Professional Documents

Culture Documents

Determination of Trace Elements: Reagents

Uploaded by

Gustavo Tovar GaitanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determination of Trace Elements: Reagents

Uploaded by

Gustavo Tovar GaitanCopyright:

Available Formats

Determination of trace elements

EN 13805:2002

This is a method for the determination of iron, magnesium, potassium, sodium and calcium in

foodstuffs. The sample is mineralized through pressurized digestion with nitric acid. In the

resulting digestion solution, iron, magnesium, potassium, sodium and calcium are quantified by

inductively coupled plasma optical emission spectrometry (ICP-OES).

Reagents:

(only use recognized analytical grades, unless otherwise specified. The concentration of iron,

magnesium, potassium, sodium and calcium in the reagents and water used shall be low enough

not to affect the results of the determination)

Water, LiChrosolv® (1.15333)

Nitric acid 65% Suprapur® (1.00441)

Multi-element stock solution-Certipur® ICP multi-element standard solution IV (1.11355.0100)

ρ(Fe) = 1000 mg/L

ρ(Mg) = 1000 mg/L

ρ(K) = 1000 mg/L

ρ(Na) = 1000 mg/L

ρ(Ca) = 1000 mg/L

Multi-element standard and calibration solutions

The standard and calibration solutions are prepared from the stock solution by dilution in glass

volumetric flasks. For calibration, prepare at least five (5) calibration solutions of different

concentrations. The acid concentration shall correspond to the concentration in the measurement

solution. The preparation of the solutions below is given as an example.

of ρ(Fe, Mg, K, Na, Ca) = 0.5 mg/L, 1.0 mg/L, 2.5 mg/L, 5.0 mg/L, 10.0 mg/L for ICP-OES.

Fill five 100 mL volumetric flasks with 10-20 mL of water, add 10 mL of nitric acid and mix. Cool

the solutions to ambient temperature, and pipette exactly 0.05, 0.1, 0.25, 0.5, 1.0 mL of multi-

element stock solution for the respective calibration solutions of mass concentrations 0.5 mg/L,

1.0 mg/L, 2.5 mg/L, 5.0 mg/L, 10.0 mg/L into the five different 100 mL volumetric flasks.

Mix the solutions and dilute to volume with water.

The calibration solutions described here shall be understood as examples. The concentrations

prepared shall be in the linear range of the measuring device. The acid concentration of the

calibration solutions shall be matched to the acid concentration in the sample solution.

MilliporeSigma, a part of Merck KGaA, Darmstadt, Germany

www.emdmillipore.com/food-analysis 33

Determination of trace elements

EN 13805:2002

Blank solution

The blank solution contains water, nitric acid in amounts that correspond to the concentrations in

the measurement solution, for example 10 mL of nitric acid in 100 mL of water.

Apparatus

Microwave Reaction System

ICP- OES (Axial viewing).

Digestion of the sample

Mineralize the sample in pressurized digestion in accordance with EN 13805:2002. The digestion

requirements are based on the specifications of the instrument manufacturer, the reactivity of the

sample, the maximum pressure stability of the digestion vessel and the attainable temperature.

Precisely weigh 0.8-0.9 g of sample in digestion vessel and mix it 5 mL nitric acid and 1 mL water.

The digestion solution that results from the pressurized digestion according to the norm

can be used directly or can be diluted for the subsequent quantification of iron, magnesium,

potassium, sodium and calcium.

Inductively coupled plasma optical emission spectrometry (ICP – OES)

Start the instrument and let it stabilize, then optimize it according to the manufacturer’s

specifications and begin measurements. Use the blank solution to zero the instrument.

The calibration solutions in ascending order separately into the plasma and measure the emission

of element to be determined.

Evaluations

The following table gives relevant analytical lines for the determination with ICP – OES and limited

quantities.

