Professional Documents

Culture Documents

Practice #9: Pumps in Series and in Parallel: Hydraulics Lab Professor: Jose Manuel Molano Martínez

Uploaded by

MikeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practice #9: Pumps in Series and in Parallel: Hydraulics Lab Professor: Jose Manuel Molano Martínez

Uploaded by

MikeCopyright:

Available Formats

Practice #9: Pumps in

Series and in Parallel

Hydraulics Lab

Professor: Jose Manuel Molano Martínez

Ana Fernanda González – A01363861

Jonathan Álvarez Suárez – A01204937

Rogelio Tovar Medel - A01701398

Alonso García Roa – A01207701

Campus Querétaro

HYDRAULICS LAB

PRACTICE 9. Pumps in Series and in Parallel

PART A: CENTRIFUGAL PUMPS

Objective:

To understand how pump characteristic curves are derived and how different parameters,

such as efficiency, head, and power vary according to the present flow rate.

Report:

1. Present the collected data in a table with an easy-readable format.

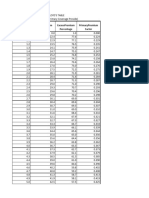

Table #1: Pump Data at 80% Speed

Pump Flow Pump 1 Combined Pump 1 Overall

Sample Setting Rate Total Total Mechanical Efficiency

Number S Q Head Head Power Egr

[%] [l/s] [m] [m] [W] [%]

1 80 0.076 5.90 5.90 67.6 6.5

2 80 0.000 5.78 5.78 67.4 0.0

3 80 0.094 5.70 5.70 70.2 7.5

4 80 0.227 5.61 5.61 73.4 16.9

5 80 0.396 5.55 5.55 77.4 27.8

6 80 0.584 5.40 5.40 83.2 37.0

7 80 0.736 5.15 5.15 88.1 42.0

8 80 0.887 5.15 5.15 93.0 48.0

9 80 0.961 4.67 4.67 97.4 45.1

10 80 1.037 4.72 4.72 99.8 48.0

11 80 1.094 4.57 4.57 102.1 47.9

12 80 1.170 4.55 4.55 102.6 50.7

13 80 1.170 4.46 4.46 101.9 50.0

14 80 1.227 4.31 4.31 99.5 52.0

15 80 1.227 4.19 4.19 100.5 50.0

16 80 1.244 4.34 4.34 102.6 51.5

17 80 1.264 4.30 4.30 104.7 50.8

18 80 1.264 4.17 4.17 102.6 50.2

19 80 1.244 4.34 4.34 104.9 50.3

20 80 1.301 4.32 4.32 101.9 54.0

21 80 1.283 4.07 4.07 104.2 49.0

22 80 1.283 4.24 4.24 103.7 51.3

23 80 1.301 4.15 4.15 104.7 50.5

24 80 1.283 4.20 4.20 106.1 49.7

2 Practice from Armfield Manual

Campus Querétaro

Table #2: Pump Data at 60% Speed

Pump Flow Pump 1 Combined Pump 1 Overall

Sample Setting Rate Total Total Mechanical Efficiency

Number S Q Head Head Power Egr

[%] [l/s] [m] [m] [W] [%]

