Professional Documents

Culture Documents

Bechtffs Software: The Becht Difference

Uploaded by

Octavio ChableOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bechtffs Software: The Becht Difference

Uploaded by

Octavio ChableCopyright:

Available Formats

BechtFFS SOFTWARE

The Becht Difference

Becht Engineering is a specialty engineering provider for the refinery, petrochemical, and chemical

industries. Becht has provided Fitness for Service evaluations to many clients in the past. Becht

personnel, most with over 25 years of experience, had long term careers within Owner

Organizations and, as a result, approach a project with an owners’ perspective of quality, cost

and schedule.

The benefits of BechtFFS Software Overview of the BechtFFS Software

Immediate access from any internet-enabled device The BechtFFS is an API 579-1/ASME

Developed by leading industry FFS experts FFS-1 2016 edition compliant, web-

based software designed to assist

User-friendly format operators/owners in evaluating

Quick, fee-based consulting support from FFS equipment items which have developed

Subject Matter Experts defects in service. The quantitative

calculations performed in BechtFFS

assess the structural integrity of the flawed component and ultimately provide a recommendation

whether the component should be taken out of service and retired or repaired, or is fit for

continued service.

The software’s calculation methodology was developed by Becht’s API 579-1/ASME FFS-1

experts. Our FFS experts include contributors to the API 579-1/ASME FFS-1 guideline document.

A number of our FFS experts are current or past members of the API 579-1/ASME FFS-1

committee, including

several committee vice-

chairs.

The BechtFFS software

is easy to use, with a

paged format that

Eileen Chant

Becht Engineering

Software Solutions

ffs@becht.com

Graphics https://bechtffs.com

throughout the Fracture Mechanics

application Geometry Input Page

facilitate data Becht Engineering

entry

We Solve Problems…

For more information, contact:

Becht Engineering

908-580-1119

https://bechtffs.com

provides logical input sequences and

comprehensive pop-up help for all input

pages.

Popup help with

detailed input

descriptions on The web-based format allows users to begin

every screen

using it immediately once logon credentials

are approved. The software can be used

from any device with an Internet connection.

Fracture Mechanics Failure Assessment

Diagram (FAD) and Crack Growth Chart

Level 1 LTA Data Input Screen

The software is compatible with mobile devices. Finally,

the web-based format ensures that users are always

working with the most up-to-date version of the

software.

Paid-for-FFS consultation is also available from the

software’s dashboard, so that you can quickly connect

with one of our FFS experts. We guarantee a quick

response!

The software allows easy sharing of FFS assessment

data with other BechtFFS users. The application gives

you the option of either storing your FFS assessment

Becht Engineering Code Expertise

data on your local network or on our server.

Becht Engineering holds over 40 positions in

The software generates a series of reports for each ASME, API, and ASTM Codes and Standards

assessment module, from summary to detailed reports Committees, and has chaired many of them.

documenting the outcome of the assessment. The Bob Sims was one of the original developers of

the API 579-1/ASME FFS-1 guideline

user can select the format of the report from HTML, document. A number of our experts are current

Excel, Word and PDF. or past members of the API 579-1/ASME FFS-1

committee, including several committee vice-

chairs.

Becht Engineering Co., Inc.

22 Church Street, P.O. Box 300; Liberty Corner, New Jersey 07938 – Phone (908) 580-1119

http://becht.com

Architecture

BechtFFS is a web-based software application service custom-built on Microsoft’s Windows Server,

Internet information services (IIS), ASP.NET, and SQL Server technologies.

Reports are generated using SQL Server Reporting Services and are available in HTML, MS-Excel,

PDF, or MS-Word format.

Local Metal Loss Level 2 Input Page

Brittle Fracture MAT Plot and Component Summary

Becht Engineering Co., Inc.

22 Church Street, P.O. Box 300; Liberty Corner, New Jersey 07938 – Phone (908) 580-1119

http://becht.com

BechtFFS Web-based Software Features

Brittle Fracture per API 579-1/ASME FFS-1 Part 3, Levels 1, 2A, 2B and 2C

Level 2 Method A stress ratio thickness basis including longitudinal stresses for B31.3 piping

Output is envelope of allowable operating temperatures as a function of pressure (0 to design pressure)

User Entered and Vapor Pressure (autorefrigeration) library of curves selectable for inclusion in MAT plot

Analyzes interconnected (welded, bolted) assemblies

Fracture Mechanics per API 579-1/ASME FFS-1 Part 9 & ASME VIII, Div 3, Article KD-4

20 Annex 9B stress intensity and Annex 9C reference stress geometries

FAD Stability Assessment including FAD diagram

Library of crack growth rate factors from Table KD430 and API 579/ASME FFS

Multiple Load Cases

User entered stress profiles include cycling loads, primary only, secondary only and weld residual.

