Professional Documents

Culture Documents

PC-Transparent 144R

Uploaded by

santosh.bhattOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PC-Transparent 144R

Uploaded by

santosh.bhattCopyright:

Available Formats

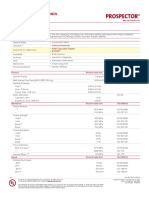

LEXAN™ 144R resin

Polycarbonate

SABIC Innovative Plastics www.ulprospector.com

Technical Data

Product Description

UL rated HB. 200 series recommended when V-2 rating required. MFR 10.5. Internal mold release. FDA food contact compliant in limited

colors.Effective January 15th, 2007 this grade will no longer be supported with biocompatibility information and should not be used for medical

applications which require biocompatibility. Alternative grade HP4.

General

Material Status • Commercial: Active

Literature 1 • Technical Datasheet

UL Yellow Card 2 • E121562-220863

Search for UL Yellow Card

• SABIC Innovative Plastics

• LEXAN™

Availability • North America

Additive • Mold Release

Features • Food Contact Acceptable

Agency Ratings • FDA Food Contact, Unspecified Rating

Processing Method • Injection Molding

Multi-Point Data • Viscosity vs. Shear Rate (ASTM D3835)

Physical Nominal Value Unit Test Method

Specific Gravity ASTM D792

-- 1.20 g/cm³

-- 1.19 g/cm³

Specific Volume 0.830 cm³/g ASTM D792

Melt Mass-Flow Rate (MFR) (300°C/1.2 kg) 11 g/10 min ASTM D1238

Melt Volume-Flow Rate (MVR) (300°C/1.2 kg) 10.0 cm³/10min ISO 1133

Molding Shrinkage - Flow (3.20 mm) 0.50 to 0.70 % Internal Method

Water Absorption ASTM D570

24 hr 0.15 %

Equilibrium, 23°C 0.35 %

Equilibrium, 100°C 0.58 %

Mechanical Nominal Value Unit Test Method

Tensile Modulus

-- 4 2370 MPa ASTM D638

-- 2350 MPa ISO 527-2/1

Tensile Strength

Yield 5 62.0 MPa ASTM D638

Yield 63.0 MPa ISO 527-2/50

Break 5 68.0 MPa ASTM D638

Break 70.0 MPa ISO 527-2/50

Tensile Elongation

Yield 5 7.0 % ASTM D638

Yield 6.0 % ISO 527-2/50

Break 5 130 % ASTM D638

Break 110 % ISO 527-2/50

Flexural Modulus

50.0 mm Span 6 2340 MPa ASTM D790

-- 7 2300 MPa ISO 178

Flexural Stress

-- 7, 8 90.0 MPa ISO 178

Yield, 50.0 mm Span 6 97.0 MPa ASTM D790

1 of 5 Form No. TDS-17556-en

UL and the UL logo are trademarks of UL LLC © 2015. All Rights Reserved. Document Created: Tuesday, July 21, 2015

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November, 2000

Last Updated: 3/19/2014

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial

efforts to assure the accuracy of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that

upon final material selection, data points are validated with the material supplier.