1 60 0.000 3.20 3.20 25.35 0.0

2 60 0.000 3.24 3.24 24.30 0.0

3 60 0.020 3.13 3.13 26.05 2.3

4 60 0.150 3.08 3.08 25.35 17.8

5 60 0.301 3.06 3.06 29.02 31.0

6 60 0.434 2.91 2.91 32.00 38.6

7 60 0.547 2.86 2.86 33.57 45.5

8 60 0.641 2.77 2.77 36.19 48.0

9 60 0.717 2.63 2.63 37.24 49.5

10 60 0.773 2.55 2.55 36.89 52.3

11 60 0.793 2.44 2.44 37.59 50.2

12 60 0.850 2.47 2.47 36.72 55.9

13 60 0.867 2.35 2.35 36.19 55.0

14 60 0.887 2.37 2.37 37.59 54.7

15 60 0.904 2.38 2.38 36.54 57.5

16 60 0.904 2.26 2.26 37.94 52.5

17 60 0.904 2.33 2.33 39.16 52.6

18 60 0.904 2.18 2.18 39.16 49.3

19 60 0.943 2.25 2.25 39.69 52.2

20 60 0.943 2.16 2.16 38.99 51.2

21 60 0.943 2.24 2.24 38.99 53.0

22 60 0.943 2.33 2.33 38.46 55.9

23 60 0.924 2.27 2.27 38.11 53.8

24 60 0.961 2.29 2.29 39.51 54.3

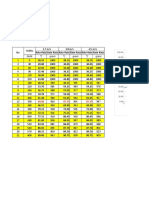

2. Plot graph of Head against flowrate, with the 2 runs in the same plot.

Flow Rate Vs. Head

Pump Speed 80% Pump Speed 60%

7.00

6.00

5.00

Head (m)

4.00

3.00

2.00

1.00

0.00

0.000 0.200 0.400 0.600 0.800 1.000 1.200 1.400

Flow Rate (dm3/s)

3 Practice from Armfield Manual

Campus Querétaro

3. Plot a graph of mechanical power against flowrate on one axis (primary axis-Y),

and efficiency against flowrate on the secondary axis-Y, with the 2 runs in the

same plot.

Flow Rate Vs. Mechanical Power and Efficiency

Power Curve Pump Speed 80% Power Curve Pump Speed 60%

Efficiency Curve Pump Speed 80% Efficiency Curve Pump Speed 60%

120.0 70.0

60.0

100.0

50.0

80.0

Mechanical Power (W)

Efficiency (%)

40.0

60.0

30.0

40.0

20.0

20.0

10.0

0.0 0.0

0.000 0.200 0.400 0.600 0.800 1.000 1.200 1.400

Flow Rate (dm3/s)

4 Practice from Armfield Manual

Campus Querétaro

4. Plot a graph of head against flowrate on one axis, and mechanical power against

flowrate against flowrate on the secondary axis, with the 2 runs in the same plot.

Flow Rate Vs. Head and Mechanical Power

Head Curve Pump Speed 80% Head Curve Pump Speed 60%

Power Curve Pump Speed 80% Power Curve Pump Speed 60%

7.00 120.0

6.00

100.0

5.00

80.0

4.00

Head (m)

60.0

3.00

40.0

2.00

20.0

1.00

0.00 0.0

0.000 0.200 0.400 0.600 0.800 1.000 1.200 1.400

Flow Rate (dm3/s)

5. For the results with the pump at 80%, examine and describe the shapes of the

graphs obtained, relating this to the flowrate.

As it can be observed in the obtained results and the graphical representations,

whenever flowrate suffers a change, naturally efficiency, head, and power vary as well.

At higher flowrates, head decreases, while power and efficiency tend to increase. Such

relationships observed make sense as a higher flow will require more energy yet

allowing higher efficiency in the process. It is important to notice that the data obtained

presents a certain amount of error, which can be observed in the data dispersion as

well as the overall shape of the relationships, which should be more curved rather than

straight or linear for all cases.

5 Practice from Armfield Manual

Campus Querétaro

6. For the results with the pump at 80%, determine the maximum efficiency and the

flowrate at which it occurs.

The maximum efficiency value with the pump speed at 80% is 54%, occurring at a

flowrate of 1.301 dm3/s.

PART B: PUMPS IN SERIES AND IN PARALLEL

Objective:

To understand the use of pumps in series and in parallel, and the effect that each

configuration has over head and flowrate.

Report:

7. Present the collected data in a table with an easy-readable format.

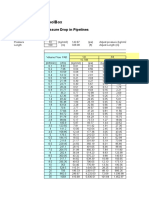

Table #3: Pumps in Series

Flow Pump 1 Pump 2 Combined

Sample Rate Total Total Total

Number Q Head Head Head

[l/s] [m] [m] [m]