Annex 9D weld residual stress profiles

Hydrogen Environment crack growth parameters

Simultaneous simulation of 2 sets of FEA stress profiles

General Metal Loss per API 579-1/ASME FFS-1 Part 4, Levels 1 and 2

Point Thickness Reading (PTR) assessment

Critical Thickness Profile (CTP) assessment

Accommodates large scanned dataset and software color codes the grid, and identifies and analyzes

individual LTAs (CTP)

Assessments at nozzles and branch connections per para 4.4.3.3

Local Metal Loss per API 579-1/ASME FFS-1 Part 5 and B31G, Levels 1 and 2

Maximum External Pressure

Accommodates large scanned dataset and software color codes the grid, and identifies and analyzes

individual LTAs (Level 2)

Assessments at nozzles and branch connections per para 4.4.3.3

Pitting per API 579-1/ASME FFS-1 Part 6, Level 1

Display pitting charts 6.6 through 6.13

Upload damage image for comparison with pitting charts and inclusion in report

Weld Misalignment per API 579-1/ASME FFS-1 Part 8, Level 2

Centerline offset and/or angular misalignment

Creep Rupture Life per API 579-1/ASME FFS-1 Part 10

Omega Project and LMP Creep Rupture Life per 10.5.2

Fatigue Damage Screening per API 579-1/ASME FFS-1 Part 14

Additional

MAWP/tmin calculations (for ASME Section VIII, Div 1 Shells, and Heads, B31.3 and API 650.

Becht Engineering Co., Inc.

22 Church Street, P.O. Box 300; Liberty Corner, New Jersey 07938 – Phone (908) 580-1119

http://becht.com

You might also like

- VPAT2 0 TA 8002iDocument16 pagesVPAT2 0 TA 8002iJosé Bonifácio Marques de AmorimNo ratings yet

- Securing Application Deployment with Obfuscation and Code Signing: How to Create 3 Layers of Protection for .NET Release BuildFrom EverandSecuring Application Deployment with Obfuscation and Code Signing: How to Create 3 Layers of Protection for .NET Release BuildNo ratings yet

- More Inside!: Festo Software Tool FST 4.10Document2 pagesMore Inside!: Festo Software Tool FST 4.10ohiNo ratings yet

- Ulmer-System IntegrationDocument17 pagesUlmer-System IntegrationriponcseNo ratings yet

- Phoenix WorkBenchDocument4 pagesPhoenix WorkBenchHeru Rahman GintingNo ratings yet

- Promis.e DataSheet PDFDocument2 pagesPromis.e DataSheet PDFScout StNo ratings yet

- Welcome To ETABSDocument57 pagesWelcome To ETABSmizanaNo ratings yet

- Study of Piping Stress Parametric Analysis Based On Computer SimulationDocument9 pagesStudy of Piping Stress Parametric Analysis Based On Computer SimulationSakuNo ratings yet

- Delphi Informant Magazine Vol 6 No 7Document39 pagesDelphi Informant Magazine Vol 6 No 7sharkfinmikeNo ratings yet

- Chernyscv PDFDocument11 pagesChernyscv PDFatnNo ratings yet

- BEx FrontEnd PerformanceDocument9 pagesBEx FrontEnd PerformanceFabrizio ReginiNo ratings yet

- Richard J Troiano 122 Fantages Way Folsom CA 95630 916-985-6473Document5 pagesRichard J Troiano 122 Fantages Way Folsom CA 95630 916-985-6473Richard TroianoNo ratings yet

- Edt Drilling Summaryreleasenotes5000.1Document88 pagesEdt Drilling Summaryreleasenotes5000.1jafarNo ratings yet

- Meenakshi KDocument5 pagesMeenakshi Kshantibhushan.saleNo ratings yet

- Richard J Troiano 122 Fantages Way Folsom CA 95630 916-985-6473Document4 pagesRichard J Troiano 122 Fantages Way Folsom CA 95630 916-985-6473Richard TroianoNo ratings yet

- Using Embedded Web-Servers in Industrial ApplicationsDocument8 pagesUsing Embedded Web-Servers in Industrial ApplicationsBharath PalanisamyNo ratings yet

- Customizing A CAE Interface To PointwiseDocument2 pagesCustomizing A CAE Interface To Pointwisefajar anggaraNo ratings yet

