Professional Documents

Culture Documents

ABS Sabic Cycolac MG94 Cust.c

Uploaded by

Murillo AraujoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABS Sabic Cycolac MG94 Cust.c

Uploaded by

Murillo AraujoCopyright:

Available Formats

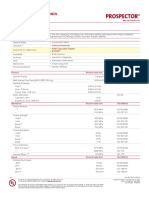

CYCOLAC™ MG94 resin

Acrylonitrile Butadiene Styrene

SABIC Innovative Plastics ides.com/prospector

Technical Data

Product Description

Superior flow, injection molding ABS. Good impact. For thin-wall applications.

General

Material Status • Commercial: Active

Literature 1 • Technical Datasheet

UL Yellow Card 2 • E121562-220727

Search for UL Yellow Card

• SABIC Innovative Plastics

• CYCOLAC™

Availability • North America

Features • Good Flow • Good Impact Resistance

Uses • Thin-walled Parts

Processing Method • Injection Molding

• Coefficient of Thermal Expansion vs. Temperature (ASTM E831)

• Flexural DMA (ASTM D4065)

• Shear DMA (ASTM D4065)

• Specific Heat vs. Temperature (ASTM D3417)

Multi-Point Data • Tensile Creep (ASTM D2990)

• Tensile Fatigue

• Tensile Stress vs. Strain (ASTM D638)

• Thermal Conductivity vs. Temperature (ASTM E1530)

• Viscosity vs. Shear Rate (ASTM D3835)

Physical Nominal Value (English) Nominal Value (SI) Test Method

Specific Gravity

-- 1.05 1.05 g/cm³ ASTM D792

-- 1.04 g/cm³ 1.04 g/cm³ ISO 1183

Melt Mass-Flow Rate (MFR)

230°C/3.8 kg 12 g/10 min 12 g/10 min ASTM D1238

220°C/10.0 kg 42 g/10 min 42 g/10 min ISO 1133

220°C/5.0 kg 13 g/10 min 13 g/10 min ISO 1133

Molding Shrinkage - Flow (0.126 in (3.20 mm)) 0.0050 to 0.0080 in/in 0.50 to 0.80 % Internal Method

Mechanical Nominal Value (English) Nominal Value (SI) Test Method

Tensile Modulus

-- 4 360000 psi 2480 MPa ASTM D638

-- 355000 psi 2450 MPa ISO 527-2/1

Tensile Strength

Yield 5 6670 psi 46.0 MPa ASTM D638

Yield 6670 psi 46.0 MPa ISO 527-2/50

Break 5 5080 psi 35.0 MPa ASTM D638

Break 5080 psi 35.0 MPa ISO 527-2/50

Tensile Elongation

Yield 5 2.0 % 2.0 % ASTM D638

Yield 2.3 % 2.3 % ISO 527-2/50

Break 5 18 % 18 % ASTM D638

Break 40 % 40 % ISO 527-2/50

Flexural Modulus

1.97 in (50.0 mm) Span 6 380000 psi 2620 MPa ASTM D790

-- 7 363000 psi 2500 MPa ISO 178

1 of 4 Form No. TDS-57277-en

UL and the UL logo are trademarks of UL LLC © 2013. All Rights Reserved. Document Created: June 21, 2013

UL IDES | 800-788-4668 or 307-742-9227 | www.ides.com. Added to Prospector: May, 2002

Last Updated: 17/05/2013

The information presented on this datasheet was acquired by UL IDES from the producer of the material. UL IDES makes substantial efforts to assure the

accuracy of this data. However, UL IDES assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are

validated with the material supplier.

CYCOLAC™ MG94 resin

Acrylonitrile Butadiene Styrene

SABIC Innovative Plastics ides.com/prospector

Mechanical Nominal Value (English) Nominal Value (SI) Test Method

Flexural Strength

-- 7, 8 10200 psi 70.0 MPa ISO 178

6 11500 psi 79.0 MPa ASTM D790

Yield, 1.97 in (50.0 mm) Span

Impact Nominal Value (English) Nominal Value (SI) Test Method

Charpy Notched Impact Strength 9 (73°F (23°C)) 8.6 ft·lb/in² 18 kJ/m² ISO 179/1eA

Notched Izod Impact

-22°F (-30°C) 1.5 ft·lb/in 80 J/m ASTM D256

73°F (23°C) 4.5 ft·lb/in 240 J/m ASTM D256

-22°F (-30°C) 10 3.3 ft·lb/in² 7.0 kJ/m² ISO 180/1A

73°F (23°C) 10 7.6 ft·lb/in² 16 kJ/m² ISO 180/1A

Instrumented Dart Impact ASTM D3763

-22°F (-30°C), Total Energy 44.3 in·lb 5.00 J

73°F (23°C), Total Energy 186 in·lb 21.0 J

Hardness Nominal Value (English) Nominal Value (SI) Test Method

Rockwell Hardness (R-Scale) 113 113 ASTM D785

Thermal Nominal Value (English) Nominal Value (SI) Test Method

Deflection Temperature Under Load

66 psi (0.45 MPa), Unannealed, 0.126 in (3.20

205 °F 96.0 °C ASTM D648

mm)

66 psi (0.45 MPa), Unannealed, 3.94 in (100

192 °F 89.0 °C ISO 75-2/Be

mm) Span 11

264 psi (1.8 MPa), Unannealed, 0.126 in (3.20

180 °F 82.0 °C ASTM D648

mm)

264 psi (1.8 MPa), Unannealed, 3.94 in (100

169 °F 76.0 °C ISO 75-2/Ae

mm) Span 11

Vicat Softening Temperature

ASTM D1525 12

-- 208 °F 98.0 °C

ISO 306/B50 12

-- 212 °F 100 °C ISO 306/B120

CLTE ASTM E831

Flow: -40 to 104°F (-40 to 40°C) 0.000049 in/in/°F 0.000088 cm/cm/°C ISO 11359-2

Transverse: -40 to 104°F (-40 to 40°C) 0.000047 in/in/°F 0.000085 cm/cm/°C

RTI Elec 140 °F 60.0 °C UL 746

RTI Imp 140 °F 60.0 °C UL 746

RTI Str 140 °F 60.0 °C UL 746

Flammability Nominal Value (English) Nominal Value (SI) Test Method

Flame Rating (0.0600 in (1.52 mm)) HB HB UL 94

Fill Analysis Nominal Value (English) Nominal Value (SI) Test Method

Melt Viscosity (464°F (240°C), 1000 sec^-1) 173 Pa·s 173 Pa·s ASTM D3835

Injection Nominal Value (English) Nominal Value (SI)

Drying Temperature 180 to 190 °F 82.2 to 87.8 °C

Drying Time 2.0 to 4.0 hr 2.0 to 4.0 hr

Drying Time, Maximum 8.0 hr 8.0 hr

Suggested Max Moisture 0.010 % 0.010 %

Suggested Shot Size 50 to 70 % 50 to 70 %

Rear Temperature 370 to 390 °F 188 to 199 °C

Middle Temperature 390 to 410 °F 199 to 210 °C

Front Temperature 400 to 440 °F 204 to 227 °C

Nozzle Temperature 400 to 475 °F 204 to 246 °C

Processing (Melt) Temp 400 to 475 °F 204 to 246 °C

Mold Temperature 120 to 160 °F 48.9 to 71.1 °C

Back Pressure 50.0 to 100 psi 0.345 to 0.689 MPa

Screw Speed 30 to 60 rpm 30 to 60 rpm

2 of 4 Form No. TDS-57277-en

UL and the UL logo are trademarks of UL LLC © 2013. All Rights Reserved. Document Created: June 21, 2013

UL IDES | 800-788-4668 or 307-742-9227 | www.ides.com. Added to Prospector: May, 2002

Last Updated: 17/05/2013

The information presented on this datasheet was acquired by UL IDES from the producer of the material. UL IDES makes substantial efforts to assure the

accuracy of this data. However, UL IDES assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are

validated with the material supplier.

CYCOLAC™ MG94 resin

Acrylonitrile Butadiene Styrene

SABIC Innovative Plastics ides.com/prospector

Injection Nominal Value (English) Nominal Value (SI)

Vent Depth 0.0015 to 0.0020 in 0.038 to 0.051 mm

Notes

1

These links provide you with access to supplier literature. We work hard to keep them up to date; however you may find the most current

literature from the supplier.

2

A UL Yellow Card contains UL-verified flammability and electrical characteristics. UL IDES continually works to link Yellow Cards to individual

plastic materials in Prospector, however this list may not include all of the appropriate links. It is important that you verify the association between

these Yellow Cards and the plastic material found in Prospector. For a complete listing of Yellow Cards, visit the UL Yellow Card Search.

3

Typical properties: these are not to be construed as specifications.

4

0.20 in/min (5.0 mm/min)

5

Type I, 0.20 in/min (5.0 mm/min)

6

0.051 in/min (1.3 mm/min)

7

0.079 in/min (2.0 mm/min)

8

Yield

9

80*10*4 sp=62mm

10

80*10*4

11

120*10*4 mm

12

Rate B (120°C/h), Loading 2 (50 N)

3 of 4 Form No. TDS-57277-en

UL and the UL logo are trademarks of UL LLC © 2013. All Rights Reserved. Document Created: June 21, 2013

UL IDES | 800-788-4668 or 307-742-9227 | www.ides.com. Added to Prospector: May, 2002

Last Updated: 17/05/2013

The information presented on this datasheet was acquired by UL IDES from the producer of the material. UL IDES makes substantial efforts to assure the

accuracy of this data. However, UL IDES assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are

validated with the material supplier.

CYCOLAC™ MG94 resin

Acrylonitrile Butadiene Styrene

SABIC Innovative Plastics ides.com/prospector

Where to Buy

Supplier

SABIC Innovative Plastics

Pittsfield, MA USA

Telephone: 800-845-0600

Web: http://www.sabic-ip.com/

Distributor

Nexeo Solutions

Telephone: 800-531-7106

Web: http://www.nexeosolutions.com/

Availability: North America

4 of 4 Form No. TDS-57277-en

UL and the UL logo are trademarks of UL LLC © 2013. All Rights Reserved. Document Created: June 21, 2013

UL IDES | 800-788-4668 or 307-742-9227 | www.ides.com. Added to Prospector: May, 2002

Last Updated: 17/05/2013

The information presented on this datasheet was acquired by UL IDES from the producer of the material. UL IDES makes substantial efforts to assure the

accuracy of this data. However, UL IDES assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are

validated with the material supplier.

Founded in 1986 and based in Laramie, Wyoming, IDES is now part of the UL family of companies. UL is a premier

global independent safety science company with more than a century of proven history. Employing nearly 10,000

professionals in over 100 countries, UL has five distinct business units -- Product Safety, Environment, Life & Health,

Knowledge Services and Verification Services -- to meet the expanding needs of our customers and to deliver on our

public safety mission.

Prospector Plastics Database - www.ides.com/prospector

Prospector is a searchable online database that includes 85,000 data sheets from 875 manufacturers and 44,000 UL yellow

cards. Each data sheet includes property, processing and supplier contact information. Prospector is relied on by nearly

400,000 design engineers and plastics processors. Using Prospector, they save time with plastic material selection by

quickly and easily referencing technical information critical to the success of their products.

“Prospector is absolutely the best and most well-known search engine for plastic raw materials in the world. We use

Prospector every day – it’s a real time saver!”

– Birgit Elvardt Bader, Production Manager, Micotron

Power Searches

Property Search – select plastics by 500 key properties and design parameters.

Alternative Resins Search – find replacement plastics within minutes.

Automotive Plastics Search – easily locate automotive approved plastics.

Curve Data – view, overlay and export curve data.

Material Data Management – www.ides.com/datasheets

With our data management services, plastic suppliers and distributors can have custom search interfaces available on their

website for their customers, website visitors, sales and customer service teams. These provide intuitive ways to find and

view technical data sheets for their products.

“With UL IDES data services, our website now displays the most current information on the products we distribute and links

to our backend RFQ and sales order system, adding both value and service for our customers.”

– Kevin Chase, Owner & President, Chase Plastics

Advertising – www.ides.com/advertise

Reach 365,000 pre-qualified plastics professionals and generate leads with proven techniques. Electronic newsletter

insertions, sponsored webinars and powerful online ads are available to make the most of your lead-generation program.

For more information, call: 800.788.4668 or 307.742.9227 ext. 220

UL and the UL logo are trademarks of UL LLC © 2013.

You might also like

- PEI Ultem 2310R 30%GLDocument4 pagesPEI Ultem 2310R 30%GLcountzeroaslNo ratings yet

- PC Lexan 3412R 20% GL - IdesDocument5 pagesPC Lexan 3412R 20% GL - IdescountzeroaslNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- PBT Valox 865 30% GLDocument4 pagesPBT Valox 865 30% GLcountzeroaslNo ratings yet

- Kumho ABS 750SWDocument3 pagesKumho ABS 750SWVu TranNo ratings yet

- Abs Ex58f - AsiaDocument4 pagesAbs Ex58f - AsiaGiang CaoNo ratings yet

- RTPU Isoplast 101 LGF40 idesDocument1 pageRTPU Isoplast 101 LGF40 idescountzeroaslNo ratings yet

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinDocument3 pagesCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaNo ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- PC-Transparent 144RDocument5 pagesPC-Transparent 144Rsantosh.bhattNo ratings yet

- Ryton R-4-200NA: Polyphenylene SulfideDocument3 pagesRyton R-4-200NA: Polyphenylene SulfideMatteo BaldiniNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- Kumho ABS 750Document2 pagesKumho ABS 750Murundu EstudioNo ratings yet

- Sabic® PP 38MK10RDocument2 pagesSabic® PP 38MK10RGiang CaoNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- 202-Trinseo Calibre Megarad 2081-15 TDSDocument3 pages202-Trinseo Calibre Megarad 2081-15 TDSobeckoneNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- Sabic® PP 37MK10RDocument2 pagesSabic® PP 37MK10RGiang CaoNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- XENOY™ Resin X2300WX - AmericasDocument3 pagesXENOY™ Resin X2300WX - AmericasWellington C. de AraujoNo ratings yet

- SABIC® PC Resin PC0703R - AsiaDocument4 pagesSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhNo ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- Solvay - Ixef BXT2000Document5 pagesSolvay - Ixef BXT2000Renan GadioliNo ratings yet

- Starex SD 0150Document5 pagesStarex SD 0150claudiaNo ratings yet

- Hanwha Total PP BJ550Document2 pagesHanwha Total PP BJ550Nguyễn Hồng NamNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- Shear Flat SlabDocument1 pageShear Flat Slabadnan-651358No ratings yet

- Datenblatt Rohstoff Torlon 4301Document4 pagesDatenblatt Rohstoff Torlon 4301DarkedgeNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- TDS - Acrylic V825 - From PolyOneDocument2 pagesTDS - Acrylic V825 - From PolyOneVio Amariei0% (1)

- CPVC Geon PM280Document1 pageCPVC Geon PM280angelokyoNo ratings yet

- Product PDF 37723Document2 pagesProduct PDF 37723hocineNo ratings yet

- Polylac® Pa-747Document3 pagesPolylac® Pa-747vicenteNo ratings yet

- POLYLAC® PA-765: Chi Mei CorporationDocument3 pagesPOLYLAC® PA-765: Chi Mei CorporationagungNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- Pc-Iso: Mechanical Properties Test Method ValueDocument2 pagesPc-Iso: Mechanical Properties Test Method ValuekaledioskoppNo ratings yet

- Lupol® GP3156FDocument3 pagesLupol® GP3156FYo ANo ratings yet

- PP GF30 - Hostacom PC072-3 Naturale-2Document2 pagesPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- Wonderlite® PC-110Document3 pagesWonderlite® PC-110Rhekron PlasticsNo ratings yet

- Product PDF 37692Document2 pagesProduct PDF 37692Ing. Uriel SánchezNo ratings yet

- Solef PVDF 6008Document2 pagesSolef PVDF 6008topteam123No ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- Nexeo-Plastics-Kumho+PS-HI+425EDocument2 pagesNexeo-Plastics-Kumho+PS-HI+425Epedro pedroNo ratings yet

- Achieve™ Advanced PP8285E1: Polypropylene Impact CopolymerDocument2 pagesAchieve™ Advanced PP8285E1: Polypropylene Impact CopolymermosesNo ratings yet

- Esd 800 HBDocument3 pagesEsd 800 HBsrinivasaNo ratings yet

- Rhetech Polypropylene Gc10P100-00Document3 pagesRhetech Polypropylene Gc10P100-00James FaunceNo ratings yet

- Abs Irpc Polimaxx SP100Document2 pagesAbs Irpc Polimaxx SP100countzeroaslNo ratings yet

- Kopla Pa6 KNG1015Document3 pagesKopla Pa6 KNG1015agungNo ratings yet

- 400 00030953en Engage 8180 TdsDocument3 pages400 00030953en Engage 8180 TdsSIDDHARTH BHASNEYNo ratings yet

- Hanwha Total PP FH44Document3 pagesHanwha Total PP FH44Nguyễn Hồng NamNo ratings yet

- Exxonmobil™ Pp7905E1: Polypropylene Impact CopolymerDocument2 pagesExxonmobil™ Pp7905E1: Polypropylene Impact CopolymermosesNo ratings yet

- Pmma Plexigals Hfi7-101Document4 pagesPmma Plexigals Hfi7-101countzeroaslNo ratings yet

- PBT GF17% DR48-7001Document2 pagesPBT GF17% DR48-7001pava16230.meNo ratings yet

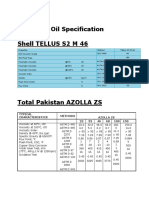

- Specifications For Hydraulic OilDocument3 pagesSpecifications For Hydraulic OilAliya NaseemNo ratings yet

- Product PDF 4956Document2 pagesProduct PDF 4956Mohammad PoostforushNo ratings yet

- Solvay - Halar 513 LCDocument3 pagesSolvay - Halar 513 LCRenan GadioliNo ratings yet

- Atmel 7810 Automotive Microcontrollers ATmega328P - Datasheet PDFDocument294 pagesAtmel 7810 Automotive Microcontrollers ATmega328P - Datasheet PDFnagendra2195No ratings yet

- Arduino - Modelo - v1.2018-MHADocument2 pagesArduino - Modelo - v1.2018-MHAMurillo AraujoNo ratings yet

- Poli Olefin AsDocument36 pagesPoli Olefin AsHelton MotaNo ratings yet

- Poli Olefin AsDocument36 pagesPoli Olefin AsHelton MotaNo ratings yet

- Thermodynamic GlossaryDocument3 pagesThermodynamic GlossaryAdrian ArroyoNo ratings yet

- PLATE TECTONICS: Plate Boundaries: A Detailed Lesson Plan in Grade 10 ScienceDocument8 pagesPLATE TECTONICS: Plate Boundaries: A Detailed Lesson Plan in Grade 10 ScienceGerald Agacid BangeroNo ratings yet

- Solutions Practice Test: Multiple ChoiceDocument7 pagesSolutions Practice Test: Multiple Choicesana iqbalNo ratings yet

- Energy Performance Assessment of Boilers: Subject Guide: Prof. Karthikeyan A.KDocument50 pagesEnergy Performance Assessment of Boilers: Subject Guide: Prof. Karthikeyan A.Ksamy005No ratings yet