1 1.35742188 1.49096516 3.54636205 5.03732721

2 1.33984375 1.56021872 3.53110858 5.0913273

3 1.33984375 1.48533497 3.63215387 5.11748884

4 1.35742188 1.62277718 3.49280165 5.11557883

5 1.30078125 1.49736249 3.64026319 5.13762568

6 1.37695313 1.60114249 3.70242701 5.3035695

7 1.33984375 1.60166405 3.7025857 5.30424975

8 1.30078125 1.56985639 3.67765503 5.24751142

9 1.3203125 1.59849617 3.73187338 5.33036955

10 1.30078125 1.63455336 3.51540896 5.14996232

11 1.26367188 1.5841327 3.82215938 5.40629208

12 1.28320313 1.56806324 4.0452447 5.61330794

13 1.26367188 1.81677478 3.82243981 5.63921459

14 1.2265625 1.76040976 4.31872284 6.0791326

15 1.1875 1.85021226 4.10943789 5.95965015

16 1.13085938 1.89422327 4.78687432 6.68109759

17 1.13085938 2.0985264 5.04321202 7.14173842

18 1 2.26984239 5.48339659 7.75323898

19 0.84960938 2.46473056 6.2203932 8.68512376

20 0.69726563 2.67523131 6.95226443 9.62749574

21 0.43359375 2.91467046 7.51307674 10.4277472

22 0.26367188 3.05167086 7.77901446 10.8306853

23 0.09375 3.15159117 8.05551391 11.2071051

24 0.07617188 3.16565681 8.50120702 11.6668638

6 Practice from Armfield Manual

Campus Querétaro

Table #4: Pumps in Parallel

Flow Pump 1 Pump 2 Combined

Sample Rate Total Total Total

Number Q Head Head Head

[l/s] [m] [m] [m]

1 2.07421875 5.27373797 6.27946111 5.77659954

2 2.09375 5.21376218 6.28670589 5.75023403

3 2.09375 5.34855622 6.21473378 5.781645

4 2.07421875 5.28456882 6.30591414 5.79524148

5 2.0546875 5.33181155 6.23164359 5.78172757

6 2.07421875 5.34892678 6.34176847 5.84534762

7 2.03710938 5.33628461 6.27747371 5.80687916

8 2 5.38088121 6.2755695 5.82822536

9 1.94335938 5.398606 6.43294375 5.91577487

10 1.92382813 5.49325684 6.40091643 5.94708664

11 1.81054688 5.44410186 6.4137935 5.92894768

12 1.7734375 5.52481983 6.52298678 6.02390331

13 1.71679688 5.5723256 6.61705547 6.09469054

14 1.58398438 5.70540814 6.72185191 6.21363003

15 1.43359375 5.76000153 6.82293297 6.29146725

16 1.3203125 5.73888088 6.81227582 6.27557835

17 1.13085938 5.75340986 6.92250507 6.33795747

18 0.9609375 5.92912602 6.94039705 6.43476153

19 0.79296875 6.28049141 7.15476805 6.71762973

20 0.56640625 6.68638678 7.29426124 6.99032401

21 0.4140625 7.01776293 7.51439345 7.26607819

22 0.18945313 7.55074395 7.94391604 7.74732999

23 0.07617188 7.6656269 7.99156674 7.82859682

24 0 7.70095752 8.12002303 7.91049027

8. Plot a graph of total head against discharge for a single pump (data from section

A) and for two pumps connected in series, both at 60%.

7 Practice from Armfield Manual

Campus Querétaro

Flow Rate Vs. Head Single and in Series

Single Pump Two Pumps in Series

14.00

12.00

10.00

Head (m)

8.00

6.00

4.00

2.00

0.00

0.000 0.200 0.400 0.600 0.800 1.000 1.200 1.400 1.600

Flow Rate (dm3/s)

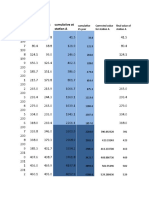

9. Calculate the head gain by connecting 2 pumps in series.

Table #5: Head Gain

Type Head (m) Maximum Flowrate (dm3/s)

Single 4.32 1.301

Parallel 5.776599539 2.07421875

Total flowrate gain (dm3/s) 0.77

10. Which would be the reason to connect 2 pumps in series?

Connecting two pumps in series can be useful when there is no single pump available

to reach a certain needed head, or when such single pump is too expensive. Flowrate

remains constant but head increases in order to meet a required altitude where water

has to be moved.

11. Plot a graph of total head against discharge for a single pump and for two pumps

connected in parallel, both at 80%.