- 4 02 0250 20010 Vci en A4Document20 pages4 02 0250 20010 Vci en A4Yean Jen ChanNo ratings yet

- PNIO DKSW Description V300Document30 pagesPNIO DKSW Description V300Fabio MachadoNo ratings yet

- Mark Burak ResumeDocument2 pagesMark Burak Resumeapi-204440638No ratings yet

- Labcenter Electronics - Proteus VSM - SPICE Co-Simulation - Debugging Benefits For PIC, 8051, AVR, HC11 and ARMDocument2 pagesLabcenter Electronics - Proteus VSM - SPICE Co-Simulation - Debugging Benefits For PIC, 8051, AVR, HC11 and ARMmohuddinNo ratings yet

- CX ONE V2.0 FuncionesDocument5 pagesCX ONE V2.0 FuncionesOmar CortesNo ratings yet

- Advanced Capabilities, Features, and Benefits of Proteus PCBDocument7 pagesAdvanced Capabilities, Features, and Benefits of Proteus PCBjackNo ratings yet

- Designer PM Manual 2Document664 pagesDesigner PM Manual 2marceloayadNo ratings yet

- Noodleface 310 Noodle Street Noodletown, MA, 02noodle: Software Engineer 1 - UEFI BIOS (August 2014 To Present)Document1 pageNoodleface 310 Noodle Street Noodletown, MA, 02noodle: Software Engineer 1 - UEFI BIOS (August 2014 To Present)Andrew CorsiniNo ratings yet

- GFS-400 M01 - Introduction To Proficy Process SystemsDocument20 pagesGFS-400 M01 - Introduction To Proficy Process SystemsLuchiian AlexandruNo ratings yet

- NetworkDesigner22 LIN Manual enDocument72 pagesNetworkDesigner22 LIN Manual enTeodorescu MihailNo ratings yet

- Free Structural SoftwareDocument16 pagesFree Structural SoftwareRaamkrishnanNo ratings yet

- INCOSERMTool Survey Vendor Contact InfoDocument37 pagesINCOSERMTool Survey Vendor Contact InfoiwatobesNo ratings yet

- ReadmeDocument10 pagesReadmenihal_ahmad2068No ratings yet

- Modelling Analysis Welding Process Abaqus Virtual 2008 PDFDocument1 pageModelling Analysis Welding Process Abaqus Virtual 2008 PDFsaeed-21No ratings yet

- Promis E V8: I (Selectseries 7)Document2 pagesPromis E V8: I (Selectseries 7)Ishu VohraNo ratings yet

- Promis.e: Advance Your Electrical Design With Intelligent ModelingDocument2 pagesPromis.e: Advance Your Electrical Design With Intelligent ModelingRahul JadhavNo ratings yet

- Chapter - IDocument36 pagesChapter - ISom ChoudhaNo ratings yet

- Andrew Corsini Resume ReviewDocument1 pageAndrew Corsini Resume ReviewAndrew CorsiniNo ratings yet

- All You Need To Know About The SMT File Format and SMT SoftwareDocument5 pagesAll You Need To Know About The SMT File Format and SMT SoftwarejackNo ratings yet

- VbugDocument428 pagesVbugNithishNo ratings yet

- 1RE PDS Bentley Instrumentation Wiring LTR en LR 0116Document2 pages1RE PDS Bentley Instrumentation Wiring LTR en LR 0116luciaNo ratings yet

- Promis eDocument2 pagesPromis eAppleNo ratings yet

- Eb BillDocument11 pagesEb BillRaja GopalanNo ratings yet

- Admission ManagementDocument74 pagesAdmission ManagementSunny BhargavNo ratings yet

- Proficy Machine EditionDocument8 pagesProficy Machine EditionConstanza Reyes BantoNo ratings yet

- StruxureWare Building Operation PA 1.6.1Document8 pagesStruxureWare Building Operation PA 1.6.1Arman Ul NasarNo ratings yet

- Bentley AutoPIPE 2023 v23.00.01.367 x64 + CONNECTDocument10 pagesBentley AutoPIPE 2023 v23.00.01.367 x64 + CONNECTSDNo ratings yet

- Webex Video Bandwidth GuideDocument15 pagesWebex Video Bandwidth GuidearielenryNo ratings yet

- Cibw781995 TheprojectmodelofanautomatedbuildingsystemDocument14 pagesCibw781995 TheprojectmodelofanautomatedbuildingsystemMECH 503 ShivamNo ratings yet

- Access Control SpecsDocument31 pagesAccess Control SpecsLawrence MagureNo ratings yet

