Professional Documents

Culture Documents

Product PDF 406967

Uploaded by

hocineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product PDF 406967

Uploaded by

hocineCopyright:

Available Formats

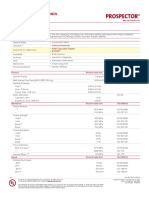

LG ASA LI911F

LG Chem Ltd. - Acrylonitrile Styrene Acrylate Wednesday, September 20, 2023

General Information

Product Description

Description

LI911F is a General Purpose ASA product for injection molding, designed to have good weatherability and high fluidity.

Key Features

Weatherability, High Flow

Application

Tractor, Lawn Mower, Roller Shutter, Electrical/Electronic Products

General

Material Status • Commercial: Active

• Asia Pacific • Latin America

Availability

• Europe • North America

Features • Good Weather Resistance • High Flow

Uses • Electrical/Electronic Applications • Lawn and Garden Equipment

Processing Method • Injection Molding

ASTM & ISO Properties 1

Physical Nominal Value Unit Test Method

Density / Specific Gravity 2 1.07 g/cm³ ASTM D792

Melt Mass-Flow Rate (MFR) (220°C/10.0 kg) 25 g/10 min ASTM D1238

Molding Shrinkage - Flow (23°C, 3.20 mm, Injection Molded) 0.40 to 0.70 % ASTM D955

Mechanical Nominal Value Unit Test Method

3 ASTM D638

Tensile Strength

Yield, 23°C, 3.20 mm, Injection Molded 44.0 MPa

Tensile Elongation 3 ASTM D638

Break, 23°C, 3.20 mm, Injection Molded > 40 %

Flexural Modulus 4 (23°C, 6.40 mm, Injection Molded) 2100 MPa ASTM D790

Flexural Strength 4 (23°C, 6.40 mm, Injection Molded) 68.0 MPa ASTM D790

Impact Nominal Value Unit Test Method

Notched Izod Impact (23°C, 6.40 mm, Injection Molded) 120 J/m ASTM D256

Hardness Nominal Value Unit Test Method

Rockwell Hardness (R-Scale, 23°C, Injection Molded) 97 ASTM D785

Thermal Nominal Value Unit Test Method

5 ASTM D648

Deflection Temperature Under Load

1.8 MPa, Unannealed, 6.40 mm, Injection Molded 86.0 °C

Processing Information

Injection Nominal Value Unit

Drying Temperature 70 to 80 °C

Drying Time 3.0 to 4.0 hr

Processing (Melt) Temp 200 to 250 °C

Mold Temperature 40 to 80 °C

UL LLC ©2023. All rights reserved.

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL assumes no

responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product or material selection

information is validated with the manufacturer. This website provides links to other websites owned by third parties. The content of such third party sites is not within

www.ulprospector.com our control, and we cannot and will not take responsibility for the information or content.

Page: 1 of 2

LG ASA LI911F

LG Chem Ltd. - Acrylonitrile Styrene Acrylate

Injection Nominal Value Unit

Screw Speed 30 to 60 rpm

Notes

1

Typical properties: these are not to be construed as specifications.

2

23°C

3

50 mm/min

4

10 mm/min

5

Edgewise

UL LLC ©2023. All rights reserved.

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL assumes no

responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product or material selection

information is validated with the manufacturer. This website provides links to other websites owned by third parties. The content of such third party sites is not within

www.ulprospector.com our control, and we cannot and will not take responsibility for the information or content.

Page: 2 of 2

You might also like

- Product-pdf-ABS HI121Document2 pagesProduct-pdf-ABS HI121hocineNo ratings yet

- Product PDF 37723Document2 pagesProduct PDF 37723hocineNo ratings yet

- Product PDF 37692Document2 pagesProduct PDF 37692Ing. Uriel SánchezNo ratings yet

- Product PDF 61718Document2 pagesProduct PDF 61718Mario Alberto BustosNo ratings yet

- Nexeo Plastics Kumho+PS HI+425EDocument2 pagesNexeo Plastics Kumho+PS HI+425Epedro pedroNo ratings yet

- Product PDF 398216Document2 pagesProduct PDF 398216Bruno CastroNo ratings yet

- Ds CoPP-20900Document1 pageDs CoPP-20900rubser05No ratings yet

- XENOY™ Resin X2300WX - AmericasDocument3 pagesXENOY™ Resin X2300WX - AmericasWellington C. de AraujoNo ratings yet

- Certene™ HGB-0354Document2 pagesCertene™ HGB-0354Eleannys Garcias0% (1)

- Product 301485Document1 pageProduct 301485Geovani Daniel Gonzalez LopezNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- Lupol® GP3156FDocument3 pagesLupol® GP3156FYo ANo ratings yet

- Nexeo Plastics InStruc™ PPAIMDocument1 pageNexeo Plastics InStruc™ PPAIMMax SalogniNo ratings yet

- Product PDF 210710Document1 pageProduct PDF 210710vaibhav ShindeNo ratings yet

- Denyl 6 NDocument2 pagesDenyl 6 NPhung LucNo ratings yet

- Solvay - Halar 513 LCDocument3 pagesSolvay - Halar 513 LCRenan GadioliNo ratings yet

- PP GF15 - Hifill PP Co GF15 CCDocument1 pagePP GF15 - Hifill PP Co GF15 CCarmandoNo ratings yet

- SCG PP P483Ju: SCG Chemicals Co., LTDDocument2 pagesSCG PP P483Ju: SCG Chemicals Co., LTDTruc Thao NguyenNo ratings yet

- Denyl 6 0037 HDocument2 pagesDenyl 6 0037 HPhung LucNo ratings yet

- Esd 800 HBDocument3 pagesEsd 800 HBsrinivasaNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- Solef PVDF 6008Document2 pagesSolef PVDF 6008topteam123No ratings yet

- Braskem Braskem PE GP100ORXP Pead GAS PE100Document2 pagesBraskem Braskem PE GP100ORXP Pead GAS PE100weimar solizNo ratings yet

- PermaStat 600 UVDocument2 pagesPermaStat 600 UVPhung LucNo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Hypro-F Ppc-gf10 NaturalDocument2 pagesHypro-F Ppc-gf10 NaturalsygabrielaNo ratings yet

- Product PDF 4956Document2 pagesProduct PDF 4956Mohammad PoostforushNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)hugo santiago chavez godoyNo ratings yet

- TDS M330F enDocument1 pageTDS M330F enJuan Sebastian YeglesNo ratings yet

- CPVC Geon PM280Document1 pageCPVC Geon PM280angelokyoNo ratings yet

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- Lustran® 433: INEOS StyrolutionDocument3 pagesLustran® 433: INEOS StyrolutionJames FaunceNo ratings yet

- LEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetRamesh KannanNo ratings yet

- PC-Transparent 144RDocument5 pagesPC-Transparent 144Rsantosh.bhattNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- PBT Data SheetDocument2 pagesPBT Data Sheetabhishek chaudharyNo ratings yet

- Sabic® PP 37MK10RDocument2 pagesSabic® PP 37MK10RNguyễn Xuân KỳNo ratings yet

- Solvay - Duradex D3000Document3 pagesSolvay - Duradex D3000Renan GadioliNo ratings yet

- Ryton R-4-200NA: Polyphenylene SulfideDocument3 pagesRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniNo ratings yet

- Product PDF 38528Document1 pageProduct PDF 38528phu nghiaNo ratings yet

- Hoja Tecnica ASADocument2 pagesHoja Tecnica ASAFernando AngioliniNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- Pa6 GF20 - Basf Ultramid B3eg4Document2 pagesPa6 GF20 - Basf Ultramid B3eg4armandoNo ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- Solvay - Ixef BXT2000Document5 pagesSolvay - Ixef BXT2000Renan GadioliNo ratings yet

- Cycoloy Resin C1200 Americas: COMMERCIAL: PropertyDocument2 pagesCycoloy Resin C1200 Americas: COMMERCIAL: PropertymarceloNo ratings yet

- 2.2.Tds Astm-Abs Lgchem Hi121Document2 pages2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNo ratings yet

- Pc-Iso: Mechanical Properties Test Method ValueDocument2 pagesPc-Iso: Mechanical Properties Test Method ValuekaledioskoppNo ratings yet

- RTPU Isoplast 101 LGF40 IdesDocument1 pageRTPU Isoplast 101 LGF40 IdescountzeroaslNo ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- CYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetDocument2 pagesCYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetmarceloNo ratings yet

- Abs Irpc Polimaxx SP100Document2 pagesAbs Irpc Polimaxx SP100countzeroaslNo ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- ABS LG HI21H. Rev.01Document2 pagesABS LG HI21H. Rev.01Ivan TimarevNo ratings yet

- Geogrid Standard Material SpecificationDocument2 pagesGeogrid Standard Material SpecificationBriccioNo ratings yet

- Notes On Lean ManufacturingDocument15 pagesNotes On Lean ManufacturingOmar NaeemNo ratings yet