8 Practice from Armfield Manual

Campus Querétaro

Flow Rate Vs. Head Single and in Parallel

Single Two Pumps in Parallel

9.00

8.00

7.00

6.00

Head (m)

5.00

4.00

3.00

2.00

1.00

0.00

0.000 0.500 1.000 1.500 2.000 2.500

Flow Rate (dm3/s)

12. Calculate the flowrate gain by connecting 2 pumps in parallel.

Table #6: Flowrate Gain

Type Head (m) Maximum Flowrate (dm3/s)

Single 4.32 1.301

Parallel 5.776599539 2.07421875

Total flowrate gain (dm3/s) 0.77

13. Which would be the reason to connect 2 pumps in parallel?

Pumps in parallel can become useful when an increase in flowrate is needed, without

compromising or increasing the total head. For example, if a community expands and

the population increases dramatically, a higher design flowrate will be needed.

Therefore, pumps in parallel could serve to satisfy demand of a changing flow system

without increasing the head, which would remain constant.

9 Practice from Armfield Manual

Campus Querétaro

14. Compare the graphs for pumps in series and in parallel, and describe the

similarities and/or differences

As observed, in this case both graphs look relatively similar, since the data obtained

is not fully free of error. In theory, they should display the same look as figures 1 and

2. In Figure 1, pumps in parallel have a constant head with an increase in the discharge

value, while in figure 2, pumps in series present an increase in overall head with a

constant discharge value.

Fig.1: Pumps in Parallel Fig.2: Pumps in Series

Nonetheless, due to random errors generated during the measuring process and lack

of precision when allowing the system of pumps to fully stabilize, the data distribution

does not have the same precise shapes as both figures shown before. Still, It can be

seen that the values of head an discharge suffer changes due to the application of a

new pump in two different configurations.

Conclusions:

