Professional Documents

Culture Documents

Ultramid A3WG7 Iso

Uploaded by

RiccardoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultramid A3WG7 Iso

Uploaded by

RiccardoCopyright:

Available Formats

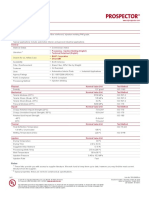

Product Information

Sep 2019

Ultramid® A3WG7

Polyamide 66

Product Description

Ultramid A3WG7 is a 35% glass fiber reinforced and heat resistance injection molding PA66 grade

for machinery for industrial items.

Applications

Typical applications include gear wheels, solenoid valve housings, cable attachments, automotive

fuel distributors and components for automotive gear shift.

PHYSICAL ISO Test Method Property Value

Density, g/cm³ 1183 1.41

Moisture, % 62

(50% RH) 1.6

(Saturation) 5

RHEOLOGICAL ISO Test Method Dry Conditioned

Melt Volume Rate (275 C/5 Kg), cc/10min. 1133 40 -

MECHANICAL ISO Test Method Dry Conditioned

Tensile Modulus, MPa 527

23C 11,500 8,500

Tensile stress at break, MPa 527

23C 210 150

80C 125 93

120C 102 77

Tensile strain at break, % 527

23C 3.0 5.0

80C 6.8 6.1

120C 7.5 6.1

Flexural Modulus, MPa 178

23C 10,000 8,480

IMPACT ISO Test Method Dry Conditioned

Izod Notched Impact, kJ/m2 180

23C 14 -

Charpy Notched, kJ/m2 179

-30C 12 -

23C 14 22

Charpy Unnotched, kJ/m2 179

-30C 75 -

23C 95 110

THERMAL ISO Test Method Dry Conditioned

Melting Point, C 3146 260 -

HDT A, C 75 250 -

HDT B, C 75 250 -

Coef. of Linear Thermal Expansion, Parallel, 0.17 X10-4 -

mm/mm C

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 1 of 3

Ultramid® A3WG7

Coef. of Linear Thermal Expansion, Normal, 0.65 X10-4 -

mm/mm C

ELECTRICAL ISO Test Method Dry Conditioned

Comparative Tracking Index IEC 60112 450 450

Volume Resistivity (Ohm-m) IEC 60093 1E13 1E11

Dielectric Constant (1 MHz) IEC 60250 3.5 5.7

Dissipation Factor (100 Hz), E-4 IEC 60250 200 3,000

Dissipation Factor (1 MHz), E-4 IEC 60250 200 3,000

UL RATINGS UL Test Method Property Value

Flammability Rating, 0.71mm UL94 HB

Relative Temperature Index, 0.71mm UL746B

Electrical, C 125

Flammability Rating, 1.5mm UL94 HB

Relative Temperature Index, 1.5mm UL746B

Mechanical w/o Impact, C 115

Mechanical w/ Impact, C 115

Electrical, C 125

Flammability Rating, 3.0mm UL94 HB

Relative Temperature Index, 3.0mm UL746B

Mechanical w/o Impact, C 130

Mechanical w/ Impact, C 120

Electrical, C 125

Processing Guidelines

Material Handling

Max. Water content: 0.15%

Product is supplied in sealed containers and drying prior to molding is not required. If drying

becomes necessary, a dehumidifying or desiccant dryer operating at 80C (176F) is recommended.

Drying time is dependent on moisture level, However 2-4 hours is generally sufficient.

Recommended moisture levels for achieving optimum surface qualities and mechanical properties

is 0.05% - 0.12%. Further information concerning safe handling procedures can be obtained from

the Safety Data Sheet. Alternatively, please contact your BASF representative.

Typical Profile

Melt Temperature 280-305C (536-581F)

Mold Temperature 80-90C (176-194F)

Injection and Packing Pressure 35-125 bar (500-1500 psi)

Mold Temperatures

A mold temperature of 80-90C (176-194F) is recommended, however temperatures of as low as

45C (113F) and as high as 105C (221F) can be used where applicable.

Pressures

Injection pressure controls the filling of the part and should be applied for 90% of ram travel.

Packing pressure affects the final part and can be used effectively in controlling sink marks and

shrinkage. It should be applied and maintained until the gate area is completely frozen off.

Back pressure can be utilized to provide uniform melt consistency and reduce trapped air and gas.

Minimal back pressure should be utilized to prevent glass breakage.

Fill Rate

Fast fill rates are recommended to ensure uniform melt delivery to the cavity and prevent premature

freezing. Surface appearance is directly affected by injection rate.

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 2 of 3

Ultramid® A3WG7

Note

Although all statements and information in this publication are believed to be accurate and reliable,

they are presented gratis and for guidance only, and risks and liability for results obtained by use of

the products or application of the suggestions described are assumed by the user. NO

WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE MADE REGARDING

PRODUCTS DESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH. Statements or

suggestions concerning possible use of the products are made without representation or warranty

that any such use is free of patent infringement and are not recommendations to infringe any

patent. The user should not assume that toxicity data and safety measures are indicated or that

other measures may not be required.