- Module 4 Rapid Tooling and Reverse Engineering PDFDocument152 pagesModule 4 Rapid Tooling and Reverse Engineering PDFDiscord YtNo ratings yet

- BiobriquetteDocument7 pagesBiobriquetteputri wahyuniNo ratings yet

- Hofmann Corporate Presentation - LR - 190219Document68 pagesHofmann Corporate Presentation - LR - 190219Jorge VillalobosNo ratings yet

- 02 Ceramic and Clay ProductsDocument133 pages02 Ceramic and Clay ProductsAngel Mine AlcantaraNo ratings yet

- Ebs1 Aaaa00 Saqa Prqa 0016Document7 pagesEbs1 Aaaa00 Saqa Prqa 0016SERT-QA/QC- BUZNo ratings yet

- AISI 4100 13CrMo4Document6 pagesAISI 4100 13CrMo4Edder NoeNo ratings yet

- 3.11 Foundry CORE PRINTSDocument10 pages3.11 Foundry CORE PRINTSKALEMA BEMME2025No ratings yet

- Bendotti Vale La DifferenzaDocument19 pagesBendotti Vale La Differenzanegar adelniaNo ratings yet

- Document 32Document17 pagesDocument 32rik.sengupta.08No ratings yet

- Infineon-AN79938 Design Guidelines For Infineon Ball Grid Array (BGA) Packaged Devices-ApplicationNotes-v06 00-ENDocument19 pagesInfineon-AN79938 Design Guidelines For Infineon Ball Grid Array (BGA) Packaged Devices-ApplicationNotes-v06 00-ENmrbustaNo ratings yet

- Commercial Reverse Osmosis Machine For Car Wash Calcium Magnesium Reduction 3000 GPD Usa Data SheetDocument4 pagesCommercial Reverse Osmosis Machine For Car Wash Calcium Magnesium Reduction 3000 GPD Usa Data SheetCareers SSPNo ratings yet

- Is 2074 - 5Document1 pageIs 2074 - 5Svapnesh ParikhNo ratings yet

- King Cobra ShakersDocument2 pagesKing Cobra ShakersAku NoshNo ratings yet

- Liye - Info PDF File of Concrete Technology Ms Shetty Download For Free PRDocument1 pageLiye - Info PDF File of Concrete Technology Ms Shetty Download For Free PRwaseem lalaNo ratings yet

- Open Ended Lab Project EmatDocument6 pagesOpen Ended Lab Project EmatAnas SattiNo ratings yet

- Syi Cata GeneDocument1 pageSyi Cata Genebelay agaNo ratings yet

- MRPDocument14 pagesMRPFareed khan ZKNo ratings yet

- Albion Leach ReactorDocument16 pagesAlbion Leach ReactorДмитрий Петкевич-СочновNo ratings yet

- Preparation of Stress-Corrosion Test Specimens For WeldmentsDocument8 pagesPreparation of Stress-Corrosion Test Specimens For Weldmentsmohammed karasnehNo ratings yet

- Micro Alloyed Steels Voestalpine EN 30102020Document4 pagesMicro Alloyed Steels Voestalpine EN 30102020pierocarnelociNo ratings yet

- Masterkure CC 1315 WB TdsDocument3 pagesMasterkure CC 1315 WB TdsRavi SinghNo ratings yet

- NSK Used Environmentally Friendly Paper and Printing Methods For This PublicationDocument150 pagesNSK Used Environmentally Friendly Paper and Printing Methods For This Publicationabhishek amNo ratings yet

- Iswp Project Internship: Mentor: Mr. Vijayant Kumar Guide: Mr. Vinod KumarDocument34 pagesIswp Project Internship: Mentor: Mr. Vijayant Kumar Guide: Mr. Vinod KumarKunal VaidyaNo ratings yet

- Fenner Keyless - BushingsDocument52 pagesFenner Keyless - BushingspurushothamNo ratings yet

- Company Profile SCMA 2023Document12 pagesCompany Profile SCMA 2023Herman BrandonNo ratings yet

- The Breakthrough Ironmaking Technologies Combined With Energiron, Blast Furnace and SyngasDocument11 pagesThe Breakthrough Ironmaking Technologies Combined With Energiron, Blast Furnace and SyngaskaustavNo ratings yet

- ASME P-NumbersDocument9 pagesASME P-NumbersAamer MohammedNo ratings yet

- Front Frame Rail Inner (Large Front Section)Document38 pagesFront Frame Rail Inner (Large Front Section)Dong NguyenNo ratings yet

- Eco ParkDocument3 pagesEco ParkJOY LEE100% (1)