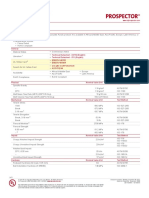

LEXAN™ 144R resin

Polycarbonate

SABIC Innovative Plastics www.ulprospector.com

Mechanical Nominal Value Unit Test Method

Taber Abrasion Resistance ASTM D1044

1000 Cycles, 1000 g, CS-17 Wheel 10.0 mg

Impact Nominal Value Unit Test Method

Charpy Notched Impact Strength (23°C) 35 kJ/m² ISO 179/2C

Notched Izod Impact

Colors 800 J/m ASTM D256

Natural, Tints 800 J/m ASTM D256

23°C 800 J/m ASTM D256

-30°C 9 10 kJ/m² ISO 180/1A

23°C 9 12 kJ/m² ISO 180/1A

Unnotched Izod Impact (23°C) 3200 J/m ASTM D4812

Instrumented Dart Impact ASTM D3763

23°C, Energy at Peak Load 63.0 J

Gardner Impact (23°C) 169 J ASTM D3029

Tensile Impact Strength 10 577 kJ/m² ASTM D1822

Hardness Nominal Value Unit Test Method

Rockwell Hardness ASTM D785

M-Scale 70

R-Scale 118

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load

0.45 MPa, Unannealed, 6.40 mm 137 °C ASTM D648

0.45 MPa, Unannealed, 100 mm Span 11 136 °C ISO 75-2/Be

1.8 MPa, Unannealed, 6.40 mm 132 °C ASTM D648

1.8 MPa, Unannealed, 100 mm Span 11 125 °C ISO 75-2/Ae

Vicat Softening Temperature

-- 154 °C ASTM D1525 12

-- 153 °C ISO 306/A50

-- 141 °C ISO 306/B50

-- 142 °C ISO 306/B120

Ball Pressure Test (125°C) Pass IEC 60695-10-2

CLTE - Flow

-40 to 95°C 6.8E-5 cm/cm/°C ASTM E831

23 to 80°C 7.0E-5 cm/cm/°C ISO 11359-2

Specific Heat 1250 J/kg/°C ASTM C351

Thermal Conductivity

-- 0.19 W/m/K ASTM C177

-- 0.20 W/m/K ISO 8302

RTI Elec 130 °C UL 746

RTI Imp 130 °C UL 746

RTI Str 130 °C UL 746

Electrical Nominal Value Unit Test Method

Surface Resistivity > 1.0E+15 ohms IEC 60093

Volume Resistivity

-- > 1.0E+17 ohms·cm ASTM D257

-- > 1.0E+15 ohms·cm IEC 60093

Dielectric Strength

3.20 mm, in Air 15 kV/mm ASTM D149

3.20 mm, in Oil 17 kV/mm IEC 60243-1

2 of 5 Form No. TDS-17556-en

UL and the UL logo are trademarks of UL LLC © 2015. All Rights Reserved. Document Created: Tuesday, July 21, 2015

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November, 2000

Last Updated: 3/19/2014

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial

efforts to assure the accuracy of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that

upon final material selection, data points are validated with the material supplier.

LEXAN™ 144R resin

Polycarbonate

SABIC Innovative Plastics www.ulprospector.com

Electrical Nominal Value Unit Test Method

Dielectric Constant

50 Hz 3.17 ASTM D150

60 Hz 3.17 ASTM D150

1 MHz 2.96 ASTM D150

50 Hz 2.70 IEC 60250

60 Hz 2.70 IEC 60250

1 MHz 2.70 IEC 60250

Dissipation Factor

50 Hz 9.0E-4 ASTM D150

60 Hz 9.0E-4 ASTM D150

ASTM D150

1 MHz 0.010

IEC 60250

50 Hz 1.0E-3 IEC 60250

60 Hz 1.0E-3 IEC 60250

Comparative Tracking Index (CTI) PLC 2 UL 746

High Amp Arc Ignition (HAI) PLC 1 UL 746

High Voltage Arc Tracking Rate (HVTR) PLC 2 UL 746

Hot-wire Ignition (HWI) PLC 2 UL 746

Flammability Nominal Value Unit Test Method

Flame Rating (1.47 mm) HB UL 94

ASTM D2863

Oxygen Index 25 %

ISO 4589-2

Optical Nominal Value Unit Test Method

Refractive Index 1.586 ASTM D542

Transmittance (2540 µm) 88.0 % ASTM D1003

Haze (2540 µm) 1.0 % ASTM D1003

Injection Nominal Value Unit

Drying Temperature 121 °C

Drying Time 3.0 to 4.0 hr

Drying Time, Maximum 48 hr

Suggested Max Moisture 0.020 %

Suggested Shot Size 40 to 60 %

Rear Temperature 271 to 293 °C

Middle Temperature 282 to 304 °C

Front Temperature 293 to 316 °C

Nozzle Temperature 288 to 310 °C

Processing (Melt) Temp 293 to 316 °C

Mold Temperature 71.1 to 93.3 °C

Back Pressure 0.345 to 0.689 MPa

Screw Speed 40 to 70 rpm

Vent Depth 0.025 to 0.076 mm

3 of 5 Form No. TDS-17556-en

UL and the UL logo are trademarks of UL LLC © 2015. All Rights Reserved. Document Created: Tuesday, July 21, 2015

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November, 2000

Last Updated: 3/19/2014

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial

efforts to assure the accuracy of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that

upon final material selection, data points are validated with the material supplier.

LEXAN™ 144R resin

Polycarbonate

SABIC Innovative Plastics www.ulprospector.com

Notes

1

These links provide you with access to supplier literature. We work hard to keep them up to date; however you may find the most current

literature from the supplier.