- SoMachine V4.3 Patch1.1-ReleaseNotes - ENDocument7 pagesSoMachine V4.3 Patch1.1-ReleaseNotes - ENAyo OtmasNo ratings yet

- Ab B1 Ac 500Document12 pagesAb B1 Ac 500Ferryus DevidsonNo ratings yet

- Electronics Circuit DesignDocument8 pagesElectronics Circuit DesignBikash RoutNo ratings yet

- SPARK UI Toolkit Release Notes 4.5.4Document22 pagesSPARK UI Toolkit Release Notes 4.5.4bpmn2008No ratings yet

- Tutorial ETS3Document37 pagesTutorial ETS3Alex KnezNo ratings yet

- Autocad Mep 2008 BrochureDocument8 pagesAutocad Mep 2008 BrochureOmar ChirinoNo ratings yet

- Etabs Mate Quick Start - enDocument27 pagesEtabs Mate Quick Start - ensipilNo ratings yet

- PEC Solution Guide: Premier Edition Cloud CurrentDocument50 pagesPEC Solution Guide: Premier Edition Cloud CurrentLaluMohan KcNo ratings yet

- Whiteboard Capture and Processing For E-LearningDocument43 pagesWhiteboard Capture and Processing For E-LearninglaxmanaNo ratings yet

- Software - PLCNEXT ENGINEER - 1046008: Your AdvantagesDocument5 pagesSoftware - PLCNEXT ENGINEER - 1046008: Your AdvantagesAyoub MouihNo ratings yet

- DGI KTS-Reihe Family Broch Ad En5Document24 pagesDGI KTS-Reihe Family Broch Ad En5Chalitha KumarapeliNo ratings yet

- Mau CV Bang Tieng Anh Curriculum VitaeDocument8 pagesMau CV Bang Tieng Anh Curriculum Vitaeduyennguyen1306No ratings yet

- 46927-Folio BaymontDocument1 page46927-Folio BaymontOctavio ChableNo ratings yet

- Asq (CSSGB) Study Guide and How To Crack Exam On Asq Certified Six Sigma Green BeltDocument5 pagesAsq (CSSGB) Study Guide and How To Crack Exam On Asq Certified Six Sigma Green BeltHrishikesh WaghNo ratings yet

- UTDocument41 pagesUTOctavio Chable100% (1)

- 42 Usd - Invoice Astm D4285Document1 page42 Usd - Invoice Astm D4285Octavio ChableNo ratings yet

- BaptismalPrayer PDFDocument5 pagesBaptismalPrayer PDFOctavio ChableNo ratings yet

- QGWB - MH48087 Flame-Resistant Clothing For Protection of Industrial Personnel Against Short-Duration Thermal Exposures From FireDocument1 pageQGWB - MH48087 Flame-Resistant Clothing For Protection of Industrial Personnel Against Short-Duration Thermal Exposures From FireOctavio ChableNo ratings yet

- Procedure Checklist ASTM C 31 Making and Curing Concrete Test Specimens in The FieldDocument1 pageProcedure Checklist ASTM C 31 Making and Curing Concrete Test Specimens in The Fieldmike murdocNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Certificate of Completion: Natural Gas Flexible Hose TOP - CA/US/MX (EN/SP)Document1 pageCertificate of Completion: Natural Gas Flexible Hose TOP - CA/US/MX (EN/SP)Octavio ChableNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Repair Epoxy Cement Fills Dents and Protects Against CorrosionDocument2 pagesRepair Epoxy Cement Fills Dents and Protects Against CorrosionOctavio ChableNo ratings yet

- 40haz - 14 Hazardous Communication PDFDocument1 page40haz - 14 Hazardous Communication PDFOctavio ChableNo ratings yet

- E XCAVACIONESDocument3 pagesE XCAVACIONESOctavio ChableNo ratings yet

- Temper Bead TechniqueDocument4 pagesTemper Bead TechniqueOctavio ChableNo ratings yet

- 40haz - 03 Fall HazardsDocument1 page40haz - 03 Fall HazardsochableNo ratings yet

- Temper Bead TechniqueDocument4 pagesTemper Bead TechniqueOctavio ChableNo ratings yet

- Certificado Portable Gas DetectionDocument1 pageCertificado Portable Gas DetectionOctavio ChableNo ratings yet

- Nail GunsDocument2 pagesNail GunsOctavio ChableNo ratings yet

- Gasurveyor 700: Gas Measurement Instruments LTDDocument49 pagesGasurveyor 700: Gas Measurement Instruments LTDOctavio ChableNo ratings yet

- 40haz - 03 Fall HazardsDocument1 page40haz - 03 Fall HazardsochableNo ratings yet

