Professional Documents

Culture Documents

Performance Test Results of Modified Bio-Asphalt.: Table 7

Uploaded by

dazulu18Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Test Results of Modified Bio-Asphalt.: Table 7

Uploaded by

dazulu18Copyright:

Available Formats

J. Liu et al.

Construction and Building Materials 305 (2021) 124784

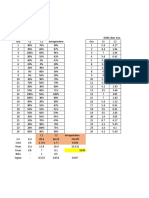

Table 7

Performance test results of modified bio-asphalt.

No. VC/% CC/% PC/% Pen Spt G*/sinδ Jnr0.1 Jnr3.2 S m

1 6 35 20 71.7 56.7 28.52 1.45 2.46 166.5 0.376

2 6 25 15 92.3 45.5 8.52 2.56 3.06 84.0 0.383

3 9 25 10 167.3 40.6 6.14 5.39 18.02 65.2 0.413

4 6 15 10 102.7 46.5 5.51 5.57 8.13 194.9 0.385

5 6 25 15 83.5 45.1 8.03 3.18 3.13 84.3 0.399

6 3 35 15 117.3 43.5 5.29 5.95 10.14 60.2 0.406

7 6 25 15 84.4 47.1 10.83 2.64 3.66 95.5 0.391

8 3 25 20 44.2 60.1 18.01 0.08 0.20 226.1 0.335

9 9 25 20 76.9 48.8 38.41 0.15 1.34 163.1 0.383

10 3 15 15 65.8 48.3 0.84 2.15 2.78 245.5 0.326

11 6 25 15 90.6 46.6 8.54 2.97 3.17 94.8 0.386

12 6 35 10 189.9 34.7 0.09 13.3 28.53 40.9 0.426

13 9 35 15 159.2 39.1 12.03 3.83 14.99 42.1 0.423

14 6 15 20 55.7 51.7 15.53 4.77 5.98 285.5 0.337

15 9 15 15 107.4 41.0 9.59 3.06 5.19 166.1 0.378

16 6 25 15 85.2 45.6 8.12 2.53 3.75 99.8 0.377

17 3 25 10 117.5 42.1 13.52 6.81 11.71 75.8 0.398

factor xi ; 2.2.4. Rheological performance tests

βij is the interaction coefficient between the two influencing factors;

βii is the quadratic effect coefficient of xi . 2.2.4.1. Temperature sweep (TS) test. In this paper, a dynamic shear

Analysis of variance was used to test for significance, and a second- rheometer model DHR-1 was used. The TS test is to uncover the rheo

order polynomial model was established by multi-factor analysis. The logical properties of asphalt and determine the high-temperature per

model is used to analysis the influence of various influencing factors on formance of asphalt through temperature sweep. The asphalt sample is

the response value, and finally generate a response surface. On the basis between two flat plates with a diameter of 25 mm, and the thickness of

of the actual conditions of different roads, different setting conditions of the asphalt between the two flat plates is 1 mm. The strain control

response values can be set, and finally the best combination suitable for method is adopted, the strain control level is 12%, the TS range is

the actual conditions of different roads can be obtained. 40–90 ◦ C, and the heating rate is 2 ◦ C/min. The rutting index is selected

as the evaluation index.

2.2.2. Preparation of modified bio-asphalt

The bio-asphalt consists of neat asphalt and vegetable oil (3%–9%) 2.2.4.2. Multiple stress creep recovery test (MSCR) test. MSCR test can

and castor oil (15%–35%) of neat asphalt. First of all, the neat asphalt determine the elastic recovery and stress effect of asphalt. The MSCR test

was heated in the oven and until it had promising fluidity. The vegetable at 58 ℃ were used to determine its high-temperature performance. In

oil and castor oil were dehydrated in a vacuum drying oven for 2–3 h at the process of actual use asphalt is subjected to continuous repeated

110 ℃ and 0.1 MPa and then cooled down for use. Then, dehydrated loads in the form of asphalt pavements rather than general static loads.

vegetable oil and dehydrated castor oil were added into the neat asphalt Therefore the DSR test can better study its deformation characteristics

in proportion, the shearing instrument was started, the rotating speed under dynamic load. The non-recoverable creep compliance is used as

was raised to 3000 r/min, the asphalt temperature was controlled at the evaluation index