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 3 of 3

You might also like

- Ultramid B3WG6 NYLON PDFDocument3 pagesUltramid B3WG6 NYLON PDFrenebbNo ratings yet

- UltrasonS6010 IsoDocument2 pagesUltrasonS6010 IsoKablayialijanNo ratings yet

- Ultraform N2320 003 BK120 Q600Document2 pagesUltraform N2320 003 BK120 Q600JoelNo ratings yet

- ULTRADUR B4300G6 (03p023)Document3 pagesULTRADUR B4300G6 (03p023)ayala castroNo ratings yet

- Ultrason E 3010: Polyethersulfone (PESU)Document2 pagesUltrason E 3010: Polyethersulfone (PESU)AmirNo ratings yet

- Abs - Terluran GP22Document2 pagesAbs - Terluran GP22armandoNo ratings yet

- ABS Terluran GP35Document2 pagesABS Terluran GP35Alan MoraisNo ratings yet

- Petra 130 SpecsDocument2 pagesPetra 130 SpecssdecarlogaNo ratings yet

- Ultradur B 4300 G4: ® PBT (Polybutylene Terephthalate)Document2 pagesUltradur B 4300 G4: ® PBT (Polybutylene Terephthalate)irisNo ratings yet

- Abs - Terluran GP35Document2 pagesAbs - Terluran GP35armandoNo ratings yet

- Aultramid Pa 66Document2 pagesAultramid Pa 66ZaldsonNo ratings yet

- Kapton HN Data SheetDocument5 pagesKapton HN Data Sheet谢朋亨No ratings yet

- Manual KAPTON-FNDocument3 pagesManual KAPTON-FNPablo Hernandez MirandaNo ratings yet

- Specifications Asfalto 50-80-2023Document1 pageSpecifications Asfalto 50-80-2023H JNo ratings yet

- YEE70G30HSLNCDocument2 pagesYEE70G30HSLNCRanjan GnanaoliNo ratings yet

- Ultraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Document2 pagesUltraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Phuoc Thinh TruongNo ratings yet

- 202-Trinseo Calibre Megarad 2081-15 TDSDocument3 pages202-Trinseo Calibre Megarad 2081-15 TDSobeckoneNo ratings yet

- Technyl Star® A 205F Natural SDocument3 pagesTechnyl Star® A 205F Natural STiago GalloNo ratings yet

- Petra 130Document2 pagesPetra 130Phung LucNo ratings yet

- LEXAN™ FR Resin 916R - EuropeDocument3 pagesLEXAN™ FR Resin 916R - EuropesrinivasaNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Pa6 GF20 - Basf Ultramid B3eg4Document2 pagesPa6 GF20 - Basf Ultramid B3eg4armandoNo ratings yet

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoNo ratings yet

- Sabic® PP 575P: PP Homopolymer For Injection MouldingDocument1 pageSabic® PP 575P: PP Homopolymer For Injection MouldingPrinchipi YounesNo ratings yet

- MTC VG-40-9080942Document1 pageMTC VG-40-9080942vyzjhxypdcNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Product Technical Data Sheet: Unit Value MethodDocument2 pagesProduct Technical Data Sheet: Unit Value Methodhamza OUADINo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Isoplast 300 ETP: Advancing MaterialsDocument2 pagesIsoplast 300 ETP: Advancing MaterialsDanielNo ratings yet

- محطة توليد كهرباء العين السخنةDocument1 pageمحطة توليد كهرباء العين السخنةfarid.chira2No ratings yet

- Classification 14009Document2 pagesClassification 14009Sayyid AbulkhairNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- LEXAN™ Resin - 141R - Europe - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Europe - Technical - Data - SheetMinh Quãng PhạmNo ratings yet

- Tabla Compartiva Fluidos Hidraulicos - FormexDocument4 pagesTabla Compartiva Fluidos Hidraulicos - Formexirvingsr91No ratings yet

- Data Sheet - Zytel 80g33 Hs1-L-nc-10Document3 pagesData Sheet - Zytel 80g33 Hs1-L-nc-10Ranjan GnanaoliNo ratings yet

- POM Delrin 500Document2 pagesPOM Delrin 500countzeroaslNo ratings yet

- Technical Data Sheet Chryso Cwa10 6039 1322Document3 pagesTechnical Data Sheet Chryso Cwa10 6039 1322velmurug_balaNo ratings yet

- Chryso Cwa 10Document2 pagesChryso Cwa 10Kiran KumarNo ratings yet

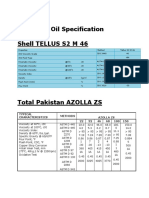

- Specifications For Hydraulic OilDocument3 pagesSpecifications For Hydraulic OilAliya NaseemNo ratings yet

- RT Duroid 5870 5880 Data Sheet PDFDocument2 pagesRT Duroid 5870 5880 Data Sheet PDFNom MonNo ratings yet

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Document3 pagesBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNo ratings yet

- Mobil SHC Aware™ Gear Series: Product DescriptionDocument3 pagesMobil SHC Aware™ Gear Series: Product Descriptiontxto2881No ratings yet

