Professional Documents

Culture Documents

TDS - E ColorFabb nGen-CF10 - 1

Uploaded by

PIETRO DAVID DE LUCAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS - E ColorFabb nGen-CF10 - 1

Uploaded by

PIETRO DAVID DE LUCACopyright:

Available Formats

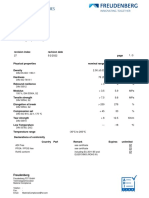

Technical datasheet

nGen-CF10

Date of issue: July 1, 2021

Version: v1.0

Our great all-round 3D printing filament just got better with the addition of a chopped carbon fiber blend.

nGen-CF10 retains good toughness and adds the matte carbon fiber high quality surface finish look to your 3D

printed parts. This filament is very easy to print and requires little to no adjustments compared to printing

regular nGen.

TYPICAL MATERIAL PROPERTIES – 3D Printed

Physical properties Unit Value Method

Tensile modulus MPa 2945,78 ISO 527

Yield strength MPa 54,30 ISO 527

Yield strain % 3,75 ISO 527

Tensile strength MPa 54,71 ISO 527

Tensile strain at tensile strength % 3,66 ISO 527

Tensile stress at break MPa 52,26 ISO 527

Tensile strain at break % 4,56 ISO 527

Flexural modulus MPa - ISO 178

Flexural strain at standard deflection MPa - ISO 178

Flexural strength MPa - ISO 178

Flexural strain at flexural strength % - ISO 178

Flexural stress at break MPa - ISO 178

Flexural strain at break % - ISO 178

Charpy unnotched impact strength kJ/m2 - ISO 179-1/1 eU

Charpy notched impact strength kJ/m2 2,06 ISO 179-1/1 eU

Heat Deflection Temperature (HDT) ºC - ISO 75

TYPICAL MATERIAL PROPERTIES – Injection molded

Physical properties Unit Value Method

Density g/cm3 -

Glass Transition Temperature ºC - DSC

Tensile Strength MPa - ISO 527-1

Tensile Modulus MPa - ISO 527-1

Tensile Elongation % - ISO 727-1

2

Impact Strength (Ch-N 23ºC) kJ/m - ISO 179-1

colorFabb B.V. T +31 (0)77 – 4664015 KvK nr: 53498607

Bremweg 7 F +31 (0)77 – 3971414 VAT nr: NL850902770B01

5951 DK Belfeld E sales@colorfabb.com IBAN: NL54RABO0151849188

The Netherlands I colorfabb.com BIC: RABONL2U

Technical datasheet

nGen-CF10

Date of issue: July 1, 2021

Version: v1.0

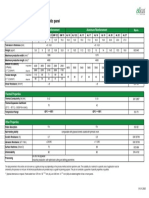

FILAMENT SPECIFICATION

Nominal diameter: Diameter tolerance Ovality

1,75 mm ± 0,05 ≥ 95%

2,85 mm ± 0,10 ≥ 95%

GUIDELINE FOR PRINT SETTINGS

Nozzle temperature 220 - 230ºC*

Bed temperature 75 - 85ºC

Bed surface / modification -

Active cooling fan 0-80%**

Print speed 40-70 mm/s

* Please note: A special point of attention is the abrasive nature of the carbon fibers. In general these fibers will

accelerate the nozzle-wear of brass nozzles, much faster than unfilled filaments. We recommend to use from

stainless steel nozzles or nozzles made with hardened copper alloys.

** For best possible layer-to-layer adhesion it’s recommended use the minimum amount of fan cooling

needed.

Notes

The reported properties are an average of a batch of 3D printed specimens. The specimens have been printed

in XY plane, using 0.15mm layerheight, 100% infill, 0.4mm nozzle, 230 °C nozzle temperature and 80 °C bed

temperature.

