Professional Documents

Culture Documents

Ejemplo PDF

Ejemplo PDF

Uploaded by

Octavio ChableOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ejemplo PDF

Ejemplo PDF

Uploaded by

Octavio ChableCopyright:

Available Formats

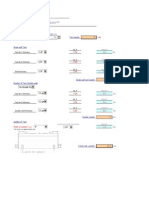

Pipe Branch Reinforcement Page 1 of 2

3/11/2012, ReinfS1.xls per ASME B31.1 -2010 Power Piping Code

Branch (1) Calculations

Client: Description: Prepared By Approval Date Rev.

Ben A. Nottingham 0

Customer No.: Item No.: 1

2

Owner No.: Dwg. No.: 3

4

The user is responsible to verify method and results.

Refer to para. 104.3.1 and Fig. 104.3.1(D) of the Code

Design Temperature -20 to 400 deg. F (to 204 deg. C) Dimensional Units Inch

Design Pressure Rating is based on design

Design pressure: 350 psig = 24.6 kg/cm^2 = 24.1 bar-G = 2413 kPa

Materials: Material Data per ASME B31.1 -2010, Tables A-1 thru A-9

Run Pipe: Appendix H, Example 4, Run & Branch: Carbon Steel, API 5L-A Seamless Pipe UNS no.: ----

Line Pipe

Allowable stress, SEh = 16 ksi = 110 MPa Coefficient Y = 0.4 Weld joint factor, E h = 1.00

Notes: para. H304 in ASME B31.3 Weld: S-1 Weld strength red. factor, W h = 1.00

Branch: Appendix H, Example 4, Run & Branch: Carbon Steel, API 5L-A Seamless Pipe UNS no.: ----

Line Pipe

Allowable stress, SEb = 16 ksi = 110 MPa Coefficient Y = 0.4 Weld joint efficiency factor, E b = 1.00

Notes: para. H304 in ASME B31.3 Weld: S-1 Weld strength reduction factor, W b = 1.00

Reinf: Appendix H, Example 4, Run & Branch: Carbon Steel, API 5L-A Seamless Pipe UNS no.: ----

Line Pipe

Allowable stress, SEr = 16 ksi = 110 MPa Weld: S-1 Notes: para. H304 in ASME B31.3

Longitudinal Weld Intersection? Does Branch-1 intersect a longitudinal weld on the run? Yes

Allowable stress of run for reinforcement design, SE hr = SE h when branch intersects a weld on the run,

or SE hr = SE h / E h when the branch does not intersect a weld on the run. SE hr = 16.0 ksi

Allowances Thickness allowance (corrosion, etc.) A= 0.1882 in.

Run Dimensions Branch Dimensions

Pipe size: NPS 8 (DN 200) Pipe size: NPS 4 (DN 100)

Wall thk: Sch 40 per ASME B36.10M Wall thk: Sch 40 per ASME B36.10M

Pipe outside diameter Doh = 8.625 in. Pipe outside diameter Dob = 4.5 in.

Pipe nominal thickness tnh = 0.322 in. Pipe nominal thickness: tnb = 0.237 in.

Thk. tolerance: Millh = 12.5% or h1 = 0.000 in. Thk. tolerance: Millb = 0.0% or h2 = 0.000 in.

Check if diameter and thickness ratios are reasonable using criteria from ASME B31.3, para. 304.3.1(b)(1) & (2).

(D ob / D oh ) must not exceed 1.0 OK … Branch OD is not greater than Run OD. D ob / D oh = 0.52

(D oh /T h ) must not exceed 100, unless D ob <(D oh / 2) OK… Run OD/ Run Thk. < 100. See below. D oh / T h = 30.6

Is branch size less than 1/2 of run size? OK… Branch OD may be any size not exceeding Run OD. D oh / 2 = 4.3 in.

Required minimum wall thicknesses. Refer to para. 104.1.2 Eq. (3) and Table 104.1.2(A) of B31.1 Code,

t m = [ P D o / (2 (SE + PY )) ] + A

Minimum required run thickness, t mh = [ P D oh / (2 (SE h + PY )) ] + A t mh = 0.2817 in.

Minimum required run thickness for reinforcement design, t mhr = [ P D oh / (2 (SE hr + P Y ) ] + A t mhr = 0.2817 in.