130–140 ℃, and the bio-asphalt was gained by shearing at a constant

speed for 30 min. 2.2.4.3. Bending beam rheometer test (BBR) test. Since the two bio-oils

Then, chain extender and polyurethane are mixed to the bio-asphalt contain more impurities, the asphalt is prone to stress concentration

successively. The mass of the chain extender is 5% of the total mass of during the stretching process, which will affect the ductility test results.

monomer, and the mass of polyurethane is 10%–20% of the mass of neat Consequently, in this paper, the low-temperature performance was

asphalt. While the polyurethane and chain extender were added, the evaluated according to the BBR test. The length of the sample is 127 mm

chain extender and polyurethane were manually stirred by a glass rod to ± 2.0 mm, the thickness is 6.35 mm ± 0.05 mm, and the width is 12.70

make them distributed evenly in the bio-asphalt. Then the shearing in mm ± 0.05 mm. The BBR test temperature is − 18 ℃, the data acquisi

strument was started, the shearing rate was controlled at 3000 r/min, tion system records the load and deformation of the sample in 240 s, and

the temperature of the mixture was controlled at 130–140 ℃, and the the stiffness modulus S and creep rate m are automatically calculated by

shearing time was 45 min. Therefore, the CPBA was prepared in a total the computer. The low-temperature performance of asphalt is judged by

of 75 min. stiffness modulus and creep rate.

2.2.3. Physical tests 2.2.5. Microstructure analysis

2.2.3.1. Penetration test. The penetration test was carried out according 2.2.5.1. Fourier transform infrared reflection (FTIR) test. The functional

to the specification [35]. In a 25 ◦ C water bath, let the standard needle group molecules that make up asphalt vibrate constantly and have

fall freely for 5 s to test the penetration of the CPBA. There are five different absorption peaks in the infrared spectrum. Due to the different

parallel tests in the same test, and the average value is used as the result absorption frequencies of different functional groups, they will be in

of the penetration test. different positions on the infrared spectrum in order to obtain the

functional group information of the asphalt. In this study, the IS5 Fourier

2.2.3.2. Softening point test. The softening point test was carried out Infrared Spectrometer manufactured by Thermo Fisher Scientific is

according to the specification [35]. The softening point reflects the high- selected to analysis the functional groups of neat asphalt, bio-oil, and

temperature performance of asphalt. In this study, 17 groups CPBA were CPBA. The wavelength range used in the experiment is 4000–600 cm− 1 ,

tested, and two parallel tests were carried out. the resolution is 4 cm− 1 , and the scan is repeated 32 times.

You might also like

- Detailed Lesson Plan in General MathematicsDocument6 pagesDetailed Lesson Plan in General MathematicsAira Jane Irarum78% (18)

- Acetic Acid Production ReportDocument15 pagesAcetic Acid Production ReportArya Lodha100% (1)

- Grain Size DistributionDocument4 pagesGrain Size Distributionirfan bashirNo ratings yet

- CL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarDocument6 pagesCL351: Chemical Engineering Lab-II Semester 1, 2014-2015 IIT GandhinagarPradeep DiwakarNo ratings yet

- Tyre Pressure Conversion TableDocument12 pagesTyre Pressure Conversion Tableakeem aimanNo ratings yet

- Chilled Water PipeDocument4 pagesChilled Water PipeBalaNo ratings yet

- Jis g3466-3Document1 pageJis g3466-3Nhuận PhạmNo ratings yet

- E112340 - 2 - TD-bearb Therma Brake TempDocument6 pagesE112340 - 2 - TD-bearb Therma Brake TemppetriNo ratings yet

- OscilacionesDocument4 pagesOscilacionesJULIO CESAR HERRERA ROJASNo ratings yet

- Practice #9: Pumps in Series and in Parallel: Hydraulics Lab Professor: Jose Manuel Molano MartínezDocument12 pagesPractice #9: Pumps in Series and in Parallel: Hydraulics Lab Professor: Jose Manuel Molano MartínezMikeNo ratings yet

