Professional Documents

Culture Documents

Ultraform N2320 003 BK120 Q600

Uploaded by

JoelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultraform N2320 003 BK120 Q600

Uploaded by

JoelCopyright:

Available Formats

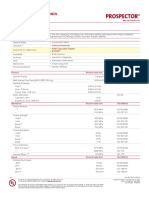

Product Information Ultraform® N 2320 003 BK120

Apr 2015 Q600

Polyoxymethylene

Product Description

Ultraform N 2320 003 BK120 Q600 is a pigmented black, rapidly freezing general-purpose injection-

molding POM grade. It contains a mold release agent.

Applications

Typical applications include spring elements, clips, gas filler caps, gears wheels, small motor parts,

curtain hooks and release buttons for safety belts.

PHYSICAL ISO Test Method Property Value

Density, g/cm 1183 1.4

Moisture, % 62

(50% RH) 0.2

(Saturation) 0.8

MECHANICAL ISO Test Method Property Value

Tensile Modulus, MPa 527

23C 2,810

Tensile stress at yield, MPa 527

23C 62

Tensile strain at yield, % 527

23C 10

Nominal strain at break, % 527

23C 25

Flexural Modulus, MPa 178

23C 2,340

IMPACT ISO Test Method Property Value

Izod Notched Impact, kJ/m2 180

23C 7

-40C 5.8

Charpy Notched, kJ/m2 179

23C 6.1

THERMAL ISO Test Method Property Value

Melting Point, C 3146 167

HDT A, C 75 96

ELECTRICAL ISO Test Method Property Value

Comparative Tracking Index IEC 60112 600

Volume Resistivity IEC 60093 1E13

Surface Resistivity IEC 60093 1E13

Dielectric Constant (100 Hz) IEC 60250 3.8

Dielectric Constant (1 MHz) IEC 60250 3.8

Dissipation Factor (100 Hz) IEC 60250 10

Dissipation Factor (1 MHz) IEC 60250 50

Dielectric Strength, KV/mm IEC 60243-1 40

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 1 of 2

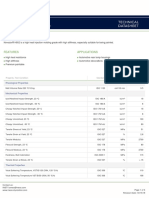

Ultraform® N 2320 003 BK120 Q600

Processing Guidelines

Material Handling

Max. Water content: 0.15%

Product is supplied in polyethylene bags and drying prior to molding is not required. However, after

relatively long storage or when handling material from previously opened containers, preliminary

drying is recommended in order to remove any moisture which has been absorbed. If drying is

required, a dehumidifying or desiccant dryer operating at 80 - 110 degC (176 - 230 degF) is

recommended. Drying time is dependent on moisture level, but 2-4 hours is generally sufficient.

Further information concerning safe handling procedures can be obtained from the Safety Data

Sheet. Alternatively, please contact your BASF representative.

Typical Profile

Melt Temperature 190-230 degC (375-446 degF)

Mold Temperature 60-120 degC (140-248 degF)

Injection and Packing Pressure 35-70 bar (500-1000psi)

Mold Temperatures

A mold temperature of 80-90 degC (176-194 degF) is recommended, but temperatures of as low as

45 degC (113 degF) and as high as 105 degC (221 degF) can be used where applicable.

Pressures

Injection speed must be optimized. A filling rate which is too high results in anisotropic mechanical

properties, while a filling rate which is too low yields parts with poor surface finish. The tool must be

vented to avoid burn marks and prevent mold deposits. Injection pressure controls the filling of the

part and should be applied for 90% of ram travel. Packing pressure affects the final part and can be

used effectively in controlling sink marks and shrinkage. It should be applied and maintained until

the gate area is completely frozen off.

Back pressure can be utilized to provide uniform melt consistency and reduce trapped air and gas.

Fill Rate

Injection speed must be optimized. A filling rate which is too high results in anisotropic mechanical

properties, while a filling rate which is too low yields parts with poor surface finish. The tool must be

vented to avoid burn marks and prevent mold deposits.

Note

Although all statements and information in this publication are believed to be accurate and reliable,

they are presented gratis and for guidance only, and risks and liability for results obtained by use of

the products or application of the suggestions described are assumed by the user. NO

WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE MADE REGARDING

PRODUCTS DESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH. Statements or

suggestions concerning possible use of the products are made without representation or warranty

that any such use is free of patent infringement and are not recommendations to infringe any

patent. The user should not assume that toxicity data and safety measures are indicated or that

other measures may not be required.

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 2 of 2

You might also like

- Molecular Biology of The Cell, 5th EditionDocument82 pagesMolecular Biology of The Cell, 5th EditionBee Nunes25% (67)

- Sunoco Marcus Hook Ethylene Fire - AIChE-EPC Paper Rev1Document14 pagesSunoco Marcus Hook Ethylene Fire - AIChE-EPC Paper Rev1Arthur JensenNo ratings yet

- ULTRADUR B4300G6 (03p023)Document3 pagesULTRADUR B4300G6 (03p023)ayala castroNo ratings yet

- UltrasonS6010 IsoDocument2 pagesUltrasonS6010 IsoKablayialijanNo ratings yet

- Abs - Terluran GP22Document2 pagesAbs - Terluran GP22armandoNo ratings yet

- Ultramid A3WG7 IsoDocument3 pagesUltramid A3WG7 IsoRiccardoNo ratings yet

- Ultrason E 3010: Polyethersulfone (PESU)Document2 pagesUltrason E 3010: Polyethersulfone (PESU)AmirNo ratings yet

- Petra 130 SpecsDocument2 pagesPetra 130 SpecssdecarlogaNo ratings yet

- Ultramid B3WG6 NYLON PDFDocument3 pagesUltramid B3WG6 NYLON PDFrenebbNo ratings yet

- Ultraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Document2 pagesUltraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Phuoc Thinh TruongNo ratings yet

- ABS Terluran GP35Document2 pagesABS Terluran GP35Alan MoraisNo ratings yet

- Torelina® A490MA50: Toray Resin CompanyDocument2 pagesTorelina® A490MA50: Toray Resin CompanyChunYenHuangNo ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Aultramid Pa 66Document2 pagesAultramid Pa 66ZaldsonNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Tarolox 10 g6 Standard 003 enDocument3 pagesTarolox 10 g6 Standard 003 enMohamed Ali MaâlaouiNo ratings yet

- Abs - Terluran GP35Document2 pagesAbs - Terluran GP35armandoNo ratings yet

- Diakon® ST35G8: Lucite International Holland BVDocument3 pagesDiakon® ST35G8: Lucite International Holland BVbobNo ratings yet

- NG30-02JBK - Next PolymersDocument4 pagesNG30-02JBK - Next PolymersdigiarkanandNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- 202-Trinseo Calibre Megarad 2081-15 TDSDocument3 pages202-Trinseo Calibre Megarad 2081-15 TDSobeckoneNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- PC-Transparent 144RDocument5 pagesPC-Transparent 144Rsantosh.bhattNo ratings yet

- Technical Data Sheet: Typical PropertiesDocument2 pagesTechnical Data Sheet: Typical PropertiesahmedNo ratings yet

- Product Summary: FZ-3600 Is A Glass Fiber and Mineral Filled Branched PPSDocument1 pageProduct Summary: FZ-3600 Is A Glass Fiber and Mineral Filled Branched PPSMark DingalNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Material Data Center - Datasheet Teldene® R40MLTDocument2 pagesMaterial Data Center - Datasheet Teldene® R40MLTAndy KayNo ratings yet

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Document3 pagesBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- TDS - Terluran GP-22 PDFDocument3 pagesTDS - Terluran GP-22 PDFebercueNo ratings yet

- Luran 368R: Technical DatasheetDocument3 pagesLuran 368R: Technical DatasheetVictor PuertoNo ratings yet

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- Sabic® PP 575P: PP Homopolymer For Injection MouldingDocument1 pageSabic® PP 575P: PP Homopolymer For Injection MouldingPrinchipi YounesNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- GENESTAR™ GP2300S - KurarayDocument4 pagesGENESTAR™ GP2300S - KurarayRafael CastroNo ratings yet

- Desmopan 6064A - en - 81165785 05123103 20014072Document2 pagesDesmopan 6064A - en - 81165785 05123103 20014072shahin_723No ratings yet

- MTC VG-40-9080942Document1 pageMTC VG-40-9080942vyzjhxypdcNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- Bayblend T85 XF ISO enDocument3 pagesBayblend T85 XF ISO enryanNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- Pa 6 GF 30 (En)Document1 pagePa 6 GF 30 (En)Alessandro WeissNo ratings yet

- Ixef 1032 1Document2 pagesIxef 1032 1Renan Lucena da CruzNo ratings yet

- PU SEAL Jed-337 008 en ADocument4 pagesPU SEAL Jed-337 008 en Aரஞ்சன் ஞானயோளிNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Technyl - A 218GV30 Natural - J20005Document6 pagesTechnyl - A 218GV30 Natural - J20005Leandro LacerdaNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Radipol A45 TDSDocument1 pageRadipol A45 TDSxy2zjgNo ratings yet

- Pa6 GF20 - Basf Ultramid B3eg4Document2 pagesPa6 GF20 - Basf Ultramid B3eg4armandoNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Grand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsDocument1 pageGrand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsPhuoc Thinh TruongNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- Datasheet - Solargiga 560W JMPV-X1 72Document2 pagesDatasheet - Solargiga 560W JMPV-X1 72tacianoNo ratings yet

- Datasheet - Solargiga 560W JMPV-X1 72Document2 pagesDatasheet - Solargiga 560W JMPV-X1 72Everaldo LiborioNo ratings yet

- TDS - Bayblend FR3040 EVDocument3 pagesTDS - Bayblend FR3040 EVRachit RanjanNo ratings yet

