Professional Documents

Culture Documents

TDS GLACE - en

Uploaded by

mr.mennensOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS GLACE - en

Uploaded by

mr.mennensCopyright:

Available Formats

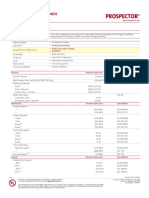

TECHNICAL DATA SHEET VERSION 1.

2

REVISION: 22/02/2023

GLACE

SMARTFIL GLACE is a thermoplastic polymer with superior mechanical

properties to ABS and PLA, with good impact resistance and high flexibility*.

Without warping, so large parts can be manufactured with excellent quality.

In addition, a chemical polishing with alcohol can be applied, so that parts

with high transparency and a completely smooth finish can be

manufactured.

*The material increases its flexibility after chemical polishing with alcohol.

VALUES UNIT OF MEASUREMENT STANDARD

PHYSICAL PROPERTIES

Chemical name Polyvinyl Butyral

Density 1,1 g/cm3 ASTM D792

MECHANICAL PROPERTIES 1 XY PLANE ZX PLANE

Tensile strength 31,2 9,8 MPa ISO 527

Traction module - - MPa ISO 527

Flexion strength 59,2 22,5 MPa ISO 178

Flexion module 1923,7 1359,5 MPa ISO 178

Elongation at maximum effort 1,8 0,3 % ISO 527

Elongation by traction at break 6,6 0,3 % ISO 527

Elongation by flexion at break 14,8 3,3 % ISO 178

Charpy Impact Force (non-notched) 37,5 2,5 kJ/m2 ISO 179

Hardness - Shore D ISO 7619-1

Values obtained on printed specimens, nozzle 0,4 mm, rectilinear infill 100%, layer height 0,2 mm. For more information please contact us by email at info@smartmaterials.com or

(1)

visit our website www.smartmaterials3d.com

THERMAL PROPERTIES

Glass transition temperature (Tg) 68 ˚C ISO 11357

VICAT B (50 N 50°C/h) 62 ˚C ISO 306

HDT B (0,45 MPa) 62 ˚C ISO 75

PRINTING PROPERTIES

Printing temperature 210 – 230 ˚C

Bed temperature 50 – 70 ˚C

Layer fan 70 – 90 %

Material flow 100 %

Layer height ≥ 0,2 mm

Nozzle recommendations ≥ 0,2 mm

Print speed 30 – 40 mm/s

SIZE NET WEIGHT GROSS WEIGHT DIAMETER COLOR PACKAGING

M 750 g 975 g 1,75 mm/2,85 mm Natural SmartBag, security seal,

desiccant bag.

NOTICE: The information provided in the data sheets is intended for reference only. It should not be used as design or quality control

values. Actual values may differ significantly depending on printing conditions. The final performance of printed components not only

depends on materials, design and printing conditions are also important.

@ www.smartmaterials3d.com info@smartmaterials3d.com +34 953 041 993

You might also like

- International Standard: Metallic Materials - Charpy Pendulum Impact Test - Verification of Testing MachinesDocument45 pagesInternational Standard: Metallic Materials - Charpy Pendulum Impact Test - Verification of Testing MachinesИрина Михайлова100% (2)

- Australian Standard: Methods For Impact Tests On Metals Part 1: IzodDocument25 pagesAustralian Standard: Methods For Impact Tests On Metals Part 1: Izodanoop jNo ratings yet

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- TDS FLEX 93A - enDocument1 pageTDS FLEX 93A - enmr.mennensNo ratings yet

- TDS Nylon V3.011-EnDocument3 pagesTDS Nylon V3.011-Enmartinf090574No ratings yet

- Kimya Abs Carbon: Abs Carbon Filament Improves Interlayer Adhesion and Increases Compression StrengthDocument2 pagesKimya Abs Carbon: Abs Carbon Filament Improves Interlayer Adhesion and Increases Compression StrengthZach T. ElmerNo ratings yet

- Pet-G - UkDocument1 pagePet-G - UkamilcarbrrNo ratings yet

- Petg TDS1-1Document1 pagePetg TDS1-1Jonas SamsaNo ratings yet

- Petg TDS1Document1 pagePetg TDS1CosminNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Addigy FPB 2684 000000 A - en - 86299607 22256723 22681304Document4 pagesAddigy FPB 2684 000000 A - en - 86299607 22256723 22681304propornhub42No ratings yet

- Technical Sheet Extruded AcrylicDocument1 pageTechnical Sheet Extruded AcrylicG GutierrezNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Advaboard TDSDocument1 pageAdvaboard TDSMohammed AbugharbiehNo ratings yet

