Professional Documents

Culture Documents

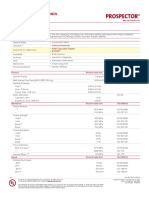

XENOY™ Resin X2300WX - Americas

Uploaded by

Wellington C. de AraujoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XENOY™ Resin X2300WX - Americas

Uploaded by

Wellington C. de AraujoCopyright:

Available Formats

XENOY™ Resin X2300WX - Americas

Polycarbonate + PET www.ulprospector.com

SABIC

Technical Data

Product Description

Unreinforced, opaque PC+PET alloy. Chemical resistance, dimensional stability/mechanical performance. UV-stabilized.

General

Material Status • Commercial: Active

Search for UL Yellow Card

• SABIC

• XENOY™ Resin

Availability • Latin America • North America

Additive • UV Stabilizer

Processing Method • Injection Molding

• Coefficient of Thermal Expansion vs. Temperature (ASTM E831)

• Flexural DMA (ASTM D4065)

• Pressure-Volume-Temperature (PVT - Zoller Method)

Multi-Point Data • Specific Heat vs. Temperature (ASTM D3417)

• Tensile Fatigue

• Tensile Stress vs. Strain (ASTM D638)

• Thermal Conductivity vs. Temperature (ASTM E1530)

Physical Nominal Value Unit Test Method

Density / Specific Gravity 1.21 g/cm³ ASTM D792

Melt Mass-Flow Rate (MFR) (266°C/5.0 kg) 35 g/10 min ASTM D1238

Molding Shrinkage - Flow (3.20 mm) 0.80 to 1.0 % Internal Method

Mechanical Nominal Value Unit Test Method

Tensile Modulus 2 2410 MPa ASTM D638

Tensile Strength 3 ASTM D638

Yield 58.0 MPa

Break 44.0 MPa

Tensile Elongation 3 ASTM D638

Yield 5.0 %

Break 120 %

Flexural Modulus 4 (50.0 mm Span) 2200 MPa ASTM D790

Flexural Strength 4 (Yield, 50.0 mm Span) 86.0 MPa ASTM D790

Impact Nominal Value Unit Test Method

Notched Izod Impact (23°C) 640 J/m ASTM D256

Instrumented Dart Impact ASTM D3763

23°C, Total Energy 48.0 J

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load ASTM D648

0.45 MPa, Unannealed, 3.20 mm 126 °C

1.8 MPa, Unannealed, 3.20 mm 110 °C

CLTE ASTM E831

Flow : -40 to 40°C 7.2E-5 cm/cm/°C

Transverse : -40 to 40°C 7.2E-5 cm/cm/°C

Injection Nominal Value Unit

Drying Temperature 110 °C

Drying Time 4.0 to 6.0 hr

Suggested Max Moisture 0.020 %

Suggested Shot Size 50 to 80 %

Rear Temperature 250 to 270 °C

Middle Temperature 255 to 275 °C

Front Temperature 260 to 280 °C

Nozzle Temperature 255 to 275 °C

1 of 3 Form No. TDS-54540-en

UL and the UL logo are trademarks of UL LLC © 2021. All Rights Reserved. Document Created: Tuesday, May 4, 2021

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: August 2001

Last Updated: 1/22/2021

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

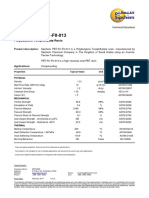

XENOY™ Resin X2300WX - Americas

Polycarbonate + PET

SABIC www.ulprospector.com

Injection Nominal Value Unit

Processing (Melt) Temp 260 to 280 °C

Mold Temperature 65 to 95 °C

Back Pressure 0.300 to 0.600 MPa

Screw Speed 50 to 80 rpm

Vent Depth 0.013 to 0.020 mm

Injection Notes

Injection Molding Parameters

• Drying Time (Cumulative): 8 hrs

Notes

1 Typical properties: these are not to be construed as specifications.

2 50 mm/min

3 Type I, 50 mm/min

4 1.3 mm/min

2 of 3 Form No. TDS-54540-en

UL and the UL logo are trademarks of UL LLC © 2021. All Rights Reserved. Document Created: Tuesday, May 4, 2021

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: August 2001

Last Updated: 1/22/2021

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

XENOY™ Resin X2300WX - Americas

Polycarbonate + PET

SABIC www.ulprospector.com

Where to Buy

Supplier

SABIC

,

Web: http://www.sabic.com/

Distributor

3Polymer (Guangzhou) Chemical Technology Co., Ltd.