- Mitocondria y ParkinsonDocument13 pagesMitocondria y ParkinsonEstebanNo ratings yet

- Cell Growth Protocol For Jurkat Cell LineDocument2 pagesCell Growth Protocol For Jurkat Cell LineMihaela BalasNo ratings yet

- PKLPPC300N Operating ManualDocument231 pagesPKLPPC300N Operating ManualLonCin123No ratings yet

- Shrinky Dink MoleculaDocument42 pagesShrinky Dink Moleculaisrael43No ratings yet

- Crej2: Alkaline PHDocument7 pagesCrej2: Alkaline PHMadalina Cioroiu-AndronescuNo ratings yet

- Preparation and Chemical Properties of Carboxylic AcidDocument12 pagesPreparation and Chemical Properties of Carboxylic AciddayhunterNo ratings yet

- Answers To End-Of-Chapter Questions: Chapter 3 Elements and CompoundsDocument2 pagesAnswers To End-Of-Chapter Questions: Chapter 3 Elements and CompoundsAjay LakshmananNo ratings yet

- Unit 8Document25 pagesUnit 8Kinnari PatelNo ratings yet

- GAHUMAN Dalton's LawDocument19 pagesGAHUMAN Dalton's LawTito V. Bautista Jr.No ratings yet

- 165D6 - Thermo King 2000 Hose System: 3/8/14Document75 pages165D6 - Thermo King 2000 Hose System: 3/8/14Elliot WuNo ratings yet

- Manual Piston Cylinder Sampling For Volatile Crude Oils, Condensates, and Liquid Petroleum ProductsDocument14 pagesManual Piston Cylinder Sampling For Volatile Crude Oils, Condensates, and Liquid Petroleum ProductsjiandapaNo ratings yet

- Development of An Electrochemical Metal-Ion Biosensor Using Self-Assembled Peptide NanofibrilsDocument7 pagesDevelopment of An Electrochemical Metal-Ion Biosensor Using Self-Assembled Peptide NanofibrilsRenan Guilherme de Oliveira GuihNo ratings yet

- Wunthunyarat 2020 - Effects of Germination Conditions On Enzyme Activities and Starch Hydrolysis of Long Grain Brown Rice in Relation To Flour Properties and Bread Qualities.Document9 pagesWunthunyarat 2020 - Effects of Germination Conditions On Enzyme Activities and Starch Hydrolysis of Long Grain Brown Rice in Relation To Flour Properties and Bread Qualities.ridaira.raNo ratings yet

- Prodrugs and Drug Latentiation: Forrest ClarkDocument105 pagesProdrugs and Drug Latentiation: Forrest ClarkSajadRoyanNo ratings yet

- Portland Cement: Joe Diedrich Technical Services ManagerDocument44 pagesPortland Cement: Joe Diedrich Technical Services ManagerdoxamariaNo ratings yet

- Uv SpectrumDocument22 pagesUv SpectrumFarah KhanNo ratings yet

- Experiment 2 Gen Chem 2 LabDocument4 pagesExperiment 2 Gen Chem 2 LabSam BenjaminNo ratings yet

- Topic 3.2 - Modeling A Gas Formative Assessment NAMEDocument2 pagesTopic 3.2 - Modeling A Gas Formative Assessment NAMEDharmesh Ramnarayan YadavNo ratings yet

- How To Paint A Sunset Seascape - Samuel Earp ArtistDocument1 pageHow To Paint A Sunset Seascape - Samuel Earp ArtistMohamed Abou El hassanNo ratings yet

- Lecture 3 Enthalpy and Heat CapacityDocument46 pagesLecture 3 Enthalpy and Heat CapacitylisaNo ratings yet

- Food and Nutrition ReportDocument23 pagesFood and Nutrition ReportMariel LagradanteNo ratings yet

- BS 2 FiltrationDocument70 pagesBS 2 FiltrationRavi Kumar VermaNo ratings yet

- Australian/New Zealand Standard: Welding Consumables For Build-Up and Wear ResistanceDocument7 pagesAustralian/New Zealand Standard: Welding Consumables For Build-Up and Wear ResistanceKavinNo ratings yet

- DN Turbine OilDocument2 pagesDN Turbine OilPrapat SabsinthaweelapNo ratings yet

- As Tute 1 September 2016Document2 pagesAs Tute 1 September 2016Piyumi ObeyesekeraNo ratings yet

- Korepox H.S. EH4158 (Two-Component) : Product DescriptionDocument2 pagesKorepox H.S. EH4158 (Two-Component) : Product DescriptionTrịnh Minh KhoaNo ratings yet

- MO Khumalo 22021337 GA AssignmentDocument8 pagesMO Khumalo 22021337 GA AssignmentMusa OtoNo ratings yet

- Determination Essential and Toxic Metals Blood Icp Ms Using Calibration Synthetic MatrixDocument10 pagesDetermination Essential and Toxic Metals Blood Icp Ms Using Calibration Synthetic MatrixmarkodefenNo ratings yet