Element Wavelength of emission (nm) LOQ (mg/kg)

Fe 239.562 2.0

Mg 280.271 1.0

Ca 315.887 3.0

Na 589.592 3.0

K 766.490 1.5

MilliporeSigma, a part of Merck KGaA, Darmstadt, Germany

www.emdmillipore.com/food-analysis 34

Determination of trace elements

EN 13805:2002

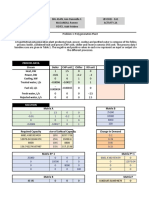

Calibration Data – Calcium (Ca):

100000

Sample ID ”Intensity” "Conc

80000 Y=8838x + 2955

(Height)" (mg/L)

R2=0.9975

1 9208 0.5 Intensity 60000

2 12475 1.0 40000

3 25234 2.5 20000

4 48070 5.0

0

5 90670 10.0 0 2 4 6 8 10

Concentration (mg/L)

Calibration Data – Sodium (Na)

1200000

Sample ID ”Intensity” "Conc Y=103514x + 15308

1000000

(Height)" (mg/L) R2=0.9964

800000

1 52753 0.5

Intensity

600000

2 91055 1.0

400000

3 224058 2.5

200000

4 464668 5.0

0

5 1042380 10.0 0,0 2,0 4,0 6,0 8,0 10,0

Concentration (mg/L)

Calibration Data – Magnesium (Mg) 2000000

Y=177736x + 5992

Sample ID ”Intensity” "Conc 1500000 R2=0.99996

(Height)" (mg/L)

Intensity

1000000

1 98003 0.5

2 184064 1.0 500000

3 453123 2.5

4 895895 5.0 0

0,0 2,0 4,0 6,0 8,0 10,0

5 1781856 10.0

Concentration (mg/L)

MilliporeSigma, a part of Merck KGaA, Darmstadt, Germany

www.emdmillipore.com/food-analysis 35

Determination of trace elements

EN 13805:2002

Calibration Data – Iron (Fe):

200000

Sample ID ”Intensity” "Conc Y=15634x + 622.1

(Height)" (mg/L) 150000 R2=0.9998

1 9052 0.5 Intensity 100000

2 16226 1.0

3 38950 2.5 50000

4 80062 5.0 0

5 156491 10.0 0,0 2,0 4,0 6,0 8,0 10,0

Concentration (mg/L)

Calibration Data –Potassium (K)

250000

Sample ID ”Intensity” "Conc Y=22793x + 4053.4

(Height)" (mg/L) 200000

R2=0.9964

Intensity

1 22605 0.5 150000

2 30335 1.0 100000

3 56651 2.5 50000

4 112827 5.0

0

5 234966 10.0

0,0 2,0 4,0 6,0 8,0 10,0

Concentration (mg/L)

Results: The table below present mean values of Iron (Fe), Magnesium (Mg), Calcium (Ca),

Sodium (Na) and Potassium (K) found in the three different type of samples.

Sample Fe Mg Ca Na K

(mg/Kg)

Beef 31.04 246.3 69.34 921.8 2692.5

Chicken 4.996 364.8 38.91 499.9 2946.3

Milk 1.329 123.5 402.2 402.2 1284.3

MilliporeSigma, a part of Merck KGaA, Darmstadt, Germany

www.emdmillipore.com/food-analysis 36

You might also like

- KinetikaDocument3 pagesKinetika'Dora Myron Jeruzielski'No ratings yet

- ShockDocument2 pagesShockSam GeorgeNo ratings yet

- Kurva Kalibrasi STD PCT: Analisis Data Pengujian Paracetamol Dengan HPLCDocument4 pagesKurva Kalibrasi STD PCT: Analisis Data Pengujian Paracetamol Dengan HPLCaprilia kurnia putriNo ratings yet

- Penentuan Uji Kelarutan KTI ParacetamolDocument6 pagesPenentuan Uji Kelarutan KTI ParacetamolMinul1412No ratings yet

- Supplementary MaterialDocument7 pagesSupplementary MaterialInigo JohnsonNo ratings yet

- Fugacity and Fugacity Coefficient of Steam at 300°CDocument2 pagesFugacity and Fugacity Coefficient of Steam at 300°Cczargee27No ratings yet

- OPTISONIC 3400 C - 4 InchDocument3 pagesOPTISONIC 3400 C - 4 InchMuhammad RizkyNo ratings yet

- Data Mentah PenelitianDocument6 pagesData Mentah PenelitianIrham KusumaNo ratings yet