- Water Dynamic LoadDocument27 pagesWater Dynamic LoadsolarpolNo ratings yet

- Reactive Sputter Negative SpeedDocument7 pagesReactive Sputter Negative SpeedEric KurmanNo ratings yet

- Data Penyelidikan Lapangan Pengujian Ducth Cone Penetrometer Test/Sondir Rumah TinggalDocument2 pagesData Penyelidikan Lapangan Pengujian Ducth Cone Penetrometer Test/Sondir Rumah TinggalAgus CnsNo ratings yet

- HE2!10!11 DenisNuicaDocument4 pagesHE2!10!11 DenisNuicaDenis NuicaNo ratings yet

- Utilizarea EnergieiDocument4 pagesUtilizarea EnergieiDenis NuicaNo ratings yet

- Partial Vapour Pressure of SO2 Over H2ODocument1 pagePartial Vapour Pressure of SO2 Over H2OJia Yuan ChngNo ratings yet

- Pipes - European Standards: EEMUA 144 10 Bar 20 Bar 14 Bar 16 BarDocument4 pagesPipes - European Standards: EEMUA 144 10 Bar 20 Bar 14 Bar 16 BarjoehodohNo ratings yet

- Master PipeDocument8 pagesMaster PipeArifin ZakyNo ratings yet

- Gerco Export Industrial Supply Co, Inc. Excelente Proveedor de TuberíaDocument1 pageGerco Export Industrial Supply Co, Inc. Excelente Proveedor de TuberíaRoloNo ratings yet

- Experiment 3,4Document9 pagesExperiment 3,4AsifMutahirNo ratings yet

- Copper Nickel Metric Pipe StandardsDocument1 pageCopper Nickel Metric Pipe StandardsRahul JeganathanNo ratings yet

- Akh Knitting & Dyeing Ltd. BangladeshDocument1 pageAkh Knitting & Dyeing Ltd. BangladeshMd. Mamunur RashidNo ratings yet

- Laboratory of Unit Operations: Packed ColumnDocument18 pagesLaboratory of Unit Operations: Packed ColumnNguyễn ThuNo ratings yet

- CAlcio Fino y Grueso Polo MatiasDocument2 pagesCAlcio Fino y Grueso Polo MatiasCarlos M. LópezNo ratings yet

- Hychill Pressure Temperature Chart AutomotiveDocument1 pageHychill Pressure Temperature Chart AutomotiveKane BrownlowNo ratings yet

- Data Hujan Menitan dalam 10 TahunDocument36 pagesData Hujan Menitan dalam 10 TahunFarisy JannahNo ratings yet

- Uji SondirDocument11 pagesUji SondirHamidAffandyNo ratings yet

- Plate Bearing Test: Time Dial Gauge Readings, MM Load Guage 1 Gauge 2 Average ReadingDocument13 pagesPlate Bearing Test: Time Dial Gauge Readings, MM Load Guage 1 Gauge 2 Average ReadingmaherNo ratings yet

- Rate Analysis For 1CUM ConcreteDocument7 pagesRate Analysis For 1CUM ConcreteHitesh JaniNo ratings yet

- Taller Modelos de ViscosidadDocument12 pagesTaller Modelos de ViscosidadAlejandraMNo ratings yet

- 12FLB200PDocument1 page12FLB200PBurim TolajNo ratings yet

- Tabel Data SondirDocument9 pagesTabel Data SondirPramudyo Bayu Pamungkas, S.T.No ratings yet

- Sondir - Uraian Hasil PraktikumDocument9 pagesSondir - Uraian Hasil PraktikumDendy Rizky PrabowoNo ratings yet

- PVC WT Per Meter 2Document2 pagesPVC WT Per Meter 2webhareggebru06No ratings yet

- Tiempo (Min) Peso (G) 1 Peso (G) 2 Promedio (G) X (G H2O/gMCS) WDocument3 pagesTiempo (Min) Peso (G) 1 Peso (G) 2 Promedio (G) X (G H2O/gMCS) WVicky MoralesNo ratings yet

