Professional Documents

Culture Documents

Product PDF 398216

Uploaded by

Bruno CastroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product PDF 398216

Uploaded by

Bruno CastroCopyright:

Available Formats

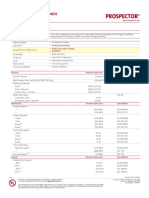

LG ABS ER468

LG Chem Ltd. - Acrylonitrile Butadiene Styrene Tuesday, April 2, 2024

General Information

Product Description

Description

ER468 is a Heat Resistant ABS product for injection molding, designed to have medium heat resistance and high fluidity..

Key Features

Medium Heat Resistance, High Flow

Application

Electrical/Electronic Products, Miscellaneous Goods

General

Material Status • Commercial: Active

• Asia Pacific • Latin America

Availability

• Europe • North America

Features • High Flow • Medium Heat Resistance

Uses • Electrical/Electronic Applications

Processing Method • Injection Molding

ASTM & ISO Properties 1

Physical Nominal Value Unit Test Method

Density / Specific Gravity 2 1.04 g/cm³ ASTM D792

Density (23°C) 1.04 g/cm³ ISO 1183

Melt Mass-Flow Rate (MFR) (220°C/10.0 kg) 35 g/10 min ASTM D1238

Melt Mass-Flow Rate (MFR) (220°C/10.0 kg) 37 g/10 min ISO 1133

Molding Shrinkage - Flow (23°C, 3.20 mm, Injection Molded) 0.40 to 0.70 % ASTM D955

Molding Shrinkage (23°C, 3.20 mm) 0.40 to 0.70 % ISO 294-4

Mechanical Nominal Value Unit Test Method

3 ASTM D638

Tensile Strength

Yield, 23°C, 3.20 mm, Injection Molded 44.0 MPa

Tensile Stress ISO 527-2/50

Yield, 23°C, 4.00 mm, Injection Molded 45.0 MPa

Tensile Elongation 3 ASTM D638

Break, 23°C, 3.20 mm, Injection Molded > 10 %

Tensile Strain ISO 527-2/50

Break, 23°C, 4.00 mm, Injection Molded > 15 %

Flexural Modulus 4 (23°C, 6.40 mm, Injection Molded) 2400 MPa ASTM D790

Flexural Modulus 5 (23°C, 4.00 mm, Injection Molded) 2500 MPa ISO 178

4 73.0 MPa ASTM D790

Flexural Strength (23°C, 6.40 mm, Injection Molded)

5 70.0 MPa ISO 178

Flexural Stress (23°C, 4.00 mm, Injection Molded)

Impact Nominal Value Unit Test Method

6 ISO 179/1eA

Charpy Notched Impact Strength

-30°C, Injection Molded 9.0 kJ/m²

23°C, Injection Molded 20 kJ/m²

UL LLC ©2024. All rights reserved.

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL assumes no

responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product or material selection

information is validated with the manufacturer. This website provides links to other websites owned by third parties. The content of such third party sites is not within

www.ulprospector.com our control, and we cannot and will not take responsibility for the information or content.