Disclaimer

The product- and technical information provided in this datasheet is correct to the best of our knowledge. The

information given is provided as a guidance for good use, handling and processing and is not to be considered

as a quality specification. The information only relates to the specific product and the material properties.

colorFabb B.V. T +31 (0)77 – 4664015 KvK nr: 53498607

Bremweg 7 F +31 (0)77 – 3971414 VAT nr: NL850902770B01

5951 DK Belfeld E sales@colorfabb.com IBAN: NL54RABO0151849188

The Netherlands I colorfabb.com BIC: RABONL2U

You might also like

- Joint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardFrom EverandJoint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardNo ratings yet

- TDS - ColorFabb Vibers PLADocument2 pagesTDS - ColorFabb Vibers PLAPIETRO DAVID DE LUCANo ratings yet

- TDS - ColorFabb StoneFillDocument2 pagesTDS - ColorFabb StoneFillPIETRO DAVID DE LUCANo ratings yet

- E PlaDocument1 pageE PlaYilmer SanchezNo ratings yet

- Petg TDS1Document1 pagePetg TDS1CosminNo ratings yet

- Petg TDS1-1Document1 pagePetg TDS1-1Jonas SamsaNo ratings yet

- Materialdatasheet 75 FKM 595 2Document3 pagesMaterialdatasheet 75 FKM 595 2Pillar ManufacturingNo ratings yet

- Kimya Abs Carbon: Abs Carbon Filament Improves Interlayer Adhesion and Increases Compression StrengthDocument2 pagesKimya Abs Carbon: Abs Carbon Filament Improves Interlayer Adhesion and Increases Compression StrengthZach T. ElmerNo ratings yet

- 487-tds s1s15 g30-4247 Dinarex Eng PDFDocument2 pages487-tds s1s15 g30-4247 Dinarex Eng PDFtebanzalesNo ratings yet

- Dinarex GRDocument2 pagesDinarex GRHrafnaet SorgenNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- Pla Texture Wood ArceDocument4 pagesPla Texture Wood ArceRoberto Gonzalo PelazNo ratings yet

- TDS GLACE - enDocument1 pageTDS GLACE - enmr.mennensNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueSekar AyuNo ratings yet

- Advanced-PP 1101SC-NDocument1 pageAdvanced-PP 1101SC-NEduardo JorgeNo ratings yet

- Datasheet Cawiton PR13665 - 002 PDFDocument1 pageDatasheet Cawiton PR13665 - 002 PDFFred HahnNo ratings yet

- Advanced-PP 1102LQ - 0Document1 pageAdvanced-PP 1102LQ - 0Narender RawatNo ratings yet

- Data Sheet Advanced-PP 1101 SC: DescriptionDocument1 pageData Sheet Advanced-PP 1101 SC: DescriptionNguyễn Hồng Nam100% (1)

- Advanced PP 1102KDocument1 pageAdvanced PP 1102KLaxman AhirNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetGeorge DonosaNo ratings yet

- Vesbo PPR EnglishDocument50 pagesVesbo PPR Englishcool.boys4200No ratings yet

- Plexiglas Satinice Df21 8n - enDocument3 pagesPlexiglas Satinice Df21 8n - enjonathan6657No ratings yet

- Pet-G - UkDocument1 pagePet-G - UkamilcarbrrNo ratings yet

- Datasheet Cawiton PR13650 - 004 PDFDocument1 pageDatasheet Cawiton PR13650 - 004 PDFFred HahnNo ratings yet

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data Sheetrenaat.vanwayenbergeNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueErnesto Cheguavara100% (1)

- TRO CX7323 - E11 - Ad PDFDocument2 pagesTRO CX7323 - E11 - Ad PDFJosip DuvnjakNo ratings yet

- Tds Carbon enDocument1 pageTds Carbon engegacolucNo ratings yet

- Volumic FT en Pla UltraDocument2 pagesVolumic FT en Pla UltrakaleniaNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Advanced-PP 1104K-NDocument1 pageAdvanced-PP 1104K-NgovindNo ratings yet

- 300.056 Magnum 3416 SCDocument3 pages300.056 Magnum 3416 SCEnrique ChavezNo ratings yet

- Product Information Product Information Product Information Product InformationDocument2 pagesProduct Information Product Information Product Information Product InformationMorkizgaNo ratings yet

- MAGNUM™ 3416 SC: ABS ResinDocument3 pagesMAGNUM™ 3416 SC: ABS ResinEduardo MazariegosNo ratings yet

- Mafill CRXG6344H 0Document1 pageMafill CRXG6344H 0mikeburnsthrowaccNo ratings yet

- TDS FLEX 93A - enDocument1 pageTDS FLEX 93A - enmr.mennensNo ratings yet

- 75 FKM 585Document3 pages75 FKM 585Victor CadilloNo ratings yet

- Datasheet Cawiton PR13675 - 002Document1 pageDatasheet Cawiton PR13675 - 002Fred HahnNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- TDS Nylon V3.011-EnDocument3 pagesTDS Nylon V3.011-Enmartinf090574No ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- PP Gf30 - Suplen v30 LCDocument2 pagesPP Gf30 - Suplen v30 LCarmandoNo ratings yet

- Datasheet Cawiton PR13635 - 002Document1 pageDatasheet Cawiton PR13635 - 002Fred HahnNo ratings yet

- Tarolox 10 g6 Standard 003 enDocument3 pagesTarolox 10 g6 Standard 003 enMohamed Ali MaâlaouiNo ratings yet

- BasfDocument3 pagesBasfBanupriya BalasubramanianNo ratings yet

- Technical Data Sheet (ABS)Document7 pagesTechnical Data Sheet (ABS)Kelvin Tai Wei LimNo ratings yet

- 72 NBR 902-En - 1Document3 pages72 NBR 902-En - 1Pierre PescayNo ratings yet

- Datasheet-Ultra Hh-4115-Hi-IsoDocument3 pagesDatasheet-Ultra Hh-4115-Hi-IsoDiegoTierradentroNo ratings yet

- Datasheet Cawiton PR13630 - 004Document1 pageDatasheet Cawiton PR13630 - 004Fred HahnNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- POM KEPITAL F30-03 enDocument2 pagesPOM KEPITAL F30-03 enAthonioMourinhoNo ratings yet

- PU SEAL Jed-337 008 en ADocument4 pagesPU SEAL Jed-337 008 en Aரஞ்சன் ஞானயோளிNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Datasheet Cawiton PR13615 - 001Document1 pageDatasheet Cawiton PR13615 - 001Fred HahnNo ratings yet

- TDS E ColorFabb Varioshore TPUDocument1 pageTDS E ColorFabb Varioshore TPUPIETRO DAVID DE LUCANo ratings yet

- Isoplast 300 ETP: Advancing MaterialsDocument2 pagesIsoplast 300 ETP: Advancing MaterialsDanielNo ratings yet

- Estane BF92Document2 pagesEstane BF92Ronaldo CamargoNo ratings yet

- Icare Recover PDFDocument1 pageIcare Recover PDFPIETRO DAVID DE LUCANo ratings yet

- TDS E ColorFabb Varioshore TPUDocument1 pageTDS E ColorFabb Varioshore TPUPIETRO DAVID DE LUCANo ratings yet

- Armadillo TDSDocument1 pageArmadillo TDSPIETRO DAVID DE LUCANo ratings yet

- TDS PRO - HT-HI-TEMP BigRepDocument2 pagesTDS PRO - HT-HI-TEMP BigRepPIETRO DAVID DE LUCANo ratings yet

- Filament PM Prusa Original Silvertechnical - Data-SheetDocument1 pageFilament PM Prusa Original Silvertechnical - Data-SheetPIETRO DAVID DE LUCANo ratings yet

- Fiat Cr32 Radio ModellerDocument8 pagesFiat Cr32 Radio ModellerPIETRO DAVID DE LUCANo ratings yet

- 1 DLA CorrosionProbe Getting StartedDocument11 pages1 DLA CorrosionProbe Getting StartedPIETRO DAVID DE LUCANo ratings yet

- BigRep Technical - Specification HI TEMPDocument2 pagesBigRep Technical - Specification HI TEMPPIETRO DAVID DE LUCANo ratings yet

- Planet Print SettingDocument2 pagesPlanet Print SettingPIETRO DAVID DE LUCANo ratings yet

- Corsair F4u RCDocument6 pagesCorsair F4u RCPIETRO DAVID DE LUCANo ratings yet

- Famous Scientists and Inventors-Merged-CompressedDocument299 pagesFamous Scientists and Inventors-Merged-CompressedMaldives CanadaNo ratings yet

- MODULE 1 Properties of Working Substance, Concepts of Energy, Laws of ThermodynamicsDocument58 pagesMODULE 1 Properties of Working Substance, Concepts of Energy, Laws of ThermodynamicsNhite NatisonNo ratings yet

- Lecture 6Document18 pagesLecture 6Tural EmirliNo ratings yet

- A New Model For Thermodynamic Analysis of A Drying Process: I. Dincer, A.Z. SahinDocument8 pagesA New Model For Thermodynamic Analysis of A Drying Process: I. Dincer, A.Z. Sahinzhor El hallaouiNo ratings yet