- Radilon S Hs 105 M NT: Product InformationDocument3 pagesRadilon S Hs 105 M NT: Product InformationOptimuz TsNo ratings yet

- Pa66-G30 Ahbk003 Tds-Iso-EngDocument2 pagesPa66-G30 Ahbk003 Tds-Iso-EngVinoth SekarNo ratings yet

- Tarolox 10 g6 Standard 003 enDocument3 pagesTarolox 10 g6 Standard 003 enMohamed Ali MaâlaouiNo ratings yet

- Tds Carbon enDocument1 pageTds Carbon engegacolucNo ratings yet

- Isoplast 300 ETP: Advancing MaterialsDocument2 pagesIsoplast 300 ETP: Advancing MaterialsDanielNo ratings yet

- ULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Document2 pagesULTRAMID Sup ® Sup +B3WG6+BGVW+BLACK+00564Luis Enrique Ramos PérezNo ratings yet

- PC Makrolon 2458 - 2006Document4 pagesPC Makrolon 2458 - 2006countzeroaslNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroNo ratings yet

- 202-Trinseo Calibre Megarad 2081-15 TDSDocument3 pages202-Trinseo Calibre Megarad 2081-15 TDSobeckoneNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data Sheetrenaat.vanwayenbergeNo ratings yet

- Datasheet-Ultra Hh-4115-Hi-IsoDocument3 pagesDatasheet-Ultra Hh-4115-Hi-IsoDiegoTierradentroNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Styrolution TDS400900481370Document3 pagesStyrolution TDS400900481370joshNo ratings yet

- Pla Texture Wood ArceDocument4 pagesPla Texture Wood ArceRoberto Gonzalo PelazNo ratings yet

- Polyamide Carbon Fiber: DissipativeDocument2 pagesPolyamide Carbon Fiber: DissipativeLeonardo MurilloNo ratings yet

- Makrolon 2405: General Purpose Grades / Low Viscosity / High ProductivityDocument4 pagesMakrolon 2405: General Purpose Grades / Low Viscosity / High ProductivityagungNo ratings yet

- Makrolon 2405 ISO enDocument4 pagesMakrolon 2405 ISO enJuan Daniel Ledezma Alonso100% (1)

- Makrolon LED2245 - en - 81038415 00003726 19218403Document4 pagesMakrolon LED2245 - en - 81038415 00003726 19218403dave judayaNo ratings yet

- Makrolon 2858 ISO enDocument4 pagesMakrolon 2858 ISO enRushyanth KRNo ratings yet

- Datasheet Cawiton PR13665 - 002 PDFDocument1 pageDatasheet Cawiton PR13665 - 002 PDFFred HahnNo ratings yet

- RADILONAESL128100NTDocument4 pagesRADILONAESL128100NTRicardoNo ratings yet

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaNo ratings yet

- Ficha Makrolon 2607 ISO enDocument4 pagesFicha Makrolon 2607 ISO enPatriciaNo ratings yet

- Natpet Teldene H03TFDocument2 pagesNatpet Teldene H03TFTychNo ratings yet

- Estane GP 72Db Tpu: Advancing MaterialsDocument2 pagesEstane GP 72Db Tpu: Advancing MaterialsDanielNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- TDS ABS FP ES LowDocument2 pagesTDS ABS FP ES Lowjuan palomoNo ratings yet

- Makrolon 3206 - en - 56817747 00003433 19231690Document4 pagesMakrolon 3206 - en - 56817747 00003433 19231690noto.sugiartoNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- Makrolon UV: Solid Polycarbonate SheetDocument2 pagesMakrolon UV: Solid Polycarbonate SheetKIMIKA Industrial CorporationNo ratings yet

- Product Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minDocument2 pagesProduct Data Sheet: Sasol Polymers PP: HNR100 MFR: 12g/10minAlbert FortunatoNo ratings yet

- Makrolon 2407 - en - 56977361 00009645 19213223Document4 pagesMakrolon 2407 - en - 56977361 00009645 19213223vaibhav ShindeNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- Ultraform N2320 003 BK120 Q600Document2 pagesUltraform N2320 003 BK120 Q600JoelNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Makrolon 6485 - en - 56978635 00009652 18539090Document4 pagesMakrolon 6485 - en - 56978635 00009652 18539090Lin DanNo ratings yet

- SABIC Cycolac MG47FDocument3 pagesSABIC Cycolac MG47FChu ChuNo ratings yet

- TDS Pla enDocument1 pageTDS Pla encristianNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- TDS - E ColorFabb nGen-CF10 - 1Document2 pagesTDS - E ColorFabb nGen-CF10 - 1PIETRO DAVID DE LUCANo ratings yet