PRACTICE 9. Pumps in Series and in Parallel

Rúbrica de Evaluación

Presentó la tabla con los datos Presentó la

No presentó la tabla con los

resumidos, en un formato fácil tabla con los

datos

de leer de la pregunta 1 datos

0 puntos

5 puntos 2.5 puntos

10 Practice from Armfield Manual

Campus Querétaro

Realizó

correctamente

Realizó correctamente las No realizó correctamente las

las gráficas de

gráficas de la pregunta 2, con gráficas de la pregunta 2, y no

la pregunta 2,

títulos y unidades contienen títulos ni unidades

sin títulos y

5 puntos 0 puntos

unidades

2.5 puntos

Realizó

correctamente

Realizó correctamente las No realizó correctamente las

las gráficas de

gráficas de la pregunta 3, con gráficas de la pregunta 3, y no

la pregunta 3,

títulos y unidades contienen títulos ni unidades

sin títulos y

5 puntos 0 puntos

unidades

2.5 puntos

Realizó

correctamente

Realizó correctamente las No realizó correctamente las

las gráficas de

gráficas de la pregunta 4, con gráficas de la pregunta 4, y no

la pregunta 4,

títulos y unidades contienen títulos ni unidades

sin títulos y

5 puntos 0 puntos

unidades

2.5 puntos

Respondió No Respondió correctamente

correctamente la pregunta 5 la pregunta 5

10 puntos 0 puntos

Respondió No Respondió correctamente

correctamente la pregunta 6 la pregunta 6

10 puntos 0 puntos

Presentó la tabla con los datos Presentó la

No presentó la tabla con los

resumidos, en un formato fácil tabla con los

datos

de leer de la pregunta 7 datos

0 puntos

5 puntos 2.5 puntos

Realizó

correctamente

Realizó correctamente las No realizó correctamente las

las gráficas de

gráficas de la pregunta 8, con gráficas de la pregunta 8, y no

la pregunta 8,

títulos y unidades contienen títulos ni unidades

sin títulos y

5 puntos 0 puntos

unidades

2.5 puntos

11 Practice from Armfield Manual

Campus Querétaro

Respondió No Respondió correctamente

correctamente la pregunta 9 la pregunta 9

5 puntos 0 puntos

Respondió No Respondió correctamente

correctamente la pregunta 10 la pregunta 10

10 puntos 0 puntos

Realizó

correctamente

Realizó correctamente las No realizó correctamente las

las gráficas de

gráficas de la pregunta 11, con gráficas de la pregunta 8, y no

la pregunta 8,

títulos y unidades contienen títulos ni unidades

sin títulos y

5 puntos 0 puntos

unidades

2.5 puntos

Respondió No Respondió correctamente

correctamente la pregunta 12 la pregunta 12

5 puntos 0 puntos

Respondió No Respondió correctamente

correctamente la pregunta 13 la pregunta 13

10 puntos 0 puntos

Respondió No Respondió correctamente

correctamente la pregunta 14 la pregunta 14

5 puntos 0 puntos

Realizó Realizó Realizó Realizó Realizó

conclusiones conclusiones conclusiones conclusiones conclusiones

objetivas, poco objetivas, poco objetivas, poco objetivas, subjetivas, sin

comparando comparando comparando sin comparar comparar

resultados resultados resultados resultados resultados

obtenidos, y obtenidos, y obtenidos, y obtenidos, y obtenidos, y no

demostró demostró demostró poco demostró poco demostró

aprendizaje del aprendizaje del aprendizaje del aprendizaje del aprendizaje del

objetivo de la objetivo de la objetivo de la objetivo de la objetivo de la

práctica práctica práctica práctica práctica

10 puntos 7.5 puntos 5 puntos 2.5 puntos 0 puntos

12 Practice from Armfield Manual

You might also like

- 1SBC009500R1002Document118 pages1SBC009500R1002Mohamad Kanzul fikri xii-mipa-8 20No ratings yet

- AP Calculus: Rate of Change & LimitsDocument4 pagesAP Calculus: Rate of Change & LimitsmohamedNo ratings yet

- Using Excel PlotsDocument12 pagesUsing Excel PlotsGera VillaNo ratings yet

- 000 215 1221 A02 31mar05Document2 pages000 215 1221 A02 31mar05Felipe FloresNo ratings yet

- Pipe Schedule Table - PT. PUSTEKDocument1 pagePipe Schedule Table - PT. PUSTEKOpen Knowledge and Education Book ProgramsNo ratings yet

- Fluxómetro y tanque demanda curvas comparaciónDocument1 pageFluxómetro y tanque demanda curvas comparaciónMarschall Nuñez GrandisonNo ratings yet

- Grafice-tabele-Ungureanu andrei.SSDocument20 pagesGrafice-tabele-Ungureanu andrei.SSuandrei630No ratings yet

- Intervalo de Clase (M) Marca de Clase Frec. Absoluta (X) Frec. Relativa (%) Frec. Relativa AcumuladaDocument5 pagesIntervalo de Clase (M) Marca de Clase Frec. Absoluta (X) Frec. Relativa (%) Frec. Relativa AcumuladaBrayanNo ratings yet

- Lloyds TableDocument4 pagesLloyds Tablerf.rifki3No ratings yet

- Export SRRDocument25 pagesExport SRRSyd ShahedNo ratings yet

- Azrak Pipe ScheduleDocument1 pageAzrak Pipe ScheduleErcan YilmazNo ratings yet

- Table Standar Pipa.xlsxDocument12 pagesTable Standar Pipa.xlsxpanjiajinugroho23No ratings yet

- Cam AnalysisDocument7 pagesCam Analysisk4k4zimNo ratings yet

- Pipe ScheduleDocument1 pagePipe SchedulePraveenNo ratings yet

- Section I: Pipes Flowing Under Pressure Tables For Discharge and Loss of Head and PowerDocument42 pagesSection I: Pipes Flowing Under Pressure Tables For Discharge and Loss of Head and PowerVishakha PatelNo ratings yet

- Set 03Document5 pagesSet 03ajaydenNo ratings yet

- Retaining Rings MetricDocument18 pagesRetaining Rings MetricEmmanuelNo ratings yet

- Schedule 40 MS PipesDocument2 pagesSchedule 40 MS PipesASIM MURTAZANo ratings yet

- 39 Mouse-PadDocument1 page39 Mouse-Padzhang_taoNo ratings yet

- Long Radius Elbow 20.4.2020Document2 pagesLong Radius Elbow 20.4.2020Sunil GurubaxaniNo ratings yet

