Professional Documents

Culture Documents

w12 Series 4 Rolls Hydraulic CNC Rolling Machine

Uploaded by

Marishal Van DititchOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

w12 Series 4 Rolls Hydraulic CNC Rolling Machine

Uploaded by

Marishal Van DititchCopyright:

Available Formats

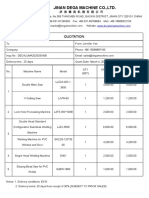

Maanshan Gilde CNC Machine Tool Co., Ltd Web: http://www.gldma.

com

W12 Series 4 Rolls Hydraulic CNC Rolling Machine

BRIEF INTRODUCTION

1.The 4 roller plate rolling machine widely used in petroleum, chemical industry, cement, boiler,

shipbuilding, aviation, water conservancy, power transmission towers and other machinery and equipment.

2. W12 hydraulic CNC 4 rolls rolling machine, be used to roll plate sheet into cylinder shape, The up roller is

fixed, the bottom roller and two side rollers can move up and down.The up and down rollers are main

driving rollers,used to pre-bend the plate sheet. the two side rollers are assisstant rollers.Upward and

downward, the side rollers are forming the shape.

3.The products passed CE certification. For higher precision and intensity, all equipment is the whole body

by annealing stress relief, all the machines are made of solid engineering 3 d programming design, using the

latest technology to improve the quality of the st44-1.

4.The sheet plate can be rolled tapered workpiece. Coiled conical workpiece, since the single-end by a larger

force, thus requiring the tapered workpiece rolled for 60% of the device capability. Rolled conical taper of

the workpiece is generally not more than 30 °. But with plate slab width decreases, the equipment load is

reduced, taper increase accordingly.

5. CNC control system:

Special bending aircraft, numerical control.

HMI (human machine interface), intelligent operation.

Self-compensating, single operate, high efficiency, safe and convenient.

More models for choice, economic numerical control model, TC computerized numerical control.

6.The offloading device is used after the round cylinder have been finished. Before leaving the left bearing

seat, raises the upper roller to standard height, and make the upper roller stop with balance pull rod at the

bottom of upper roller. Then draw out pin shaft on the tilting bearing seat, overturn the tilting bearing seat,

then the coiled product can emerge from one end of the upper roller.

Web: http://www.gldma.com/ Email: admin@gldma.com TELL: +86-18298235825 (whatsapp)

Maanshan Gilde CNC Machine Tool Co., Ltd Web: http://www.gldma.com

STANDARD EQUIPMENT

Removable console is very easy for operate,

Full hydraulic drive,Drive power saving 40%,

Schneider electrics,

CNC system controller,

Pre-bending function,

Surround metal cover: safety grade 4,

Overload protection.

Detailed Pictures:

Web: http://www.gldma.com/ Email: admin@gldma.com TELL: +86-18298235825 (whatsapp)

Maanshan Gilde CNC Machine Tool Co., Ltd Web: http://www.gldma.com

Front view of rolling machine:

Surround metal cover: safety grade 4.

Side of the rolling machine:

Rolling plate once forming. productivity is higher

60%-80% than 3-roller rolling machine.

CNC Control System:

Digital readout for position of each rollers.High

accuracy and precision circle.

The rolls of the rolling machine:

Full hydraulic drive, driving power is equivalent to

60% of tradition.

Three-dimensional analytic

diagram:

The top and bottom roller clamp the plate during

rolling without slipping.

Web: http://www.gldma.com/ Email: admin@gldma.com TELL: +86-18298235825 (whatsapp)

Maanshan Gilde CNC Machine Tool Co., Ltd Web: http://www.gldma.com

Electrics(Schneider France):

High performance electrical appliances ensure

more stable performance and longer service life.

