ListgiridharNo ratings yet

- Bang Dieu Khien CurtisDocument23 pagesBang Dieu Khien CurtisHoa Nguyen Van100% (1)

- ZR 145 Aif - 085 444Document2 pagesZR 145 Aif - 085 444surendra SinghNo ratings yet

- Domnick Hunter Filter Housings & ElementsDocument1 pageDomnick Hunter Filter Housings & ElementsmuppetscrapNo ratings yet

- As90&110 Operation & Maintenance Manual 88291010-131 (01) - enDocument104 pagesAs90&110 Operation & Maintenance Manual 88291010-131 (01) - enDeased to ExistNo ratings yet

- Za 45-185 PDFDocument72 pagesZa 45-185 PDFSharad KokateNo ratings yet

- JN18 Parts Manual PDFDocument42 pagesJN18 Parts Manual PDFDionisio Ivan Martinez MercadoNo ratings yet

- Atlas Copco GA30-37-45 Stationary Air Compressor Parts ListDocument43 pagesAtlas Copco GA30-37-45 Stationary Air Compressor Parts ListPorfirioDuarteZarateNo ratings yet

- Requisition No. ITEM No. Description: Automiser Shaft SS ATM 160Document2 pagesRequisition No. ITEM No. Description: Automiser Shaft SS ATM 160Vaibhav KapadiNo ratings yet

- Qsi 490Document80 pagesQsi 490Javier CevallosNo ratings yet

- Ningbo Yinzhou H.T. Industry Co. LTD.: AF1-CMF/CM/CMH Single Pump Inverter Booster Brief IntroductionDocument6 pagesNingbo Yinzhou H.T. Industry Co. LTD.: AF1-CMF/CM/CMH Single Pump Inverter Booster Brief Introductionallah ditta shafiNo ratings yet

- Installation and Servicing Instructions for PGUH Range Series 3 Gas Fired Air HeatersDocument19 pagesInstallation and Servicing Instructions for PGUH Range Series 3 Gas Fired Air HeatersMalcolm WhittleNo ratings yet

- Regina Downtown Community Support Team ReportDocument28 pagesRegina Downtown Community Support Team ReportJeremy SimesNo ratings yet

- LPC Licensure Process HandbookDocument14 pagesLPC Licensure Process HandbookMac PatelNo ratings yet

- Vessel and Conveyors - VPDDocument4 pagesVessel and Conveyors - VPDAntonio Mizraim Magallon SantanaNo ratings yet

- Balanced Scorecard ThesisDocument59 pagesBalanced Scorecard Thesisapi-3825626100% (5)

- Intersecting Lines Intersecting Lines Parallel Lines Same LineDocument7 pagesIntersecting Lines Intersecting Lines Parallel Lines Same Lineapi-438357152No ratings yet

- History of DentistryDocument24 pagesHistory of DentistryEzhilarasi INo ratings yet

- Saberry ® - Cosmeceutical Applications of SaberryDocument2 pagesSaberry ® - Cosmeceutical Applications of SaberryGopalaKrishnan SivaramanNo ratings yet

- National Capital Region Schools Division Office Novaliches High School MAPEH Department Definitive Budget of Work for Blended Learning Modality Quarter 1 Grade 10Document9 pagesNational Capital Region Schools Division Office Novaliches High School MAPEH Department Definitive Budget of Work for Blended Learning Modality Quarter 1 Grade 10Ma. Cristina Angenel RamosNo ratings yet

- The Management of Productivity and Technology in Manufacturing PDFDocument333 pagesThe Management of Productivity and Technology in Manufacturing PDFmythee100% (2)

- ST Patrick Lodge 199 BibleDocument5 pagesST Patrick Lodge 199 Bibletofique_fatehiNo ratings yet

- Arm Cortex InstructionsDocument14 pagesArm Cortex InstructionsHamsini ShreenivasNo ratings yet

- Daniel J. Wood - Realm of The Vampire - History and The Undead-Galde Press (2013)Document156 pagesDaniel J. Wood - Realm of The Vampire - History and The Undead-Galde Press (2013)Jerry KanneNo ratings yet

- S1.8 Template of REAL Table For Power and Supporting CompetenciesDocument3 pagesS1.8 Template of REAL Table For Power and Supporting CompetenciesJamir SalongaNo ratings yet

- Hoshizaki IM-500SAA Icemaker Service ManualDocument39 pagesHoshizaki IM-500SAA Icemaker Service ManualBenjamin DoverNo ratings yet

- YLE - Top Tips and Common MistakesDocument15 pagesYLE - Top Tips and Common Mistakeskuvan alievNo ratings yet

- The Right Help at The Right Time: MatterDocument24 pagesThe Right Help at The Right Time: MattermariustudoracheNo ratings yet

- KR 280 R3080 F technical specificationsDocument1 pageKR 280 R3080 F technical specificationsDorobantu CatalinNo ratings yet

- Mapeh-7pe Q2 Summative-TestDocument2 pagesMapeh-7pe Q2 Summative-TestVhannie AcquiatanNo ratings yet

- Rulings On Healing and RukiyaDocument324 pagesRulings On Healing and RukiyatheproboxerNo ratings yet

- Technical Information No. 12 Vermicular Graphite Cast Iron: MicrostructureDocument1 pageTechnical Information No. 12 Vermicular Graphite Cast Iron: MicrostructureVelina MilevaNo ratings yet

- Resilience WorkbookDocument54 pagesResilience WorkbookLeo Siu100% (1)

- Business Model Canvas TemplateDocument5 pagesBusiness Model Canvas TemplateAsraihan Raihan100% (1)

- PR & PublicityDocument16 pagesPR & PublicityVipul Partap100% (2)

- ZISCO Installs World LongestDocument11 pagesZISCO Installs World LongestJoshua GrahitaNo ratings yet

- Vedic Healing Through Gems4Document3 pagesVedic Healing Through Gems4gesNo ratings yet

- Senior Power Apps Engineer JobDocument3 pagesSenior Power Apps Engineer JobMichałNo ratings yet

- Marketing Strategies Audit On Hewlett Packard (HP)Document19 pagesMarketing Strategies Audit On Hewlett Packard (HP)auraNo ratings yet

- تركيب وتشغيل وحدات تكييف الهواءDocument49 pagesتركيب وتشغيل وحدات تكييف الهواءOmar NabilNo ratings yet

- VELMATIC Well Service Air ValveDocument2 pagesVELMATIC Well Service Air Valvecarlos37No ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet