Professional Documents

Culture Documents

ULTEM™ AUT230 Resin: SABIC Innovative Plastics

Uploaded by

Leandro LacerdaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ULTEM™ AUT230 Resin: SABIC Innovative Plastics

Uploaded by

Leandro LacerdaCopyright:

Available Formats

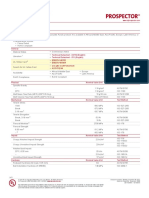

ULTEM™

AUT230 resin

Polyether Imide

SABIC Innovative Plastics www.ulprospector.com

Technical Data

Product Description

Transparent polyetherimide (Tg 247 degC). Very low outgassing and plateout, for automotive lighting applications where highly metallized,

reflective surfaces are required. Haze onset temperature of 230 degC (SABIC Innovative Plastics method)

General

Material Status • Commercial: Active

Literature 1 • Technical Datasheet

Search for UL Yellow Card

• SABIC Innovative Plastics

• ULTEM™

Availability • North America

Features • Low to No Outgassing

Uses • Automotive Applications

Appearance • Clear/Transparent

Processing Method • Injection Molding

Physical Nominal Value Unit Test Method

ASTM D792

Specific Gravity 1.30 g/cm³

ISO 1183

Melt Volume-Flow Rate (MVR) (360°C/5.0 kg) 8.00 cm³/10min ISO 1133

Molding Shrinkage Internal Method

Flow 3 0.50 to 0.70 %

Flow : 3.20 mm 0.50 to 0.70 %

Across Flow : 3.20 mm 0.50 to 0.70 %

Water Absorption ISO 62

Saturation, 23°C 1.8 %

Equilibrium, 23°C, 50% RH 0.60 %

Mechanical Nominal Value Unit Test Method

Tensile Modulus

-- 4 3510 MPa ASTM D638

-- 3110 MPa ISO 527-2/1

Tensile Strength

Yield 5 96.0 MPa ASTM D638

Yield 95.0 MPa ISO 527-2/5

Break 5 96.0 MPa ASTM D638

Break 78.0 MPa ISO 527-2/5

Tensile Elongation

Yield 5 6.0 % ASTM D638

Yield 8.5 % ISO 527-2/5

Break 5 25 % ASTM D638

Break 17 % ISO 527-2/5

Flexural Modulus

50.0 mm Span 6 3170 MPa ASTM D790

-- 7 3080 MPa ISO 178

7, 8 123 MPa ISO 178

Flexural Stress

Impact Nominal Value Unit Test Method

Notched Izod Impact

-30°C 74 J/m ASTM D256

23°C 69 J/m ASTM D256

-30°C 9 5.0 kJ/m² ISO 180/1A

23°C 9 4.0 kJ/m² ISO 180/1A

1 of 4 Form No. TDS-114763-en

UL and the UL logo are trademarks of UL LLC © 2017. All Rights Reserved. Document Created: Tuesday, June 13, 2017

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: May 2008

Last Updated: 3/19/2014

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial

efforts to assure the accuracy of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that

upon final material selection, data points are validated with the material supplier.

ULTEM™ AUT230 resin

Polyether Imide

SABIC Innovative Plastics www.ulprospector.com

Impact Nominal Value Unit Test Method

Unnotched Izod Impact

ASTM D4812

23°C No Break

ISO 180/1U

-30°C 9 No Break ISO 180/1U

Instrumented Dart Impact ASTM D3763

23°C, Total Energy 33.0 J

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load

0.45 MPa, Unannealed, 6.40 mm 237 °C ASTM D648

1.8 MPa, Unannealed, 3.20 mm 217 °C ASTM D648

1.8 MPa, Unannealed, 6.40 mm 230 °C ASTM D648

1.8 MPa, Unannealed, 64.0 mm Span 10 228 °C ISO 75-2/Af

Vicat Softening Temperature

ASTM D1525 11

-- 242 °C

ISO 306/B50 11

-- 238 °C ISO 306/B120

Ball Pressure Test (125°C) Pass IEC 60695-10-2

CLTE

Flow : -40 to 150°C 5.0E-5 cm/cm/°C ASTM E831

Flow : 23 to 150°C 5.0E-5 cm/cm/°C ISO 11359-2

Transverse : -40 to 150°C 5.0E-5 cm/cm/°C ASTM E831

Transverse : 23 to 150°C 5.0E-5 cm/cm/°C ISO 11359-2

Additional Information Nominal Value Unit Test Method

Metallized Haze Onset 230 °C Internal Method

Injection Nominal Value Unit

Drying Temperature 149 °C

Drying Time 4.0 to 6.0 hr

Drying Time, Maximum 24 hr

Suggested Max Moisture 0.020 %

Suggested Shot Size 40 to 60 %

Rear Temperature 332 to 399 °C

Middle Temperature 338 to 399 °C

Front Temperature 343 to 399 °C

Nozzle Temperature 343 to 399 °C

Processing (Melt) Temp 349 to 399 °C

Mold Temperature 135 to 163 °C

Back Pressure 0.345 to 0.689 MPa

Screw Speed 40 to 70 rpm

Vent Depth 0.025 to 0.076 mm

2 of 4 Form No. TDS-114763-en

UL and the UL logo are trademarks of UL LLC © 2017. All Rights Reserved. Document Created: Tuesday, June 13, 2017

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: May 2008

Last Updated: 3/19/2014

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial

efforts to assure the accuracy of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that

upon final material selection, data points are validated with the material supplier.

ULTEM™ AUT230 resin

Polyether Imide

SABIC Innovative Plastics www.ulprospector.com

Notes

1

These links provide you with access to supplier literature. We work hard to keep them up to date; however you may find the most current

literature from the supplier.

2

Typical properties: these are not to be construed as specifications.

3

Tensile Bar

4

5.0 mm/min

5

Type I, 5.0 mm/min

6

1.3 mm/min

7

2.0 mm/min

8

Yield

9

80*10*4

10

80*10*4 mm

11

Rate B (120°C/h), Loading 2 (50 N)

3 of 4 Form No. TDS-114763-en

UL and the UL logo are trademarks of UL LLC © 2017. All Rights Reserved. Document Created: Tuesday, June 13, 2017

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: May 2008

Last Updated: 3/19/2014

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial

efforts to assure the accuracy of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that

upon final material selection, data points are validated with the material supplier.

ULTEM™ AUT230 resin

Polyether Imide

SABIC Innovative Plastics www.ulprospector.com

Where to Buy

Supplier

SABIC Innovative Plastics

Pittsfield, MA USA

Telephone: 800-845-0600

Web: http://www.sabic-ip.com/

Distributor

Nexeo Solutions

Telephone: 888-594-6009

Web: http://www.nexeosolutions.com/

Availability: North America

Reseller

A Reseller is not a distributor authorized by the Supplier.

Guangzhou Huaxiu Plastics Co., Ltd.

Telephone: +86-20-82582555

Web: http://www.va-so.com

Availability: China

4 of 4 Form No. TDS-114763-en

UL and the UL logo are trademarks of UL LLC © 2017. All Rights Reserved. Document Created: Tuesday, June 13, 2017

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: May 2008

Last Updated: 3/19/2014

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial

efforts to assure the accuracy of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that

upon final material selection, data points are validated with the material supplier.

You might also like

- PP GF30 - Hostacom PC072-3 Naturale-2Document2 pagesPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- PC-Transparent 144RDocument5 pagesPC-Transparent 144Rsantosh.bhattNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- Abs Ex58f - AsiaDocument4 pagesAbs Ex58f - AsiaGiang CaoNo ratings yet

- SABIC® PC Resin PC0703R - AsiaDocument4 pagesSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhNo ratings yet

- Akulon F136-C1: DSM Engineering Materials - Polyamide 6Document2 pagesAkulon F136-C1: DSM Engineering Materials - Polyamide 6bobNo ratings yet

- ACRYREX® CM-211: Chi Mei CorporationDocument3 pagesACRYREX® CM-211: Chi Mei CorporationPhuoc Thinh TruongNo ratings yet

- 202-Trinseo Calibre Megarad 2081-15 TDSDocument3 pages202-Trinseo Calibre Megarad 2081-15 TDSobeckoneNo ratings yet

- Tenac 4013ADocument3 pagesTenac 4013APhung LucNo ratings yet

- Tenac C 4520Document2 pagesTenac C 4520Phung LucNo ratings yet

- LEXAN™ FR Resin 916R - EuropeDocument3 pagesLEXAN™ FR Resin 916R - EuropesrinivasaNo ratings yet

- Resina Nueva Validacion SkytronDocument2 pagesResina Nueva Validacion SkytronAlbert FortunatoNo ratings yet

- ABS Sabic Cycolac MG94 Cust.cDocument5 pagesABS Sabic Cycolac MG94 Cust.cMurillo AraujoNo ratings yet

- Ryton R-4-200NA: Polyphenylene SulfideDocument3 pagesRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniNo ratings yet

- POLYLAC® PA-765: Chi Mei CorporationDocument3 pagesPOLYLAC® PA-765: Chi Mei CorporationagungNo ratings yet

- Polylac® Pa-747Document3 pagesPolylac® Pa-747vicenteNo ratings yet

- Lexan 121RDocument4 pagesLexan 121RJavier RuizNo ratings yet

- Product PDF 398216Document2 pagesProduct PDF 398216Bruno CastroNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Infino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateDocument2 pagesInfino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateVenkatesan Manikandan0% (1)

- Kumho ABS 750SWDocument3 pagesKumho ABS 750SWVu TranNo ratings yet

- Diakon® ST35G8: Lucite International Holland BVDocument3 pagesDiakon® ST35G8: Lucite International Holland BVbobNo ratings yet

- Denyl 6 NDocument2 pagesDenyl 6 NPhung LucNo ratings yet

- Product PDF 37723Document2 pagesProduct PDF 37723hocineNo ratings yet

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinDocument3 pagesCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaNo ratings yet

- Amilan® CM3001G30Document3 pagesAmilan® CM3001G30agungNo ratings yet

- PC Lexan 3412R 20% GL - IdesDocument5 pagesPC Lexan 3412R 20% GL - IdescountzeroaslNo ratings yet

- 4lex® 10F13500Document2 pages4lex® 10F13500srinivasaNo ratings yet

- Calibre™ 603-3Document3 pagesCalibre™ 603-3bobNo ratings yet

- Product PDF 37692Document2 pagesProduct PDF 37692Ing. Uriel SánchezNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- Technyl Star® A 205F Natural SDocument3 pagesTechnyl Star® A 205F Natural STiago GalloNo ratings yet

- Sabic® PP 37MK10RDocument2 pagesSabic® PP 37MK10RNguyễn Xuân KỳNo ratings yet

- Solvay - Ixef BXT2000Document5 pagesSolvay - Ixef BXT2000Renan GadioliNo ratings yet

- Adsyl 7423 XCP: Lyondellbasell IndustriesDocument4 pagesAdsyl 7423 XCP: Lyondellbasell Industriesnouman ashrafNo ratings yet

- Amilan™ CM3006: Technical Data Nylon 66Document3 pagesAmilan™ CM3006: Technical Data Nylon 66hamdany danyNo ratings yet

- TDS - TS001 - Technyl A218Document3 pagesTDS - TS001 - Technyl A218oberta.andrzejNo ratings yet

- Ultradur® S 4090 G2Document4 pagesUltradur® S 4090 G2srinivasaNo ratings yet

- Wonderlite® PC-110Document3 pagesWonderlite® PC-110Rhekron PlasticsNo ratings yet

- PP GF15 - Hifill PP Co GF15 CCDocument1 pagePP GF15 - Hifill PP Co GF15 CCarmandoNo ratings yet

- Kopla Pa6 KNG1015Document3 pagesKopla Pa6 KNG1015agungNo ratings yet

- Product PDF 244478Document3 pagesProduct PDF 244478lorejaz84071127No ratings yet

- Zytel® HTN 51G35HSLR BK420Document3 pagesZytel® HTN 51G35HSLR BK420Vignesh CmvrNo ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- Duracon® CP15XDocument3 pagesDuracon® CP15XRhekron PlasticsNo ratings yet

- Amilan® CM1026: Toray Industries, IncDocument3 pagesAmilan® CM1026: Toray Industries, IncAgoenk KertawijayaNo ratings yet

- Product PDF 61718Document2 pagesProduct PDF 61718Mario Alberto BustosNo ratings yet

- XENOY™ Resin X2300WX - AmericasDocument3 pagesXENOY™ Resin X2300WX - AmericasWellington C. de AraujoNo ratings yet

- Starex GR-4020: Lotte Advanced Materials Co., LTDDocument5 pagesStarex GR-4020: Lotte Advanced Materials Co., LTDsivalingabeastboy2002No ratings yet

- Datenblatt Rohstoff Torlon 4301Document4 pagesDatenblatt Rohstoff Torlon 4301DarkedgeNo ratings yet

- Nexeo Plastics InStruc™ PPAIMDocument1 pageNexeo Plastics InStruc™ PPAIMMax SalogniNo ratings yet

- Product PDF 406967Document2 pagesProduct PDF 406967hocineNo ratings yet

- Natpet Teldene H03TFDocument2 pagesNatpet Teldene H03TFTychNo ratings yet

- Ems Tsg50 4 50% GF Nylon 66Document2 pagesEms Tsg50 4 50% GF Nylon 66elevendotNo ratings yet

- Kumho ABS 750Document2 pagesKumho ABS 750Murundu EstudioNo ratings yet

- PermaStat 600 UVDocument2 pagesPermaStat 600 UVPhung LucNo ratings yet

- Ultraform N2320 003 BK120 Q600Document2 pagesUltraform N2320 003 BK120 Q600JoelNo ratings yet

- Hypro-F Ppc-gf10 NaturalDocument2 pagesHypro-F Ppc-gf10 NaturalsygabrielaNo ratings yet

- PC Lexan HP6NR Healthcare - ProspectorDocument5 pagesPC Lexan HP6NR Healthcare - ProspectorcountzeroaslNo ratings yet

- Abs XR 404 LGDocument2 pagesAbs XR 404 LGLeandro LacerdaNo ratings yet

- Plexiglas® V825-100 Acrylic Resin: Material Safety Data SheetDocument9 pagesPlexiglas® V825-100 Acrylic Resin: Material Safety Data SheetLeandro LacerdaNo ratings yet

- VG621 PPGF30 BorealisDocument3 pagesVG621 PPGF30 BorealisLeandro LacerdaNo ratings yet

- PC TARFLON - IDEMITSU - lc1500 - enDocument1 pagePC TARFLON - IDEMITSU - lc1500 - enLeandro LacerdaNo ratings yet

- Bayer Makrolon - AL2447 - LensDocument4 pagesBayer Makrolon - AL2447 - LensLeandro LacerdaNo ratings yet

- Technyl - A 218GV30 Natural - J20005Document6 pagesTechnyl - A 218GV30 Natural - J20005Leandro LacerdaNo ratings yet

- Indian Institute of Technology (Indian School of Mines) DhabadDocument23 pagesIndian Institute of Technology (Indian School of Mines) DhabadAmit KumarNo ratings yet

- Uploading, Sharing, and Image Hosting PlatformsDocument12 pagesUploading, Sharing, and Image Hosting Platformsmarry janeNo ratings yet