Run actual measured or minimum thickness, T h = t nh (1 - Mill h ) - h 1 Th = 0.282 in.

Run actual corroded thickness (measured or minimum thickness, less corrosion allowance), t ha = T h - A t ha = 0.094 in.

OK… Run thickness IS sufficient at design pressure.

Minimum required branch thickness, t mb = [P D ob / (2 (SE b + PY b1 )) ] + A t mb = 0.2370 in.

Branch actual measured or minimum thickness, T b = t nb (1 - Mill b ) - h 2 Tb = 0.237 in.

Branch actual corroded thickness (measured or minimum thickness, less corrosion allowance), t ba = T b - A t ba = 0.049 in.

OK… Branch thickness IS sufficient at design pressure

Pipe Branch Reinforcement Page 2 of 2

3/11/2012, ReinfS1.xls per ASME B31.1 -2010 Power Piping Code

Branch (1) Calculations

wwr r wwr r

wr

t nr = 0.322

Nom. thk. of pad: in. = 8.18 mm

ααtn

α

tri

w r = 0.875 thnr

tn rs trrnr

Width of pad from edge of branch: in. = 22.23 mm

Height of saddle above run: h s = n/a --

Optional Special Weld Dimensions:

Weld at pad or ring to branch periphery: W 1s = n/a -- Ring Reinforced (re-pad), 90-degree

Branch

Weld at ring, pad, or saddle outer edge: W 2s = n/a --

Weld at saddle-to-branch periphery: W 3s = n/a -- Comments:

-- -- -- -- --

Angle between run and branch: α = 90 degrees -- -- -- -- --

Integrally Reinforced B31.1 Branch: -- --

Leg of 60 deg. triangle = n/a t r i = n/a --

Width integral reinf. area = (tr i) tan 30 w r i = n/a --

Other Dimensions

Inside centerline longitudinal dimension of finished branch opening = [ D ob - 2 (T b - A ) ] / sin α d1 = 4.402 in.

Half width of reinf. zone = d 1 or (T b - A )+(T h -A ) + d 1 / 2, whichever is greater, but not more than D oh d2 = 4.402 in.

Reinf. zone height outside of run pipe, for ring or saddle = 2.5 (T h - A ) or 2.5 (T b - A ) + t nr , whichever is less Lr = 0.234 in.

Reinf. zone height outside of run pipe, for integrally reinforced fitting = 2.5 (T h - A ) Li = 0.000 in.

Reinf. zone height outside of run pipe = L r + L i L4 = 0.234 in.

Outside dimension of reinforcing ring or saddle (along run) = 2 w r + [ (D ob ) ( 2 - sin α ) ] Dr = 6.250 in.

Minimum throat of fillet weld at saddle-to-branch = (smaller of t nb or t nr ) ---[weld reference para. 127.4.8(B)] t min = 0.000 in.

Min. throat of weld at branch periphery (except saddle or integrally reinf.) = smaller of 6.0 mm (1/4") or 0.7 t nb tc = 0.166 in.

Minimum leg of weld at branch periphery (except saddle or integrally reinf.) = t c / 0.707 W 1(min) = 0.235 in.

Leg height of weld at branch periphery (except saddle or integrally reinf.) = greater of W 1(min) or W 1s W1 = 0.235 in.

Minimum leg of weld at outer edge of ring, pad, or saddle = 0.5 t nr / 0.707 W 2(min) = 0.228 in.

Leg height of weld at outer edge of ring, pad, or saddle = greater of W 2(min) , or W 2s , but W2 = 0.228 in.

not more than smaller of t nr or L 4 (must fit within the reinf. zone)

Minimum leg height of fillet weld at saddle-to-branch periphery = 0.7t min /0.707 W 3(min) = 0.000 in.

Leg height of fillet weld at saddle-to-branch periphery = greater of W 3(min) or W 3s W3 = 0.000 in.

Maximum width of ring, pad, or saddle which would apply = d 2 - (D ob / 2 ) / sin α WR max = 2.152 in.

Reinforcement height (except weld) = lesser of ( t nr or L 4 ) , or lesser of ( t r i or L 4 ), as applicable Rh = 0.234 in.

Reinforcement width (except weld) = (lesser of w r or WR max ), or (lesser of w r i or t ri ) tan 30, as applicable Rw = 0.875 in.