- Evaluacion Erick Moya - Melany ToralDocument7 pagesEvaluacion Erick Moya - Melany ToralErick DslNo ratings yet

- Detik C Gram C Gram C GramDocument5 pagesDetik C Gram C Gram C GramSunset GamingNo ratings yet

- Expansion Rate For Piping Material SingaflexDocument2 pagesExpansion Rate For Piping Material Singaflexandistwn99No ratings yet

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Equal TeesDocument1 pageDimensions (Based On ASME/ANSI B16.9) and Example Weights For Equal TeesHassan SleemNo ratings yet

- Herzpack - Lpi-BcmDocument1 pageHerzpack - Lpi-BcmMohammed Abdul HaleemNo ratings yet

- QY130K Boom Lifting Chart: With 38 T CounterweightDocument8 pagesQY130K Boom Lifting Chart: With 38 T CounterweightSDARGNo ratings yet

- Acid Curing Epoxy Pipeline DatasheetDocument18 pagesAcid Curing Epoxy Pipeline DatasheetErbol KarzhaubaiulyNo ratings yet

- Butler HighwayDocument16 pagesButler HighwayK59 DAM NGOC MINH ANHNo ratings yet

- Statistics 1Document3 pagesStatistics 1CYNTHIA DEVI SIMANJUNTAK 19520283No ratings yet

- Ejercicio metodo ABC analisis productosDocument6 pagesEjercicio metodo ABC analisis productosFreddy G. AcostaNo ratings yet

- 300 LB WELDING NECK FLANGE DIMENSIONSDocument2 pages300 LB WELDING NECK FLANGE DIMENSIONSemre ozdemirNo ratings yet

- ANSI B16.9 Buttweld Elbow DimensionsDocument1 pageANSI B16.9 Buttweld Elbow Dimensionsabhi_libra14No ratings yet

- Laprak STRDocument9 pagesLaprak STRAliya SyNo ratings yet

- Gerco Export Industrial Supply Co, Inc. Excelente Proveedor de TuberíaDocument1 pageGerco Export Industrial Supply Co, Inc. Excelente Proveedor de TuberíaRoloNo ratings yet

- Buttweld Fittings Dimensions and WeightsDocument3 pagesButtweld Fittings Dimensions and WeightsHai lm5No ratings yet

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsDocument3 pagesDimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsRAFAEL BRAVONo ratings yet

- ANSI B16.9 Elbow PDFDocument3 pagesANSI B16.9 Elbow PDFRamadan RashadNo ratings yet

- Elbow 2Document3 pagesElbow 2robert_candra_tarunaNo ratings yet

- M S Pipe Weight CalculationDocument3 pagesM S Pipe Weight CalculationArun NandaNo ratings yet

- Water Dynamic LoadDocument27 pagesWater Dynamic LoadsolarpolNo ratings yet

- 45º Elbows: Standard WeightDocument2 pages45º Elbows: Standard WeightcuznadiNo ratings yet

- Pipe Dimensions Chart Rev Jan 2012Document1 pagePipe Dimensions Chart Rev Jan 2012Thomas CalvinNo ratings yet

- JIS G3444 Tube For General structureDocument1 pageJIS G3444 Tube For General structurelukmanNo ratings yet

- PRESSURE DROP CALCULATORDocument6 pagesPRESSURE DROP CALCULATORSobhy GendykhelaNo ratings yet

- Head CalculationDocument13 pagesHead CalculationRamadan RashadNo ratings yet

- Plate Bearing Test: Time Dial Gauge Readings, MM Load Guage 1 Gauge 2 Average ReadingDocument13 pagesPlate Bearing Test: Time Dial Gauge Readings, MM Load Guage 1 Gauge 2 Average ReadingmaherNo ratings yet

- Data Sondir: Depth CW TW KW QC LF LF X 20 CM JHP FR (M) (TW - CW) (KG/CM) (KG/CM) (%) (KG/CM) (KG/CM) (KG/CM) (KG/CM)Document3 pagesData Sondir: Depth CW TW KW QC LF LF X 20 CM JHP FR (M) (TW - CW) (KG/CM) (KG/CM) (%) (KG/CM) (KG/CM) (KG/CM) (KG/CM)Tri PrasetyoNo ratings yet