2

A UL Yellow Card contains UL-verified flammability and electrical characteristics. UL Prospector continually works to link Yellow Cards to

individual plastic materials in Prospector, however this list may not include all of the appropriate links. It is important that you verify the

association between these Yellow Cards and the plastic material found in Prospector. For a complete listing of Yellow Cards, visit the UL Yellow

Card Search.

3

Typical properties: these are not to be construed as specifications.

4

50 mm/min

5

Type I, 50 mm/min

6

1.3 mm/min

7

2.0 mm/min

8

Yield

9

80*10*4

10

Type S

11

120*10*4 mm

12

Rate B (120°C/h), Loading 2 (50 N)

4 of 5 Form No. TDS-17556-en

UL and the UL logo are trademarks of UL LLC © 2015. All Rights Reserved. Document Created: Tuesday, July 21, 2015

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November, 2000

Last Updated: 3/19/2014

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial

efforts to assure the accuracy of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that

upon final material selection, data points are validated with the material supplier.

LEXAN™ 144R resin

Polycarbonate

SABIC Innovative Plastics www.ulprospector.com

Where to Buy

Supplier

SABIC Innovative Plastics

Pittsfield, MA USA

Telephone: 800-845-0600

Web: http://www.sabic-ip.com/

Distributor

Nexeo Solutions

Telephone: 888-594-6009

Web: http://www.nexeosolutions.com/

Availability: North America

5 of 5 Form No. TDS-17556-en

UL and the UL logo are trademarks of UL LLC © 2015. All Rights Reserved. Document Created: Tuesday, July 21, 2015

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November, 2000

Last Updated: 3/19/2014

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial

efforts to assure the accuracy of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that

upon final material selection, data points are validated with the material supplier.

You might also like

- Harold Aspden - Power From Space: The Correa InventionDocument45 pagesHarold Aspden - Power From Space: The Correa InventionSonyRedNo ratings yet

- Transmission Line (KABADI)Document101 pagesTransmission Line (KABADI)Kifaru Micro-electronicsNo ratings yet

- Abs Ex58f - AsiaDocument4 pagesAbs Ex58f - AsiaGiang CaoNo ratings yet

- 202-Trinseo Calibre Megarad 2081-15 TDSDocument3 pages202-Trinseo Calibre Megarad 2081-15 TDSobeckoneNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- PP GF30 - Hostacom PC072-3 Naturale-2Document2 pagesPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- Ryton R-4-200NA: Polyphenylene SulfideDocument3 pagesRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniNo ratings yet

- SABIC® PC Resin PC0703R - AsiaDocument4 pagesSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhNo ratings yet

- ABS Sabic Cycolac MG94 Cust.cDocument5 pagesABS Sabic Cycolac MG94 Cust.cMurillo AraujoNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinDocument3 pagesCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaNo ratings yet

- Product PDF 37692Document2 pagesProduct PDF 37692Ing. Uriel SánchezNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- PC Lexan 3412R 20% GL - IdesDocument5 pagesPC Lexan 3412R 20% GL - IdescountzeroaslNo ratings yet

- Hypro-F Ppc-gf10 NaturalDocument2 pagesHypro-F Ppc-gf10 NaturalsygabrielaNo ratings yet

- Sabic® PP 37MK10RDocument2 pagesSabic® PP 37MK10RNguyễn Xuân KỳNo ratings yet

- PC Lexan 104Document4 pagesPC Lexan 104countzeroaslNo ratings yet

- Product PDF 37723Document2 pagesProduct PDF 37723hocineNo ratings yet

- Product 301485Document1 pageProduct 301485Geovani Daniel Gonzalez LopezNo ratings yet

- Infino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateDocument2 pagesInfino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateVenkatesan ManikandanNo ratings yet

- Kumho ABS 750SWDocument3 pagesKumho ABS 750SWVu TranNo ratings yet

- Tenac C 4520Document2 pagesTenac C 4520Phung LucNo ratings yet

- ACRYREX® CM-211: Chi Mei CorporationDocument3 pagesACRYREX® CM-211: Chi Mei CorporationPhuoc Thinh TruongNo ratings yet

- PP GF15 - Hifill PP Co GF15 CCDocument1 pagePP GF15 - Hifill PP Co GF15 CCarmandoNo ratings yet