- RegresilinierotkDocument4 pagesRegresilinierotkRanti RahayuNo ratings yet

- Diesel CalculationsDocument5 pagesDiesel CalculationspavanraneNo ratings yet

- Data EksperimenDocument1 pageData EksperimenAn Nur Zajar BmtNo ratings yet

- Material Data Sheet For NH35-45MICDocument3 pagesMaterial Data Sheet For NH35-45MICJean-Noël LerouxNo ratings yet

- Data PFR FixDocument7 pagesData PFR FixAnisa Mutia UlfaNo ratings yet

- P (Atm) C (Mol/g Gel) (1/PA) 1/C: Langmuir DisociativaDocument4 pagesP (Atm) C (Mol/g Gel) (1/PA) 1/C: Langmuir DisociativaTito PuloNo ratings yet

- Ejercicio 1. Método Integral Método Integral T CA 1/CA LN (CA)Document11 pagesEjercicio 1. Método Integral Método Integral T CA 1/CA LN (CA)Giselle Labanda JaramilloNo ratings yet

- Omnia 08206 - Datasheet SampleDocument8 pagesOmnia 08206 - Datasheet Samplepatra.thomiNo ratings yet

- Bab 4 IsoDocument4 pagesBab 4 IsoAkidah TahirNo ratings yet

- Concentration Vs Conductivity: 1.0 Results, Discussion and Analysis 1.1 Calibration CurveDocument9 pagesConcentration Vs Conductivity: 1.0 Results, Discussion and Analysis 1.1 Calibration CurveAhZaiSkyNo ratings yet

- Tercer Metodo: Curva Exponencial IDocument11 pagesTercer Metodo: Curva Exponencial Idavid calle alamoNo ratings yet

- Lab Report Batch Reactor GGDocument25 pagesLab Report Batch Reactor GGFrost Orchid100% (1)

- Omnia 08207 - Datasheet SampleDocument8 pagesOmnia 08207 - Datasheet Samplepatra.thomiNo ratings yet

- DataDocument6 pagesDataαγαπημένη του ΧριστούNo ratings yet

- BKF 2453 Chemical Reaction Engineering 1 Assignment 1: Lecturer: DR Sureena Binti AbdullahDocument9 pagesBKF 2453 Chemical Reaction Engineering 1 Assignment 1: Lecturer: DR Sureena Binti AbdullahThurgah VshinyNo ratings yet

- Acon (SMD) RVS SeriesDocument2 pagesAcon (SMD) RVS Serieskle98kNo ratings yet

- Beer-Lambert Law GraphsDocument2 pagesBeer-Lambert Law GraphsNona NanoNo ratings yet

- Kurva N Vs Light Kurva N Vs Heavy: N (RPM) N (RPM)Document4 pagesKurva N Vs Light Kurva N Vs Heavy: N (RPM) N (RPM)Jihan AzizahNo ratings yet

- Pengolah Data PFR (Abang)Document6 pagesPengolah Data PFR (Abang)Anonymous vjTWskvNo ratings yet

- LBYCHEJ - EA1 - Act2 - Group2 - Big-Asan, Macandili, Reyes-1Document12 pagesLBYCHEJ - EA1 - Act2 - Group2 - Big-Asan, Macandili, Reyes-1Romeo Anton MacandiliNo ratings yet

- Ejercicio 3 Tarea 1Document4 pagesEjercicio 3 Tarea 1Yajaira QuevedoNo ratings yet

- Municipal Solid Waste To MethanolDocument46 pagesMunicipal Solid Waste To MethanolShehla RiazNo ratings yet

- CH330 GroupC Plug Flow ReactorDocument8 pagesCH330 GroupC Plug Flow Reactorunnati singhNo ratings yet

- Batch ReactorDocument16 pagesBatch ReactorZharifah Bari'ah Basa'ahNo ratings yet

- Kurva Kalibrasi Standarpct: Konsentrasi (%)Document3 pagesKurva Kalibrasi Standarpct: Konsentrasi (%)aprilia kurnia putriNo ratings yet

- Experiment 1: The Visible Spectra of Soft Drinks: A. Pre-Laboratory QuestionsDocument5 pagesExperiment 1: The Visible Spectra of Soft Drinks: A. Pre-Laboratory QuestionsMuhd Mirza HizamiNo ratings yet