Count of Welds Within Reinforcement Zone

Factor for complete fillet welds, other than on ring, pad, or saddle edge, which will fit within the reinf. zone height N wh = 0

Factor for complete fillet welds on ring, pad, or saddle edge which will fit within reinforcement zone width N ww = 2

Strength Correction Factors

Factor for strength correction of branch area = 1 if SE b > SE h , or = (SE b / SE h ) if SE b <= SE h Fb = 1.000

Strength correction factor for reinforcing material = 1 if SE r > SE h , or = (SE r / SE h ) if SE r <= SE h Fr = 1.000

Strength correction factor for welds, F w = lesser of F b or F r Fw = 1.000

Areas

Pressure design area expected at end of service life = (t mhr - A ) d 1 A6 = 0.412 in.^2

Required reinforcement area = A 6 (2 - sin α ) A7 = 0.412 in.^2

Area of excess thickness in run pipe wall = (2 d 2 - d 1 ) (T h - t mhr ) A1 = 0.000 in.^2

Area of excess thickness in branch pipe wall = 2 L 4 (T b - t mb ) / sin α A2 = 0.000 in.^2

2 2 2

Total area of welds within zone = (N wh / 2)(W 1 )+(N wh / 2)(W 3 )+(N ww / 2)(W 2 ) A3 = 0.052 in.^2

Area of added reinforcement metal, except welds, within the reinforcement zone = 2 x R h x R w A4 = 0.409 in.^2

Area provided in B31.1 integrally reinforced fitting [See Fig. 104.3.1(D), Example B], = R h x R w A 4i = 0.000 in.^2

Total contributing area (with strength correction for added metal within the reinf. zone) Ac = 0.461 in.^2

A c = A 1 + (A 2 )(F b ) + (A 3 )(F w ) + (A 4 + A 4i )(F r )

Percent of area replaced = A c / A 7 % This branch has sufficient reinforcement. % Area 112%

You might also like

- Calculation of PipeReinforcement ASMEB31.1Document3 pagesCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Es Emp Iocal Colo en 13480Document25 pagesEs Emp Iocal Colo en 13480castibraNo ratings yet

- ASME B31.3 Area ReplacementDocument2 pagesASME B31.3 Area ReplacementJahsbuck100% (1)

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document3 pagesCalculation of Pipe Reinforcement ASME B31 3Brant AkkanNo ratings yet

- Pipe Support CalculationDocument2 pagesPipe Support Calculationjsmnjasmines86% (7)

- Pressure Design Straight Pipe (Run Pipe)Document6 pagesPressure Design Straight Pipe (Run Pipe)gembirasekaliNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document5 pagesCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- Cone Design Tool: Pressure Vessel Engineering LTDDocument1 pageCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleNithin ZsNo ratings yet

- Shell Inputs: Use Asme Code Section-8 Division I (Ug-37)Document34 pagesShell Inputs: Use Asme Code Section-8 Division I (Ug-37)Bashu PoudelNo ratings yet

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadNo ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Compress CalculationDocument106 pagesCompress CalculationKrupal Patel100% (1)

- Thickness Calculation of Pressure Vessel ShellDocument17 pagesThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- Asme b31 3 03 PDFDocument3 pagesAsme b31 3 03 PDFAtallah BoufatahNo ratings yet

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhobleNo ratings yet

- Agitator Nozzle Load Data SheetDocument1 pageAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBENo ratings yet

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindeNo ratings yet

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- WRC For NozzleDocument43 pagesWRC For NozzleSachin55860% (1)

- Branch RF CalcDocument6 pagesBranch RF CalcHarish Harish0% (1)

- Manual Design Validation CalculationDocument21 pagesManual Design Validation CalculationToniNo ratings yet

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- Pressure Vessel ExampleDocument48 pagesPressure Vessel ExamplemohamedNo ratings yet

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocument12 pagesMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00No ratings yet

- Branch Reinforcement Pad Requirement CalculationDocument1 pageBranch Reinforcement Pad Requirement Calculations.mladinNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Reinforcement Pad CalculationDocument5 pagesReinforcement Pad Calculationsada siva100% (1)

- Section VIII CalDocument22 pagesSection VIII Calthodathers100% (1)

- DummyDocument1 pageDummythopa_nath100% (2)

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Nozzle Calcs Rev ADocument6 pagesNozzle Calcs Rev AbolivarNo ratings yet