- Solvay - Ixef BXT2000Document5 pagesSolvay - Ixef BXT2000Renan GadioliNo ratings yet

- XENOY™ Resin X2300WX - AmericasDocument3 pagesXENOY™ Resin X2300WX - AmericasWellington C. de AraujoNo ratings yet

- POLYLAC® PA-765: Chi Mei CorporationDocument3 pagesPOLYLAC® PA-765: Chi Mei CorporationagungNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- PC Lexan HP6NR Healthcare - ProspectorDocument5 pagesPC Lexan HP6NR Healthcare - ProspectorcountzeroaslNo ratings yet

- Denyl 6 NDocument2 pagesDenyl 6 NPhung LucNo ratings yet

- LEXAN™ FR Resin 916R - EuropeDocument3 pagesLEXAN™ FR Resin 916R - EuropesrinivasaNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- Ds CoPP-20900Document1 pageDs CoPP-20900rubser05No ratings yet

- Product PDF 210710Document1 pageProduct PDF 210710vaibhav ShindeNo ratings yet

- PEI Ultem 2310R 30%GLDocument4 pagesPEI Ultem 2310R 30%GLcountzeroaslNo ratings yet

- RTPU Isoplast 101 LGF40 idesDocument1 pageRTPU Isoplast 101 LGF40 idescountzeroaslNo ratings yet

- Product-pdf-398216Document2 pagesProduct-pdf-398216Bruno CastroNo ratings yet

- PX2938Document2 pagesPX2938TRUONGNo ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- Achieve™ Advanced PP8285E1: Polypropylene Impact CopolymerDocument2 pagesAchieve™ Advanced PP8285E1: Polypropylene Impact CopolymermosesNo ratings yet

- Product PDF 406967Document2 pagesProduct PDF 406967hocineNo ratings yet

- Ultraform N2320 003 BK120 Q600Document2 pagesUltraform N2320 003 BK120 Q600JoelNo ratings yet

- Polylac® Pa-747Document3 pagesPolylac® Pa-747vicenteNo ratings yet

- Lexan 121RDocument4 pagesLexan 121RJavier RuizNo ratings yet

- Product-pdf-ABS HI121Document2 pagesProduct-pdf-ABS HI121hocineNo ratings yet

- Hyosung Topilene J740 PP Properties and ApplicationsDocument2 pagesHyosung Topilene J740 PP Properties and ApplicationsEmmylouCasanovaNo ratings yet

- NG30-02JBK - Next PolymersDocument4 pagesNG30-02JBK - Next PolymersdigiarkanandNo ratings yet

- Product PDF 4956Document2 pagesProduct PDF 4956Mohammad PoostforushNo ratings yet

- Kumho ABS 750Document2 pagesKumho ABS 750Murundu EstudioNo ratings yet

- Product PDF 61718Document2 pagesProduct PDF 61718Mario Alberto BustosNo ratings yet

- Tenac 4013ADocument3 pagesTenac 4013APhung LucNo ratings yet

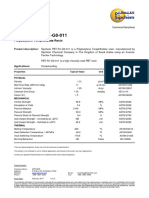

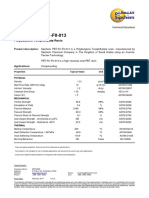

- Sipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Datenblatt Rohstoff Torlon 4301Document4 pagesDatenblatt Rohstoff Torlon 4301DarkedgeNo ratings yet

- PermaStat 600 UVDocument2 pagesPermaStat 600 UVPhung LucNo ratings yet

- Bapolene 200fDocument2 pagesBapolene 200fDiana SarmientoNo ratings yet

- Wonderlite® PC-110Document3 pagesWonderlite® PC-110Rhekron PlasticsNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- Sipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Geogrid Standard Material SpecificationDocument2 pagesGeogrid Standard Material SpecificationBriccioNo ratings yet

- Kopla Pa6 KNG1015Document3 pagesKopla Pa6 KNG1015agungNo ratings yet

- Diakon® ST35G8: Lucite International Holland BVDocument3 pagesDiakon® ST35G8: Lucite International Holland BVbobNo ratings yet

- Simotics HV M Catalog d84 3 2021 enDocument2 pagesSimotics HV M Catalog d84 3 2021 enreza nasiriNo ratings yet

- Micro-Nano-Scale Mechanics PDFDocument48 pagesMicro-Nano-Scale Mechanics PDFM.ThirunavukkarasuNo ratings yet