- 1 PBDocument1 page1 PBYordiantoNo ratings yet

- Excel Lab 2Document3 pagesExcel Lab 2Jean Pierre Cuadros PachecoNo ratings yet

- Omnia 08256 - Datasheet SampleDocument8 pagesOmnia 08256 - Datasheet Samplepatra.thomiNo ratings yet

- Omnia 08257 - Datasheet SampleDocument8 pagesOmnia 08257 - Datasheet Samplepatra.thomiNo ratings yet

- Exp 3Document2 pagesExp 3astay6318No ratings yet

- Šļ°íž Chapter2 RevisedDocument6 pagesŠļ°íž Chapter2 Revisedwhddnjs0815No ratings yet

- Prueba ReactoresDocument5 pagesPrueba ReactoresmariaNo ratings yet

- Viscosity Standard n4000 5181005110Document1 pageViscosity Standard n4000 5181005110Rachel McArdleNo ratings yet

- Trabalho Cinética - Grupo 1 - Relatório FinalDocument13 pagesTrabalho Cinética - Grupo 1 - Relatório FinalMariana AssadeNo ratings yet

- L52 Online Assignment Question 1Document3 pagesL52 Online Assignment Question 1Raj PatelNo ratings yet

- Bondocch4810 ActivitycoefficientDocument4 pagesBondocch4810 ActivitycoefficientTope BondocNo ratings yet

- Practical Considerations For Conductivity and Total Dissolved Solids MeasurementDocument5 pagesPractical Considerations For Conductivity and Total Dissolved Solids MeasurementVarun KumarNo ratings yet

- Reverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018Document3 pagesReverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018unconformistNo ratings yet

- Experiment Eight: Spectrophotometric Analysis of A Complex MixtureDocument12 pagesExperiment Eight: Spectrophotometric Analysis of A Complex MixtureMark AwNo ratings yet

- Simulated Data For A High Performance Mustang: Time MPH Accel - Gs Miles C - RPM Engrpm Log (Dist) /MPHDocument4 pagesSimulated Data For A High Performance Mustang: Time MPH Accel - Gs Miles C - RPM Engrpm Log (Dist) /MPHRiza Gabaya AliaNo ratings yet

- Table & FigureDocument5 pagesTable & FigureNabilla Putri AndiniNo ratings yet

- Bromatologia CurvasDocument9 pagesBromatologia CurvasMarco Antonio Cabana MezaNo ratings yet

- Contoh Val-Ver Ortofosfat-OkDocument15 pagesContoh Val-Ver Ortofosfat-OkRANY RAMADHANINo ratings yet

- Oriental Aquamarine Biotech India Oriental Aquamarine Biotech India (P) Limited CoimbatoreDocument35 pagesOriental Aquamarine Biotech India Oriental Aquamarine Biotech India (P) Limited CoimbatorevlabdulazeemNo ratings yet

- Sample Number Sample Time Elapsed Time Sodium Hydroxide Concentaion (Mol/dm ) Ethyl Acetate Concentraio N (Mol/dm )Document5 pagesSample Number Sample Time Elapsed Time Sodium Hydroxide Concentaion (Mol/dm ) Ethyl Acetate Concentraio N (Mol/dm )Kelly Sheine SisonNo ratings yet

- Sample Number Sample Time Elapsed Time Sodium Hydroxide Concentaion (Mol/dm ) Ethyl Acetate Concentraio N (Mol/dm )Document5 pagesSample Number Sample Time Elapsed Time Sodium Hydroxide Concentaion (Mol/dm ) Ethyl Acetate Concentraio N (Mol/dm )Kelly Sheine SisonNo ratings yet

- s5 TabDocument6 pagess5 TabDaniel DichosoNo ratings yet

- Pub Ammonia FWTDocument3 pagesPub Ammonia FWTMuhammad NaeemNo ratings yet

- Carga (N) Dist. Entre Puntos (MM)Document7 pagesCarga (N) Dist. Entre Puntos (MM)Enrique GonzálezNo ratings yet

- 2) Result For Coffea RobustaDocument6 pages2) Result For Coffea RobustaVinda PatriciaNo ratings yet

- Geometry of Middle SurfaceDocument29 pagesGeometry of Middle SurfaceParth ShahNo ratings yet