- 02 Experiment Manual 2 Determination of The Sound Wave Velocity With The Method of Lissajous Figures PDFDocument5 pages02 Experiment Manual 2 Determination of The Sound Wave Velocity With The Method of Lissajous Figures PDFNikko GalarosaNo ratings yet

- QC 3 001d-DraftDocument29 pagesQC 3 001d-DraftPravilNo ratings yet

- Mass Transfer Reaction Conversion Packed BedDocument2 pagesMass Transfer Reaction Conversion Packed Bedjamy862004No ratings yet

- Xi Chemistry Old Book 2 Day Target PaperDocument2 pagesXi Chemistry Old Book 2 Day Target Paperuzairabbasi96098No ratings yet

- Development of A Filter Cake Permeability Test MethodologyDocument8 pagesDevelopment of A Filter Cake Permeability Test Methodologydileep vytlaNo ratings yet

- Sea Level: Ashrae Psychrometric Chart No.3Document7 pagesSea Level: Ashrae Psychrometric Chart No.3TramAnh DuongNo ratings yet

- Petroleum Exploration MethodsDocument19 pagesPetroleum Exploration MethodsSarosh Farid75% (4)

- UntitledDocument289 pagesUntitledDeepanshu digariNo ratings yet

- MGPSDocument9 pagesMGPSMikhail BagliukNo ratings yet

- Technical Data Air Cooled Chiller 105 TRDocument3 pagesTechnical Data Air Cooled Chiller 105 TRHaris Siena100% (1)

- Module 3 Hydrostatic Force On Surfaces PDFDocument14 pagesModule 3 Hydrostatic Force On Surfaces PDFAragones, Trisha Marie CNo ratings yet

- When Poor Solubility Becomes An Issue From Early Stage To Proof of ConceptDocument20 pagesWhen Poor Solubility Becomes An Issue From Early Stage To Proof of ConceptÁdina SantanaNo ratings yet

- Piezoelectric Drug Delivery SystemDocument15 pagesPiezoelectric Drug Delivery Systemakib jawadNo ratings yet

- JEE (ADVANCED) 2015 PHYSICS TEST INFORMATIONDocument22 pagesJEE (ADVANCED) 2015 PHYSICS TEST INFORMATIONPranav GurjarNo ratings yet

- Sigma Phase Charectaristaion in AISI 316 SSDocument2 pagesSigma Phase Charectaristaion in AISI 316 SSAlMawali76No ratings yet

- Muk Kamala 2017Document22 pagesMuk Kamala 2017Ankit LonareNo ratings yet

- Prepared By: Wendy B. LabastillaDocument42 pagesPrepared By: Wendy B. LabastillaWendy LabastillaNo ratings yet

- Leak Check in GCDocument4 pagesLeak Check in GCfahim2806No ratings yet

- Lecture 08Document10 pagesLecture 08Rakib HasanNo ratings yet

- Mechanical Workshop Practice ReportDocument6 pagesMechanical Workshop Practice ReportMuhd AkmalNo ratings yet

- CRYSTALLIZATION PROCESS OPTIMIZATIONDocument42 pagesCRYSTALLIZATION PROCESS OPTIMIZATIONKTINE0894% (16)

- Lec6 PDFDocument27 pagesLec6 PDFSANJAY KUMAR YADAV MtechNo ratings yet

- Amico Ci LXSG 15 40e PDFDocument1 pageAmico Ci LXSG 15 40e PDFAgam Alfian NazriNo ratings yet

- Platinum Active Surface PDFDocument3 pagesPlatinum Active Surface PDFR.SubramanianNo ratings yet

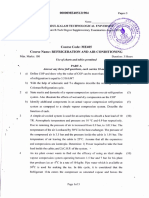

- An SEO-Optimized Title for a Refrigeration and Air Conditioning Exam DocumentDocument3 pagesAn SEO-Optimized Title for a Refrigeration and Air Conditioning Exam DocumentKrishnaNo ratings yet

- 080Document9 pages080Stefano Del TedescoNo ratings yet