Different types of 4-roller rolling machine:

Web: http://www.gldma.com/ Email: admin@gldma.com TELL: +86-18298235825 (whatsapp)

Maanshan Gilde CNC Machine Tool Co., Ltd Web: http://www.gldma.com

Machining process-of-rolling-machine:

Components:

Serial No. Part Description Brief instruction Country of origin

1 Electrical components Schneider Electrical France

2 Main Motor Siemens Germany

3 Seal Ring NOK Japan

4 Digital display system Delta Taiwan,China

5 Foot switch KACON Korea

6 Travel switch Schneider Electrical French

7 Seal Ring NOK Japan

Web: http://www.gldma.com/ Email: admin@gldma.com TELL: +86-18298235825 (whatsapp)

Maanshan Gilde CNC Machine Tool Co., Ltd Web: http://www.gldma.com

8 PLC OMRON Japan

9 Electricity leakage protection ■Yes□No

10 Safety standards ■CE□CSA■NR-12□OSHA

Technical Parameter:

W12 4- Rollers Hydraulic Plate Rolling Machine Technical Parameters

Max

Plate Dia.of Dia.of Dia.of

Max Pre-bending working Main

Model yield top bottom side

thickness thickness length of power

limit roller roller roller

rolls

(mm) (mm) (mm) (Mpa) (mm) (mm) (mm) (KW)

W12-4*2000 4 3.5 2050 245 160 140 120 3

W12-6*2000 6 5 2050 245 190 170 150 4

W12-8*2000 8 6.5 2050 245 210 190 170 5.5

W12-10*2000 10 8 2050 245 230 210 190 7.5

W12-12*2000 12 10 2050 245 270 250 210 11

W12-16*2000 16 13 2050 245 300 270 220 11

W12-20*2000 20 16 2050 245 330 300 240 11

W12-25*2000 25 20 2050 245 360 330 250 15

W12-30*2000 30 25 2050 245 390 360 300 18.5

W12-35*2000 35 28 2050 245 430 390 330 22

W12-40*2000 40 32 2050 245 460 420 360 30

W12-45*2000 45 36 2050 245 510 460 390 37

W12-50*2000 50 40 2050 245 550 510 420 45

W12-4*2500 4 3.5 2550 245 190 170 150 4

Web: http://www.gldma.com/ Email: admin@gldma.com TELL: +86-18298235825 (whatsapp)

Maanshan Gilde CNC Machine Tool Co., Ltd Web: http://www.gldma.com

W12-6*2500 6 5 2550 245 210 190 170 5.5

W12-8*2500 8 9.5 2550 245 230 210 190 7.5

W12-10*2500 10 8 2550 245 270 250 210 11

W12-12*2500 12 10 2550 245 300 270 220 11

W12-16*2500 16 13 2550 245 330 300 240 11

W12-20*2500 20 16 2550 245 360 330 250 15

W12-25*2500 25 20 2550 245 390 360 300 18.5

W12-30*2500 30 25 2550 245 430 390 330 22

W12-35*2500 35 28 2550 245 460 420 360 30

W12-40*2500 40 32 2550 245 510 460 390 37

W12-45*2500 45 36 2550 245 550 510 420 45

W12-4*3000 4 3.5 3100 245 210 190 170 5.5

W12-6*3000 6 5 3100 245 230 210 190 7.5

W12-8*3000 8 6.5 3100 245 270 250 210 11

W12-10*3000 10 8 3100 245 300 270 220 11

W12-12*3000 12 10 3100 245 330 300 240 11

W12-16*3000 16 13 3100 245 360 330 250 15

W12-20*3000 20 16 3100 245 390 360 300 18.5

W12-25*3000 25 20 3100 245 430 390 330 22

W12-30*3000 30 25 3100 245 460 420 360 30

W12-35*3000 35 28 3100 245 510 460 390 37

W12-40*3000 40 32 3100 245 550 510 420 45

W12-50*3000 50 40 3100 245 610 560 480 55

W12-60*3000 60 48 3100 245 670 620 520 75

Contacts:

Manufacturer: Maanshan Gilde CNC Machine Tool Co., Ltd

Web: http://www.gldma.com/ Email: admin@gldma.com TELL: +86-18298235825 (whatsapp)

Maanshan Gilde CNC Machine Tool Co., Ltd Web: http://www.gldma.com

Email: admin@gldma.com

Web: http://www.gldma.com/

TELL: +86-18298235825 (whatsapp)