- Technical Data Sheet ADFLEX F 500Document2 pagesTechnical Data Sheet ADFLEX F 500leftpowtaNo ratings yet

- Nylon - Easymid-b-gf30-Bkig - Tds - enDocument1 pageNylon - Easymid-b-gf30-Bkig - Tds - enscribdNo ratings yet

- ULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetDocument2 pagesULTEM™ Resin - DT1820EV - Global - Technical - Data - SheetKishore Gowda A SNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Manufacturing Surface Technology: Surface Integrity and Functional PerformanceFrom EverandManufacturing Surface Technology: Surface Integrity and Functional PerformanceRating: 5 out of 5 stars5/5 (1)

- CBM 2016 1Document14 pagesCBM 2016 1SHEIKH MUHAMMAD FAHADNo ratings yet

- EGTYPDocument277 pagesEGTYPThe MatrixNo ratings yet

- Effect of Dents in PipelinesDocument9 pagesEffect of Dents in PipelinesAnonymous avGU1iNo ratings yet

- Abschn 04Document52 pagesAbschn 04dongwook712No ratings yet

- Tugas Pendahuluan Mt2205 Laboratorium Teknik Material 1 Modul F Uji Impak (Impact Test)Document7 pagesTugas Pendahuluan Mt2205 Laboratorium Teknik Material 1 Modul F Uji Impak (Impact Test)Muhammad SiddiqNo ratings yet

- Specifications For Plates: Specification GradeDocument15 pagesSpecifications For Plates: Specification Gradeppd9890No ratings yet

- PSP00203 Cold Drawn Seamless Steel Tubes For Hydraulic CylindersDocument12 pagesPSP00203 Cold Drawn Seamless Steel Tubes For Hydraulic CylindersTomislav ČerinaNo ratings yet

- Mil-A-12560h GDocument39 pagesMil-A-12560h Gjitendra25252No ratings yet

- Materials 13 04965Document14 pagesMaterials 13 04965paulo passeiosNo ratings yet

- Tension and Compression TestDocument37 pagesTension and Compression TestLydiaNo ratings yet

- L11a Weld - DesignDocument36 pagesL11a Weld - Designtan zhiyuNo ratings yet

- Mechanical Testing - Notched Bar or Impact TestingDocument7 pagesMechanical Testing - Notched Bar or Impact TestingFsNo ratings yet

- Testbars Vs Casting PropertiesDocument36 pagesTestbars Vs Casting Propertiescastco@iafrica.comNo ratings yet

- Electrical Properties 1Document80 pagesElectrical Properties 1SarumathiNo ratings yet

- KASTO 094 (금속용 Charpy 충격시험기) PDFDocument52 pagesKASTO 094 (금속용 Charpy 충격시험기) PDFTJNo ratings yet

- Journal of Constructional Steel ResearchDocument9 pagesJournal of Constructional Steel ResearchChiheb BaNo ratings yet

- Rules For The Classification of Ships - Amendments To Part D - Materials and WeldingDocument22 pagesRules For The Classification of Ships - Amendments To Part D - Materials and WeldingPiang KamalNo ratings yet

- A545-736-11-42-DS-0034 - A - Flow TeeDocument2 pagesA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranNo ratings yet

- Standard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsDocument20 pagesStandard Test Methods For Determining The Izod Pendulum Impact Resistance of PlasticsJosué Licona MármolNo ratings yet

- Specification For Carbon Steel Pipes & FittingsDocument27 pagesSpecification For Carbon Steel Pipes & FittingsNoor Anter100% (1)

- Astm A420Document6 pagesAstm A420Joffre ValladaresNo ratings yet

- Unit IIDocument23 pagesUnit IIvizhideepaNo ratings yet

- ASME e EN STDDocument23 pagesASME e EN STDmatteo2009No ratings yet

- Charpy Impact TestDocument4 pagesCharpy Impact TestBaibhav MohantyNo ratings yet

- SDM 1Document13 pagesSDM 1prodecoy 9No ratings yet

- Ultramid® A3HG5 en SI - Product DatasheetDocument2 pagesUltramid® A3HG5 en SI - Product Datasheetshahin_723No ratings yet

- Lanxess Durethan Bkv130h2.0 901510 Iso enDocument3 pagesLanxess Durethan Bkv130h2.0 901510 Iso enRICARDONo ratings yet

- Charpy Impact TestDocument6 pagesCharpy Impact Testanil chejara83% (6)