- District-Wise Depth To Water Level and Distribution of Percentage of Wells For The Period of Premonsoon, 2018 in ChhatishgarhDocument1 pageDistrict-Wise Depth To Water Level and Distribution of Percentage of Wells For The Period of Premonsoon, 2018 in ChhatishgarhDr. Surendra Kumar ChandnihaNo ratings yet

- Xappx 9 - Talbots Culvert TableDocument1 pageXappx 9 - Talbots Culvert TableMichael Migwi NgigiNo ratings yet

- Section I: Pipes Flowing Under Pressure Tables For Discharge and Loss of Head and PowerDocument42 pagesSection I: Pipes Flowing Under Pressure Tables For Discharge and Loss of Head and PowerVishakha PatelNo ratings yet

- Conductor THW 90Document1 pageConductor THW 90anggelo_0203100% (1)

- Training FlavoDocument72 pagesTraining FlavoMiguel Angelo Miranda JNo ratings yet

- Fluxómetro y tanque demanda curvas comparaciónDocument1 pageFluxómetro y tanque demanda curvas comparaciónMarschall Nuñez GrandisonNo ratings yet

- Laboratorio 3 ExcelDocument9 pagesLaboratorio 3 ExcelJhoel Elias Zela MontenegroNo ratings yet

- Examen 1 - PS1-Uribe Garcia Jairo LeviDocument31 pagesExamen 1 - PS1-Uribe Garcia Jairo LeviJairo GarciaNo ratings yet

- TechBuilder - MPPT CALCULATORDocument6 pagesTechBuilder - MPPT CALCULATORBabumani MandiNo ratings yet

- 16-JD-006 DataDocument2 pages16-JD-006 DatarezaNo ratings yet

- Regression analysis of variable radiation over timeDocument3 pagesRegression analysis of variable radiation over timeRonald HurtadoNo ratings yet

- Particle size analysis reportDocument5 pagesParticle size analysis reportmd azizur RahamanNo ratings yet

- Intervalo de Ebullición Peso Total % % % % Intervalo de Ebullición Promedio de Ebullición Volumen Parcial Volumen Total Peso ParcialDocument7 pagesIntervalo de Ebullición Peso Total % % % % Intervalo de Ebullición Promedio de Ebullición Volumen Parcial Volumen Total Peso ParcialCristian SantanderNo ratings yet

- Alk Gucdevir PDFDocument7 pagesAlk Gucdevir PDFshineNo ratings yet

- 03 第三篇 载荷表-20080310-译文Document15 pages03 第三篇 载荷表-20080310-译文Bishoo ShenoudaNo ratings yet

- Square Hollow Sections - Hot FormedDocument5 pagesSquare Hollow Sections - Hot FormedAristotle MedinaNo ratings yet

- Sheet1 Raceway AmpacityDocument18 pagesSheet1 Raceway AmpacityAngel CalderonNo ratings yet

- 1SBC009500R1002Document118 pages1SBC009500R1002Mohamad Kanzul fikri xii-mipa-8 20No ratings yet

- DN Pipe PDFDocument6 pagesDN Pipe PDFnassimNo ratings yet

- Metering Pumps: Models A and BDocument5 pagesMetering Pumps: Models A and Bbmanojkumar16No ratings yet

- Uraian Hasil: 1. Sondir: SondirDocument7 pagesUraian Hasil: 1. Sondir: SondirShofyan AliibrohimNo ratings yet

- Carbon Steel / Alloy Steel / Seamless Pipe: Download SpecificationDocument2 pagesCarbon Steel / Alloy Steel / Seamless Pipe: Download SpecificationSreenubabu Kandru100% (1)

- Cold Formed SQUAREDocument2 pagesCold Formed SQUAREmikarceNo ratings yet

- Hydrometer Calculations 2021-08-31Document3 pagesHydrometer Calculations 2021-08-31Ali KayaNo ratings yet

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Columbus Files Motion To Dismiss Bankruptcy Claim by Latitude Five25 OwnersDocument38 pagesColumbus Files Motion To Dismiss Bankruptcy Claim by Latitude Five25 OwnersWSYX/WTTENo ratings yet

- Violet Flame Clearing of The Heart ServiceDocument16 pagesViolet Flame Clearing of The Heart ServiceMySecret Gardenmdp82% (11)