- Flange Slip On Class 600Document1 pageFlange Slip On Class 600Jean LatorreNo ratings yet

- Intervalo de Ebullición Peso Total % % % % Intervalo de Ebullición Promedio de Ebullición Volumen Parcial Volumen Total Peso ParcialDocument7 pagesIntervalo de Ebullición Peso Total % % % % Intervalo de Ebullición Promedio de Ebullición Volumen Parcial Volumen Total Peso ParcialCristian SantanderNo ratings yet

- Superelevation FinalDocument455 pagesSuperelevation FinalEskinder KebedeNo ratings yet

- Performance Test Results of Modified Bio-Asphalt.: Table 7Document1 pagePerformance Test Results of Modified Bio-Asphalt.: Table 7dazulu18No ratings yet

- Worksheet WennerDocument26 pagesWorksheet WennerAmirullahKaisindaNo ratings yet

- Pasir Panjang Bus DepotDocument4 pagesPasir Panjang Bus DepotVaidees waranNo ratings yet

- 25-yr station data rainfall and temperature analysisDocument8 pages25-yr station data rainfall and temperature analysisTalha BhuttoNo ratings yet

- CWX (Api/Ac) (6) KWX (Api/As) (7) (6) x20 (8) Kum (7) (9) (6) / (5) x100Document3 pagesCWX (Api/Ac) (6) KWX (Api/As) (7) (6) x20 (8) Kum (7) (9) (6) / (5) x100resolina ailingNo ratings yet

- CWX (Api/Ac) (6) KWX (Api/As) (7) (6) x20 (8) Kum (7) (9) (6) / (5) x100Document3 pagesCWX (Api/Ac) (6) KWX (Api/As) (7) (6) x20 (8) Kum (7) (9) (6) / (5) x100resolina ailingNo ratings yet

- PP165 ISO Metric Size and DimensionDocument2 pagesPP165 ISO Metric Size and DimensionDar FallNo ratings yet

- Stainless Steel Pipe Thickness S (MM) DN DN Dext MM in MM: Schedule 5S 10S 40S 80SDocument5 pagesStainless Steel Pipe Thickness S (MM) DN DN Dext MM in MM: Schedule 5S 10S 40S 80SARSENo ratings yet

- Celsius to Fahrenheit conversion tableDocument20 pagesCelsius to Fahrenheit conversion tablefaisal58650No ratings yet

- Instituto Tecnológico Y de Estudios Superiores de Monterrey Campus Querétaro Hydrology Assignment #5 Due Date: Tuesday June 02Document7 pagesInstituto Tecnológico Y de Estudios Superiores de Monterrey Campus Querétaro Hydrology Assignment #5 Due Date: Tuesday June 02MikeNo ratings yet

- Hydrology Assignment #1: Due Date: Tuesday March 10Document3 pagesHydrology Assignment #1: Due Date: Tuesday March 10MikeNo ratings yet

- A, L B, S: Assignment 1: Pressure Loaded Stiffened PanelDocument3 pagesA, L B, S: Assignment 1: Pressure Loaded Stiffened PanelMikeNo ratings yet

- Midas Gen: 1. Design InformationDocument1 pageMidas Gen: 1. Design InformationMikeNo ratings yet

- CASa-Planta AltaDocument1 pageCASa-Planta AltaMikeNo ratings yet

- Practice #5: Flow Over A Broad Crested Weir.: Hydraulics Lab Professor: Jose Manuel Molano MartínezDocument7 pagesPractice #5: Flow Over A Broad Crested Weir.: Hydraulics Lab Professor: Jose Manuel Molano MartínezMikeNo ratings yet

- Practice #2: Bernoulli Equation: Hydraulics Lab Professor: Jose Manuel Molano MartínezDocument6 pagesPractice #2: Bernoulli Equation: Hydraulics Lab Professor: Jose Manuel Molano MartínezMikeNo ratings yet

- Practice #1: Hydrostatic Forces: Hydraulics Lab Professor: Jose Manuel Molano MartínezDocument8 pagesPractice #1: Hydrostatic Forces: Hydraulics Lab Professor: Jose Manuel Molano MartínezMikeNo ratings yet