Web: http://www.gldma.com/ Email: admin@gldma.com TELL: +86-18298235825 (whatsapp)

You might also like

- W11 Series 3 Rolls Mechanical Symmetrical Rolling MachineDocument5 pagesW11 Series 3 Rolls Mechanical Symmetrical Rolling Machinerynelee100% (1)

- WC67K NC Hydraulic Plate Press Brake With E21 ControllerDocument6 pagesWC67K NC Hydraulic Plate Press Brake With E21 ControllerryneleeNo ratings yet

- WC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s SystemDocument7 pagesWC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s SystemryneleeNo ratings yet

- 1546415924Document11 pages1546415924Sander DuqueNo ratings yet

- WC67K Tandem CNC Hydraulic Press Brake-E200PDocument7 pagesWC67K Tandem CNC Hydraulic Press Brake-E200PryneleeNo ratings yet

- Tongil Gu SeriesDocument3 pagesTongil Gu Seriesmatthew_k_kohNo ratings yet

- MB8 3+1 Axis CNC Hydraulic Servo Press Brake Machine - DELEM DA52SDocument8 pagesMB8 3+1 Axis CNC Hydraulic Servo Press Brake Machine - DELEM DA52SryneleeNo ratings yet

- Anhui Lai Fu CNC Machine Tool Co., Ltd. YL32 Series Four-Column Deep Drawing Hydraulic PressesDocument4 pagesAnhui Lai Fu CNC Machine Tool Co., Ltd. YL32 Series Four-Column Deep Drawing Hydraulic PressesBALANo ratings yet

- 210902quoattion of V7 CNC Milling Machine-BLIN MACHINERYDocument2 pages210902quoattion of V7 CNC Milling Machine-BLIN MACHINERYJackson SilvaNo ratings yet

- Davi - BARCODE - MCP Angle RollDocument8 pagesDavi - BARCODE - MCP Angle Rollبازرگانی راهیان کار و دانشNo ratings yet

- Brochure - 14.458 DC Spring Apllied BrakesDocument2 pagesBrochure - 14.458 DC Spring Apllied Brakeskpr_02161371No ratings yet

- Module of Adour 871Document7 pagesModule of Adour 871MURUGAN. ANo ratings yet

- Wire CutDocument60 pagesWire CutWahid Bashir67% (3)

- PM GB GearmotorDocument10 pagesPM GB GearmotorMulugeta Kiros GebeyehuNo ratings yet

- MVD Ibend Catalog ENG WebDocument15 pagesMVD Ibend Catalog ENG Webneeshakothari31No ratings yet

- MB8 Automatic Sheet Metal Press Brake Bending Machine With DA56S SystemDocument8 pagesMB8 Automatic Sheet Metal Press Brake Bending Machine With DA56S SystemryneleeNo ratings yet

- Automatic Roofing Sheet Making MachineDocument12 pagesAutomatic Roofing Sheet Making MachinesylvesterNo ratings yet

- Instructions To Mod. Zyt5402tzj Mobile Drilling RigDocument135 pagesInstructions To Mod. Zyt5402tzj Mobile Drilling RigYimmy Alexander Parra MarulandaNo ratings yet

- Jobber JR DetailsDocument2 pagesJobber JR DetailsUrvish PatelNo ratings yet

- AKG1212 CNC RouterDocument9 pagesAKG1212 CNC RouterVictor BravoNo ratings yet

- Proposal HMG-350JM SXKH Die Spotting PressDocument9 pagesProposal HMG-350JM SXKH Die Spotting Press846213No ratings yet

- CNC Wire Cut EDM Machine ManualDocument57 pagesCNC Wire Cut EDM Machine ManualAmeer shattiNo ratings yet

- Machines Used For UPVC Window DoorDocument11 pagesMachines Used For UPVC Window DoorArsalan AmjidNo ratings yet

- Hydraulic Jack Final ProjectDocument21 pagesHydraulic Jack Final ProjectAdnan WattooNo ratings yet