Page: 1 of 2

LG ABS ER468

LG Chem Ltd. - Acrylonitrile Butadiene Styrene

Impact Nominal Value Unit Test Method

Notched Izod Impact ASTM D256

23°C, 3.20 mm, Injection Molded 300 J/m

23°C, 6.40 mm, Injection Molded 200 J/m

6 ISO 180/1A

Notched Izod Impact Strength

-30°C, Injection Molded 10 kJ/m²

23°C, Injection Molded 23 kJ/m²

Hardness Nominal Value Unit Test Method

Rockwell Hardness (R-Scale, 23°C, Injection Molded) 109 ASTM D785

Rockwell Hardness (R-Scale, 23°C) 108 ISO 2039-2

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load ISO 75-2/Bf

0.45 MPa, Unannealed, 4.00 mm 93.0 °C

Deflection Temperature Under Load 7 ASTM D648

1.8 MPa, Unannealed, 6.40 mm, Injection Molded 92.0 °C

Deflection Temperature Under Load ISO 75-2/Af

1.8 MPa, Unannealed, 4.00 mm 82.0 °C

Vicat Softening Temperature 100 °C ASTM D1525 8

Vicat Softening Temperature 98.0 °C ISO 306/B50

Flammability Nominal Value Unit Test Method

Flame Rating UL 94

1.5 mm HB

3.0 mm HB

Processing Information

Injection Nominal Value Unit

Drying Temperature 80 to 90 °C

Drying Time 3.0 to 4.0 hr

Processing (Melt) Temp 220 to 260 °C

Mold Temperature 40 to 80 °C

Screw Speed 30 to 60 rpm

Notes

1

Typical properties: these are not to be construed as specifications.

2

23°C

3

50 mm/min

4

10 mm/min

5

2.0 mm/min

6

4mm

7

Edgewise

8

Rate A (50°C/h), Loading 2 (50 N)

UL LLC ©2024. All rights reserved.

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL assumes no

responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product or material selection

information is validated with the manufacturer. This website provides links to other websites owned by third parties. The content of such third party sites is not within

www.ulprospector.com our control, and we cannot and will not take responsibility for the information or content.

Page: 2 of 2

You might also like

- Product PDF 61718Document2 pagesProduct PDF 61718Mario Alberto BustosNo ratings yet

- Product PDF 37692Document2 pagesProduct PDF 37692Ing. Uriel SánchezNo ratings yet

- Product PDF 37723Document2 pagesProduct PDF 37723hocineNo ratings yet

- Product PDF 406967Document2 pagesProduct PDF 406967hocineNo ratings yet

- Product-pdf-ABS HI121Document2 pagesProduct-pdf-ABS HI121hocineNo ratings yet

- 202-Trinseo Calibre Megarad 2081-15 TDSDocument3 pages202-Trinseo Calibre Megarad 2081-15 TDSobeckoneNo ratings yet

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinDocument3 pagesCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Magnum 3904 DatasheetDocument3 pagesMagnum 3904 DatasheetbobNo ratings yet

- Infino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateDocument2 pagesInfino SC-1220R: Lotte Advanced Materials Co., Ltd. - PolycarbonateVenkatesan Manikandan0% (1)

- ULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetDocument2 pagesULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetKishore Gowda A SNo ratings yet

- CYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetDocument2 pagesCYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetmarceloNo ratings yet

- LNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetDocument2 pagesLNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetcoroNo ratings yet

- Abs Ex58f - AsiaDocument4 pagesAbs Ex58f - AsiaGiang CaoNo ratings yet

- Magnum 3904 SmoothDocument3 pagesMagnum 3904 SmoothbobNo ratings yet

- Hoja Tecnica ASADocument2 pagesHoja Tecnica ASAFernando AngioliniNo ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- PC-Transparent 144RDocument5 pagesPC-Transparent 144Rsantosh.bhattNo ratings yet

- PP GF30 - Hostacom PC072-3 Naturale-2Document2 pagesPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- SABIC® PC Resin PC0703R - AsiaDocument4 pagesSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhNo ratings yet

- A GD VDBDocument3 pagesA GD VDBthehoang12310No ratings yet

- LG Abs - Hi100hDocument2 pagesLG Abs - Hi100hqshakimNo ratings yet

- ABS Sabic Cycolac MG94 Cust.cDocument5 pagesABS Sabic Cycolac MG94 Cust.cMurillo AraujoNo ratings yet

- LEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Copolymer - 4795R - Americas - Technical - Data - SheetRamesh KannanNo ratings yet

- SABIC® PPcompound - G3230A - Americas - Technical - Data - SheetDocument2 pagesSABIC® PPcompound - G3230A - Americas - Technical - Data - SheetAarón González MedinaNo ratings yet

- XENOY™ Resin X2300WX - AmericasDocument3 pagesXENOY™ Resin X2300WX - AmericasWellington C. de AraujoNo ratings yet