- Zuk-Nuclear Physics B 280 1987Document22 pagesZuk-Nuclear Physics B 280 1987Tin ZNo ratings yet

- Lesson 6 - Chain Rule - General FormulaDocument12 pagesLesson 6 - Chain Rule - General FormulaJacob SanchezNo ratings yet

- Solved Example On MasonryDocument53 pagesSolved Example On MasonrysanketNo ratings yet

- Robotics in Healthcare 2Document2 pagesRobotics in Healthcare 2Lenster GondorNo ratings yet

- Bct-Module 5Document22 pagesBct-Module 5ValarlaksNo ratings yet

- Sample Structural AnalysisDocument66 pagesSample Structural AnalysisJohn Vincent L. Ambrocio50% (2)

- Leica Zoom 2000Document6 pagesLeica Zoom 2000HaienasrNo ratings yet

- Chapter 1: Quantum Defect Theory: I. The Hydrogen AtomDocument11 pagesChapter 1: Quantum Defect Theory: I. The Hydrogen AtomElbis Santos CardosoNo ratings yet

- Acoustics and Its Treatment in Auditorium: SynopsisDocument7 pagesAcoustics and Its Treatment in Auditorium: SynopsisHanumant pandeyNo ratings yet

- 3CD358 145pcf ASD 40ksiDocument2 pages3CD358 145pcf ASD 40ksiLitharienNo ratings yet

- Polymer Compositions InjectionDocument14 pagesPolymer Compositions InjectionJessiNo ratings yet

- DM210434 - 180309 - Rev. 0 - UKDocument154 pagesDM210434 - 180309 - Rev. 0 - UKrobNo ratings yet

- A Comprehensive Overview of Power Converter Topologies For Induction Heating ApplicationsDocument33 pagesA Comprehensive Overview of Power Converter Topologies For Induction Heating ApplicationsFajar MaulanaNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: T.S. Nguyen, Zhenze Li, Grant Su, M.H.B. Nasseri, R.P. YoungDocument19 pagesJournal of Rock Mechanics and Geotechnical Engineering: T.S. Nguyen, Zhenze Li, Grant Su, M.H.B. Nasseri, R.P. YoungMoezselmi.12 SelmiNo ratings yet

- Efforts Dans Boulons Sur Bride CirculaireDocument6 pagesEfforts Dans Boulons Sur Bride CirculaireBrice Patrice GollyNo ratings yet

- Natural Draught and Chimney - 1Document1 pageNatural Draught and Chimney - 1Sam RagNo ratings yet

- Cymbeline SlidesCarnivalDocument14 pagesCymbeline SlidesCarnivalrocio nataly huaman nuñezNo ratings yet

- Lecture Notes - Econometrics I - Andrea WeberDocument119 pagesLecture Notes - Econometrics I - Andrea WeberBaigalmaa NyamtserenNo ratings yet

- Ae4440z Fz1aDocument2 pagesAe4440z Fz1aMageon7No ratings yet

- Simple & Geometric Thesis Defense by SlidesgoDocument55 pagesSimple & Geometric Thesis Defense by Slidesgogabimen19No ratings yet

- Average Lifetime Component (Rev)Document8 pagesAverage Lifetime Component (Rev)hamim hamzahNo ratings yet

- Nonlinear Analysis of Pre Stressed Concrete FramesDocument18 pagesNonlinear Analysis of Pre Stressed Concrete FramesLauNo ratings yet

- Chapter 6 - 1st and 2nd Order Transient Analysis ElectricalDocument54 pagesChapter 6 - 1st and 2nd Order Transient Analysis ElectricalDouglas OngomNo ratings yet

- Vector Calculus WikibookDocument52 pagesVector Calculus WikibookLynn Hollenbeck BreindelNo ratings yet

- M2 (UNIT-3) (PPT & NOTEs)Document40 pagesM2 (UNIT-3) (PPT & NOTEs)Lord SavitarNo ratings yet

- The Largest Coke Drum Bulge Repairs in Industry History Jani Reliance Industries Limited Samman Houston Engineering Solutions DCU New Delhi 2013Document30 pagesThe Largest Coke Drum Bulge Repairs in Industry History Jani Reliance Industries Limited Samman Houston Engineering Solutions DCU New Delhi 2013Nano QuinnNo ratings yet