- Chapter 3 DiodeDocument246 pagesChapter 3 DiodeLittle VoiceNo ratings yet

- Simulation and Optimization of An Adiabatic Multi-Bed Catalytic Reactor For The Oxidation of SODocument7 pagesSimulation and Optimization of An Adiabatic Multi-Bed Catalytic Reactor For The Oxidation of SOMaria Luisa Sandoval OchoaNo ratings yet

- REGENT UNIVERSITY ELECTROMAGNETIC THEORY SECTIONDocument5 pagesREGENT UNIVERSITY ELECTROMAGNETIC THEORY SECTIONeyyzeyyNo ratings yet

- Tugas 1 KL - 3204 Metode Eksperimen Laboratorium Dr. Eng. Hendra Achiari, S.T, M.TDocument5 pagesTugas 1 KL - 3204 Metode Eksperimen Laboratorium Dr. Eng. Hendra Achiari, S.T, M.TRaka FirmansyahNo ratings yet

- Pdu Lab Manual 104Document94 pagesPdu Lab Manual 104Rana FaizanNo ratings yet

- Carrier Serie 50TC (15-27.5 Ton) PDFDocument98 pagesCarrier Serie 50TC (15-27.5 Ton) PDFRafael CentenoNo ratings yet

- The Voltage Intensifier CircuitDocument38 pagesThe Voltage Intensifier CircuitDirk MatthesNo ratings yet

- Activity No. 4Document7 pagesActivity No. 4Mary Ingrid BumatayNo ratings yet

- b13 Forced Commutation Using ArduinoDocument62 pagesb13 Forced Commutation Using ArduinoAlexandru Stefan AndriesNo ratings yet

- Pioro 2005Document25 pagesPioro 2005Thamil ThedalNo ratings yet

- Folletofototerapiabt 400pdfDocument2 pagesFolletofototerapiabt 400pdfRomel ZuloagaNo ratings yet

- Indian Standard: Specification For Electric Ceiling Type Fans and RegulatorsDocument25 pagesIndian Standard: Specification For Electric Ceiling Type Fans and RegulatorsJai KaranNo ratings yet

- SCH 3W RMU GDDocument16 pagesSCH 3W RMU GDadityasmartiNo ratings yet

- Earthing SystemDocument26 pagesEarthing SystemCenturyCorpSacNo ratings yet

- DT94 01Document2 pagesDT94 01bbs557comtwNo ratings yet

- Multi-Condenser Unit Service ManualDocument78 pagesMulti-Condenser Unit Service ManualdimashrnndzNo ratings yet

- Amana Refrigerator Tech SheetDocument11 pagesAmana Refrigerator Tech SheetSamurai Appliance Repair ManNo ratings yet

- Print Mod 3 29-66Document36 pagesPrint Mod 3 29-66sagar sainiNo ratings yet

- IKG Punjab Technical University Syllabus (3rd -8th Semester) for Undergraduate Degree Programme Bachelor of Technology in Electrical Engineering 2018 & onwardsDocument74 pagesIKG Punjab Technical University Syllabus (3rd -8th Semester) for Undergraduate Degree Programme Bachelor of Technology in Electrical Engineering 2018 & onwardsVishal KumarNo ratings yet

- Electromagnetic Relays Explained (K2Document30 pagesElectromagnetic Relays Explained (K2Vairaperumal KNo ratings yet

- Design Consideration For Converters and Input FiltersDocument16 pagesDesign Consideration For Converters and Input FiltersYeshewas DemewozNo ratings yet

- Model Question Paper-EMDocument4 pagesModel Question Paper-EMAgnes RituNo ratings yet

- Thyristor Based HVDC SystemDocument5 pagesThyristor Based HVDC SystemAnonymous hzXy93FAE0% (1)

- 04-May-21 - SDG&E - AL 3755-E - Remove Franchise Fee DifferentialsDocument103 pages04-May-21 - SDG&E - AL 3755-E - Remove Franchise Fee DifferentialsRob NikolewskiNo ratings yet

- Dynamics - Kinematics 1 PDFDocument11 pagesDynamics - Kinematics 1 PDFChuck Dave DiazNo ratings yet

- Calculating Dew Points from Gas CompositionDocument1 pageCalculating Dew Points from Gas CompositionNKNo ratings yet