- GATE sHEARING mACHINEDocument25 pagesGATE sHEARING mACHINEHugho100% (1)

- Medium Scale Machining Shop EquipmentDocument5 pagesMedium Scale Machining Shop EquipmentShahbaz AlamNo ratings yet

- Stator Motor Winding Machine: Manufacturing Systems Project Operations ManualDocument13 pagesStator Motor Winding Machine: Manufacturing Systems Project Operations ManualAnonymous ePtBZJB8ePNo ratings yet

- Machines and Equipment at KELTRAC Tool Room FacilityDocument8 pagesMachines and Equipment at KELTRAC Tool Room FacilityvarunNo ratings yet

- Hydraulic Shearing Machine with E21S ControllerDocument3 pagesHydraulic Shearing Machine with E21S ControllerIonuţ RădescuNo ratings yet

- Hydraulic Tyre KillersDocument23 pagesHydraulic Tyre KillersAgung Widi0% (1)

- Report CNC Turning LengkapDocument19 pagesReport CNC Turning LengkapFirdaus Shah25% (4)

- Knuth Ecoturn 650-1000Document2 pagesKnuth Ecoturn 650-1000Iacob CornelNo ratings yet

- Eurotech BV SeriesDocument8 pagesEurotech BV SeriesCNC SYSTEMSNo ratings yet

- Shoe Machinery Unit II & IIIDocument106 pagesShoe Machinery Unit II & IIIashutosh100% (1)

- DK7740DDocument57 pagesDK7740Dquanghuy1201100% (1)

- 2023.12.12 Offer For KJS2X1500 Slitting LineDocument9 pages2023.12.12 Offer For KJS2X1500 Slitting LineRicardo QueirogaNo ratings yet

- Installation of Bridge Cutter P31 Machine GuideDocument25 pagesInstallation of Bridge Cutter P31 Machine GuideHữu Dũng NguyễnNo ratings yet

- VTL 30 DetailsDocument4 pagesVTL 30 DetailspranaybinaykeNo ratings yet

- Hydraulic 4 Roller Rolling Machine W12-12x3000Document4 pagesHydraulic 4 Roller Rolling Machine W12-12x3000EnriqueMiguelPriceNo ratings yet

- PBA-80Tx2500 Hydraulic Press Brake With E200P CNC ControllerDocument3 pagesPBA-80Tx2500 Hydraulic Press Brake With E200P CNC ControllerJohan SneiderNo ratings yet

- Final HMTDocument45 pagesFinal HMTAnubhav SharmaNo ratings yet

- WC67K-80TX3200 Hydraulic Press Brake Machine With E21 NC ControllerDocument3 pagesWC67K-80TX3200 Hydraulic Press Brake Machine With E21 NC ControllerJohan SneiderNo ratings yet

- S934 - Instruction ManualDocument36 pagesS934 - Instruction ManualTony MarascaNo ratings yet

- Gearbox For Control Valves and Pneumatic ActuatorsDocument7 pagesGearbox For Control Valves and Pneumatic ActuatorsKi Ho ChungNo ratings yet

- AIMI说明书 (E) PDFDocument27 pagesAIMI说明书 (E) PDFrudy haryanto100% (2)

- CNG Cylinder Production LineDocument24 pagesCNG Cylinder Production LineAyman Eid Salem MoussaNo ratings yet

- Operation Manual For QC12Y-8X3200Document37 pagesOperation Manual For QC12Y-8X3200Lucas Alves RodriguesNo ratings yet

- Tractor Snow PlowDocument3 pagesTractor Snow PlowSnow Removal EquipmentNo ratings yet

- CNC002-CNC Cylindrical GrinderDocument9 pagesCNC002-CNC Cylindrical GrinderarashNo ratings yet

- Quotation For Cut To Length Line 25x2500Document13 pagesQuotation For Cut To Length Line 25x2500gourav sarafNo ratings yet

- KRAS WC67K-40TX1600 Hydraulic Press Brake Machine With E21 NC ControllerDocument3 pagesKRAS WC67K-40TX1600 Hydraulic Press Brake Machine With E21 NC ControllerJohan SneiderNo ratings yet