- IBR CalculationsDocument20 pagesIBR CalculationsSivi NallamothuNo ratings yet

- Mozzle Repad Design ToolDocument2 pagesMozzle Repad Design ToolSiddiqui Muhammad AshfaqueNo ratings yet

- What Is An ASME Appendix 2 Flange Design PDFDocument1 pageWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNo ratings yet

- Bolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Document2 pagesBolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Manoj MulikNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Ansi B16.9-16.28-MSS SP-43Document3 pagesAnsi B16.9-16.28-MSS SP-43vangie3339515No ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Branch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping CodeDocument2 pagesBranch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping Codedeua2004No ratings yet

- Reinforcement CalculationDocument2 pagesReinforcement CalculationVekaymech100% (9)

- Calculation of Pipe Reinforcement ASME B31.3Document9 pagesCalculation of Pipe Reinforcement ASME B31.3yhnsharma80% (5)

- Reinforcement CheckDocument2 pagesReinforcement Checkviv0102No ratings yet

- Asme Viii CalcsDocument20 pagesAsme Viii CalcsSriram VjNo ratings yet

- Design of Pressure ComponentsDocument34 pagesDesign of Pressure ComponentsYFFernando100% (1)

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 pagesDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNo ratings yet

- Pipe Reinforcement Calculation (ASME-B31.3)Document3 pagesPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Miter B1 ADocument55 pagesMiter B1 AFarid TataNo ratings yet

- Pipe or Tubing Support Span CalculationsDocument9 pagesPipe or Tubing Support Span CalculationskhaireddinNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document4 pagesCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 pagesPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNo ratings yet

- Pvelite PruebaDocument6 pagesPvelite PruebaLuis Cordova RamonNo ratings yet

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselDocument36 pagesBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungNo ratings yet

- ASME Code Section 8 ContentDocument6 pagesASME Code Section 8 ContenttasingenieriaNo ratings yet

- San Jose Del Rio: Suspension Bridge DesignDocument9 pagesSan Jose Del Rio: Suspension Bridge DesigntasingenieriaNo ratings yet

- Condulet® Cast Outlet Boxes 2FDocument1 pageCondulet® Cast Outlet Boxes 2FtasingenieriaNo ratings yet

- Polyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsDocument17 pagesPolyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicstasingenieriaNo ratings yet

- 1F Cast Conduit Outlet Bodies: Form 7 Snappack Pre-Assembled Body, Gasket and CoverDocument1 page1F Cast Conduit Outlet Bodies: Form 7 Snappack Pre-Assembled Body, Gasket and CovertasingenieriaNo ratings yet

- Beacon Engineers IncDocument4 pagesBeacon Engineers InctasingenieriaNo ratings yet

- Cone BottomDocument1 pageCone BottomtasingenieriaNo ratings yet

- 1F Condulet Conduit Outlet Bodies: Dimensions Pgs. 9 To 11Document1 page1F Condulet Conduit Outlet Bodies: Dimensions Pgs. 9 To 11tasingenieriaNo ratings yet

- Section8C Intrinsically Safe BarriersDocument29 pagesSection8C Intrinsically Safe BarrierstasingenieriaNo ratings yet

- 1F Condulet Conduit Outlet Bodies: Replacement GasketsDocument1 page1F Condulet Conduit Outlet Bodies: Replacement GasketstasingenieriaNo ratings yet

- 1F Mogul Pulling Elbows: ApplicationDocument1 page1F Mogul Pulling Elbows: ApplicationtasingenieriaNo ratings yet

- 1F Condulet Conduit Outlet Bodies: Covers With Gaskets On Page 15Document1 page1F Condulet Conduit Outlet Bodies: Covers With Gaskets On Page 15tasingenieriaNo ratings yet

- 5C Hazardous Factory Sealed Control DevicesDocument18 pages5C Hazardous Factory Sealed Control DevicestasingenieriaNo ratings yet

- Catalog 21Document77 pagesCatalog 21tasingenieriaNo ratings yet

- Cone BottomDocument1 pageCone BottomtasingenieriaNo ratings yet

- Copia de Tank Weight CalculatorDocument1 pageCopia de Tank Weight CalculatortasingenieriaNo ratings yet

- Catalogo Bomba 1Document4 pagesCatalogo Bomba 1tasingenieriaNo ratings yet