Telephone: +86-20-3466-7988

Web: http://3polymer.com

Availability: China

Nexeo Plastics

Nexeo Plastics is leading global resin distributor with the technical resources you need to overcome material challenges. Visit us on the web at

www.nexeoplastics.com.

Telephone: 833-446-3936

Web: https://www.nexeoplastics.com/

Availability: North America

3 of 3 Form No. TDS-54540-en

UL and the UL logo are trademarks of UL LLC © 2021. All Rights Reserved. Document Created: Tuesday, May 4, 2021

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: August 2001

Last Updated: 1/22/2021

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

You might also like

- Ketenes, Allenes and Related Compounds - Volume 1 (1980) 1980 PDFDocument492 pagesKetenes, Allenes and Related Compounds - Volume 1 (1980) 1980 PDFhemberNo ratings yet

- Strength of Materials: A New Unified Theory for the 21st CenturyFrom EverandStrength of Materials: A New Unified Theory for the 21st CenturyRating: 3.5 out of 5 stars3.5/5 (4)

- ASTM D1159 - Standard Test Method For BRDocument10 pagesASTM D1159 - Standard Test Method For BRVishal GoswamiNo ratings yet

- Symmetry Elements and Point Groups: "Symmetry Is The Quantification of Beauty"Document93 pagesSymmetry Elements and Point Groups: "Symmetry Is The Quantification of Beauty"Jyoti GabaNo ratings yet

- ANODIZING (Autosaved)Document17 pagesANODIZING (Autosaved)Sonu JajamNo ratings yet

- Rotary Kiln Handbook NEW PDFDocument40 pagesRotary Kiln Handbook NEW PDFNuno Monteiro100% (7)

- Basic Principles and Practice of Clinical Chemistry Part 1Document34 pagesBasic Principles and Practice of Clinical Chemistry Part 1Mohamed MidoNo ratings yet

- Esd 800 HBDocument3 pagesEsd 800 HBsrinivasaNo ratings yet

- PP GF15 - Hifill PP Co GF15 CCDocument1 pagePP GF15 - Hifill PP Co GF15 CCarmandoNo ratings yet

- Nexeo Plastics InStruc™ PPAIMDocument1 pageNexeo Plastics InStruc™ PPAIMMax SalogniNo ratings yet

- Product PDF 37723Document2 pagesProduct PDF 37723hocineNo ratings yet

- Nexeo Plastics Kumho+PS HI+425EDocument2 pagesNexeo Plastics Kumho+PS HI+425Epedro pedroNo ratings yet

- Product PDF 406967Document2 pagesProduct PDF 406967hocineNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- ABS Sabic Cycolac MG94 Cust.cDocument5 pagesABS Sabic Cycolac MG94 Cust.cMurillo AraujoNo ratings yet

- Pc-Iso: Mechanical Properties Test Method ValueDocument2 pagesPc-Iso: Mechanical Properties Test Method ValuekaledioskoppNo ratings yet

- Ds CoPP-20900Document1 pageDs CoPP-20900rubser05No ratings yet

- PermaStat 600 UVDocument2 pagesPermaStat 600 UVPhung LucNo ratings yet

- Product PDF 37692Document2 pagesProduct PDF 37692Ing. Uriel SánchezNo ratings yet

- Product PDF 61718Document2 pagesProduct PDF 61718Mario Alberto BustosNo ratings yet

- Solvay - Halar 513 LCDocument3 pagesSolvay - Halar 513 LCRenan GadioliNo ratings yet

- Denyl 6 NDocument2 pagesDenyl 6 NPhung LucNo ratings yet

- RTPU Isoplast 101 LGF40 IdesDocument1 pageRTPU Isoplast 101 LGF40 IdescountzeroaslNo ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- Denyl 6 0037 HDocument2 pagesDenyl 6 0037 HPhung LucNo ratings yet

- PC Lexan 3412R 20% GL - IdesDocument5 pagesPC Lexan 3412R 20% GL - IdescountzeroaslNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- Lupol® GP3156FDocument3 pagesLupol® GP3156FYo ANo ratings yet

- Braskem Braskem PE GP100ORXP Pead GAS PE100Document2 pagesBraskem Braskem PE GP100ORXP Pead GAS PE100weimar solizNo ratings yet

- Product-pdf-ABS HI121Document2 pagesProduct-pdf-ABS HI121hocineNo ratings yet

- Hypro-F Ppc-gf10 NaturalDocument2 pagesHypro-F Ppc-gf10 NaturalsygabrielaNo ratings yet

- Certene™ HGB-0354Document2 pagesCertene™ HGB-0354Eleannys Garcias0% (1)

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- PC-Transparent 144RDocument5 pagesPC-Transparent 144Rsantosh.bhattNo ratings yet

- PEI Ultem 2310R 30%GLDocument4 pagesPEI Ultem 2310R 30%GLcountzeroaslNo ratings yet

- LNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetDocument2 pagesLNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetYJ WangNo ratings yet

- Armadillo TDSDocument1 pageArmadillo TDSPIETRO DAVID DE LUCANo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- Ryton R-4-200NA: Polyphenylene SulfideDocument3 pagesRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniNo ratings yet

- SCG PP P483Ju: SCG Chemicals Co., LTDDocument2 pagesSCG PP P483Ju: SCG Chemicals Co., LTDTruc Thao NguyenNo ratings yet

- Product PDF 210710Document1 pageProduct PDF 210710vaibhav ShindeNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- Kopla Pa6 KNG1015Document3 pagesKopla Pa6 KNG1015agungNo ratings yet

- Lustran® 433: INEOS StyrolutionDocument3 pagesLustran® 433: INEOS StyrolutionJames FaunceNo ratings yet

- PP GF30 - Hostacom PC072-3 Naturale-2Document2 pagesPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- Product 301485Document1 pageProduct 301485Geovani Daniel Gonzalez LopezNo ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- PBT Valox 865 30% GLDocument4 pagesPBT Valox 865 30% GLcountzeroaslNo ratings yet

- Abs Ex58f - AsiaDocument4 pagesAbs Ex58f - AsiaGiang CaoNo ratings yet

- Product PDF 398216Document2 pagesProduct PDF 398216Bruno CastroNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- ALLEN 8300FR Technical Data SheetDocument2 pagesALLEN 8300FR Technical Data SheetRachit RanjanNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)hugo santiago chavez godoyNo ratings yet

- Sabic® PP 37MK10RDocument2 pagesSabic® PP 37MK10RNguyễn Xuân KỳNo ratings yet

- Datenblatt Rohstoff Torlon 4301Document4 pagesDatenblatt Rohstoff Torlon 4301DarkedgeNo ratings yet

- Material Data Sheet: ABS+: Mechanical Properties Test Method High Grade-ABS Stratasys Abs M30Document1 pageMaterial Data Sheet: ABS+: Mechanical Properties Test Method High Grade-ABS Stratasys Abs M30Suryas SivaNo ratings yet

- Marpol® LDF 720 CSBDocument1 pageMarpol® LDF 720 CSBDiana SarmientoNo ratings yet

- Infino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateDocument2 pagesInfino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateVenkatesan ManikandanNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Tds Ecozen t110gDocument1 pageTds Ecozen t110galfred quinNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- PX2938Document2 pagesPX2938TRUONGNo ratings yet

- Sipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- SONGWON - Technical - Sheet - Antioxidants and Light Stabilizers - V8.3 - 2022 10 12 060957 - Suud 1Document16 pagesSONGWON - Technical - Sheet - Antioxidants and Light Stabilizers - V8.3 - 2022 10 12 060957 - Suud 1Wellington C. de AraujoNo ratings yet

- PDFDocument32 pagesPDFEngr Qaisar NazeerNo ratings yet

- XENOY™ Resin 1102 - AmericasDocument3 pagesXENOY™ Resin 1102 - AmericasWellington C. de AraujoNo ratings yet

- XENOY™ Resin CL100 - AmericasDocument4 pagesXENOY™ Resin CL100 - AmericasWellington C. de AraujoNo ratings yet

- Blends of Poly (Ethylene Terephthalate) /polycarbonate by The Use of Lanthanum Acetyl Acetonate CatalystDocument7 pagesBlends of Poly (Ethylene Terephthalate) /polycarbonate by The Use of Lanthanum Acetyl Acetonate CatalystWellington C. de AraujoNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- Pet - PC BlendsDocument9 pagesPet - PC BlendsWellington C. de AraujoNo ratings yet

- 1 PBDocument17 pages1 PBResh GarciaNo ratings yet

- Cambridge IGCSE: Chemistry 0620/22Document16 pagesCambridge IGCSE: Chemistry 0620/22Tilawat KhanNo ratings yet

- As Tute 1 September 2016Document2 pagesAs Tute 1 September 2016Piyumi ObeyesekeraNo ratings yet

- Major Nutritional Compositions of Black Cumin Seeds - Cultivated in Bangladesh and The Physicochemical Characteristics of Its OilDocument6 pagesMajor Nutritional Compositions of Black Cumin Seeds - Cultivated in Bangladesh and The Physicochemical Characteristics of Its OilAdnan AliNo ratings yet

- Kumar Et Al. - 2016 - Response of Damask Rose (Rosa Damascena Mill.) To Foliar Application of Magnesium (MG), Copper (Cu) and Zinc (ZN) - AnnotatedDocument8 pagesKumar Et Al. - 2016 - Response of Damask Rose (Rosa Damascena Mill.) To Foliar Application of Magnesium (MG), Copper (Cu) and Zinc (ZN) - AnnotatedGITA NUR WIDYALOKA MAHARDIKANo ratings yet

- Insights in Industrial Microbiology 1: Constance Chinyere Ezemba Oluchi OsualaDocument122 pagesInsights in Industrial Microbiology 1: Constance Chinyere Ezemba Oluchi OsualaSolomon DereseNo ratings yet

- Cell Growth Protocol For Jurkat Cell LineDocument2 pagesCell Growth Protocol For Jurkat Cell LineMihaela BalasNo ratings yet

- 2020 Jakubas Haloantimonates HalobismuthatesDocument22 pages2020 Jakubas Haloantimonates HalobismuthatesNacho Delgado FerreiroNo ratings yet

- Building Material and Testing Swathi B VDocument14 pagesBuilding Material and Testing Swathi B Vswathi bymanaNo ratings yet

- MPR722R1412R Product SheetENLRDocument2 pagesMPR722R1412R Product SheetENLRTrường Bửu TrầnNo ratings yet

- Final PresentationDocument32 pagesFinal PresentationShourya TewariNo ratings yet

- CT MCQ 1 (Cement and Aggregates)Document4 pagesCT MCQ 1 (Cement and Aggregates)DeepakNo ratings yet

- Ecogreen OleochemicalsDocument3 pagesEcogreen OleochemicalsDavidAbelNo ratings yet

- Antiprotozoarios 2013Document10 pagesAntiprotozoarios 2013angelaparasitoNo ratings yet

- Paper 4 QuickiesDocument40 pagesPaper 4 QuickiesRobin KeaneNo ratings yet

- Cheese: Microbiology of Cheese: December 2016Document13 pagesCheese: Microbiology of Cheese: December 2016Anh MinhNo ratings yet

- Cambridge IGCSE™: Chemistry 0620/43 May/June 2020Document10 pagesCambridge IGCSE™: Chemistry 0620/43 May/June 2020JOHN MVULA IINo ratings yet

- Brochure CEPIC enDocument12 pagesBrochure CEPIC enRathawit SingpanjanateeNo ratings yet

- Experiment No. 1 - Determination of A Chemical Formula-Final-1Document4 pagesExperiment No. 1 - Determination of A Chemical Formula-Final-1Ara CaturanNo ratings yet

- Unit 3&4 Exercises Biochemistry 17.11.20Document36 pagesUnit 3&4 Exercises Biochemistry 17.11.20Nguyen Bao TranNo ratings yet

- Food Chemistry RevisionDocument3 pagesFood Chemistry RevisionHigh HopesNo ratings yet

- On The Reddish Glittery Mud The Inca UseDocument16 pagesOn The Reddish Glittery Mud The Inca UseAtul SharmaNo ratings yet

- Glossary of ForgingDocument46 pagesGlossary of ForgingBHAVESH JOSHINo ratings yet

- List of Road Right-Of-Way Claims For Lots: Project Title & LocationDocument51 pagesList of Road Right-Of-Way Claims For Lots: Project Title & LocationReymundo BejaNo ratings yet