- GTAG 1 2nd EditionDocument36 pagesGTAG 1 2nd EditionChristen Castillo100% (2)

- Lab - Report: Experiment NoDocument6 pagesLab - Report: Experiment NoRedwan AhmedNo ratings yet

- 7a.simple InterestDocument50 pages7a.simple InterestJanani MaranNo ratings yet

- GDN-206 - Guidelines On Safety Management System in Petroleum IndustryDocument49 pagesGDN-206 - Guidelines On Safety Management System in Petroleum IndustrykarpanaiNo ratings yet

- Thermal Hybrids R5Document9 pagesThermal Hybrids R5amir.kalantariNo ratings yet

- Manual de Parts ES16D6Document36 pagesManual de Parts ES16D6Eduardo CortezNo ratings yet

- Python BarchartDocument34 pagesPython BarchartSeow Khaiwen KhaiwenNo ratings yet

- Questions - Mechanical Engineering Principle Lecture and Tutorial - Covering Basics On Distance, Velocity, Time, Pendulum, Hydrostatic Pressure, Fluids, Solids, EtcDocument8 pagesQuestions - Mechanical Engineering Principle Lecture and Tutorial - Covering Basics On Distance, Velocity, Time, Pendulum, Hydrostatic Pressure, Fluids, Solids, EtcshanecarlNo ratings yet

- Compound Wall Design (1) - Layout1Document1 pageCompound Wall Design (1) - Layout1SandeepNo ratings yet

- Anklet - Google SearchDocument1 pageAnklet - Google SearchManu KhannaNo ratings yet

- RH S65A SSVR Users ManualDocument11 pagesRH S65A SSVR Users ManualMohd Fauzi YusohNo ratings yet

- General Director AdDocument1 pageGeneral Director Adapi-690640369No ratings yet

- Arvind Textiles Internship ReportDocument107 pagesArvind Textiles Internship ReportDipan SahooNo ratings yet

- Employee Conduct Policy StpsoDocument57 pagesEmployee Conduct Policy StpsoWWLTVWebteamNo ratings yet

- Ch-3 BUFFETDocument9 pagesCh-3 BUFFETJanith prakash567No ratings yet

- Java PT Android PDFDocument201 pagesJava PT Android PDFlaurablue96No ratings yet

- JJDocument119 pagesJJAnonymous 5k7iGyNo ratings yet

- 2017 Directory WO Member PagesDocument112 pages2017 Directory WO Member PagessberkowitzNo ratings yet

- Oracle Absence Management SetupDocument9 pagesOracle Absence Management SetupRavish Kumar SinghNo ratings yet

- MVC Plus User Manual REV5Document90 pagesMVC Plus User Manual REV5Adalberto FentanezNo ratings yet

- Termsconditions of JionetDocument3 pagesTermsconditions of JionetskNo ratings yet

- AMAZONS StategiesDocument2 pagesAMAZONS StategiesPrachi VermaNo ratings yet

- Why Is Inventory Turnover Important?: ... It Measures How Hard Your Inventory Investment Is WorkingDocument6 pagesWhy Is Inventory Turnover Important?: ... It Measures How Hard Your Inventory Investment Is WorkingabhiNo ratings yet

- Pas 1, Presentation of Financial Statements: Philippine Institute of Certified Public AccountantsDocument38 pagesPas 1, Presentation of Financial Statements: Philippine Institute of Certified Public AccountantsAie GeraldinoNo ratings yet

- 2018 Master Piping Products Price ListDocument84 pages2018 Master Piping Products Price ListSuman DeyNo ratings yet

- ISC 2008 Computer Science Paper 1 TheoryDocument8 pagesISC 2008 Computer Science Paper 1 TheoryShadowerNo ratings yet

- ADocument2 pagesAẄâQâŗÂlïNo ratings yet

- Big Data Hadoop Certification Training CourseDocument12 pagesBig Data Hadoop Certification Training Courseprema vNo ratings yet