- SABIC Cycolac MG47FDocument3 pagesSABIC Cycolac MG47FChu ChuNo ratings yet

- Cycolac MG 47Document3 pagesCycolac MG 47Juan DanielNo ratings yet

- 4lex® 10F10000Document3 pages4lex® 10F10000srinivasaNo ratings yet

- Braskem Braskem PE GP100ORXP Pead GAS PE100Document2 pagesBraskem Braskem PE GP100ORXP Pead GAS PE100weimar solizNo ratings yet

- PC Lexan 3412R 20% GL - IdesDocument5 pagesPC Lexan 3412R 20% GL - IdescountzeroaslNo ratings yet

- LEXAN™ Copolymer - SLX2432T - Americas - Technical - Data - SheetDocument3 pagesLEXAN™ Copolymer - SLX2432T - Americas - Technical - Data - Sheetsonia soniaNo ratings yet

- TDS Mafill CRHT6344Document1 pageTDS Mafill CRHT6344marcohang00No ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- ABSaf 312 ADocument2 pagesABSaf 312 AAdonis BasilioNo ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- Abs Af312A: Description ApplicationDocument2 pagesAbs Af312A: Description ApplicationAdonis BasilioNo ratings yet

- Abs Af312A: Description ApplicationDocument2 pagesAbs Af312A: Description ApplicationAdonis BasilioNo ratings yet

- ASA LI970: Description ApplicationDocument4 pagesASA LI970: Description ApplicationRonal Deiby Cadavid PinzonNo ratings yet

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- Pa6 GF20 - Basf Ultramid B3eg4Document2 pagesPa6 GF20 - Basf Ultramid B3eg4armandoNo ratings yet

- ABS LG HI21H. Rev.01Document2 pagesABS LG HI21H. Rev.01Ivan TimarevNo ratings yet

- Makrolon 2407 - en - 56977361 00009645 19213223Document4 pagesMakrolon 2407 - en - 56977361 00009645 19213223vaibhav ShindeNo ratings yet

- Achieve™ Advanced PP8285E1: Polypropylene Impact CopolymerDocument2 pagesAchieve™ Advanced PP8285E1: Polypropylene Impact CopolymermosesNo ratings yet

- 2.2.Tds Astm-Abs Lgchem Hi121Document2 pages2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNo ratings yet

- PC Lexan 104Document4 pagesPC Lexan 104countzeroaslNo ratings yet

- Tds Abs Hi121hDocument2 pagesTds Abs Hi121hHuyền VũNo ratings yet

- Tds Abs Hi121hDocument2 pagesTds Abs Hi121hHuyền VũNo ratings yet

- TDS GLACE - enDocument1 pageTDS GLACE - enmr.mennensNo ratings yet

- Abs-Er460 EngDocument2 pagesAbs-Er460 Engjdstore99No ratings yet

- Makrolon 2407 - en - 86286874 00009645 19213223Document4 pagesMakrolon 2407 - en - 86286874 00009645 19213223fernandoincesaNo ratings yet

- SABIC® PC Resin - PC1803R - Global - Technical - Data - SheetDocument3 pagesSABIC® PC Resin - PC1803R - Global - Technical - Data - SheetLeandro SalvadorNo ratings yet

- Ryton R-4-200NA: Polyphenylene SulfideDocument3 pagesRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniNo ratings yet

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseNo ratings yet

- Ultraform W 2320 003 UNC Q600Document3 pagesUltraform W 2320 003 UNC Q600Patricio Bravo CastilloNo ratings yet

- International Standard: Iso/Iec 7816-2Document16 pagesInternational Standard: Iso/Iec 7816-2Anwar MohamedNo ratings yet

- Engineering Data: Wireway SelectionDocument3 pagesEngineering Data: Wireway SelectionFidel Castrzzo BaeNo ratings yet

- Building A Vacuum Forming TableDocument9 pagesBuilding A Vacuum Forming TableWil NelsonNo ratings yet

- Electricity MagnetismDocument19 pagesElectricity MagnetismGray Amiel VilarNo ratings yet

- Box Transport MechanismDocument36 pagesBox Transport MechanismInzi Gardezi81% (16)

- Safe Use of Power Tools Rev0Document92 pagesSafe Use of Power Tools Rev0mohapatrarajNo ratings yet

- Webinar WinCC SCADA NL 29052018Document62 pagesWebinar WinCC SCADA NL 29052018AlexNo ratings yet

- Subordination, Non - Disturbance and Attornment AgreementDocument7 pagesSubordination, Non - Disturbance and Attornment AgreementDavid CromwellNo ratings yet

- MT6580 Android Scatter FRPDocument7 pagesMT6580 Android Scatter FRPTudor Circo100% (1)

- 10 TazmahalDocument12 pages10 TazmahalSifat E Noor SahibaNo ratings yet

- Canon JX 500 - 200 - Service ManualDocument154 pagesCanon JX 500 - 200 - Service ManualFritz BukowskyNo ratings yet

- AS Film Production Lesson.Document13 pagesAS Film Production Lesson.MsCowanNo ratings yet

- Reconductoring Using HTLS Conductors. Case Study For A 220 KV Double Circuit Transmission LINE in RomaniaDocument7 pagesReconductoring Using HTLS Conductors. Case Study For A 220 KV Double Circuit Transmission LINE in RomaniaJose ValdiviesoNo ratings yet

- Nanoimprint Lithography: Presented by Group 7Document27 pagesNanoimprint Lithography: Presented by Group 7Samia SafaNo ratings yet

- Unit-4.Vector CalculusDocument32 pagesUnit-4.Vector Calculuskhatua.deb87No ratings yet

- Attention: 6R60/6R75/6R80 Installation GuideDocument4 pagesAttention: 6R60/6R75/6R80 Installation GuideEdwinferNo ratings yet

- SolutionsManual NewDocument123 pagesSolutionsManual NewManoj SinghNo ratings yet

- Energy Management Assignment #01: Submitted BY Shaheer Ahmed Khan (MS2019198019)Document15 pagesEnergy Management Assignment #01: Submitted BY Shaheer Ahmed Khan (MS2019198019)shaheer khanNo ratings yet

- Determination of Iron in Water - SpectrophotometryDocument4 pagesDetermination of Iron in Water - Spectrophotometryhanif ahmadNo ratings yet

- 3rd Year. PunctuationDocument14 pages3rd Year. PunctuationmawarNo ratings yet

- AYURVEDA Products CatalogDocument17 pagesAYURVEDA Products CatalogFoutanke TorodoNo ratings yet

- Module 5 - Elements of Financial StatementsDocument34 pagesModule 5 - Elements of Financial StatementsRandolph ColladoNo ratings yet

- Module 1-Mathematics As A Language: Maribel D. Cariñ0Document4 pagesModule 1-Mathematics As A Language: Maribel D. Cariñ0KhalidNo ratings yet

- Paper Cutting 6Document71 pagesPaper Cutting 6Vidya AdsuleNo ratings yet

- EvoFox Katana-X Mechanical Gaming Keyboard With Outemu Blue Switches Vivid Rainbow Lighting With 13 Preset Effects DedicatedDocument1 pageEvoFox Katana-X Mechanical Gaming Keyboard With Outemu Blue Switches Vivid Rainbow Lighting With 13 Preset Effects Dedicatedsaqibdar7051236186No ratings yet

- Catalogo Repetidor EnergyAxisDocument2 pagesCatalogo Repetidor EnergyAxisolguita22No ratings yet

- A Randomised Clinical Trial Comparing Myoinositol and Metformin in PCOSDocument7 pagesA Randomised Clinical Trial Comparing Myoinositol and Metformin in PCOSAtika NajlaNo ratings yet

- Sow and Learning ObjectivesDocument14 pagesSow and Learning ObjectivesEhsan AzmanNo ratings yet

- Simulado InglesDocument6 pagesSimulado InglesWandercleyson da SilvaNo ratings yet

- 3.3 (B) Mole N MassDocument20 pages3.3 (B) Mole N MassFidree AzizNo ratings yet