- Gasurveyor 700 Series: Ensuring ComplianceDocument2 pagesGasurveyor 700 Series: Ensuring ComplianceOctavio ChableNo ratings yet

- Flexicalnethandbook PDFDocument110 pagesFlexicalnethandbook PDFOctavio ChableNo ratings yet

- Arthur Mellen WellingtonDocument2 pagesArthur Mellen WellingtonCarolina2014esNo ratings yet

- Pulsar220S PLANOS PDFDocument32 pagesPulsar220S PLANOS PDFJuan Jose MoralesNo ratings yet

- Chip Mong Noro Mall: Property OverviewDocument4 pagesChip Mong Noro Mall: Property OverviewHe VansakNo ratings yet

- Ael Igniter CordsDocument1 pageAel Igniter CordsAlexander OpazoNo ratings yet

- Store Visit ChecklistDocument5 pagesStore Visit ChecklisthayeslnlNo ratings yet

- Nature 1Document6 pagesNature 1Susanty SainudinNo ratings yet

- PWR Bi2Document11 pagesPWR Bi2GOMTINo ratings yet

- Declaration Letter - Vetagro To GSDocument3 pagesDeclaration Letter - Vetagro To GSVíctor RodríguezNo ratings yet

- Model AnswerDocument27 pagesModel AnswerdishaNo ratings yet

- Carte Blanche: The New James Bond Novel by Jeffery DeaverDocument12 pagesCarte Blanche: The New James Bond Novel by Jeffery DeaverSimon and Schuster0% (1)

- Abstract of SURYA NAMASKARDocument23 pagesAbstract of SURYA NAMASKARSarita SharmaNo ratings yet

- Chapter 2 - Coordinate GeometryDocument73 pagesChapter 2 - Coordinate GeometryFILIP CEZARNo ratings yet

- IKM - Sample Size Calculation in Epid Study PDFDocument7 pagesIKM - Sample Size Calculation in Epid Study PDFcindyNo ratings yet

- Wa0001.Document1 pageWa0001.Esmael Vasco AndradeNo ratings yet

- DL Throughput Improvement with Aperiodic CQI ReportingDocument10 pagesDL Throughput Improvement with Aperiodic CQI ReportingAqeel HasanNo ratings yet

- Radiation Safety Procedure Rev.08Document41 pagesRadiation Safety Procedure Rev.08manz29No ratings yet

- Relative Density and Load Capacity of SandsDocument14 pagesRelative Density and Load Capacity of SandsgatotNo ratings yet

- Hurqalya - HavarqalyaDocument64 pagesHurqalya - HavarqalyaBVILLARNo ratings yet

- Agard Ar 138 PDFDocument612 pagesAgard Ar 138 PDFAshwani AssamNo ratings yet

- Atoms & Ions Worksheet 1 /63: Atomic Number and Mass NumberDocument4 pagesAtoms & Ions Worksheet 1 /63: Atomic Number and Mass Numbercate christineNo ratings yet

- Mushroom Umami Taste EvaluationDocument10 pagesMushroom Umami Taste EvaluationMaryam HanifNo ratings yet

- BA Anchor Data SheetDocument17 pagesBA Anchor Data SheetbrodieNo ratings yet

- Forward Blocking ModeDocument10 pagesForward Blocking ModeSmithi SureshanNo ratings yet

- B. Ingg Paket BDocument14 pagesB. Ingg Paket BAsep Fajar IrawanNo ratings yet

- La Consolacion College - Caloocan: Module in General Physics 1 Module 5: Kinematic QuantitiesDocument6 pagesLa Consolacion College - Caloocan: Module in General Physics 1 Module 5: Kinematic QuantitiesJhon Christian ManzoNo ratings yet

- Seismic Design Coefficients and Factors TableDocument3 pagesSeismic Design Coefficients and Factors TableJonathan ColeNo ratings yet

- Revisiting The Irish Royal Sites: Susan A. JohnstonDocument7 pagesRevisiting The Irish Royal Sites: Susan A. JohnstonJacek RomanowNo ratings yet

- Scania Rear View Mirror Removal and InstallationDocument8 pagesScania Rear View Mirror Removal and InstallationRuanNo ratings yet

- Chapter 11: The EyesDocument26 pagesChapter 11: The Eyesriley2021No ratings yet

- All ProblemsDocument107 pagesAll ProblemsjoshiabhijeetNo ratings yet

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

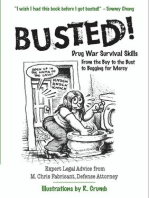

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)