- HydraulicDocument2 pagesHydraulicQuy CocanhNo ratings yet

- Amilan® CM3001G30Document3 pagesAmilan® CM3001G30agungNo ratings yet

- 4lex® 10F10000Document3 pages4lex® 10F10000srinivasaNo ratings yet

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Natpet Teldene H03TFDocument2 pagesNatpet Teldene H03TFTychNo ratings yet

- ABS Terluran GP22Document2 pagesABS Terluran GP22Alan MoraisNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Styrolution TDS401600170785Document3 pagesStyrolution TDS401600170785shahin_723No ratings yet

- TDS - Terluran GP-22 PDFDocument3 pagesTDS - Terluran GP-22 PDFebercueNo ratings yet

- PC-Transparent 144RDocument5 pagesPC-Transparent 144Rsantosh.bhattNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- Plastistrength™: Acrylic Process Aids For PVC ApplicationsDocument28 pagesPlastistrength™: Acrylic Process Aids For PVC ApplicationsJaved Iqbal100% (1)

- Manufacturing LectureDocument25 pagesManufacturing Lecturemohtram1037No ratings yet

- Module 4 Rapid Tooling and Reverse Engineering PDFDocument152 pagesModule 4 Rapid Tooling and Reverse Engineering PDFDiscord YtNo ratings yet

- Lldpe Ga564189Document3 pagesLldpe Ga564189xy2zjgNo ratings yet

- International Journal of Heat and Mass Transfer: Shaochuan Feng, Amar M. Kamat, Yutao PeiDocument28 pagesInternational Journal of Heat and Mass Transfer: Shaochuan Feng, Amar M. Kamat, Yutao PeiChien Vu NgocNo ratings yet

- Piovan Company OverviewDocument0 pagesPiovan Company OverviewderdorNo ratings yet

- Technical Data Sheet - ASTMDocument2 pagesTechnical Data Sheet - ASTMwida acNo ratings yet

- Full Project NiranjanaDocument70 pagesFull Project NiranjanaMK gamingNo ratings yet

- SOLIDWORKS Simulation in Life Sciences Ebook SourceFilesDocument13 pagesSOLIDWORKS Simulation in Life Sciences Ebook SourceFilesCADISTCNo ratings yet

- Poltolerances - Tolerances For Plastic Moulded Parts (According To Iso 20457 / Din 16742)Document28 pagesPoltolerances - Tolerances For Plastic Moulded Parts (According To Iso 20457 / Din 16742)Ahmad EltaweelNo ratings yet

- Mold Maintenance ProgramDocument14 pagesMold Maintenance ProgramLordsonNo ratings yet

- 1 Feed SystemDocument32 pages1 Feed SystemKumarMeiGandanNo ratings yet

- Moldflow Adviser 2018 BrochureDocument3 pagesMoldflow Adviser 2018 BrochureCharlesNo ratings yet

- Experiment 4Document9 pagesExperiment 4Kelvin LimNo ratings yet

- Breakthrough Applications Created by Ceramic Injection Moulding Technology (CIM)Document40 pagesBreakthrough Applications Created by Ceramic Injection Moulding Technology (CIM)eitan-dalia4971No ratings yet

- 008x TF-compressed PDFDocument66 pages008x TF-compressed PDFJosé Francisco Blanco VillalbaNo ratings yet

- System Electronics ReportZone 5system Electronics ReportDocument1,290 pagesSystem Electronics ReportZone 5system Electronics ReportwititterleyNo ratings yet

- Cipet Project WorkDocument44 pagesCipet Project WorkFarooq Naregal100% (2)

- Itp 2020 Fact SheetDocument2 pagesItp 2020 Fact Sheetapi-466451281No ratings yet

- Injection Moulding TechniqueDocument14 pagesInjection Moulding Techniquedrpooja.kaloniyaNo ratings yet

- 01.DFMA - Introduction 82Document102 pages01.DFMA - Introduction 82chaitanya kulkarni100% (1)

- Machine Shops Company DetailsDocument160 pagesMachine Shops Company DetailsYash JainNo ratings yet

- Medical Plastics Webinar 23-05-2020Document66 pagesMedical Plastics Webinar 23-05-2020Rakeshjha75No ratings yet

- A Modified Vince Gingery PlasticDocument13 pagesA Modified Vince Gingery PlasticgeppaNo ratings yet

- PPKM-List of UnitsDocument32 pagesPPKM-List of UnitsPraveen Adhidasu100% (1)

- ZYTDGeDocument62 pagesZYTDGeAnonymous JIRIzeiJ6ONo ratings yet

- Injection Molding Manufacturing Process: Review of Case-Based Reasoning ApplicationsDocument18 pagesInjection Molding Manufacturing Process: Review of Case-Based Reasoning ApplicationsDanu Adi PradanaNo ratings yet

- Jan-2020 P TDocument64 pagesJan-2020 P TmaheshgupteNo ratings yet

- Lepo It Tevin 2011Document30 pagesLepo It Tevin 2011Sanem Hazal TürkayNo ratings yet

- 3-Mold - Tooling ConsiderationsDocument37 pages3-Mold - Tooling ConsiderationsGiap NguyenNo ratings yet