- Pneumatic Sprue Picker Robot Automates Plastic Injection MoldingDocument37 pagesPneumatic Sprue Picker Robot Automates Plastic Injection MoldingAlfandel VillamartinNo ratings yet

- WC67K-50T/2500 Hydraulic Press BrakeDocument7 pagesWC67K-50T/2500 Hydraulic Press BrakeJuliano Cristino DE MatosNo ratings yet

- Micro Pneumatics Rotary ActuatorsDocument4 pagesMicro Pneumatics Rotary ActuatorsFerBotelloNo ratings yet

- Cymill Cyspeed enDocument111 pagesCymill Cyspeed enskidamdnevnoNo ratings yet

- Copper Rod Casting & Rolling LineDocument5 pagesCopper Rod Casting & Rolling LineYonathan JonathanNo ratings yet

- Manual G Ingles - V6Document68 pagesManual G Ingles - V6Phùng Thế Kiên50% (2)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- 2181819Document3 pages2181819Marishal Van DititchNo ratings yet

- Placingsalinityintocontextwithotherlandscapechallenges McFarlaneD 1992 PDFDocument10 pagesPlacingsalinityintocontextwithotherlandscapechallenges McFarlaneD 1992 PDFMarishal Van DititchNo ratings yet

- HHHGHJDocument1 pageHHHGHJMarishal Van DititchNo ratings yet

- Placing Salinity Into Context With Other Landscape ChallengesDocument10 pagesPlacing Salinity Into Context With Other Landscape ChallengesMarishal Van DititchNo ratings yet

- w12 Series 4 Rolls Hydraulic CNC Rolling MachineDocument8 pagesw12 Series 4 Rolls Hydraulic CNC Rolling MachineMarishal Van DititchNo ratings yet

- Bobinagem Motor Trifasico ImbricadoDocument90 pagesBobinagem Motor Trifasico ImbricadojorrriqueNo ratings yet

- Tension Wire ChartDocument1 pageTension Wire Chartlaspsieca100% (1)

- Welding Transformer - Principle, Requirement and Types PDFDocument11 pagesWelding Transformer - Principle, Requirement and Types PDFcivilappliNo ratings yet

- Polinder Icem 04Document7 pagesPolinder Icem 04Marishal Van DititchNo ratings yet

- Polinder Icem 04Document7 pagesPolinder Icem 04Marishal Van DititchNo ratings yet

- 2011 Production Machining Diamond Lappingand Plate ControlDocument2 pages2011 Production Machining Diamond Lappingand Plate Control4U6ogj8b9snylkslkn3nNo ratings yet

- PDF Ebooks - Org Ku 13151Document5 pagesPDF Ebooks - Org Ku 13151Marishal Van DititchNo ratings yet

- Catalogxxx CXDocument254 pagesCatalogxxx CXChevronelleNo ratings yet

- High Temperature, Fast, Electrical Stator Winding, Impregnating and Sealing ResinDocument2 pagesHigh Temperature, Fast, Electrical Stator Winding, Impregnating and Sealing ResinMarishal Van DititchNo ratings yet

- Avr sr7 2g Uvr6 Manual PDFDocument9 pagesAvr sr7 2g Uvr6 Manual PDFEdgar75% (4)

- Nouveau Document TexteDocument1 pageNouveau Document TexteinelecstarNo ratings yet

- Nouveau Document TexteDocument1 pageNouveau Document TexteinelecstarNo ratings yet

- User Guide: Thinkpad X240Document181 pagesUser Guide: Thinkpad X240danielwwcheong8981No ratings yet

- CBD-2525-4M - 3 - 4 - 3V Ver 2 PDFDocument2 pagesCBD-2525-4M - 3 - 4 - 3V Ver 2 PDFAlosh AlyosfiNo ratings yet

- Material Handiling SystemDocument19 pagesMaterial Handiling SystemSreejith M UnnikrishnanNo ratings yet