- The Singapore Success StoryDocument14 pagesThe Singapore Success StoryMaria SchiporNo ratings yet

- 5 6316334533637570613Document5 pages5 6316334533637570613Nishant PathakNo ratings yet

- ADSA Assignment-1 Group - 3Document16 pagesADSA Assignment-1 Group - 3Animesh KumarNo ratings yet

- GAP Guidelines: Management Programs (Overview)Document27 pagesGAP Guidelines: Management Programs (Overview)LleiLlei100% (1)

- MSA WorksheetDocument33 pagesMSA WorksheetSandrawarman BalasundramNo ratings yet

- D502K5+4 Operators ManualDocument68 pagesD502K5+4 Operators ManualOscar RamirezNo ratings yet

- Schlosser Distillation SSCHI 2011 256Document14 pagesSchlosser Distillation SSCHI 2011 256Brandon LizardoNo ratings yet

- Sensair Manual 1.0 en PDFDocument104 pagesSensair Manual 1.0 en PDFPaul KinsellaNo ratings yet

- FIS-Finishes Schedule - R1Document4 pagesFIS-Finishes Schedule - R1meghadurganNo ratings yet

- Scheme and Syllabus FOR M. Tech. Degree Programme IN Civil Engineering With SpecializationDocument60 pagesScheme and Syllabus FOR M. Tech. Degree Programme IN Civil Engineering With SpecializationAdila AbdullakunjuNo ratings yet

- Graphic OrganizerDocument2 pagesGraphic OrganizerLex TalionesNo ratings yet

- Shaker SK L180 SDocument1 pageShaker SK L180 SUPT LABKESDA KAB PADANG PARIAMANNo ratings yet

- 2020 Book ThePalgraveHandbookOfGlobalSocDocument1,039 pages2020 Book ThePalgraveHandbookOfGlobalSocYoussef AmzilNo ratings yet

- Online Medical Delivery ServiceDocument10 pagesOnline Medical Delivery ServiceYESHUDAS JIVTODENo ratings yet

- CH 9. Heat - Thermodynamics (Phy +1)Document84 pagesCH 9. Heat - Thermodynamics (Phy +1)tomyNo ratings yet

- Principles of Engineering Thermodynamics - SI Version 8th EditionDocument47 pagesPrinciples of Engineering Thermodynamics - SI Version 8th EditionanabNo ratings yet

- FC9170 02Document14 pagesFC9170 02ВладимирNo ratings yet

- Basic Measurement PiezoeletricDocument6 pagesBasic Measurement PiezoeletricALEX_INSPETORNo ratings yet

- Jasmi HashimDocument364 pagesJasmi HashimRudraraju ChaitanyaNo ratings yet

- Lesson Plan - The V LanguageDocument4 pagesLesson Plan - The V LanguageLê Thị Ái NhiNo ratings yet

- Chap 16Document53 pagesChap 16EveNo ratings yet

- 08 - Chapter 1 OpDocument11 pages08 - Chapter 1 OpRanjeet KoreNo ratings yet

- Domain 2 Communication and Interpersonal SkillsDocument4 pagesDomain 2 Communication and Interpersonal SkillsLip StickNo ratings yet

- Cajas de Piso General Marca HubbellDocument52 pagesCajas de Piso General Marca HubbellMax Cristiano KenuncaNo ratings yet

- English: Quarter 2 - Module 1 Listening Strategies Based On Purpose, Familiarity With The Topic, and Levels of DifficultyDocument24 pagesEnglish: Quarter 2 - Module 1 Listening Strategies Based On Purpose, Familiarity With The Topic, and Levels of DifficultyMary Ysalina100% (3)

- CBSE Class 11 History Syllabus 2021-22Document12 pagesCBSE Class 11 History Syllabus 2021-22Muskan TiwariNo ratings yet

- Annual Report Final 2017-18 enDocument232 pagesAnnual Report Final 2017-18 enNidhi DesaiNo ratings yet

- Filipino ThinkingDocument2 pagesFilipino ThinkingRheyven JuanNo ratings yet

- Rating and OTB RatingDocument7 pagesRating and OTB RatingpontathesmithjapanNo ratings yet