- Hero LetterDocument3 pagesHero LetterArunachalam Muthiah0% (1)

- 11 Physics Test Paper Ch3 1Document4 pages11 Physics Test Paper Ch3 1Devendar SharmaNo ratings yet

- Common Mistakes in Dimensional Calibration MethodsDocument16 pagesCommon Mistakes in Dimensional Calibration MethodssujudNo ratings yet

- Explore the beaches and parks of Labuan IslandDocument2 pagesExplore the beaches and parks of Labuan IslandDudeNo ratings yet

- Gem EscortingDocument7 pagesGem Escortingsuman sutharNo ratings yet

- Let Us Discover: Hairdressing-Grade 11Document5 pagesLet Us Discover: Hairdressing-Grade 11cherry d.bandolaNo ratings yet

- MidtermDocument3 pagesMidtermTrisha MondonedoNo ratings yet

- Rules For The CertificationDocument84 pagesRules For The CertificationhdelriovNo ratings yet

- PSUTIL Documentation for Monitoring System ResourcesDocument77 pagesPSUTIL Documentation for Monitoring System ResourcesImam RiadiNo ratings yet

- Computational Models For Trunk Trajectory Planning and Load Distribution: A Test-Bed For Studying Various Clinical Adaptation and Motor Control Strategies of Low Back Pain PatientsDocument13 pagesComputational Models For Trunk Trajectory Planning and Load Distribution: A Test-Bed For Studying Various Clinical Adaptation and Motor Control Strategies of Low Back Pain PatientsOTorresGonzalezNo ratings yet

- NOISE ANALYSISDocument16 pagesNOISE ANALYSISDiana Rose TapelNo ratings yet

- SFM Issue Repor 15-4-2023Document3 pagesSFM Issue Repor 15-4-2023Esdras Fransua CisnerosNo ratings yet

- z1875 Caton (BMJ) Electric Currents of The BrainDocument23 pagesz1875 Caton (BMJ) Electric Currents of The BrainUnholy VladNo ratings yet

- Rajagiri Public School Unit Test PhysicsDocument3 pagesRajagiri Public School Unit Test PhysicsNITHINKJOSEPHNo ratings yet

- Communications in Algebra: On The U-Invariant of P-Adic Function FieldsDocument9 pagesCommunications in Algebra: On The U-Invariant of P-Adic Function FieldsKarim ZahidiNo ratings yet

- STP1236 Eb.1415051 1 PDFDocument208 pagesSTP1236 Eb.1415051 1 PDFpaolaNo ratings yet

- Welcome Students!: Week 8 (3 Quarter)Document28 pagesWelcome Students!: Week 8 (3 Quarter)Erika Lloren Luyun-GaliaNo ratings yet

- Sponge BobDocument4 pagesSponge BobchabriesNo ratings yet

- Thyrotronic enDocument4 pagesThyrotronic enVladimirNo ratings yet

- Top 21 Largest EMS Companies in WorldDocument22 pagesTop 21 Largest EMS Companies in WorldjackNo ratings yet

- Pharmaceutical Ingredients and Excipient - LastpptDocument72 pagesPharmaceutical Ingredients and Excipient - LastpptFANTANo ratings yet

- Reverse Phrase Action Camera LightsDocument40 pagesReverse Phrase Action Camera LightsDINDO AzucenaNo ratings yet

- Management Foreign BodyDocument6 pagesManagement Foreign BodyRahmatia SyukrinaNo ratings yet

- Lecture No.3 Part 1 (Fan)Document6 pagesLecture No.3 Part 1 (Fan)Mohsen HassanNo ratings yet

- Air release plug and lifting lug details for 15 MVA 66/11.55 kV transformer radiatorDocument1 pageAir release plug and lifting lug details for 15 MVA 66/11.55 kV transformer radiatorshravan Kumar SinghNo ratings yet

- Pasture FatteningDocument15 pagesPasture FatteningKartika PurnamasariNo ratings yet

- New Patient Needing Continuous Renal Replacement Therapy (CRRT)Document9 pagesNew Patient Needing Continuous Renal Replacement Therapy (CRRT)sergey_1972No ratings yet