- Data Acquisition Systems Communicate With Microprocessors Over 4 WiresDocument2 pagesData Acquisition Systems Communicate With Microprocessors Over 4 WiresAnonymous Y6EW7E1Gb3No ratings yet

- Transformer Test ProceduresDocument28 pagesTransformer Test ProceduresGonzalesCha100% (25)

- NORAMLightTowers (E)Document2 pagesNORAMLightTowers (E)siranepNo ratings yet

- Peralatan Sistem Tenaga ListrikDocument13 pagesPeralatan Sistem Tenaga ListrikHarfiana MaharaniNo ratings yet

- Three Phase Induction MotorDocument16 pagesThree Phase Induction MotorPushan Kumar DattaNo ratings yet

- Jeep TJ 1999 Wrangler MOPAR Parts CatalogDocument313 pagesJeep TJ 1999 Wrangler MOPAR Parts Catalogpepw0% (1)

- API-U ELrng OilGas Cat 10.12.12 (Online) OptDocument44 pagesAPI-U ELrng OilGas Cat 10.12.12 (Online) OptMaría BossaNo ratings yet

- HP070 - EN 单页Document4 pagesHP070 - EN 单页symantec37No ratings yet

- Valve Samson Model 3241 Serial 470 132 B347W701 ENDocument1 pageValve Samson Model 3241 Serial 470 132 B347W701 ENClaudio StadelmannNo ratings yet

- PG 049-061 PDFDocument13 pagesPG 049-061 PDFfilkeNo ratings yet

- Wiring The AC in A 300ZX Engine Conversion - LOJ ConversionsDocument1 pageWiring The AC in A 300ZX Engine Conversion - LOJ ConversionsblahblahplagiaristNo ratings yet

- Lab Report 1Document3 pagesLab Report 1Hassan MehmoodNo ratings yet

- 10-2-3.0 Parts List PDFDocument61 pages10-2-3.0 Parts List PDFrfffffNo ratings yet

- Pneumax Fittings Accessories CatalogDocument32 pagesPneumax Fittings Accessories CatalogBryan Brito100% (1)

- M 95640-A125-A145 - EepromDocument44 pagesM 95640-A125-A145 - EepromTiago LeonhardtNo ratings yet

- Centrifugal Pump Dimensional SpecificationsDocument36 pagesCentrifugal Pump Dimensional SpecificationsGustavo Adolfo Quintero RuizNo ratings yet

- A8 3D Printer Installation Instructions-161230Document46 pagesA8 3D Printer Installation Instructions-161230Сергей ЖаркихNo ratings yet

- Embedded Systems Online TestingDocument6 pagesEmbedded Systems Online TestingPuspala ManojkumarNo ratings yet

- Potential transformers and other switchboard devices protectionDocument4 pagesPotential transformers and other switchboard devices protectionJoel JusayNo ratings yet

- Power Supply Systems Series 900: Control and Signalling Unit SPSC2000-A 90Document28 pagesPower Supply Systems Series 900: Control and Signalling Unit SPSC2000-A 90Oleg Kuryan0% (1)

- Tecnotest Eclod 6430 Service Manual 9206176Document48 pagesTecnotest Eclod 6430 Service Manual 9206176Waqar Waheed67% (3)

- 1.5l Duratorq-Tdci Timing BeltDocument62 pages1.5l Duratorq-Tdci Timing Beltsuysuy00100% (1)

- Water Supply Program: On/Off Diaphragm Valve Type Vm100Document1 pageWater Supply Program: On/Off Diaphragm Valve Type Vm100virtualpop3No ratings yet

- 4.4.6.4 Voltage Dependence: Chapter 4 DelayDocument1 page4.4.6.4 Voltage Dependence: Chapter 4 DelayCarlos SaavedraNo ratings yet

- Thread Repair Kits for Damaged ThreadsDocument12 pagesThread Repair Kits for Damaged Threadsvelu.gNo ratings yet

- Delta6rc FinalDocument2 pagesDelta6rc FinalsarvottamNo ratings yet

- Lecture 15 Av-334 MW TubesDocument13 pagesLecture 15 Av-334 MW TubesAli EmadNo ratings yet