- Electrical Machines Lab March 16 UpdateDocument53 pagesElectrical Machines Lab March 16 Updatepeter vanderNo ratings yet

- 13-Ref List Phoceenne Rev.1 (2010-2017)Document25 pages13-Ref List Phoceenne Rev.1 (2010-2017)Jawad BasraNo ratings yet

- Turcite Sheet TrueslideDocument5 pagesTurcite Sheet TrueslideHaitham MohammadNo ratings yet

- Anixter Energy Efficiency and Environmental Considerations For The Data Center White Paper en UsDocument8 pagesAnixter Energy Efficiency and Environmental Considerations For The Data Center White Paper en Ussaba0707No ratings yet

- NCERT Physics Class 6-10 CompilationDocument119 pagesNCERT Physics Class 6-10 Compilationvishal tiwari100% (1)

- Door Frame Cutout and Wire Transfer Installation GuideDocument1 pageDoor Frame Cutout and Wire Transfer Installation Guiderodney_massieNo ratings yet

- Sunstrip Manual PDFDocument17 pagesSunstrip Manual PDFBen ArcherNo ratings yet

- Yanmar MOTOR L48N-DDocument15 pagesYanmar MOTOR L48N-DAndre FilipeNo ratings yet

- PRO 1R - Italy PDFDocument2 pagesPRO 1R - Italy PDFShishan AhmadNo ratings yet

- South Pasadena AP Chemistry Nuclear Chemistry Practice TestDocument2 pagesSouth Pasadena AP Chemistry Nuclear Chemistry Practice Testerice12No ratings yet

- Cell Structure and OrganisationDocument15 pagesCell Structure and Organisationzulkarnain100% (4)

- Elementary Science Grade 5 Lesson Plan PDFDocument348 pagesElementary Science Grade 5 Lesson Plan PDFAruba Ashhar100% (2)

- Lecture3 EC2B1 MollDocument57 pagesLecture3 EC2B1 MolllframosunahNo ratings yet

- ST Joseph'S College of EngineeirngDocument16 pagesST Joseph'S College of EngineeirngVignesshwar VenkatachalamNo ratings yet

- SFP Catalog 1 Metal BellowsDocument92 pagesSFP Catalog 1 Metal BellowshalongvanNo ratings yet

- 3R's Recommendations for Waste ManagementDocument30 pages3R's Recommendations for Waste ManagementsarthakhomiNo ratings yet

- Improve Heavy Oil Recovery with Steam FloodingDocument11 pagesImprove Heavy Oil Recovery with Steam FloodingMuhammad Sarmad AzamNo ratings yet

- CSWIP 2017) - Compressed-483-492Document10 pagesCSWIP 2017) - Compressed-483-492Tahar DabbarNo ratings yet

- Reykjavik Smart City Case StudyDocument1 pageReykjavik Smart City Case StudyPreene Dias officialNo ratings yet

- 977 Sample PDFDocument6 pages977 Sample PDFAdrianNo ratings yet

- NCF3 PDFDocument311 pagesNCF3 PDFShivNo ratings yet

- Astm d5682Document4 pagesAstm d5682Ernesto Morales100% (1)

- .Umerical $istance 0rotection 2elay 3) 02/4%# 3!:) Nstruction - AnualDocument326 pages.Umerical $istance 0rotection 2elay 3) 02/4%# 3!:) Nstruction - AnualngocanhvyNo ratings yet

- Aux Prds Techincal SpecificationDocument30 pagesAux Prds Techincal SpecificationSwaraj BiswasNo ratings yet

- College Physics, 9th Ed.-188-200Document13 pagesCollege Physics, 9th Ed.-188-200Dave ImmanuelNo ratings yet

- BA15-18 QuotationDocument4 pagesBA15-18 QuotationRonish ChandraNo ratings yet

- Belt Drives & Bearings Reference GuideDocument124 pagesBelt Drives & Bearings Reference GuideFaizanNo ratings yet

- Technical AnalysisDocument30 pagesTechnical AnalysisasankaNo ratings yet

- AtulDocument2 pagesAtulRahul SharmaNo ratings yet